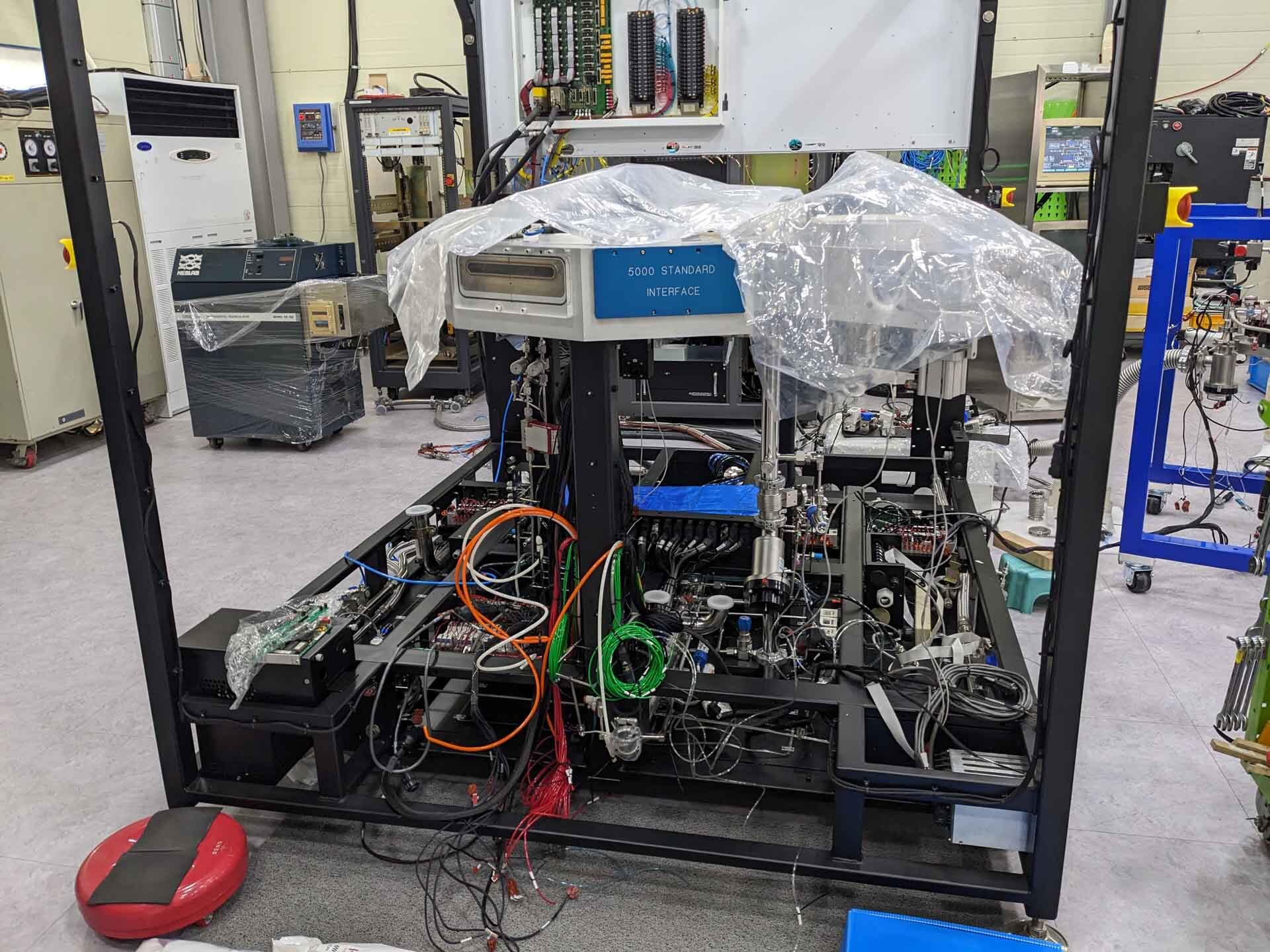

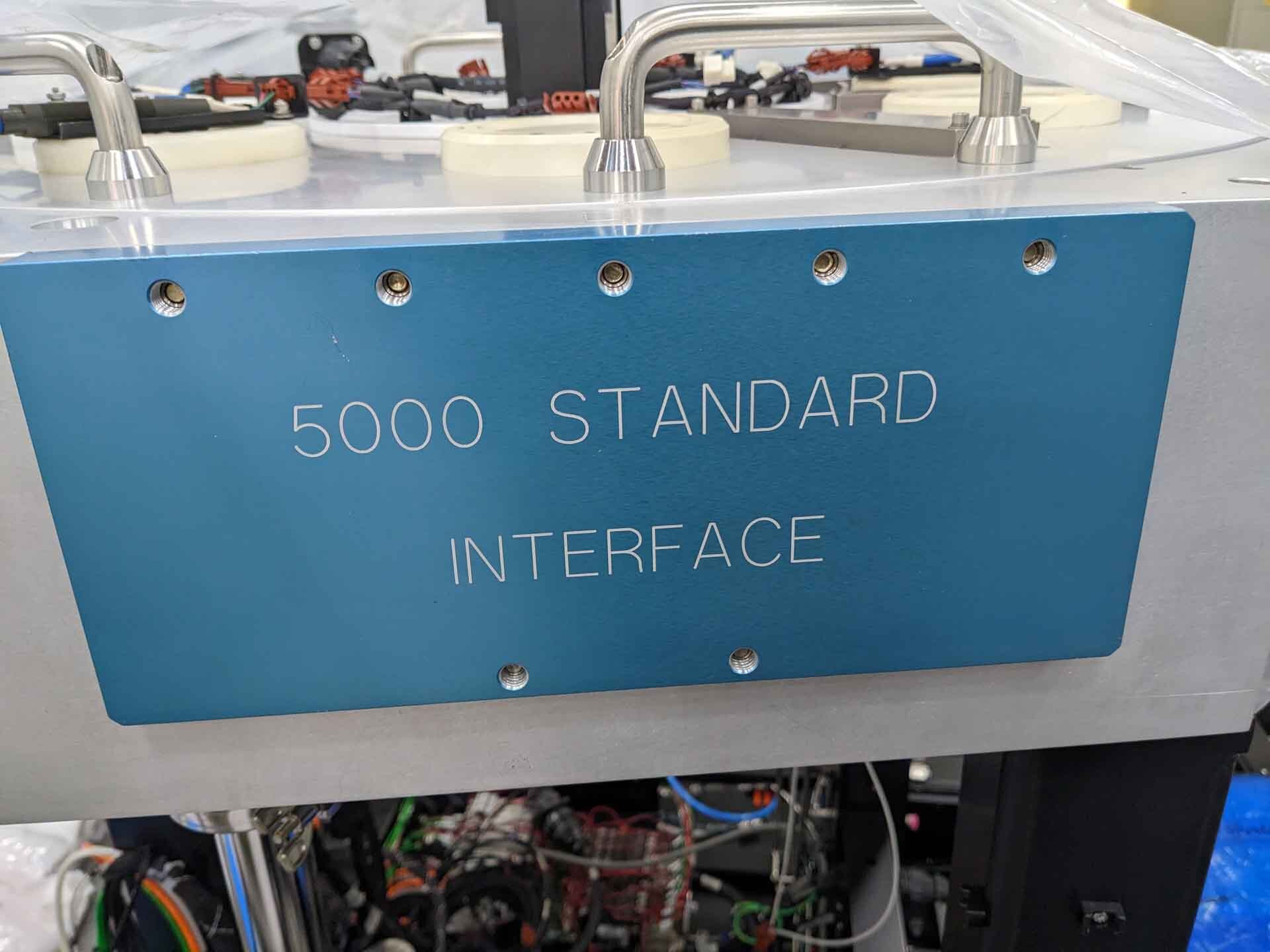

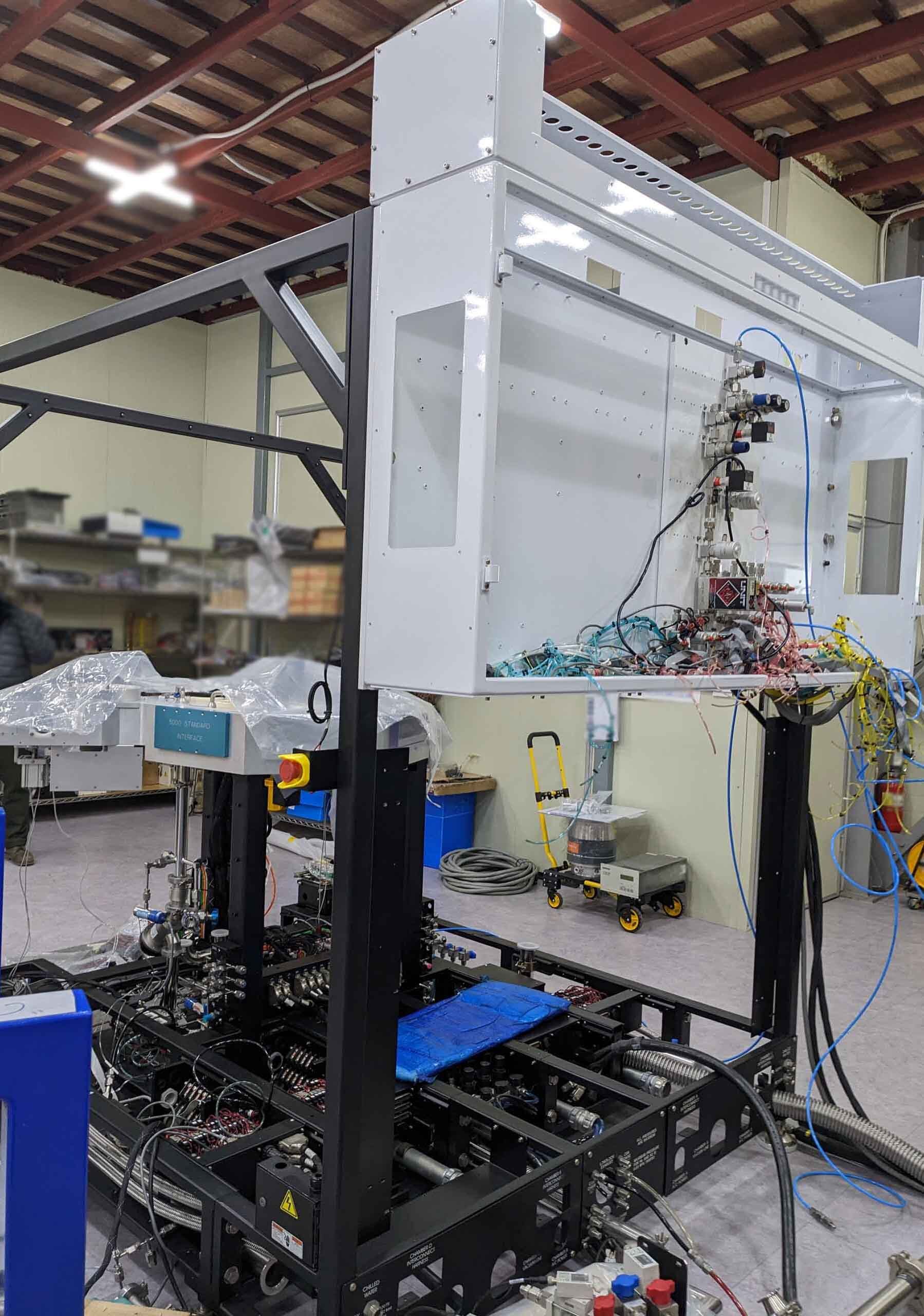

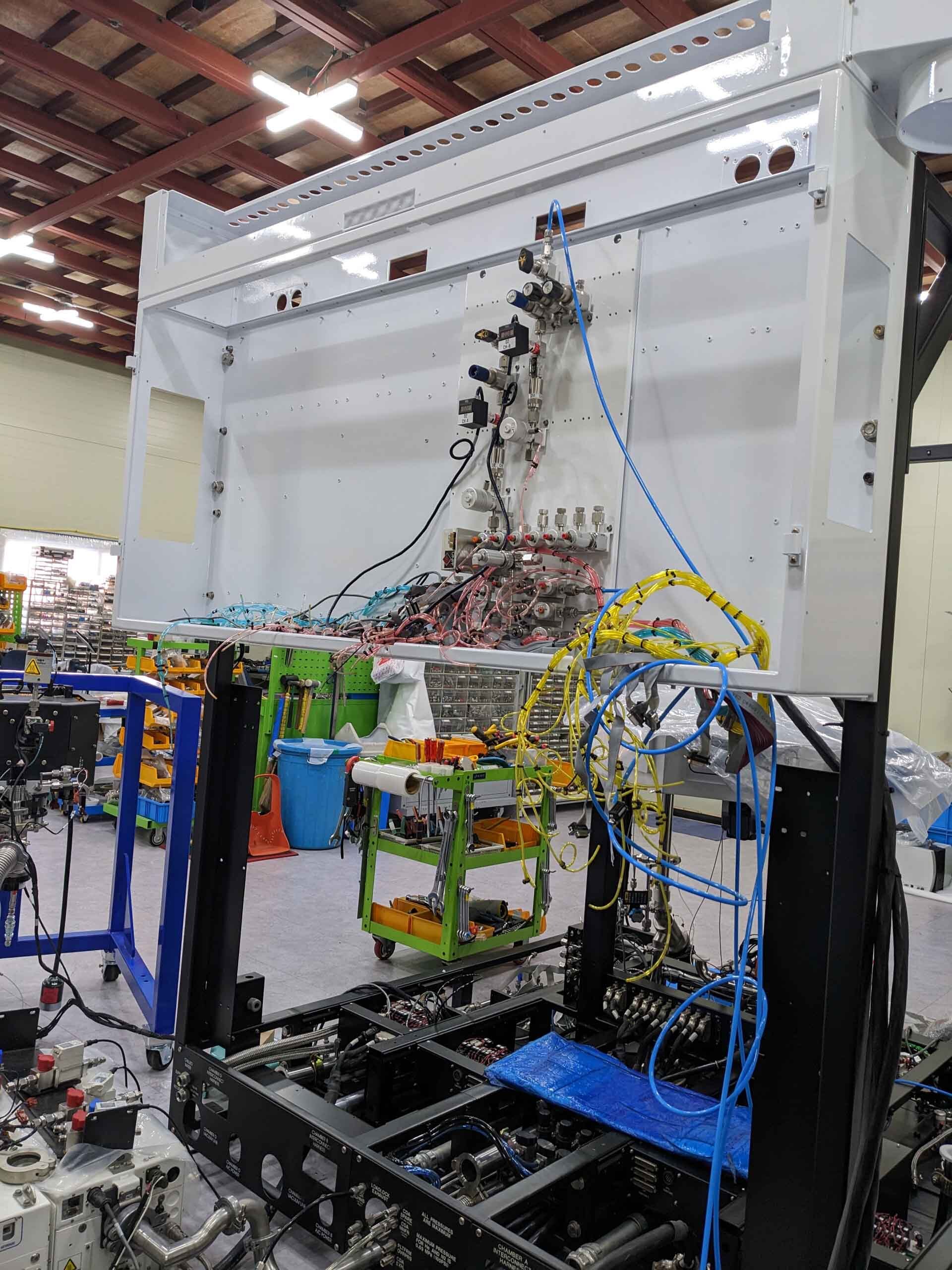

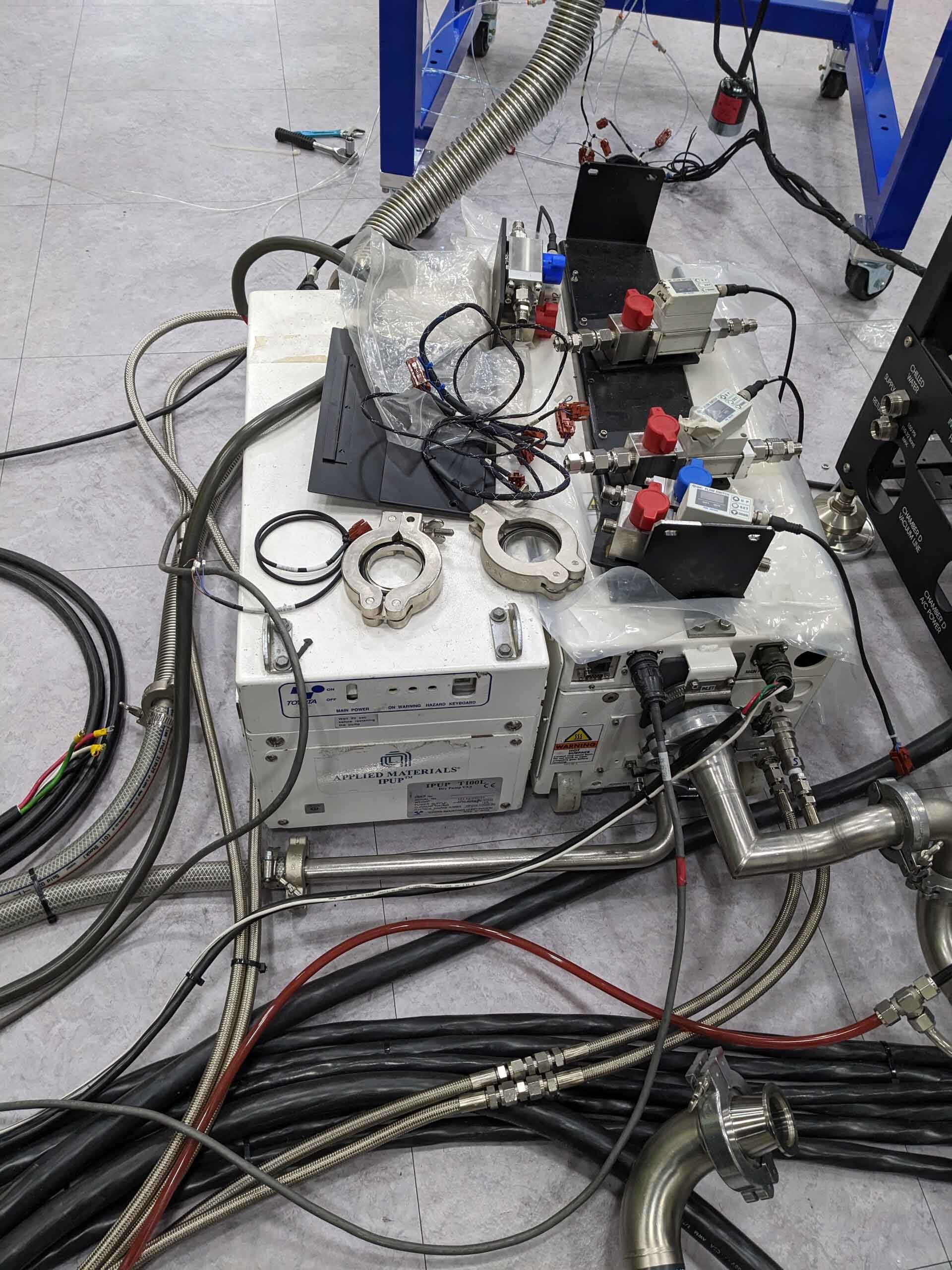

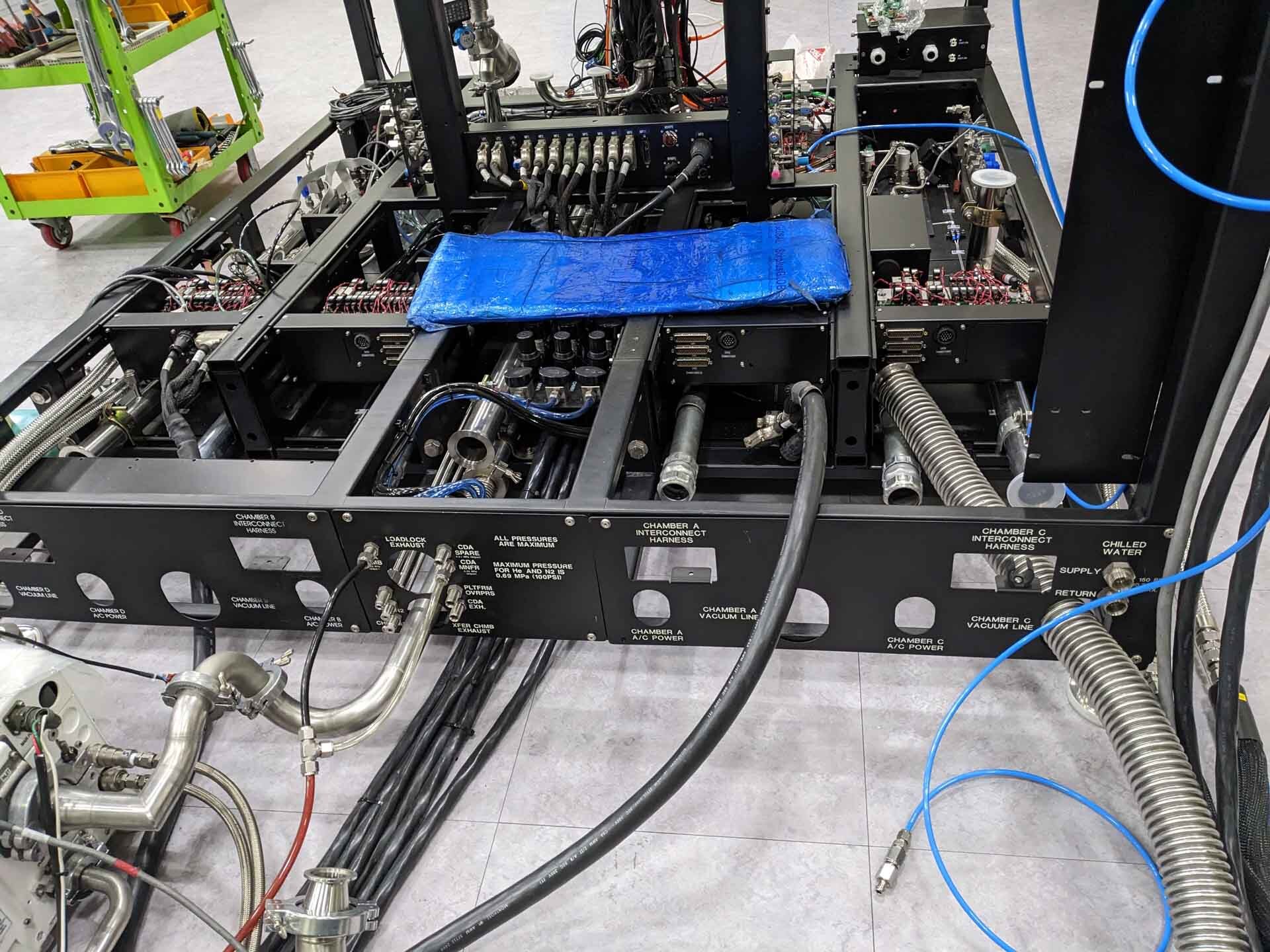

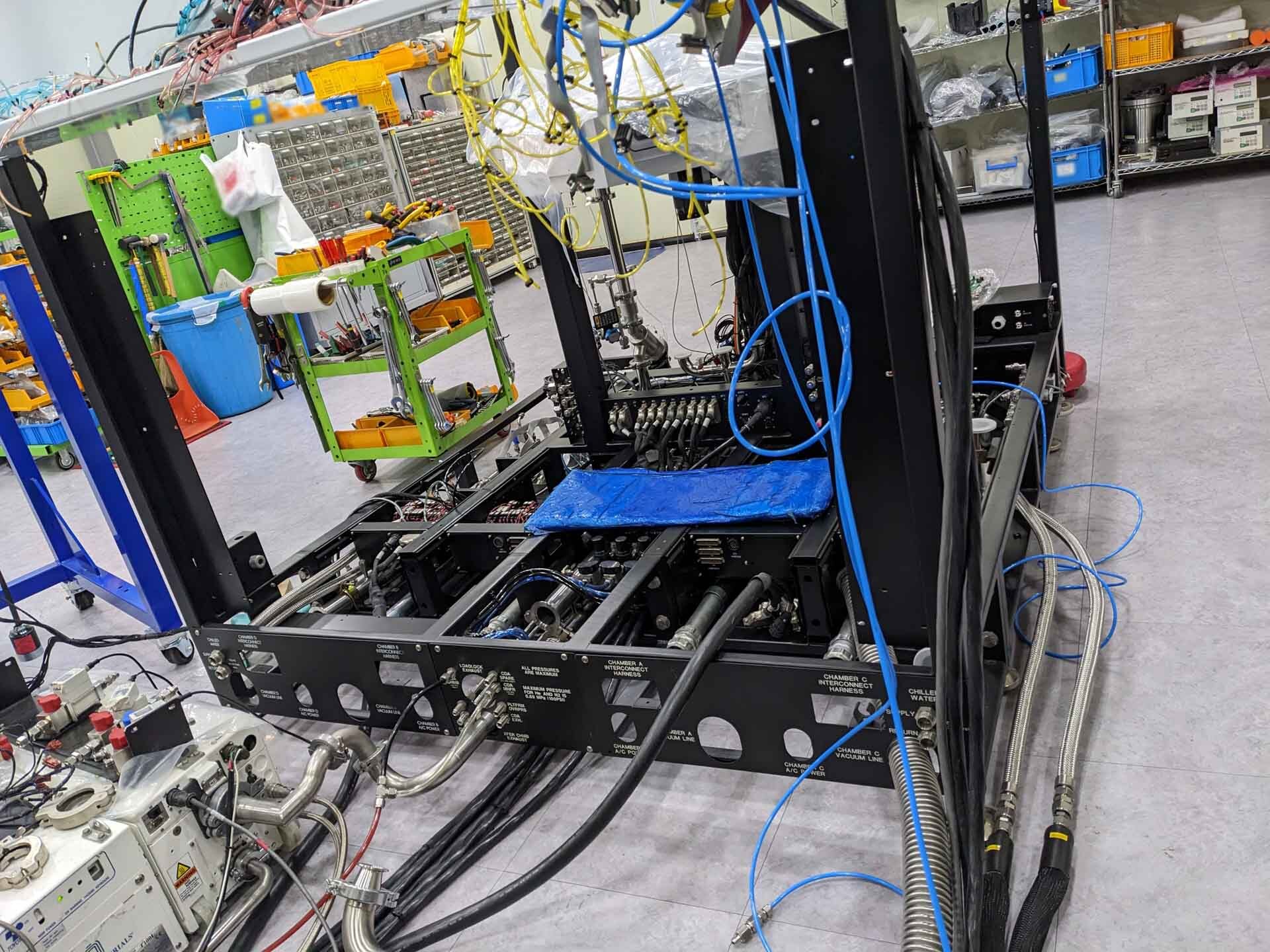

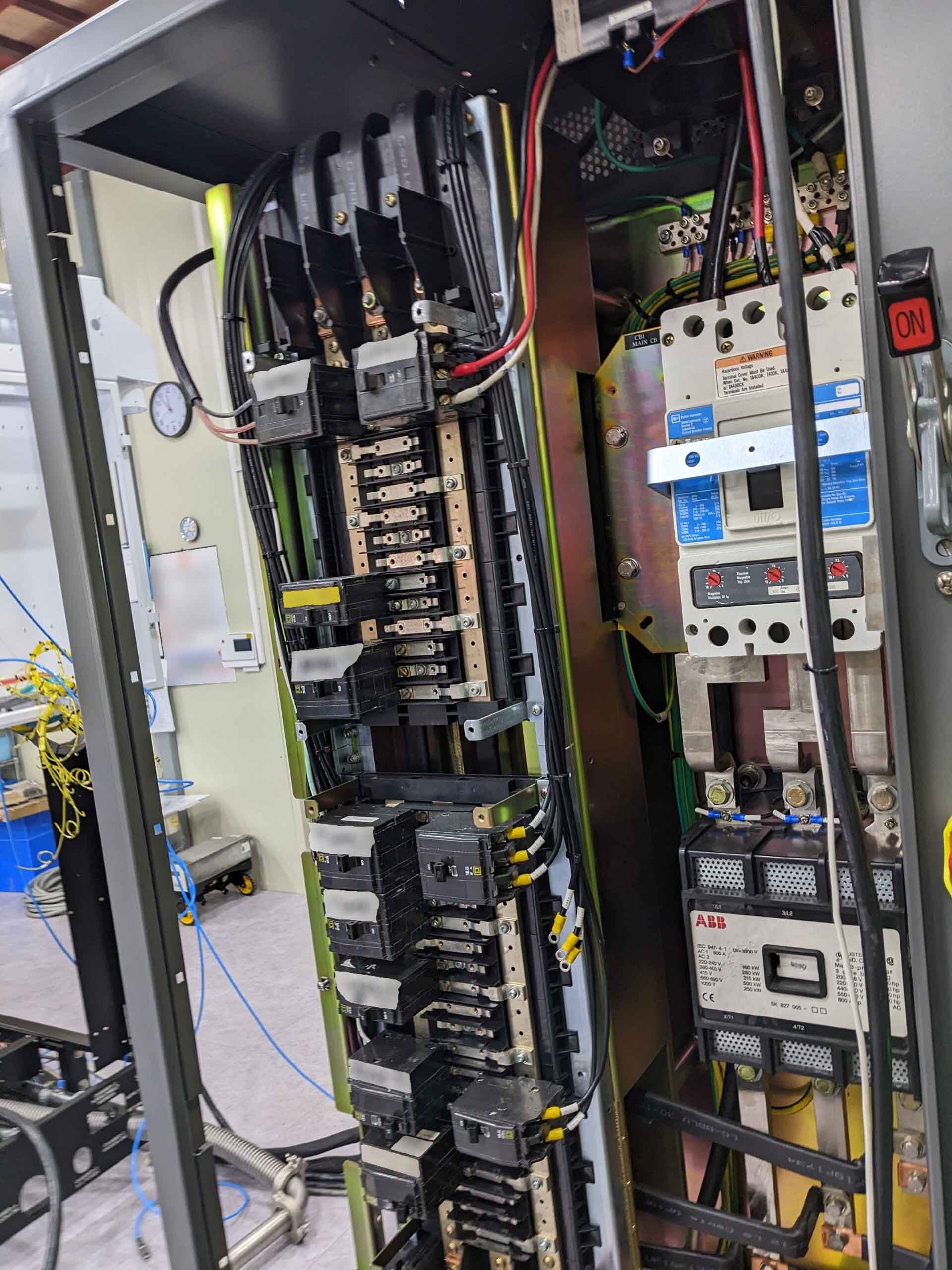

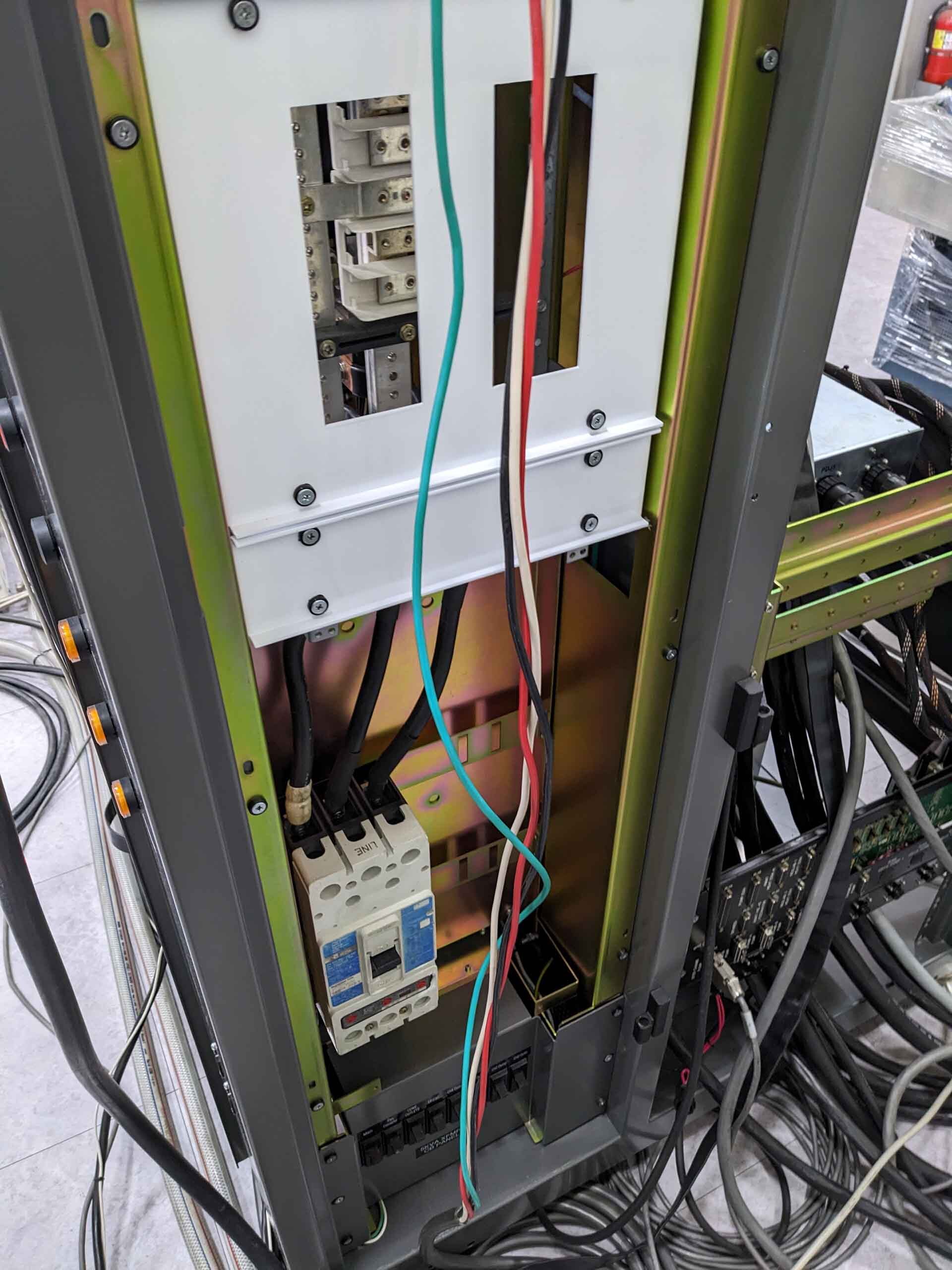

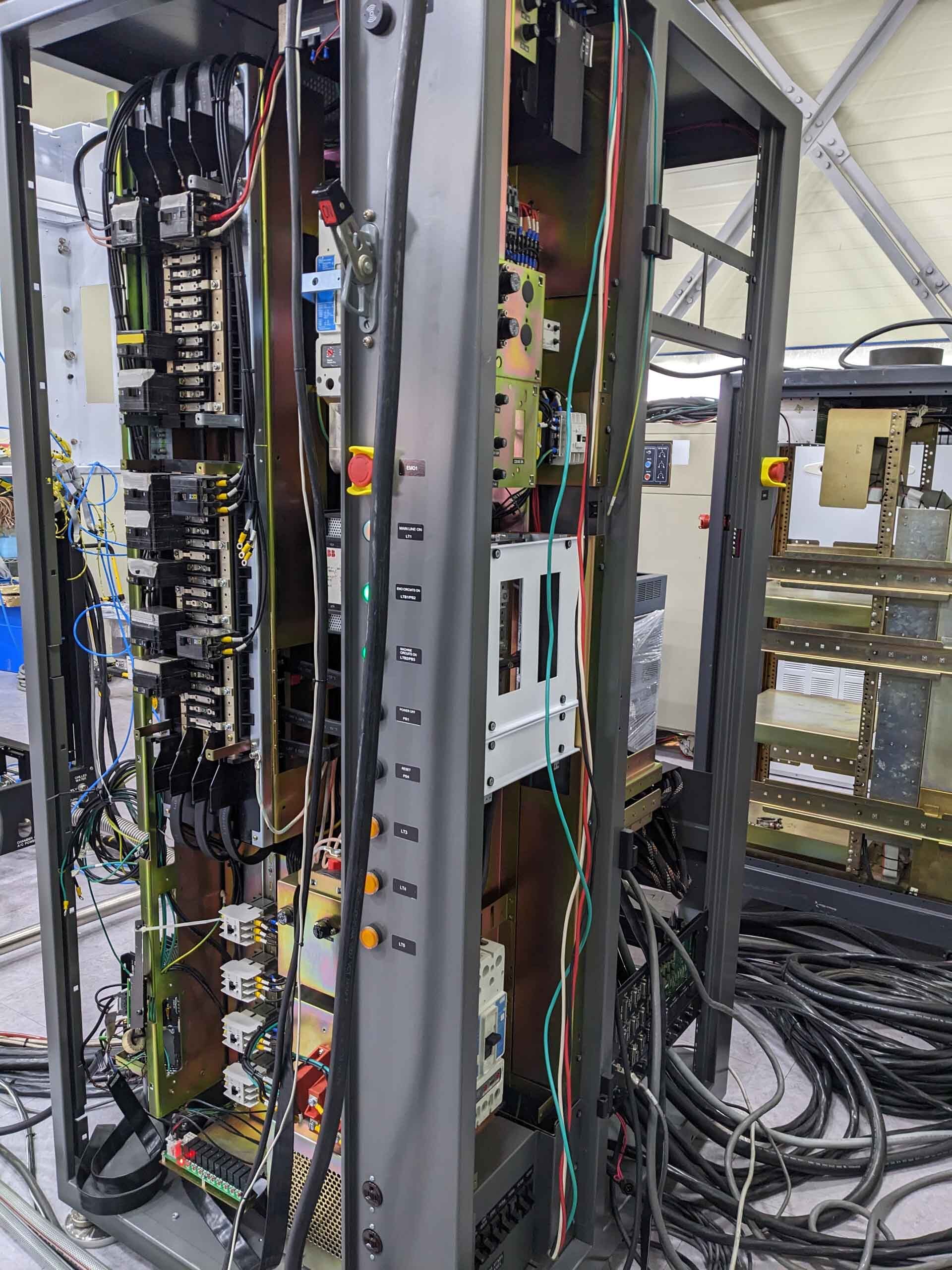

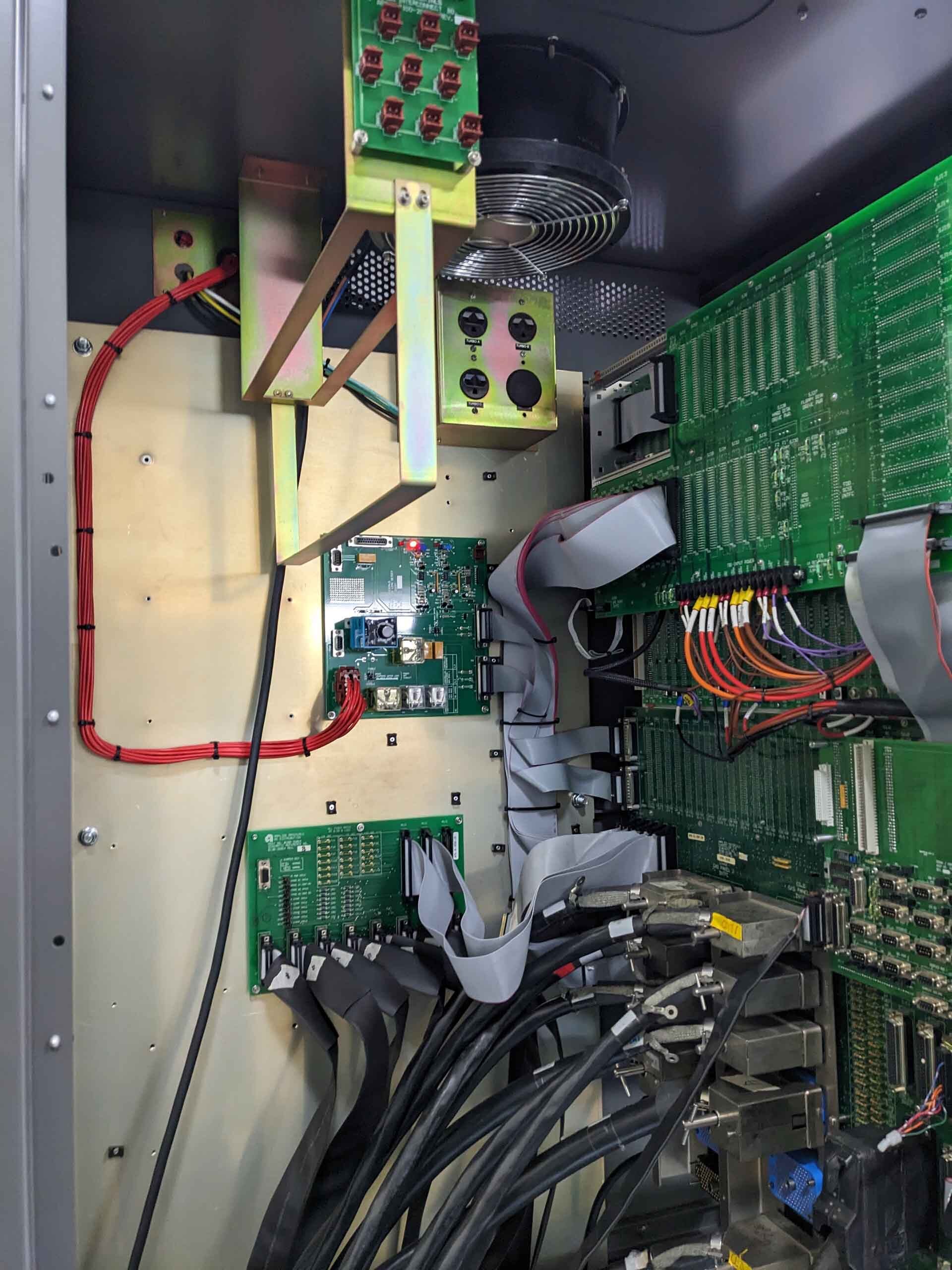

Used AMAT / APPLIED MATERIALS Centura P5000 #293651591 for sale

URL successfully copied!

Tap to zoom

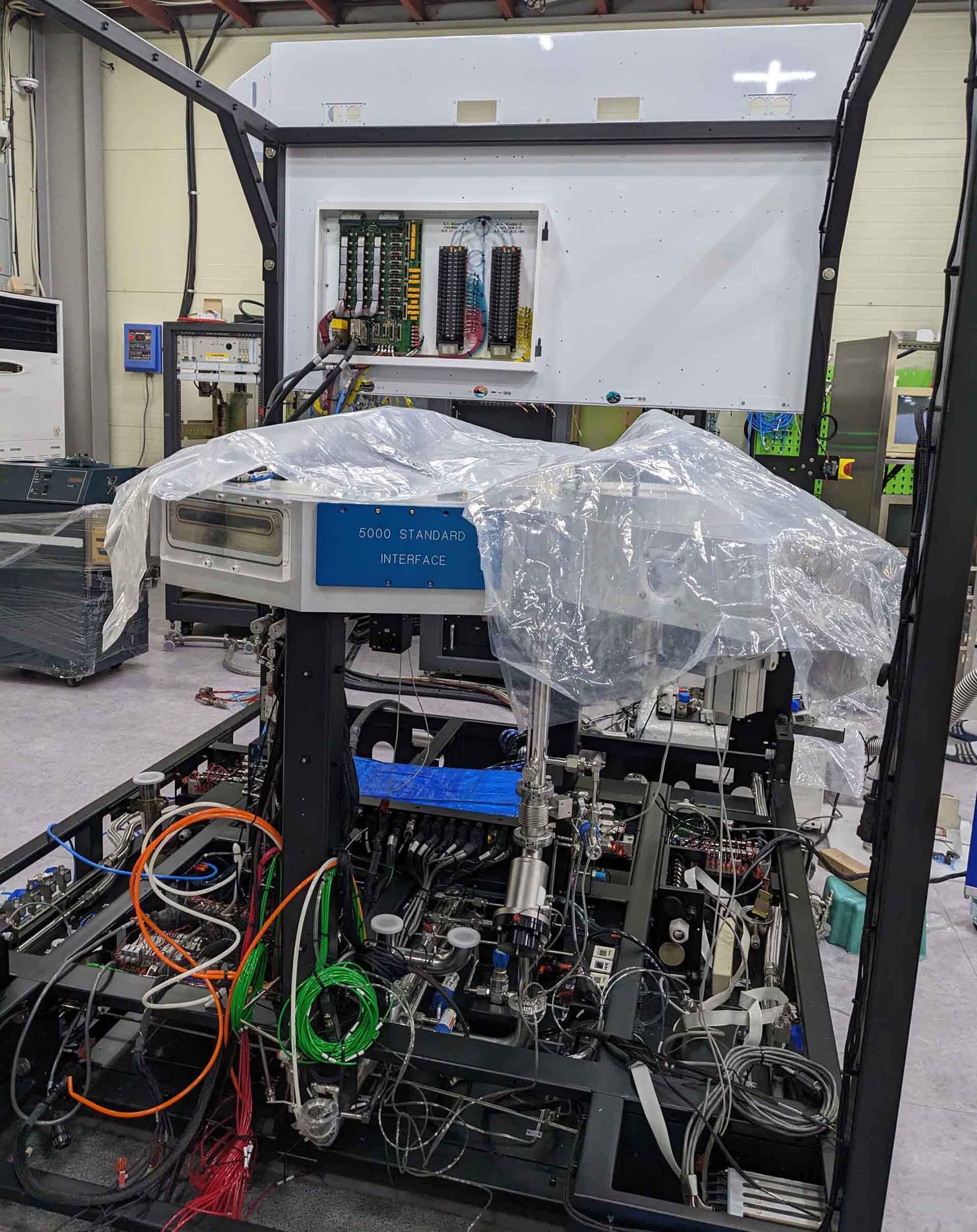

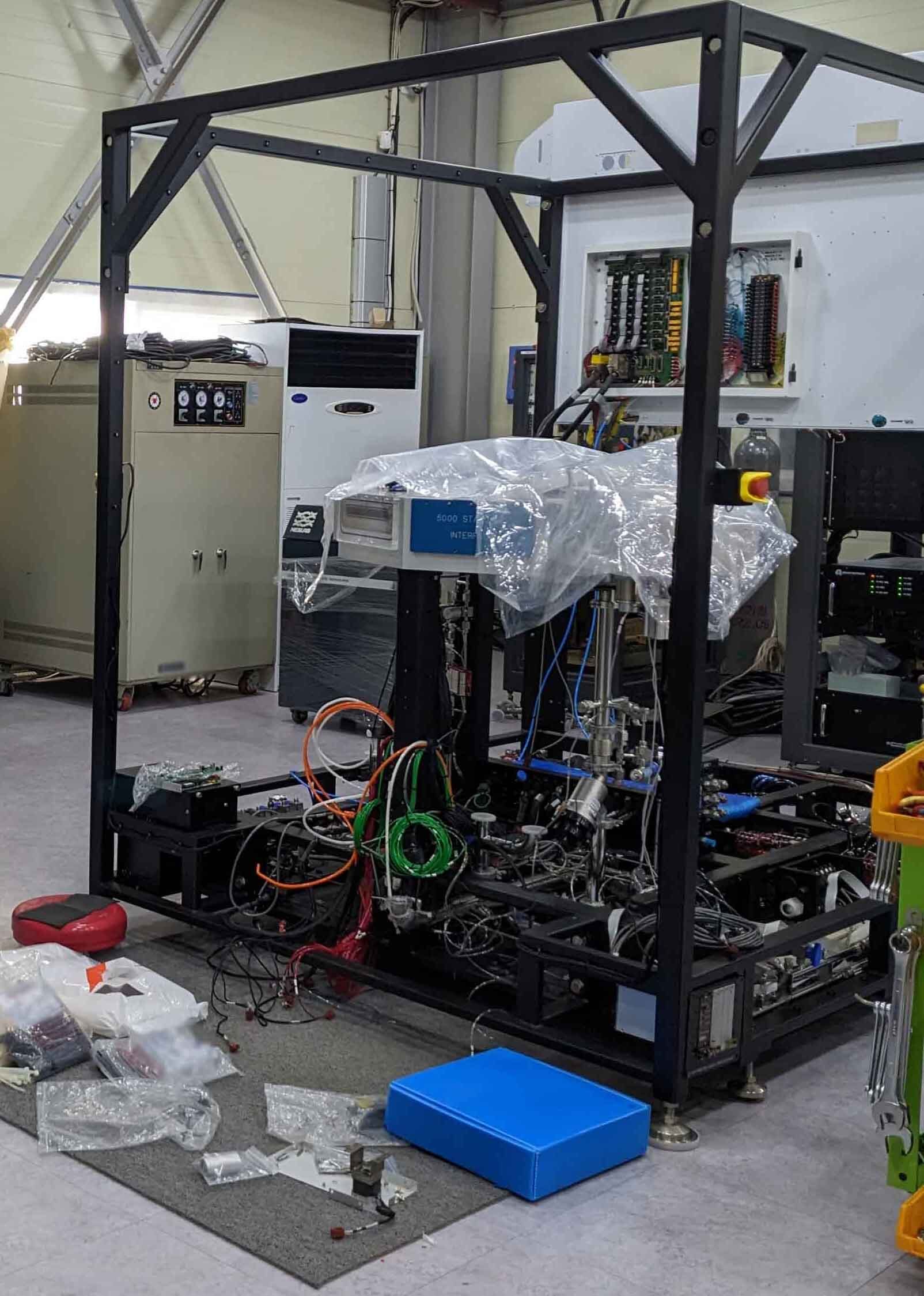

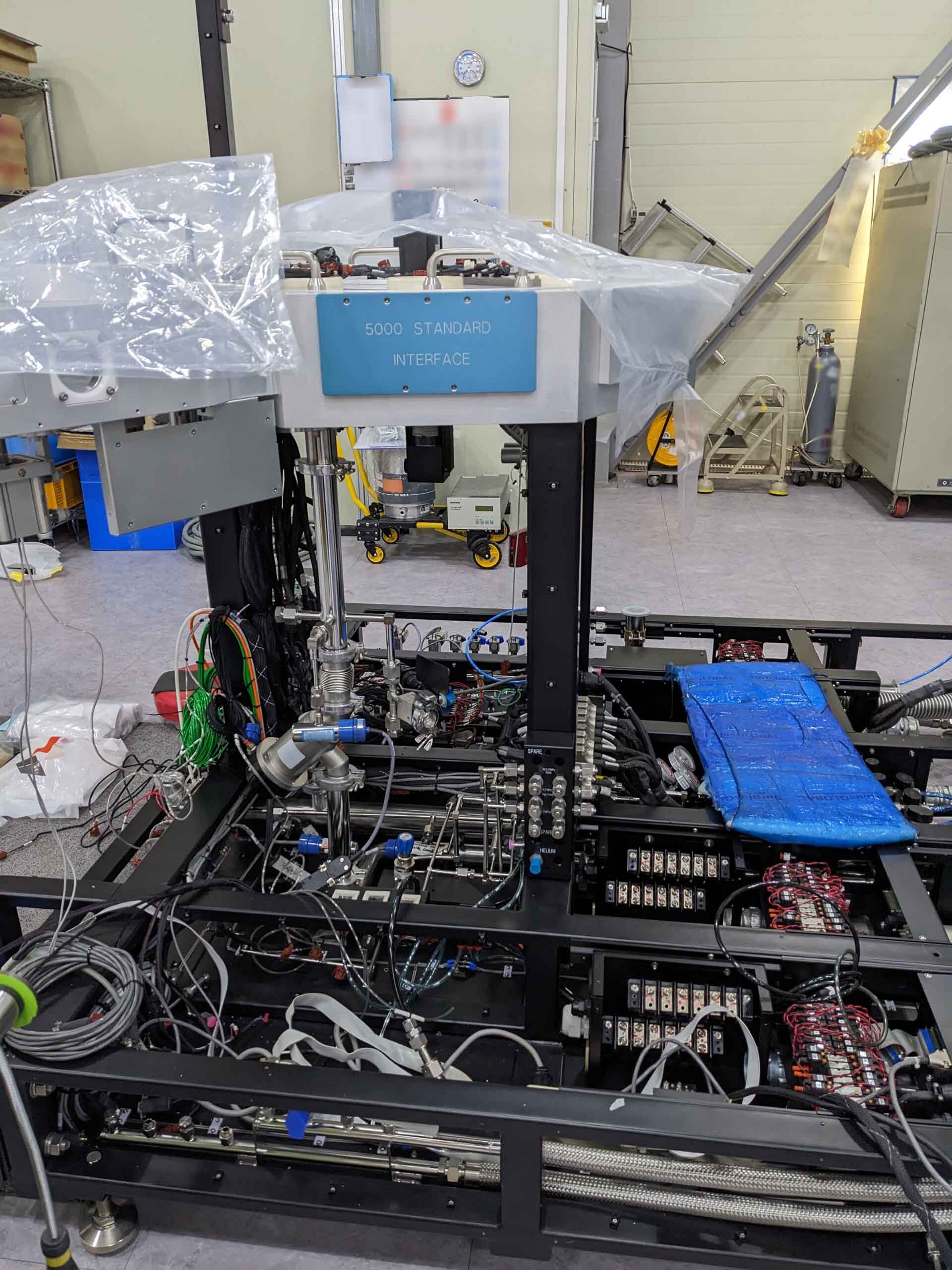

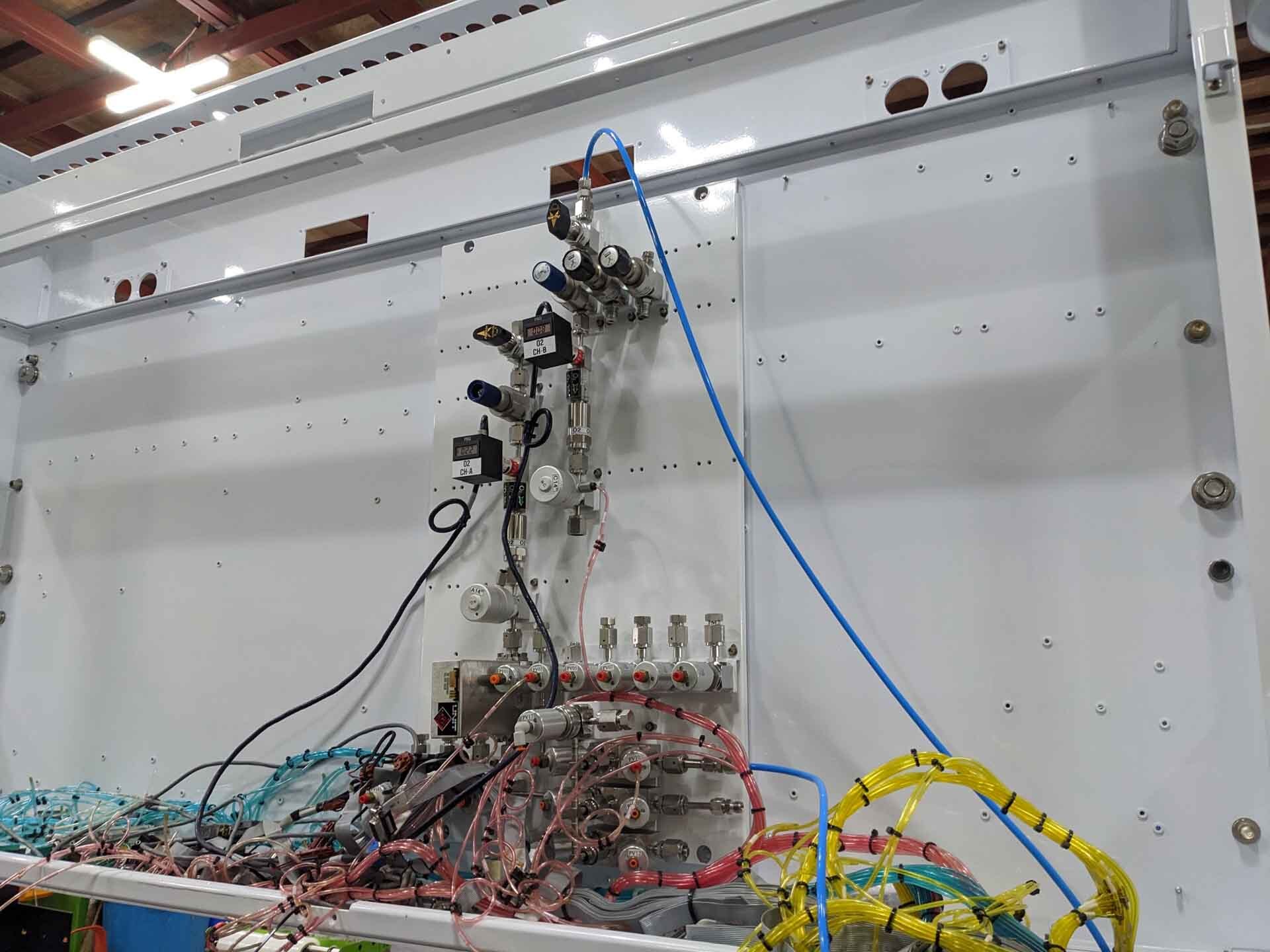

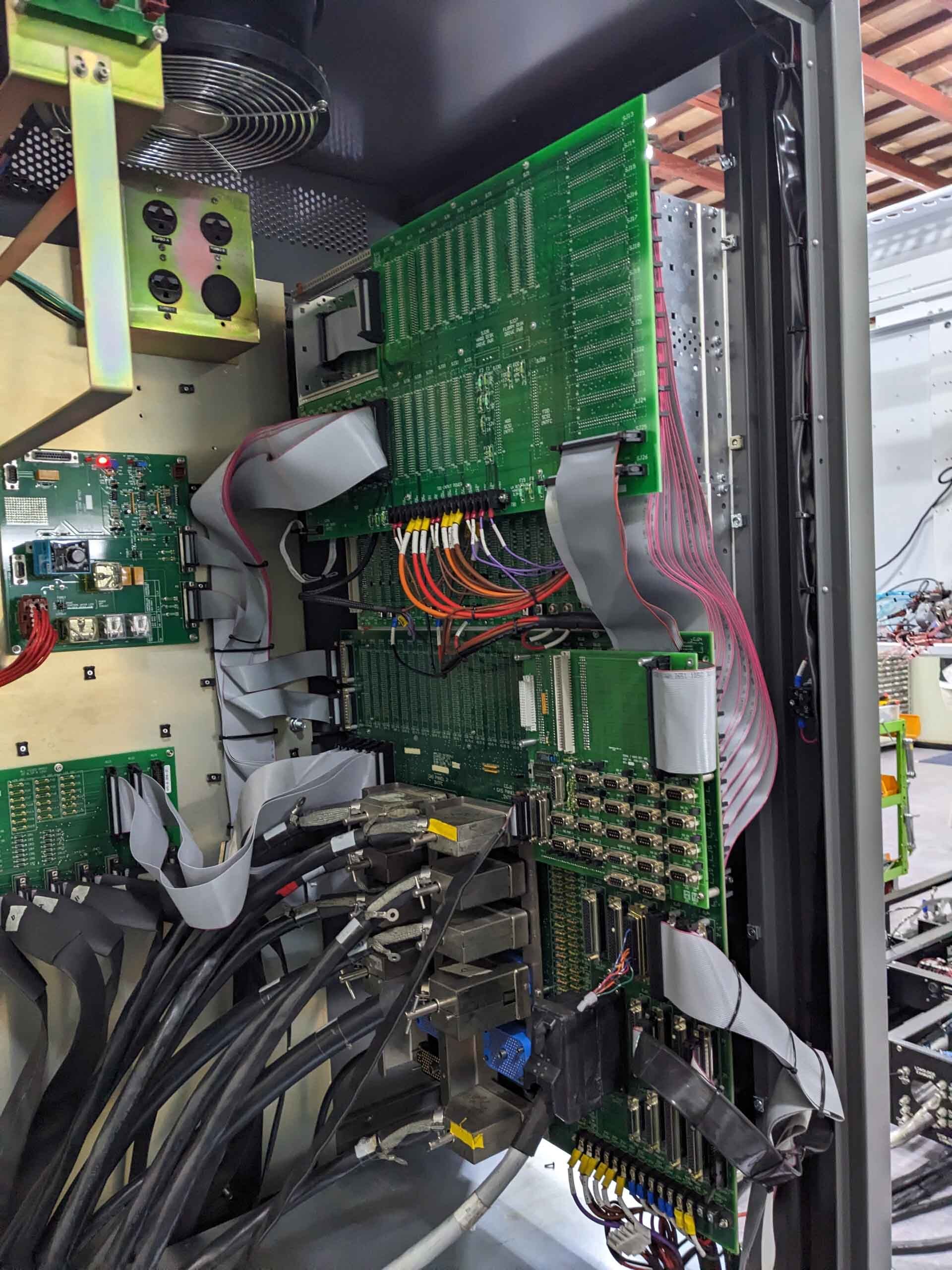

AMAT / APPLIED MATERIALS Centura P5000 is a low-pressure, multiple reactor, chemical vapor deposition (CVD) equipment for producing superior thin film lining materials for advanced device structures, as well as dielectric, passivation, adhesion and barrier layers. This versatile reactor provides high throughput and excellent uniformity for critical process steps such as vapor deposition and post-coating anneal in a wide range of semiconductor process applications. The system consists of multiple main processing chambers and up to four additional process chambers for substrate pre-cleaning, etching, and post-processing functions. The main process chamber has two primary process sources, typically two susceptor holders, that allow for the deposition of single and multiple layers of materials, such as silicon nitride, silicon oxide, aluminum oxide, tantalum oxide, aluminum nitride, silicon carbide, and other barrier materials. The susceptor holder is designed to allow for in-situ adjustment of the temperature, pressure, power, and deposition rate. This allows for greater flexibility in fine-tuning the application parameters and provides uniformity of deposited materials. The primary process chambers can accommodate substrates up to 30 cm between source and substrate. The systems state-of-the-art imaging unit with closed-loop feedback provides real time imaging to allow for precision layer control. AMAT Centura P5000 reactor can be used for a variety of semiconductor applications such as gate dielectric, passivation, contact barrier, adhesion and dielectric thin film deposition. The machine is also well-suited for shallow trench isolation, ultra-shallow junction formation, high-k deposition and annealing, forming silicide contacts, adhesion and surface conditioning, and other post-processing functions. APPLIED MATERIALS Centura P5000 provides many advantages in semiconductor manufacturing including high throughput, improved process control and excellent uniformity. The tool also comes with several user-friendly features such as high speed loadlock, automated remote control, and simple process recipes, allowing greater control and flexibility to meet customer needs.

There are no reviews yet