Used AMAT / APPLIED MATERIALS Centura Super-E #9252317 for sale

URL successfully copied!

Tap to zoom

ID: 9252317

Wafer Size: 8"

Vintage: 2000

Etcher, 8"

Install type: Thru-The-Wall (TTW)

Cassette interface:

(2) Narrow body load locks

Fast wafer mapping

Main tool:

Wafer handling robot

Signal lamp tower

Buffer lid open / Close assembly (Manual)

Wafer on blade sensor

Optical endpoint system

Chambers:

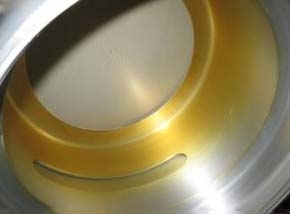

Ch-A, B, C, & D: Super-E oxide

Ch-E: Blank

Ch-F: Orienter

Chamber configuration:

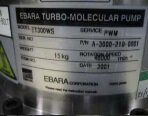

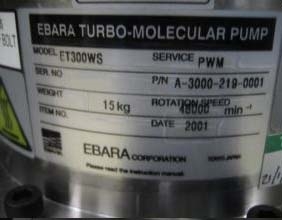

EBARA 305W Turbo controller

EBARA ET300WS Turbo pump

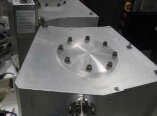

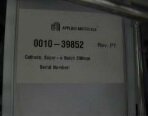

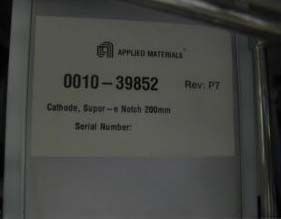

Chamber: P/N 0010-39736 REV A

Electrostatic chuck

HERF Match

Slit liner door

Autobias

Chamber liner

Cathode

Gas box / Gas pallet:

Standard gas panel interface

MFCs: AERA FC-D980C

CO 300 SCCM

C4F8 20 SCCM (TYLAN FC-2900 On chamber C)

N2 20 SCCM

O2 100 SCCM

CF4 100 SCCM

CHF3 150 SCCM (TYLAN FC-2900 On chamber A)

ARS 200 SCCM (AERA FC-D980CS)

Gas connection

User interfaces:

Front side monitor and light pen base

System side monitor and light pen base

System controller:

Equipment rack: (4) ENI OEM-28B RF Generators (Ch-A/B/C/D)

Chillers included:

B/E AEROSPACE 1231-CCN-DI-001 Dual channel

ATS 1231-CCN-DI-001 Dual channel

Power supply: 208 VAC, 4-Wire, 3 Phase

CE Marked

2000 vintage.

AMAT / APPLIED MATERIALS Centura Super-E is a reaction equipment that combines superior temperature and process control with a sophisticated design for maximum efficiency and reliability. This reactor uses a closed loop recirculation system to maintain consistent temperatures within the vessel, while providing uniform and repeatable results. The heater unit is made from quartz, which is up to three times more durable and efficient than other materials. This quartz heater machine is electronically tunable and provides precise, flat temperature control over a wide range of set points. The heater tool is further enhanced by dense thermal insulation and recirculated thermal transport medium to reduce heat loss. The process chamber is designed to enable accurate volumes of reactant to be processed, ensuring consistent and repeatable results. The lid is made from high purity quartz and is designed with a unique process isolation capability that minimizes contact between process gases and the environment. The process chamber also contains a high efficiency gas scrubber that removes corrosive and hazardous byproducts from the process chamber. The standard installation includes a comprehensive suite of monitoring and safety features that monitor environmental conditions within the chamber. This includes real-time monitoring of process chemicals, pressure, and temperature for enhanced process safety. The asset also includes a specialized warning model that alerts operators to potential process issues, helping to prevent potential catastrophic incidents. AMAT Centura Super-E includes automated process control software that allows for seamless and accurate process control. This software allows for automated calibration of process and product parameters, for increased efficiency and process reliability. This versatile and durable reactor comes in a range of sizes and configurations to meet the needs of any production requirement. The equipment is designed to provide repeatable results in the shortest amount of time, with minimal maintenance required. This superior production reactor is ideal for complex and demanding production environments.

There are no reviews yet