Used AMAT / APPLIED MATERIALS Centura Tectra TxZ #9117584 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

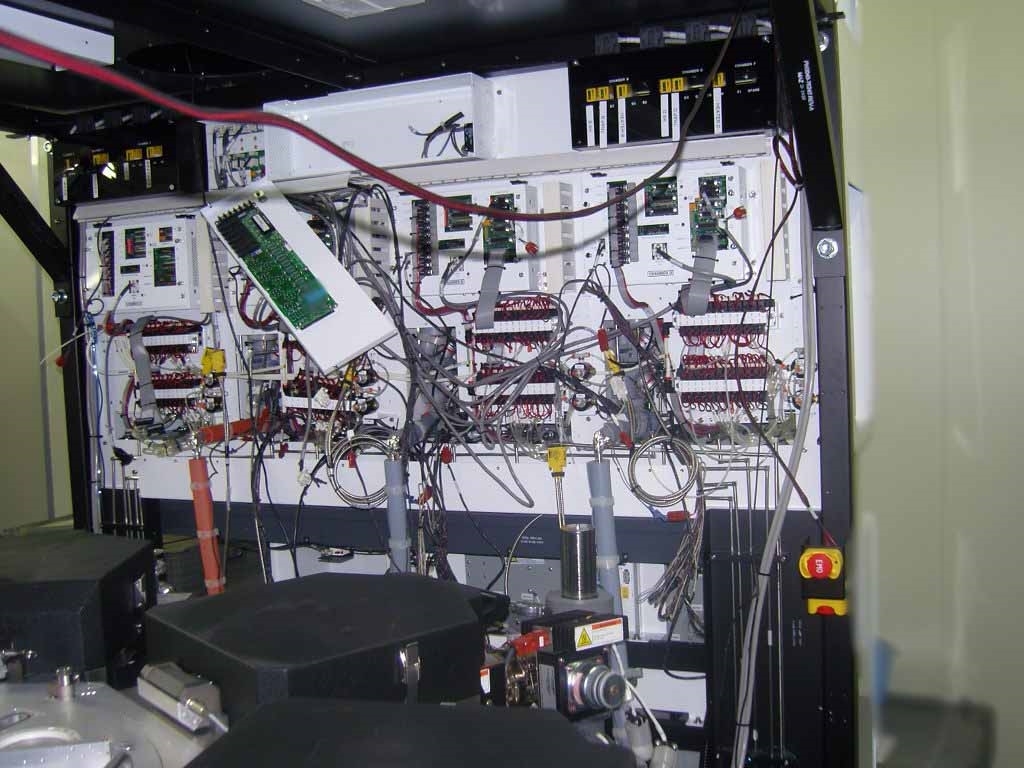

AMAT / APPLIED MATERIALS Centura Tectra TxZ is a multi-wafer processing equipment that offers both flexibility and scalability for a variety of advanced growth processes. It is a low-pressure, radio frequency sputtering system designed for the application of compound semiconductor, photovoltaic and optoelectronic materials. AMAT Centura Tectra TxZ provides advanced substrate delivery with wafer chaining capabilities, up to 10 wafers per task, automated lithography processes, and a wide variety of process parameters for enhanced material composition control. It's an efficient, all-in-one substrate delivery and multi-wafer deposition unit with a focus on increased process flexibility and scalability. APPLIED MATERIALS Centura Tectra TxZ is equipped with two wafer lift robots, load locks, high vacuum containment systems, and radio frequency power supplies. It also offers the ability to accurately calibrate process gases and radio frequency power levels for optimal substrate pre-treatment, deposition rates, and layer uniformity. It's designed to eliminate wafer-to-wafer interference while also delivering a high level of process repeatability even on large wafer arrays. The machine is supported by comprehensive process control capabilities, including real-time process monitoring. Centura Tectra TxZ also offers extensive process data for greater analytical research and data analysis capabilities. This data includes details like deposition rate, deposition thickness, growth rate, temperature gradient, and more. Its advanced heater tool allows temperatures up to 500°C on the wafers for process optimization and providing dramatic reductions in production time and cost. AMAT / APPLIED MATERIALS Centura Tectra TxZ also meets a wide range of cleanliness and safety requirements, including standards set by the US FDA. The Automated Materials Lift (AML) provides a precise wafer-to-wafer turnaround, while the Wafer Chaining asset optimizes wafer positioning and throughput for maximum efficiency. AMAT Centura Tectra TxZ was designed to complement Shallow Trench Isolation (STI), Low Temperature Oxide (LTO), T-Structure, Radio Frequency (RF) and other advanced processes to meet the needs of the semiconductor and optoelectronic industries.

There are no reviews yet