Used AMAT / APPLIED MATERIALS Centura Ultima HDP CVD #62203 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 62203

Wafer Size: 8"

Vintage: 2000

Etcher, 8"

(2) Ultima chamber

(1) Ultima plus chamber

Technology :IMD

Wafer Size : 8"

Wafer Shape : SNNF (Semi Notch No Flat)

Software Version : B4.3.14

CHAMBER TYPE AND LOCATION

Ch A : Ultima HDP-CVD

Ch B : Ultima HDP-CVD

Ch C : Ultima + HDP-CVD

Ch E : Multislot Cool Down

Ch F : Orientor

CHAMBER A,B Ultima HDP-CVD :

Nozzle : Long/Long Side

Clean Gas Distribution : Baffle

Turbo Pump : Ebara ET1600WS w/ HVA

Wafer Temperature Monitoring : Yes

Top Gas Feed : Without Top O2

Dual Independent He Control : Standard 10/10 TORR

Clean Method : Microwave

CHAMBER C - Ultima + HDP-CVD :

Nozzle : Long/Long Side

Clean Gas Distribution : Baffle

Turbo Pump : Ebara ET1600WS w/ HVA

Wafer Temperature Monitoring : Yes

Top Gas Feed : Without Top O2

Dual Independent He Control : Standard 10/10 TORR

Clean Method : Top Mount

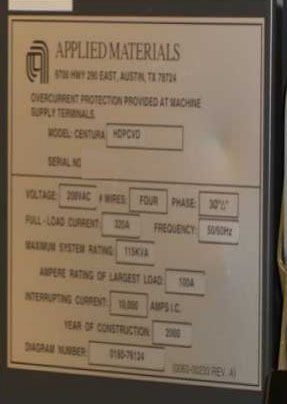

EXISTING ELECTRICAL REQUIREMENTS

Line Frequency : 60Hz

Line Voltage : 200/208V

Line Amperage : 600A Platform

EXISTING SAFETY EQUIPMENT :

EMO type : Turn to release EMO

EMO Guard Ring : Yes

System Labels : English w/Chinese Non-simplified

System Smoke Detector : Controller

EXISTING MAINFRAME :

Mainframe Type : Ultima HDP w/Multislot

Frame Type : Standard Frame

System Placement : Through the Wall

Mainframe Skins : No

Mainframe Exhaust Duct : No

Mainframe Facilities Connection : Back

Robot Type : HP Robot

Robot Blade : Ceramic

Loadlock Cassette : Narrow Body

Narrow body Loadlocks : Cassette Present Sensor

Loadlock Wafer Mapping : Basic

N2 Purge Type : STEC 4400MC 10 Ra Max

EXISTING GAS DELIVERY :

Gas Panel Surface Finish : Standard Gas Panel

MFC Type : STEC 4400MC 10 Ra Max

Valves : Fujikin 5 Ra Max

Filters : Pall Ni 10 Ra Max

Transducers : MKS w/ Display

Regulators : Veriflo

System Cabinet Exhaust : Top

Gas Panel Gas/Flow Direction Labels : Yes

APC Seriplex Cover : Yes

Gas Panel Doors : Solid

Gas Pallet Configuration :

Chamber A, B, C

Gas Stick/Process Gas/MFC size/Regulator/Transducer

#1 SiF4 100 Y Y

#2 O2 400 Y Y

#3 SiH4 200 Y Y

#4 Ar 300 Y Y

#5 SiH4 20 Y Y

#6 Ar 50 Y Y

#7 NF3 2000 Y Y

#8 Ar 2000 Y Y

REMOTES :

RF Generator Rack - Ultima Gen. Rack

ASTEX 80S09mW (3)

Quantity : Two

Ultima Stand-Alone RF Generator Rack : Yes

Generator Rack Cooling - RF Gen Rack Manifold with Quick Disconnect Ultima Gen Rack H20 Connection - Barbed Brass

Existing Heat Exchanger : SMC Thermo

Umbilicals :

System Controller Signal Cable Length : 55ft

RF Gen Rack Cable Length : 50ft

Ultima Stand-Alone Generator Rack : 98 ft

HX Hose Length : 50ft

HX Cable Length : 50ft

Pump Cable : 50ft

Ultima Microwave Generator Cable Length : 50 ft

Ultima WTM Cable Length : 32.8 ft (10m)

Vacuum Pumps, Exhaust Scrubber not included in sale

Currently crated and stored

System Can be inspected

1999-2000 vintage.

AMAT / APPLIED MATERIALS Centura Ultima HDP CVD is a chemical vapor deposition (CVD) reactor with a proprietary Hot-Wall-Delivery-Plasma (HWDP) processing chamber. This reactor is specifically designed to facilitate chemical vapor deposition of a range of materials with optimized thermal and plasma uniformity. The reactor uses chemical precursors to create layers of material on substrates such as metal, silicon, or ceramic. With the ability to produce incredibly thin, conformal layers of high-density plasma-assisted deposition (HDP), this reactor is an ideal tool for applications ranging from semiconductor packaging and advanced interconnects to biomedical and nanotechnology-related applications. AMAT Centura Ultima HDP CVD reactor is designed to provide maximum uniformity and repeatability during the CVD process. The design of the HWDP processing chamber allows for precise evaporation of precursors which are converted into a plasma state upon contact with the hot plasma source. This plasma source has a high degree of uniformity, providing the resulting coating with a consistent layer thickness throughout the substrate. Additionally, the HWDP chamber design eliminates the need for cooling, allowing for higher temperature control for improved layer density. The use of temperature sensors throughout the chamber also allows for precise temperature control for improved layer uniformity and property control. APPLIED MATERIALS Centura Ultima HDP CVD reactor is also designed to promote high throughput performance. The processing chamber is designed to operate at low pressure, allowing for high flow rates of precursor and process control gases. This high throughput can be leveraged to maximize the production volume and yield while maintaining the highest levels of process and quality control. Centura Ultima HDP CVD is an excellent tool for a variety of CVD applications. From creating high density layers for semiconductor packaging to biomedical materials and nanotechnology, this reactor has features engineered to facilitate the deposition of coatings with improved uniformity and repeatability. This reactor is ideal for applications requiring precise control of layer thickness, temperature, and uniformity, enabling the deposition of HDP layers for the most advanced technology.

There are no reviews yet