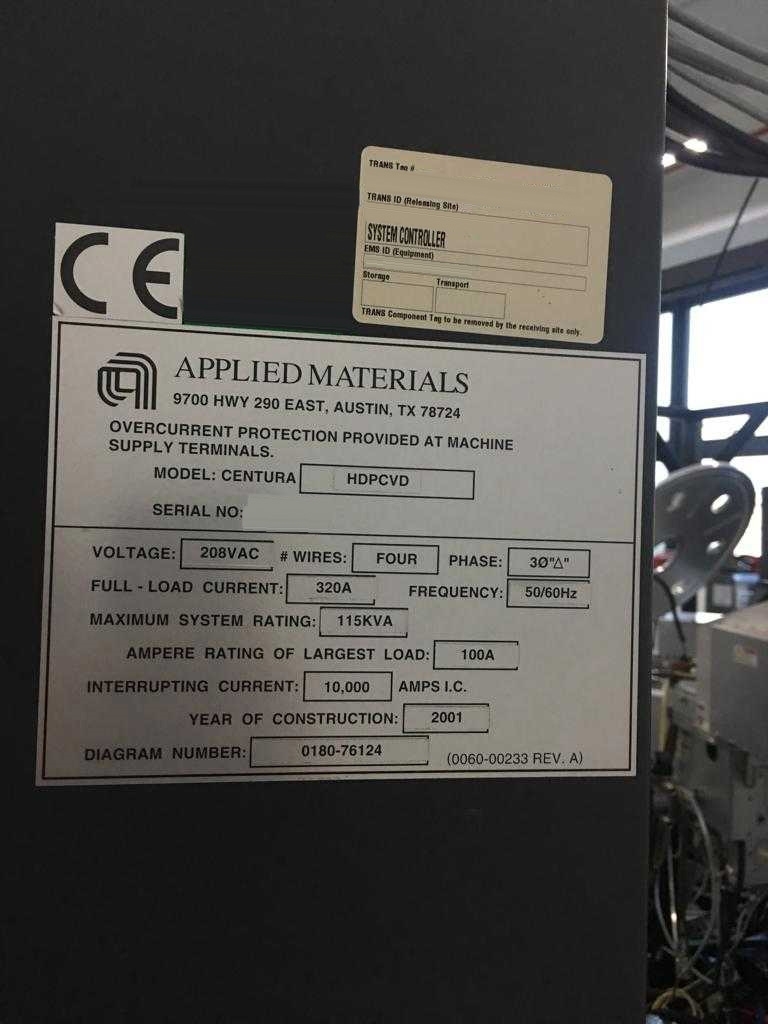

Used AMAT / APPLIED MATERIALS Centura Ultima HDP #9223731 for sale

URL successfully copied!

Tap to zoom

ID: 9223731

Wafer Size: 8"

Vintage: 2001

CVD System, 8"

System general:

Mainframe: Centura 5200 DCVD

Wafer type: Notch

Chamber position A, B, C: HDP Ultima plus chamber, 8"

Chamber E position: Multi-slot cool down chamber

Chamber F position: Wafer orienter chamber

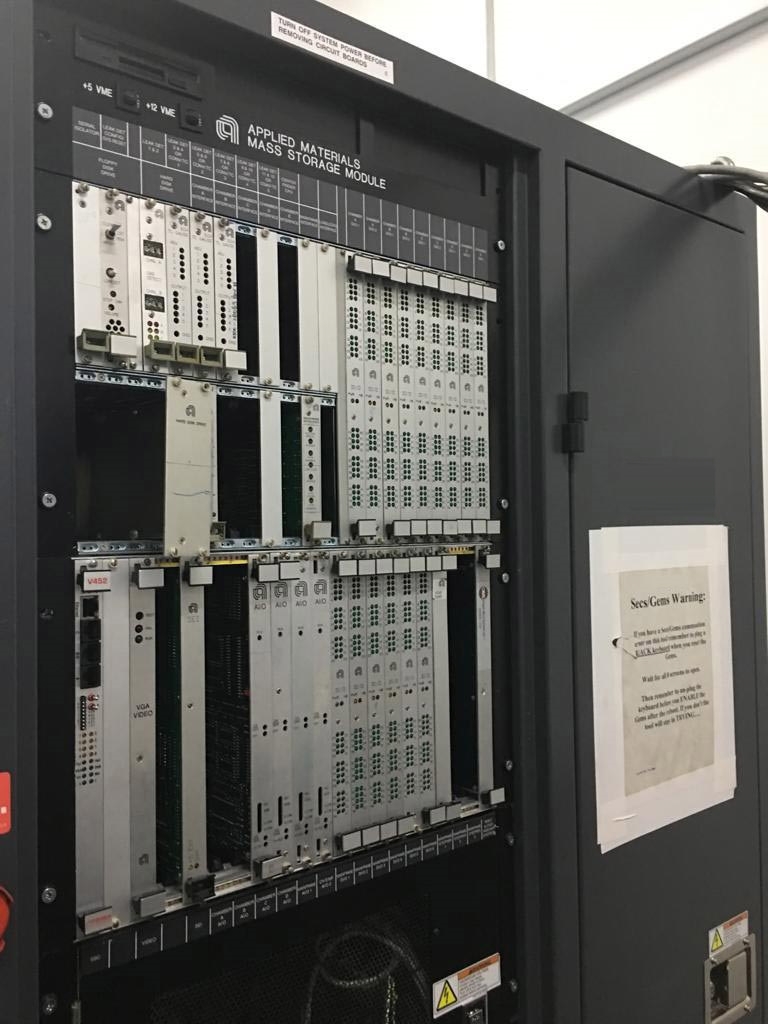

System controllers:

SBC V452 Board

VGA Board

P3 Board

Facility and safety configurations:

EMO Switch type: Turn to release EMO

EMO Guard ring

EMO Shunt trip

Bracket standoff adapter

Water and smoke detect output: Alarm

Facility power indicator

System water leak detector

Main frame:

Facilities type: Phase II

System placement: Stand alone

Front panel: Steel white polymer finish

Facilities connection: VCR

Facilities orientation: Mainframe facilities bottom connection

Facilities water: Phase II water

Controller IO interface option: I/O Expansion base card with seriplex gas panel card

Interface: GEM Interface

Load lock chamber type: Narrow body

Transfer chamber:

Transfer chamber manual lid lift

Transfer chamber sensor

Process chamber slit valve A, B, C: Bonded door with KALREZ O'ring

Robot type: HP+ Robot (Dual speed)

Basic wafer on blade detector

N2 Purge MFC type: Unit instrument (UFC-1661) 1L

Buffer purge slow vent flow: 500 sccm

Dedicated transfer rough pump: EDWARDS Pump interface

Mainframe inert gas lines:

Chamber N2 supply

Chambers N2 surface finish: 10 Ra

Mainframe N2 supply

Mainframes N2 surface finish: 10 Ra

Chamber A configuration:

Type: HDP Ultima plus chamber

Frequency type: Top, side and bias RF

Heater type: 0190-46458

Thermalogic board

Manometer type: DUAL 10/100 TORR MKS

Throttle valve: Turbo throttle valve plus rough throttle valve

Gate valve type: 3870-04276, Pendulum ISO250 (Actuator 52.3)

Turbo pump type: EBARA ET1600W

Turbo pump controller: 1604W

Turbo pump ring type:

0010-11762, CTR Ring assy, HDP-CVD Ultima plus

Chamber O'ring type: KALREZ 9100

Clean method: RPS

0190-26744, MKS Astroni AX7670

Clean gas: NF3

Chamber A process kit:

0010-03090 ESC Cathode (WTM Type)

0040-18219 ESC (WTM Type)

0190-18430 WTM Probe

0200-18109 Collar

0200-18081 Cover ceramic

0200-01009 Top nozzle

0200-18093 Side nozzle

0200-01006 Dome

0040-04650 Gas ring with (24) nozzles

0200-40156 Lift pin ceramic

Chamber B configuration:

Type: HDP Ultima plus chamber

Frequency type: Top, side and bias RF

Heater type: 0190-46458 Thermalogic board

Manometer type: Dual 10/100 TORR MKS

Throttle valve: Turbo throttle valve plus rough throttle valve

Gate valve type

3870-04276, Pendulum ISO250 Actuator 52.3

Turbo pump type: EBARA ET1600W

Turbo pump controller: 1606W TF

Turbo pump ring type:

0010-11762, CTR Ring assy, HDP-CVD Ultima plus

Chamber o ring type: KALREZ 9100

Clean method: RPS

0190-26744RPS, MKS Astroni AX7670

Clean gas: NF3

EDWARDS Rough pump interface

0010-03090 ESC Cathode (WTM Type)

0040-18219 ESC (WTM Type)

0190-18430 WTM Probe

0200-18109 Collar

0200-18081 Cover ceramic

0200-01009 Top nozzle

0200-18093 Side nozzle

0200-01006 Dome

0040-04650 Gas ring with (24) nozzles

0200-40156 Lift pin ceramic

Gas panel configurations:

Gas panel type: HP 10 Ra

Cabinet exhaust: Top exhaust

Gas panel door

Gas feed: Single-line drop (Bottom feed)

Valve type: FUJIKIN 5 Ra max

Filter: MILLIPORE Ni 10 ra max

Fitting: VCR

MFC: SEC-4400 MC (D-Sub 9 pins)

Veriflo Regulator

MKS Transducer with display unit

Gas line configuration chamber A, B, C:

Gas pallet: HDP Ultima plus

Gas feed: Single-line drop (Bottom feed)

Automatic gas line purging capability

Gas 1: SiH4, 200 sccm

Gas 2: NF3, 2000 sccm

Gas 3: SiH4 Top, 20 sccm

Gas 4: SIF4, 20 sccm

Gas 5: AR Top, 50 sccm

Gas 6: AR, 300 sccm

Gas 7: HE, 200 sccm

Gas 8: SIF4, 100 sccm

Gas 9: O2, 400 sccm

Gas 10: AR-MW, 2000 sccm

System controller:

Controller Type: Phase I Controller

Controller GFCI: 30MA GFCI

Controller UPS: Facilities ups interface

Controller electrical interface: Top feed AC cables

Controller exhaust: Top exhaust

Cursor type: Blinking cursor

Heat exchanger type:

SMC Themo chiller, INR-498-001D

Heat exchanger water fittings: Stainless steel

Generator rack:

Chamber A, B, and C top RF generator: ENI NOVA-50A

Chamber A, B and C side RF generator: ENI NOVA-50A

Chamber A, B and C bias RF generator: ENI GHW-50A

Power: 200/208 VAC, 50 Hz, 400 A

2001 vintage.

AMAT / APPLIED MATERIALS Centura Ultima HDP Reactor is an advanced tool in the world of dry-in-place etching and conformal coating. This equipment is designed to allow manufacturers to achieve a high degree of precision with minimal effort and minimal complexity. The HDP stands for High-Density Plasma, the latest plasma technology that is designed to provide the highest level of performance and cycle-time control over a variety of processes. AMAT Centura Ultima HDP Reactor meets the increasingly complex needs of semiconductor manufacturers worldwide. The system's advanced features and modular architecture enable rapid implementation, flexibility and scalability for a wide range of applications. This includes ultra-thin conformal coating, deep reactive ion etching (DRIE), electroplated copper lift-off (ECLO), and other applications. APPLIED MATERIALS CENTURA ULTIMA+ HDP Reactor offers high levels of productivity with optimized throughput and cycle-time control. Its Multi-Frequency RF plasma source and water-cooled cathode enable small feature size control and low film stress while its linear mass flow controllers enable precision control over process gases. Its modular architecture allows it to be reconfigured with minimal disruption and configured in multiple chambers enabling fast and accurate processing of a numerous parts in parallel. The HDP Reactor features latest advancements in plasma source technologies to optimize etching and conformal coating processes. Its newly designed plasma source and chamber allow for high-aspect ratio etching and coating. The HDP Reactor's advanced process control capabilities help in achieving tight process distributions, lessening the need for manual adjustment by the operators. The unit's real-time process monitoring allows for quick decisions and rapid corrective action. This machine has integrated intelligent diagnostics for fast error feedback and minimal downtime. Its online simulation capabilities enable users to quickly tweak a recipe and make necessary changes without long set-up times. Furthermore, its data output can be used to record relevant process details and improve process monitoring capabilities. AMAT / APPLIED MATERIALS CENTURA ULTIMA+ HDP Reactor is the latest and most advanced tool in the world of dry-in-place etching and conformal coating. This tool is designed for semiconductor manufacturers seeking a reliable and efficient asset with high levels of precision and repeatability. Its advanced features and modular architecture enable rapid implementation and scalability, allowing it to be reconfigured with minimal disruption and configured in multiple chambers to cover a variety of applications. AMAT CENTURA ULTIMA+ HDP Reactor provides high levels of productivity and is equipped with the latest advancements in plasma source technologies, allowing users to achieve the precision required for complex processes.

There are no reviews yet