Used AMAT / APPLIED MATERIALS Centura Ultima Plus #9046180 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9046180

Wafer Size: 8"

Vintage: 1999

CVD, 8"

Main body:

3-Chamber

Signal tower: 3-Color

Door interlock sensor

Wafer OF type: Falt type

Process chamber:

Dome heater cooling type

Ceramic ESC: WTM

Top mount remote plasma

Generator type: ENI

Local match box

Heat exchanger: SMC

Dual IHC control

Main frame:

Loadlock body: Wide

Wafer sliding sensor

Cool chamber slot: 8-slot

HP Extend robot: One ARM

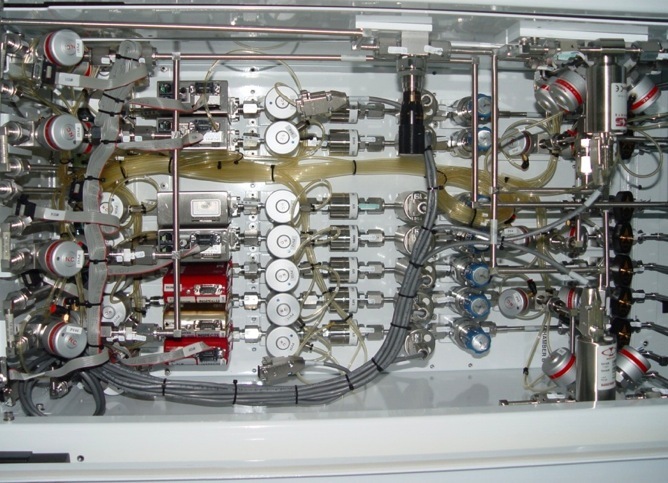

Gas panel:

Cabinet exhaust: Top

Single line drop

Gas line feed: Top

Monitor:

Third: Station

Maint: Others

Missing parts or Detaching parts list:

(3) Gas ring 0010-02616

(2) Silt valve plate 0010-20021

(1) TGV trottle valve 0020-12521

(1) RPS Al GAS line 0050-46867

(2) Ceramic dome 0200-18062

(3) TGV sol v/v ass'y 3870-01649

(1) Cold loop flow sensor

(1) NF3 MFC (2L)

(1) Top Ar MFC (50 sccm)

Packing list:

Main system

Power AC rack

Rf generator rack(eto)_1

Rf generator rack(eto)_2

Rf generator rack(eto)_3

Rf generator rack(eto)_4

Rf generator rack(eto)_5

SMC chiller

Monitor

Currently installed

1999 vintage.

AMAT / APPLIED MATERIALS Centura Ultima Plus is a powerful, fully automated, high-throughput chemical vapor deposition (CVD) reactor designed for the production of focused, high-quality thin films. This equipment features the latest in CVD technology for deposition of a wide variety of materials, including ultra-thin dielectrics, semiconductive and metallic surfaces. This system utilizes the latest in process control methods, such as advanced gases and temperature control, to maximize throughput and improve productivity and reproducibility. Additionally, the unit enables the production of a variety of novel nanostructures and microstructures to enable new device architectures. At the heart of the machine is an innovative multi-zone CVD reactor, a three-chamber design with a single large batch chamber. This chamber enables highly uniform deposition of a variety of materials across a wide range of wafer sizes, ranging from 3" to 8". The tool is also capable of handling a broad range of deposition recipes, including both powder and PLD-sourced precursors for improved process control. The deposition rates are further optimized through advanced gas delivery systems and fast wafer rotation. AMAT Centura Ultima Plus is also capable of highly precise thickness control and intricate structure formation, from CMCVD features to patterned wires. APPLIED MATERIALS Centura Ultima Plus also features automated wafer loading and unloading, with an advanced nitrogen purge asset ensuring an ultra-clean environment in which to avoid wafer contamination. In addition, the model employs an advanced optical equipment for real-time monitoring of process conditions. The installation of a single Centura Ultima Plus can handle thousands of wafers per day and yields are maximized through the implementation of advanced exhaust treatment and recovery systems. AMAT / APPLIED MATERIALS Centura Ultima Plus is an ideal system for the production of focused, high-quality thin films, nano and microstructures, and is also optimal for handling material composites and nanoparticle-based applications. The unit performs exceptionally well in a wide range of production environments and its automation capabilities maximize process speed and uniformity while providing value to your production line.

There are no reviews yet