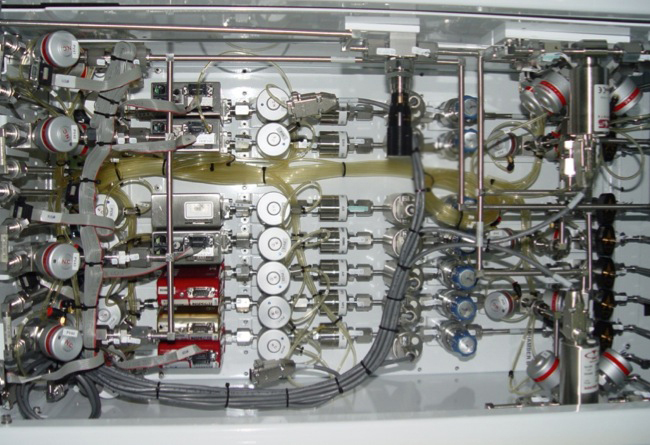

Used AMAT / APPLIED MATERIALS Centura Ultima Plus #9065273 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9065273

Wafer Size: 8"

Vintage: 1999

Etcher, 8"

(3) Chambers

Flat type

Door interlock sensor

Dome heater cooling type: yes

Ceramic ESC: WTM

Top mount remote plasma: Yes

Local match box: Yes

Heat exchanger: SMC

Dual IHC Control: Yes

Centura1 Ph 2

Wide L/L

Wafer map sensor

Wafer sliding sensor

Cool chamber slot: 8-slot

HP Extend robot: One arm

Cabinet exhaust: Top

Single line drop: Yes

Gas line feed: Top

Monitor, third: Station

SMC Chiller

Leybold Mac 2000 TMP

Alcatel ATH2300

ENI generator

1999 vintage.

AMAT / APPLIED MATERIALS Centura Ultima Plus is a chemical vapour deposition (CVD) reactor designed for optimal temperature, pressure and gas uniformity. This state-of-the-art CVD reactor has been designed to deliver high-precision performance in a variety of deposition processes. AMAT Centura Ultima Plus reactor has an advanced thermal control equipment, with two independent temperature zones for optimal reactant uniformity and process control. The reactor utilizes multiple uniform, direct thermal processes which ensure reliable, top accuracy performance. Additionally, the process chamber is heated from both sides, accelerating the rates of heating and cooling to ensure uniformity of the deposition environment. The reactor also uses an advanced electrostatic charging system, which can also be used to control the rate and amount of particles stemming from the deposition process. This process, combined with an efficient cluster tool design, allows for high-quality deposition with maximum efficiency. Furthermore, APPLIED MATERIALS Centura Ultima Plus reactor is equipped with a dual-sensor, temperature control unit for providing precise temperature control for different gases and reactants. The machine is designed to provide a highly accurate and repeatable temperature profile across the entire substrate, ensuring uniformity and accuracy in deposition processes. Centura Ultima Plus also features multiple-zone gas control, allowing for precise gas flow control to optimize the deposition process. This design feature ensures that the reactants maintain their recommended reactant purity, ensuring a reliable and efficient deposition process. Finally, AMAT / APPLIED MATERIALS Centura Ultima Plus features a process chamber size of up to 2000cc, designed for maximum efficiency and optimum volume. Its quartz reactor tube and stainless steel process chamber walls are designed to be durable, providing maximum temperature control and optimum film quality during the process. These features make AMAT Centura Ultima Plus a highly efficient and reliable reactor for a variety of deposition processes.

There are no reviews yet