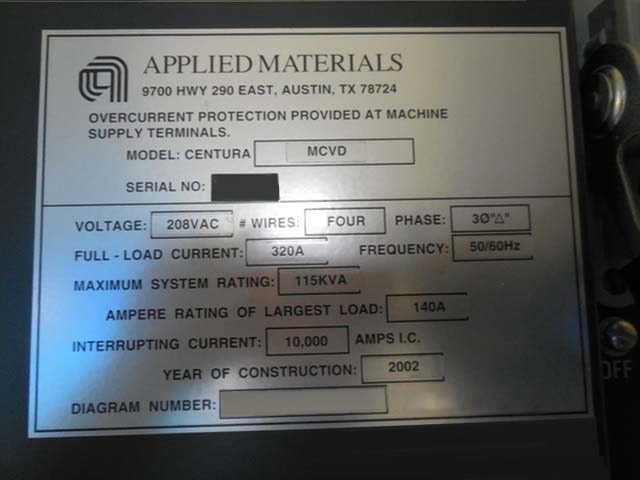

Used AMAT / APPLIED MATERIALS Centura XP #9201763 for sale

URL successfully copied!

Tap to zoom

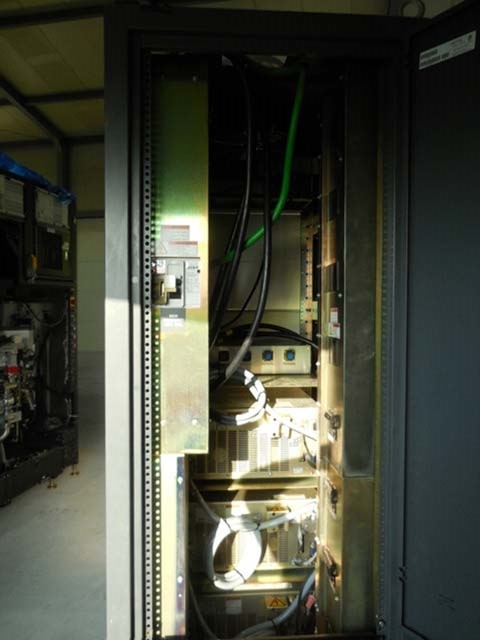

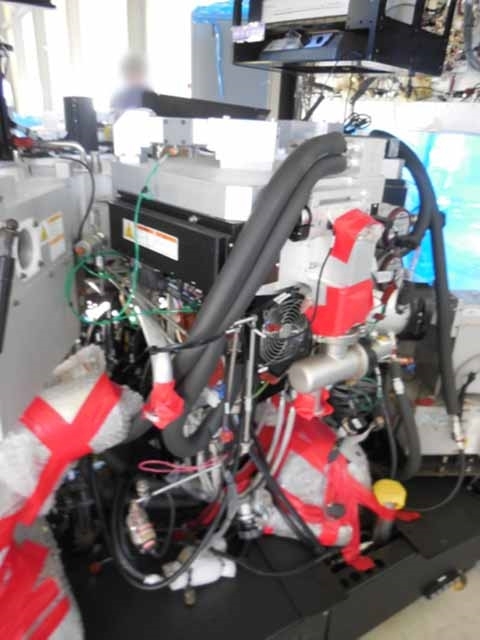

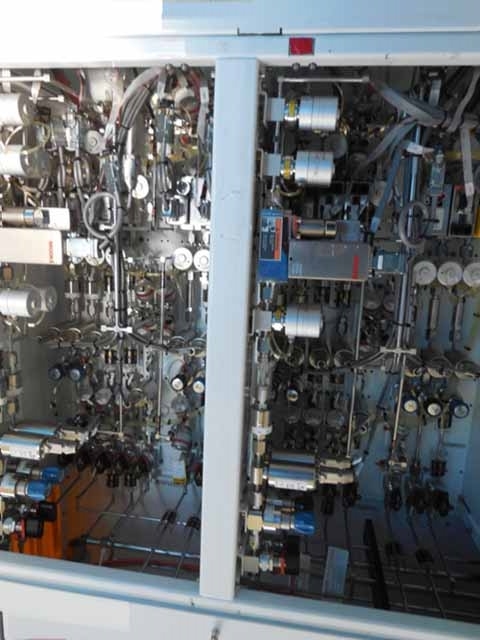

AMAT / APPLIED MATERIALS Centura XP reactor is a versatile, processing equipment designed to meet the demands of today's high-productivity semiconductor manufacturing. This piece of equipment is able to handle both advanced and legacy processes, allowing for excellent flexibility and scalability when transitioning between different technologies. AMAT Centura XP is capable of performing a wide range of different processes, including deposition, etch, and chemical vapor deposition (CVD). The system also offers advanced process monitoring and control, with options for metrology, wafer breakage detection and failure audits. APPLIED MATERIALS Centura XP provides excellent thermal control and includes automated wafer transfer support, allowing for fast cycle time and repeatable results. Centura XP reactor offers superior flexibility and accuracy, due to its dual loadlocks and an automated in-situ loadlock (ISLL) option, as well as a programmable, modular, and extendable platform. This provides users with the ability to configure the unit to their specific needs and ensures maximum process control. Additionally, the machine features high-pressure gas and liquid PRGD's, integrated safety checks and interlocks, automated pressure and temperature monitoring, and a heating tool with several options (depending on the type of application). AMAT / APPLIED MATERIALS Centura XP reactor is designed for maximum reliability and uptime, and comes with a wide range of integrated features. It supports up to 24 recipe levels, on-the-fly adjustments, oxygen, helium, and nitrogen purging, and is compatible with a range of advanced process recipes, such as downstream reactants for etching and surface damages. Additionally, the asset includes 20" cluster tools, allowing up to five recipes to be simultaneously applied on up to six wafers, while an automated cassette-to-cassette (CTC) transfer model ensures a reliable wafer transfer cycle. The equipment's construction features mirror-polished components, which reduce particulate generation and maximize performance and throughput. Furthermore, AMAT Centura XP reactor is engineered for low-cost, high-volume process reproducibility and excellent particulate control. To maximize reliability and uptime, the system is equipped with an automated process validation layer, which allows for rapid error detection and correction. Additional features include an on-board preventive maintenance unit, as well as automated alarm and fail safe systems. The machine can also be configured to automatically adjust to changes in plasma conditions, reducing the need for manual, labor-intensive adjustments.

There are no reviews yet