Used AMAT / APPLIED MATERIALS CENTURA #9150586 for sale

URL successfully copied!

Tap to zoom

ID: 9150586

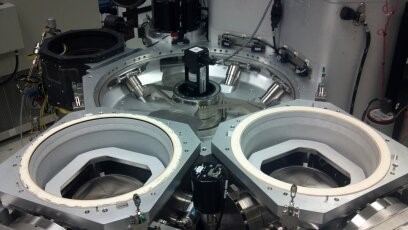

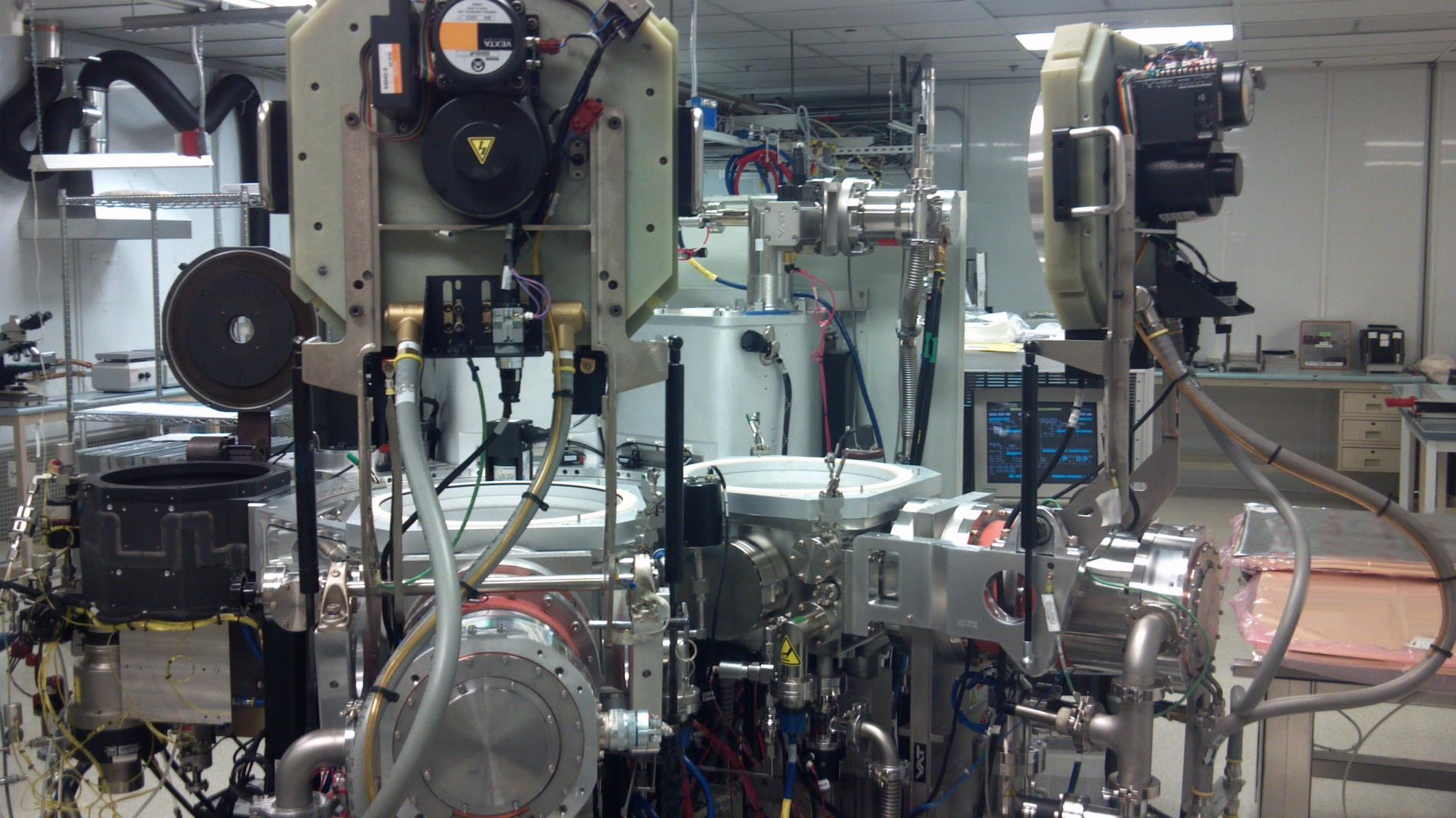

PVD system

(2) PCVD chambers

Standard body alum

(4) Finger heaters with back side gas

Orienter / Degas chamber.

AMAT / APPLIED MATERIALS CENTURA is an advanced equipment used to manufacture semiconductor devices. The system consists of two key components: an electro-chemical reactor and an Integrated Processing Unit (IPU), which both work together to create the desired semiconductor device. The electro-chemical reactor is the heart of AMAT CENTURA. It's designed to react substrates such as wafers with high-speed ion implantation, thermal diffusion and diffusion-reaction processes. The reactor uses diffused gas, laser, and plasma technologies to produce and control geometry as well as controlled temperature range. The second component of APPLIED MATERIALS CENTURA is the IPU, a computer-controlled unit that further refines the substrates that have already been processed in the reactor. The IPU is able to quickly and accurately analyze the wafers to measure parameters such as defectivity, uniformity and cleanliness. It can also perform the complex tasks of doping and patterning the surface of the wafer, creating the desired geometry or specific devices. By combining the reactor and the IPU, CENTURA can precisely and efficiently create semiconductor devices. In fact, it can recreate the same process for each wafer every time it's used, which ensures repeatable and reliable results. This makes it an invaluable tool for the semiconductor industry. Aside from its ability to create smaller, faster, and more powerful semiconductor devices, AMAT / APPLIED MATERIALS CENTURA also benefits from its low cost of ownership. Not only is the initial purchase cost surprisingly low, but it's also easy to maintain and requires little upkeep. This makes it an attractive solution to many companies looking to save costs while still producing high-quality devices. Overall, AMAT CENTURA is an incredibly advanced machine that provides unprecedented precision and repeatability. Its ability to produce reliable, high-quality devices and its low cost of ownership make it one of the most powerful tools in the semiconductor industry.

There are no reviews yet