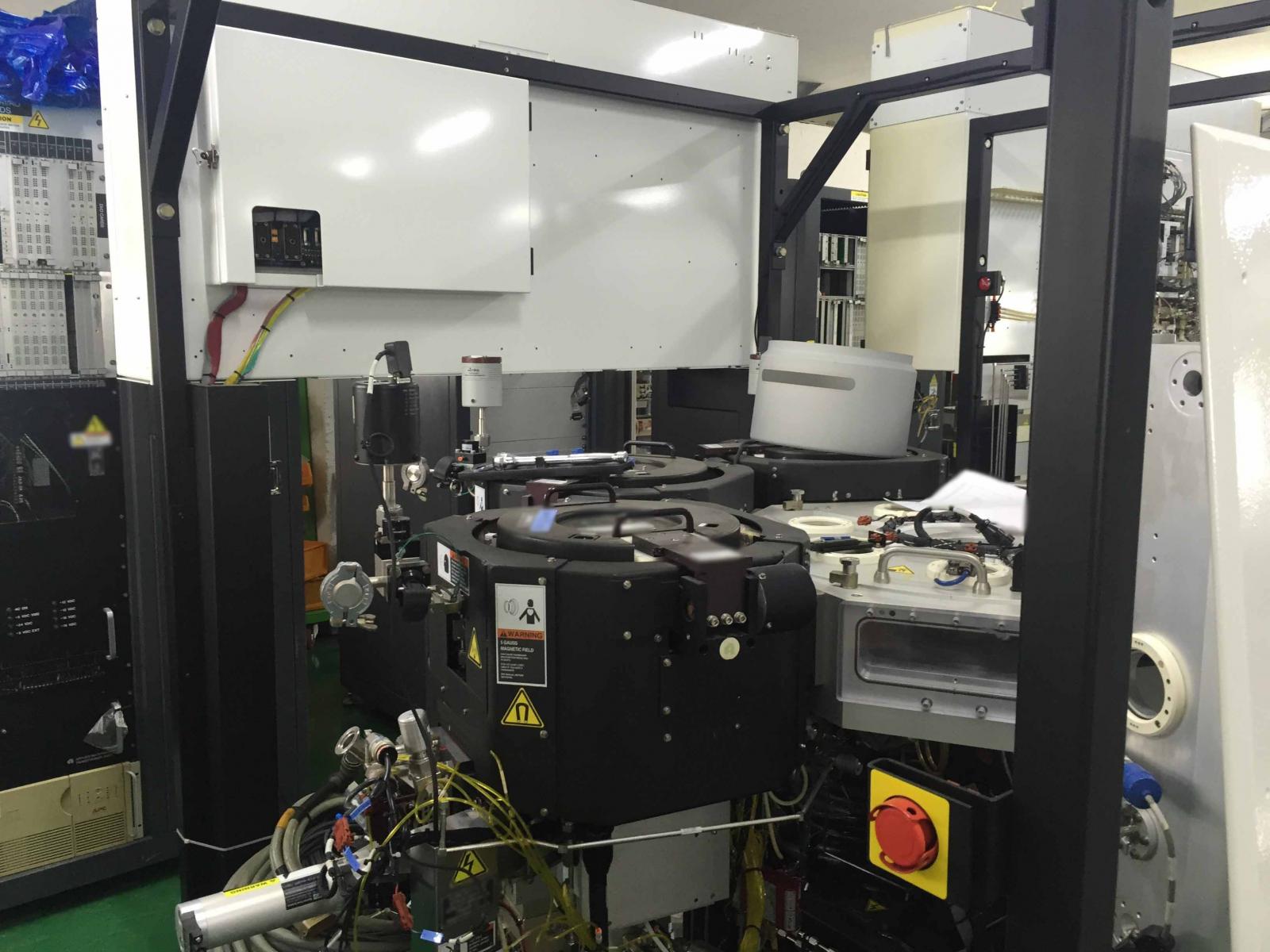

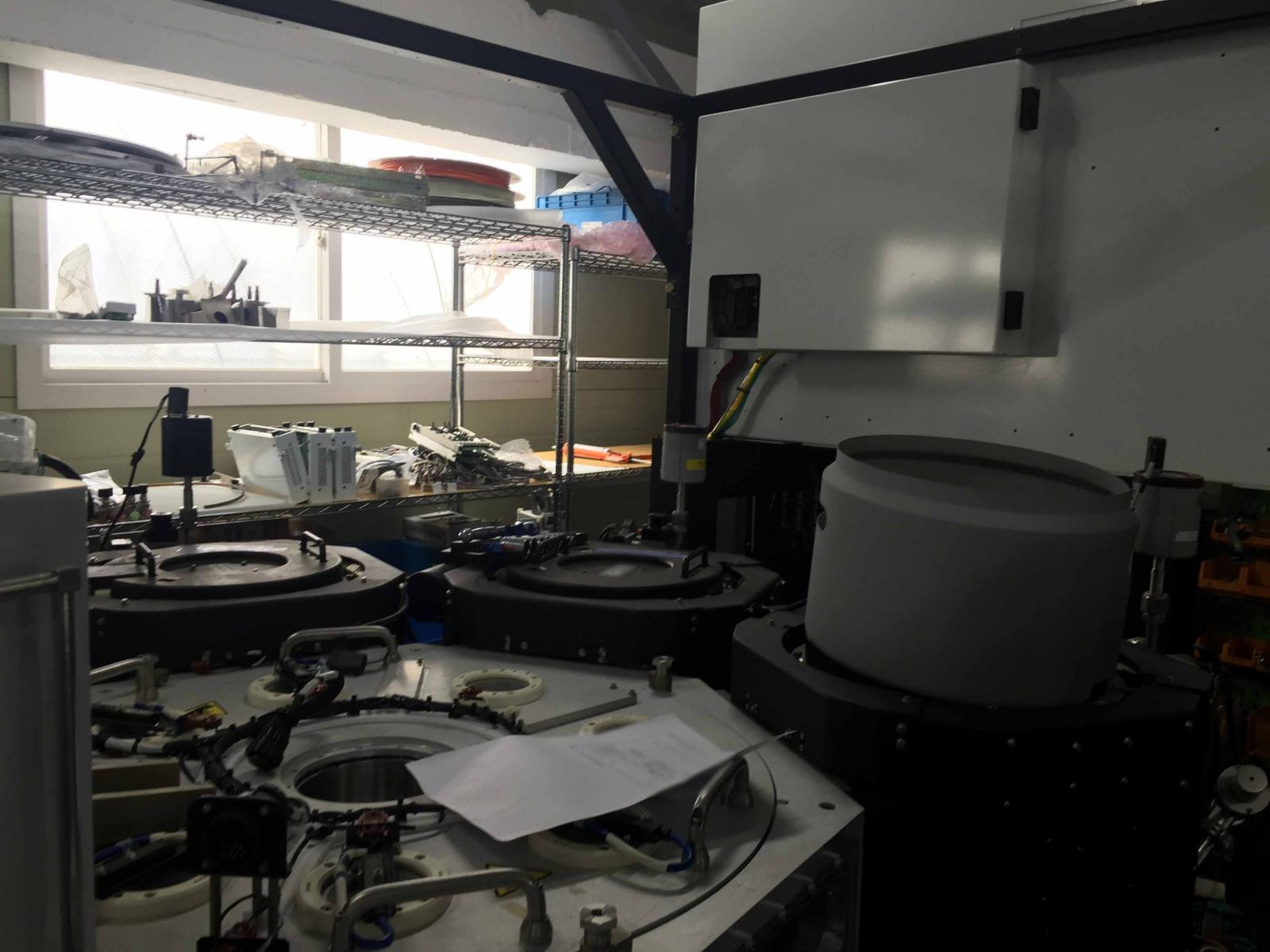

Used AMAT / APPLIED MATERIALS CENTURA #9160522 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS CENTURA reactor is a high performance, semi-automatic PECVD (plasma-enhanced chemical vapor deposition) equipment designed to provide cost-effective plasma deposition of inorganics at high rates. The process chamber contains four RF (radio frequency) sources operating at 13.56MHz that are used to ignite and sustain a microwave plasma in the process chamber. The plasma source is capable of handling low-to-moderate pressures (<10-3 torr) and powers up to 8 kW. With this versatile system, process engineers are able to deposit oxide, nitride and carbide thin-films for the fabrication and research of advanced microelectronic devices. By incorporating a single-wafer load-lock, the chamber flushes fast, eliminating user intervention and reducing the potential for contamination of the process chamber, resulting in a lower cost of ownership and operation. By utilizing a dampening unit with a bellows seal the chamber is designed to trap end vacuum and reduce cost of ownership. Additionally, the thin-film deposition process uses a gas delivery manifold and can be configured for reactive and non-reactive gases. Inside the chamber, a fine angle showerhead tool is used to evenly distribute the process gases and a predefined showerhead pattern ensures a uniform distribution of gases, resulting in better process uniformity across all wafers. AMAT CENTURA reactor also includes a user-friendly graphical user interface software. This software allows process parameters to be checked, configured and monitored from a unified menu, simplifying the interface, operation and documentation of thin-films deposition process. This machine is primarily used for fabrication of semiconductor device structures involving thin-films deposition with higher rates, better device characteristics, higher P and E quality and lower cost-per-part. APPLIED MATERIALS CENTURA reactor is compliant with the requirements with FAB20, SEMI-S2 standards and provides a clean, safe and efficient thin-films deposition process.

There are no reviews yet