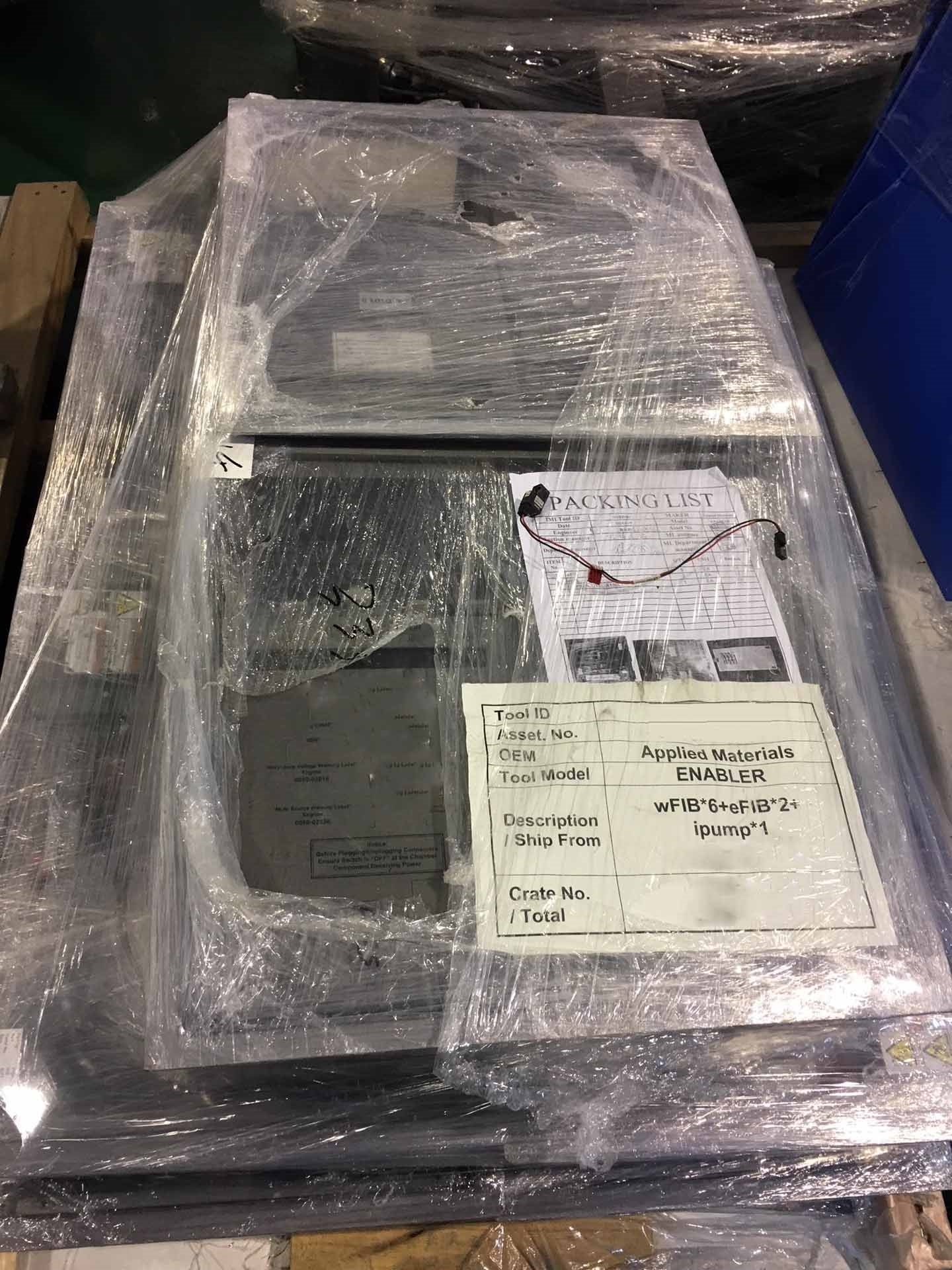

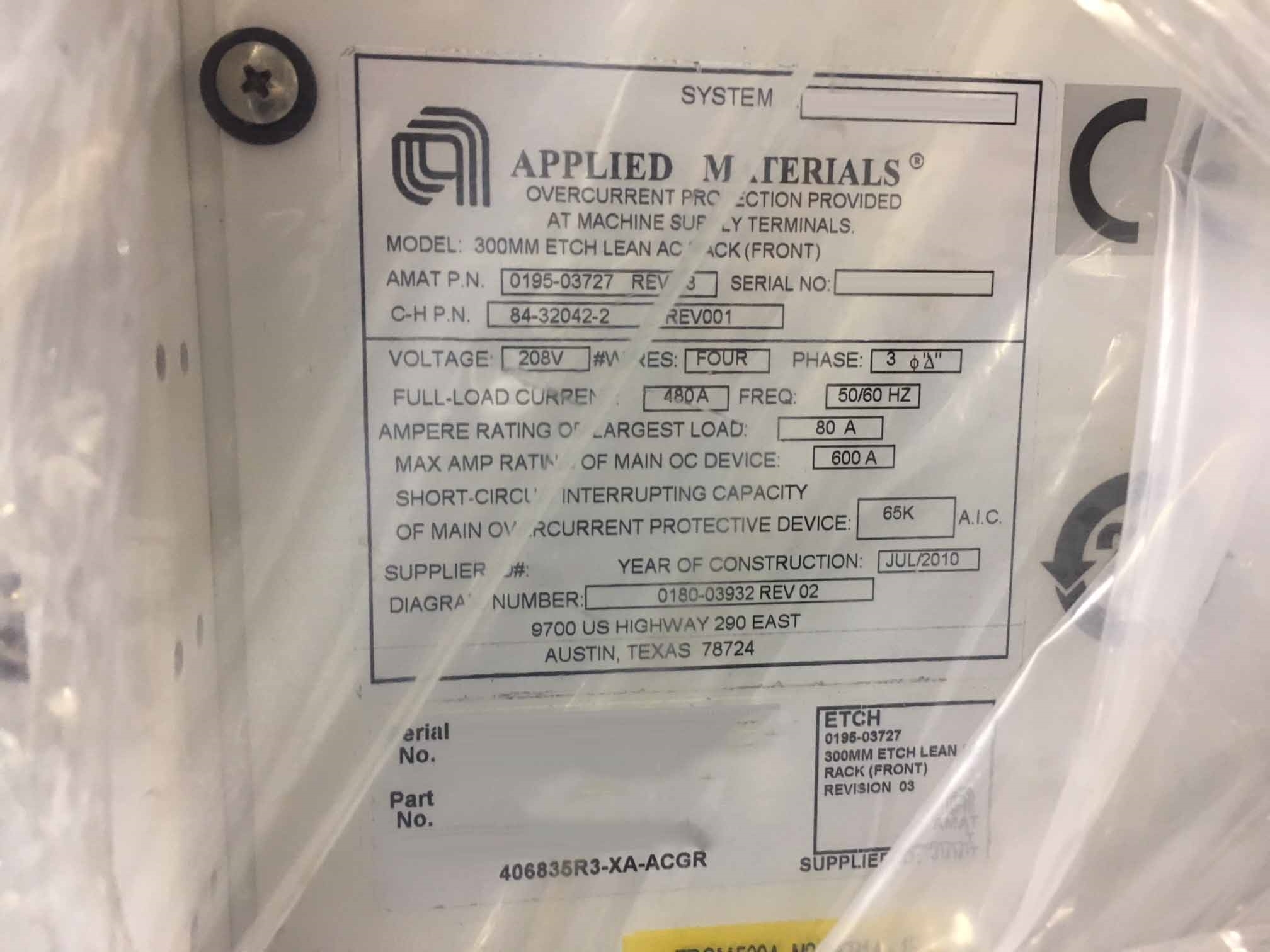

Used AMAT / APPLIED MATERIALS CENTURA #9204753 for sale

URL successfully copied!

Tap to zoom

ID: 9204753

Wafer Size: 12"

Vintage: 2010

Etcher, 12"

Process: Oxide

(3) Poly chambers

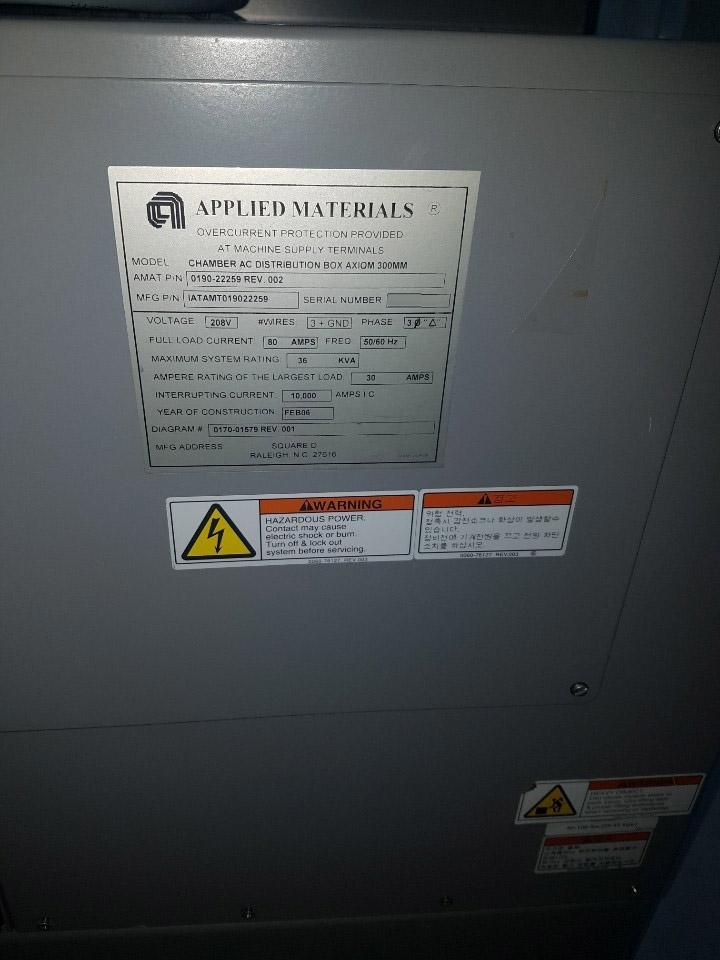

(1) Axiom chamber

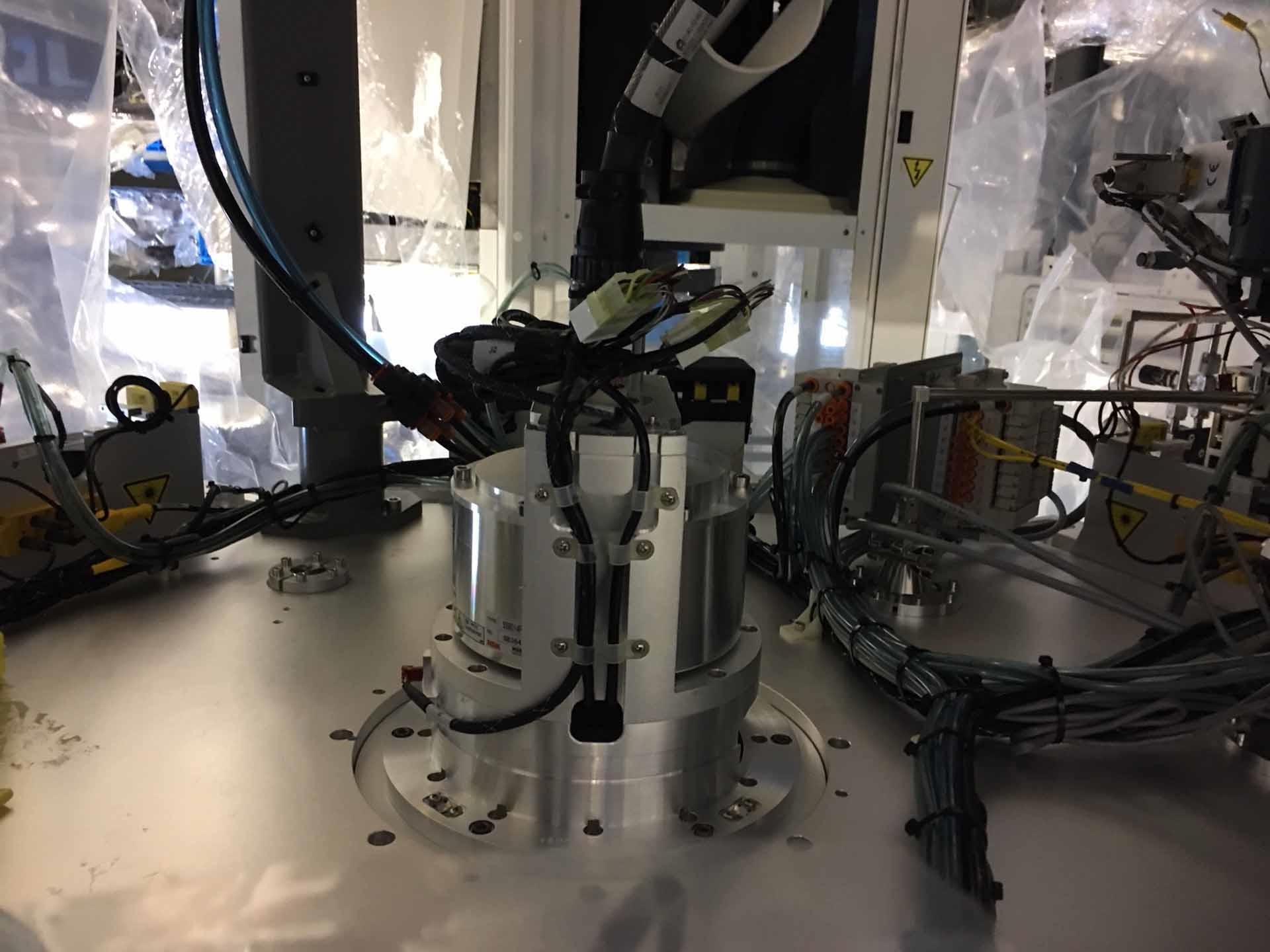

(1) EFEM with KAWASAKI Robot

2010 vintage.

AMAT / APPLIED MATERIALS Centura Enabler is a state-of-the-art substrate processing reactor that is designed to enable commercial-grade semiconductor production. This advanced etch processes reactive beam, physical vapor deposition (PVD) and chemical vapor deposition (CVD) chambers, allowing for improved throughput and increased yields. AMAT Centura Enabler's innovative design includes a wide selection of chamber sizes, allowing customers to adapt the reactor to their own production environments. In addition, APPLIED MATERIALS Centura Enabler is designed with both physical and environmental safety in mind. Its Molecular Exclustion Ink (MEI) Chamber design offers precise temperature-controlled thermal processing with ions edges, allowing for improved uniformity and process repeatability. For added safety, Centura Enabler contains a built-in gas-flow control system, allowing for precise control and consistent monitoring of the gas distribution within the chamber. The chamber also features a built-in vacuum system, making sure all components are tightly sealed, without any seals or gaskets. In addition, the chamber is designed to minimize back-diffused ions and improve control of deposition surfaces, improving uniformity and yield. AMAT / APPLIED MATERIALS Centura Enabler's efficient heat management system also ensures consistent temperatures are maintained throughout the reactor, allowing for optimal processing conditions. Its single-wall vertical design reduces the reactor's footprint and maximizes floor utilization. AMAT Centura Enabler also features an ergonomic, height adjustable user interface, allowing for easy operation and control of the reactor. APPLIED MATERIALS Centura Enabler is an essential component for commercial-grade semiconductor production. It provides a wide selection of chamber sizes, precise temperature-controlled thermal processing, gas-flow control, vacuum systems, improved uniformity and process repeatability, improved yield, efficient heat management, a single-wall vertical design and an ergonomic interface, making sure commercial-grade production is completed safely and at an optimal level.

There are no reviews yet