Used AMAT / APPLIED MATERIALS CENTURA #9231993 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9231993

Wafer Size: 8"

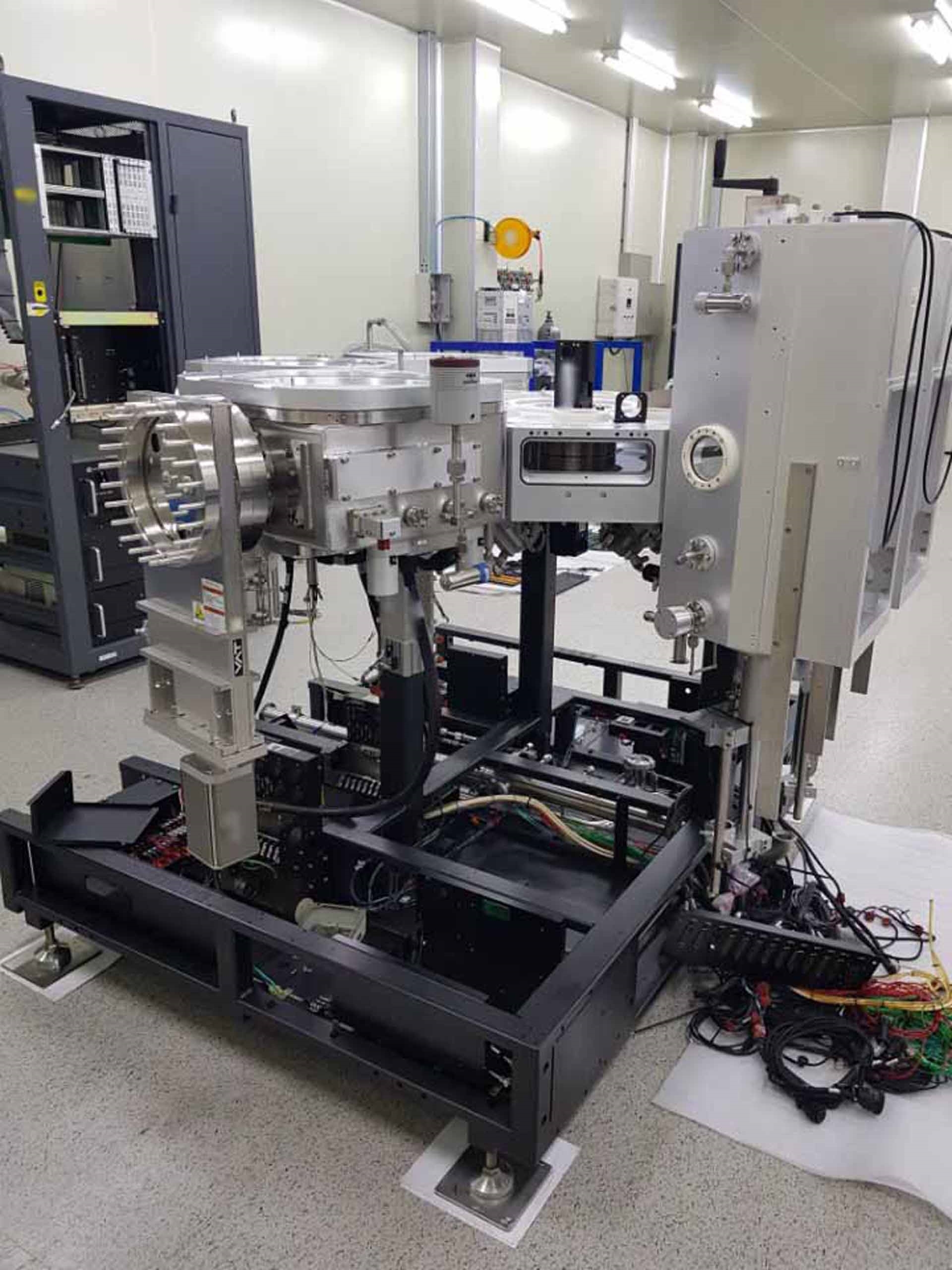

PVD System, 8"

(3) Chambers

Load lock: Narrow body

HP Robot

Position A: STD AL

Position B: G12

Position C: PC II

Position F: Orienter degass

Chamber A:

Options:

Application: AL

Chamber body: Standard

Wafer heater: Standard

Cryo gate valve: 2PGV

Source assembly: 12.9"

Source adapter: 12.9"

Magnet type: Dura source

Magnet part number: 0010-20328

Chamber B:

Options:

Application

Chamber body: Wide

Wafer heater: A101

Cryo gate valve: 2PGV

Source assembly: G12

Source adapter: G12

Magnet type: G12

Magnet part number: 0010-20768

Shutter assy included

Chamber C:

Options:

Application: PC II

Chamber body: PC II

LEYBOLD 361c Turbo pump

LEYBOLD 360 Pump controller

RF Match: 0010-20524

Generator rack options: Selected option

Position A RF generator: AE MDX-20K

Position B RF generator: AE MDX-L6K

Position C RF generator: RF Generators (CPS1001, LF-10).

AMAT / APPLIED MATERIALS CENTURA is a highly advanced, sophisticated and automated equipment capable of processing advanced semiconductor wafers. It is a production-level reactor built specifically to process 300 millimeter (mm) diameter wafers. The system is equipped with a fully automated transport, chamber, and loadport that is both efficient and economical. AMAT CENTURA unit has three main chamber components. The front chamber includes a loadport and the rear chamber is outfitted with high-energy plasma sources and a robot arm for placing and collecting wafers in the chamber. The third chamber, the process chamber, is designed to quickly and accurately process each wafer. This chamber has a combination of high-energy electron and gas sources. The full chamber-level treatment cycle takes place in the process chamber. The machine also has a large and configurable granular gas delivery tool. This asset supplies reactive gas species to the process chamber for producing and controlling reaction by-products and impurities. Configurability allows the user to choose from multiple set points to achieve the desired wafer results. The model is equipped with self-diagnosis and optical quality control (QC) modules to ensure quality production. The equipment also has a TEM (<100nm) imaging system and real-time electron microscopy unit with zoom up to 3000 times. In addition to the main chambers, the machine also includes several ancillary systems. These systems are used to manage the flow of reactive gases and to control tool parameters such as pressure, temperature, and humidity. The asset is also equipped with two independent chillers, an RF generator, and vacuum pumps. The model is equipped with a high-speed data acquisition equipment for automated data collection and analysis. APPLIED MATERIALS CENTURA system has a broad range of applications, including back-end-of-line processing and spacer defect detection. The unit also offers a number of advanced process control options such as in-situ, rapid thermal processing, and self-boundary etching. The flexibility of the machine allows users to design and tailor their production process and settings for optimal performance and quality. By optimizing the set points and parameters, the tool can meet various production needs and applications ranging from low- to high-volume production.

There are no reviews yet