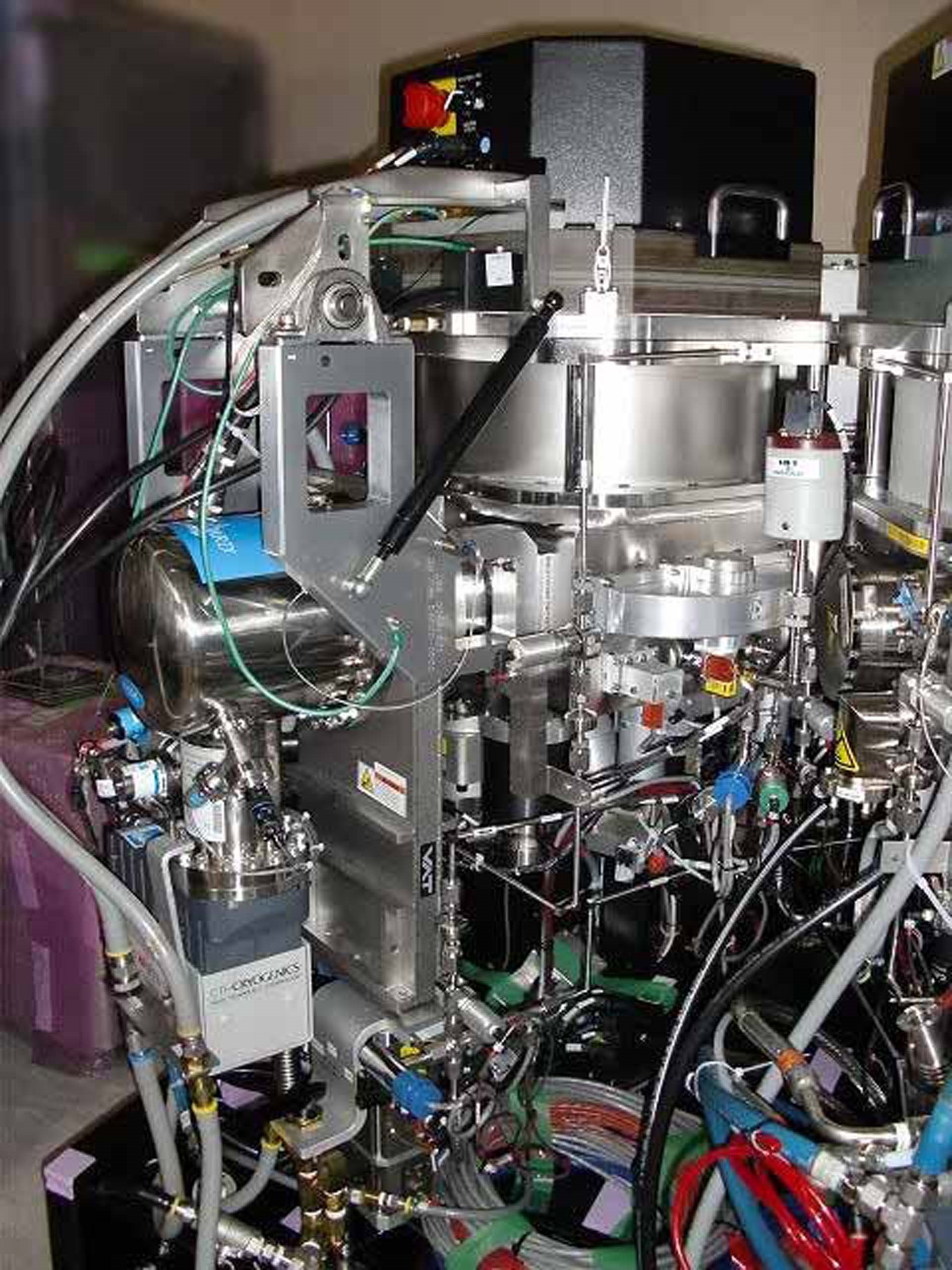

Used AMAT / APPLIED MATERIALS CENTURA #9251311 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9251311

Wafer Size: 8"

Vintage: 1996

PVD System, 8"

Load lock:

Body type: Narrow

Indexer: Automated

Buffer chamber:

HEWLETT-PACKARD Robot

Metal blade

Chamber A: GAMMA II TiN (ESC)

Chamber B: GAMMA II TiN (ESC)

Chamber C: PC-II

Chamber D: Cool down

Chamber F: Oreintor degas

Generator rack 1

0190-76118 Remote AC rack

No generator rack 2

No NESLAB

Missing parts:

NESLAB0190-76118 Chiller

Cool chamber upper

0190-01893 PVD DC Power supply 3 kV

(2) Heater drivers

SBC BD

(2) Ion gauge BD

FDD

DI/O BD

AI/O BD

Robot indexer cable

(2) CRT

(2) ESC Chuck assy Ch#A, B

(2) Heater lift motors

(2) Matchers

(2) 3620-01389 Compressors

Signal cable

0150-20678 Remote rack to Ch#A pump RJ13 - 50 ft

0150-20678 Remote rack to Ch#B pump RJ14 - 50 ft

0150-20678 Remote rack to Buffer pump RJ11 - 50 ft

0150-20678 Remote rack to LL pump RJ12 - 50 ft

1996 vintage.

AMAT / APPLIED MATERIALS CENTURA is a high-level chemical and physical vapor deposition (CVD/PVD) reactor that is a mainstay in many semiconductor fabrication facilities. AMAT CENTURA is capable of performing high-speed and high-precision thin-film deposition processes for a variety of substrate sizes. The equipment is equipped with an advanced, automated control technology that is capable of precise etch and deposition control, as well as low temperature, high-uniformity thin-film deposition. The reactor's design also features an integrated, direct coupled pump and robust thermal control technology for optimal performance. APPLIED MATERIALS CENTURA is designed for use in silicon-based semiconductor fabrication processes. It is used primarily in the production of thin-film transistors (TFTs) and integrated circuits (ICs) commonly used in a variety of electronic products, such as computers and mobile phones. CENTURA is also used to produce semiconductor photodetectors and display technologies, such as OLEDs, AMOLEDs, and other flat-panel display technologies. The reactor utilizes precise substrate handling technology that consists of a robot and indexer system that allows precise, automated handling of substrates in the range of 0.5 to 12 inches in size. The precise handling provided by AMAT / APPLIED MATERIALS CENTURA allows for precise etch and thin-film deposition without causing any damage to the substrate. The unit also utilizes an advanced diagnostics package that allows processes to be monitored in real-time and automatically adjusts the process if necessary. The machine is also equipped with an array of advanced control software, which allows for precision deposition and etch control for a variety of applications. This allows for accurate control of the deposition process as well as exact etch and deposition rates to ensure process stability. The software also allows for accurate and repeatable layer profiles that ensure precision thin-film deposition and etching results. AMAT CENTURA is the most advanced and reliable chemical and physical vapor deposition (CVD/PVD) tool available. It is capable of high-speed and high-precision thin-film deposition processes for a variety of substrate sizes, which make it the preferred asset in many semiconductor fabrication facilities around the world. The model's precise handling and advanced control technology makes it one of the most reliable and accurate systems on the market.

There are no reviews yet