Used AMAT / APPLIED MATERIALS CENTURA #9282472 for sale

URL successfully copied!

Tap to zoom

ID: 9282472

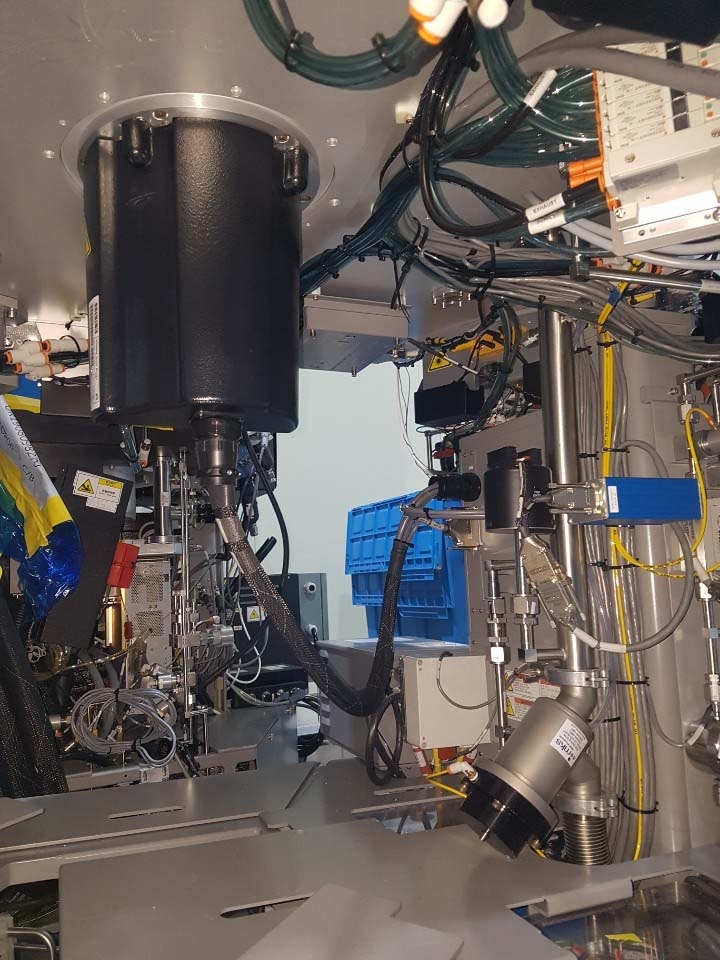

Poly etcher, 12"

(3) Poly chambers

(1) Axiom chamber

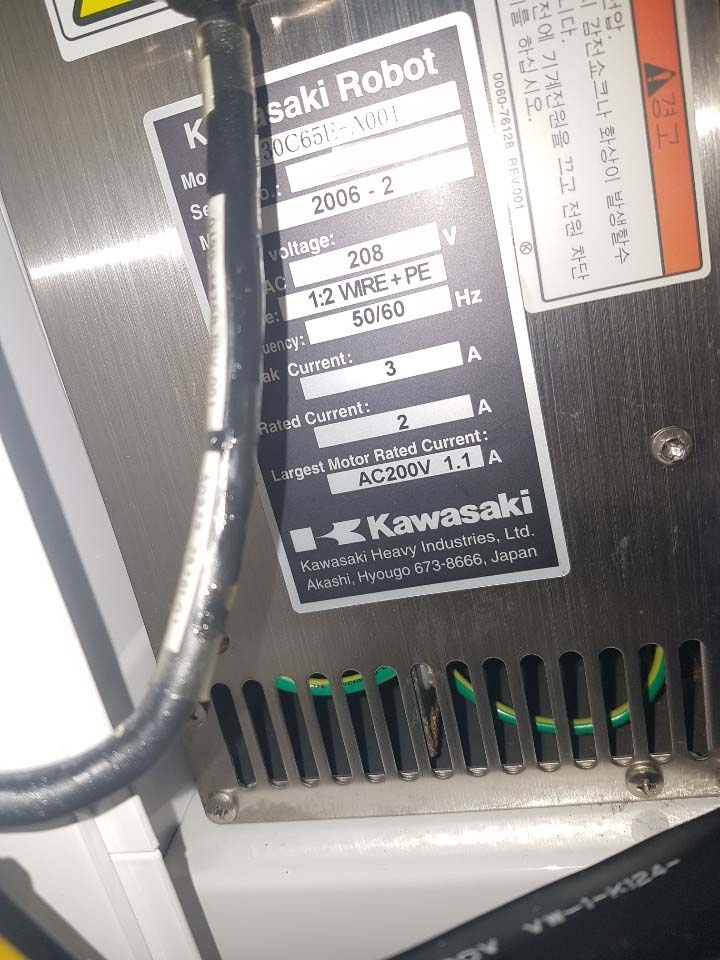

(1) EFEM with KAWASKI

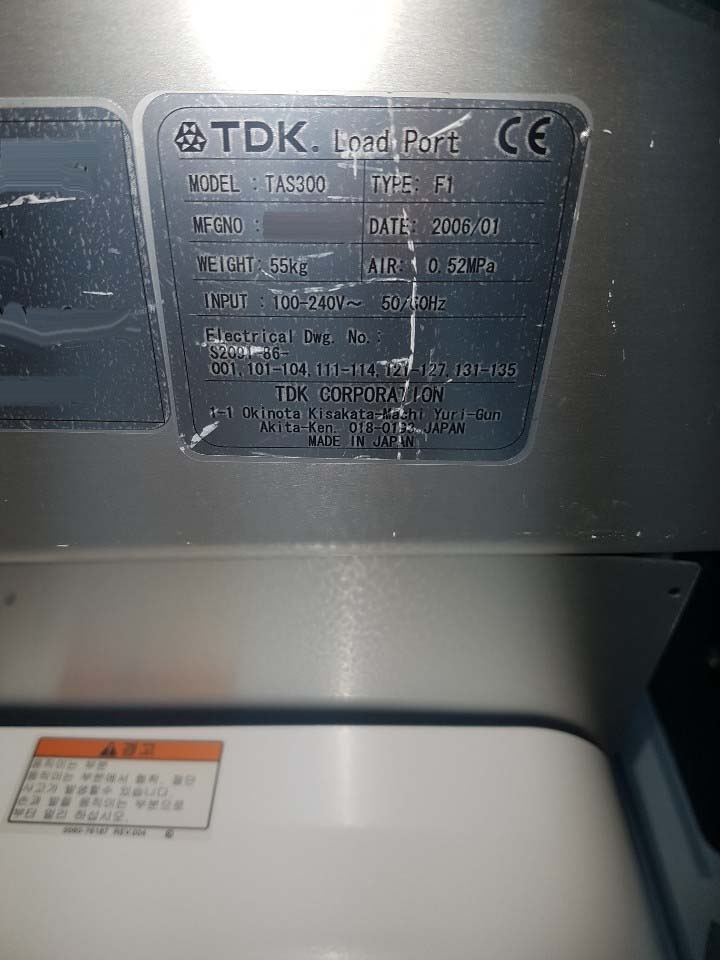

TDK TAS Loadport

VHP Robot.

AMAT / APPLIED MATERIALS CENTURA is a deposition reactor used for semiconductor processing. It is an industry-leading platform for enabling various substrate deposition technologies such as atomic layer deposition (ALD), chemical vapor deposition (CVD) and sputtering. It is one of the most widely used plasma-enhanced deposition tools in the semiconductor manufacturing industry. AMAT CENTURA reactor provides a platform for multi-step process sequences that can be tailored to the requirements of each individual process. These sequences include thermal processing, plasma-based deposition, etching, and ion implantation. This flexibility allows the tool to be used for a wide range of deposition process applications. Additionally, the reactor can be equipped with a variety of advanced analytical tools that are used to monitor the process in real-time. The Advanced Materials APPLIED MATERIALS CENTURA reactor is designed with a wide range of process and chamber components that can be configured to meet specific customer requirements. Key components include a high-vacuum chamber, high-purity gas distribution and scrubbing equipment, an electrical charging system and temperature control systems. The chambers are equipped with enough ports for the incoming wafers, gases and temperature sensors to be quickly and accurately monitored. CENTURA reactor provides excellent control over substrate temperature, gas composition, and process pressure. It features several industry-leading technologies such as a resistively heated substrate chuck, a ramping pressure unit, and advanced gas flow controllers. These features provide a greater level of process control, which is crucial for achieving consistent and repeatable processes. AMAT / APPLIED MATERIALS CENTURA reactor also features advanced metrology capabilities such as Automated Process Control (APC) and In-Situ Process Monitoring (IPM) systems. APC uses routine measurement data to determine if process parameters are meeting and/or exceeding pre-defined target conditions. This can quickly detect process drift during the deposition and prevent the quality of the product from being compromised. IPM is an ability to monitor the real-time deposition process data from the reactors within a machine architecture; this ensures that substrate uniformity and process control are maintained. AMAT CENTURA reactor is a cost effective and reliable tool for several complex semiconductor processing applications. Its advanced metrology capabilities, process control capabilities and flexibility make it the ideal choice for high-quality processes.

There are no reviews yet