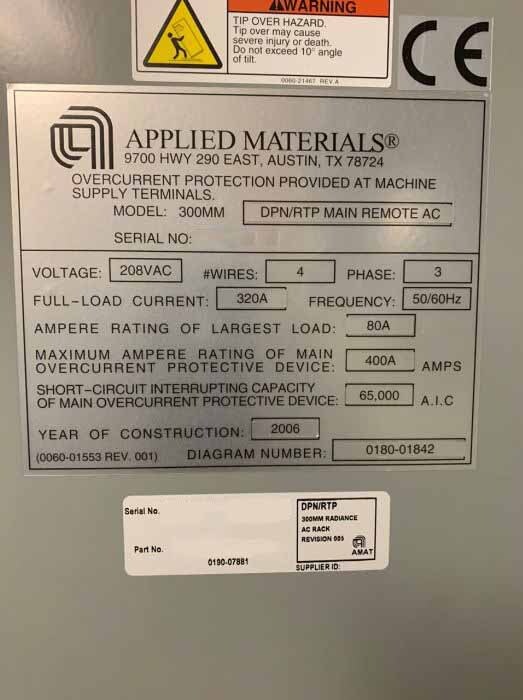

Used AMAT / APPLIED MATERIALS CENTURA #9412368 for sale

URL successfully copied!

Tap to zoom

ID: 9412368

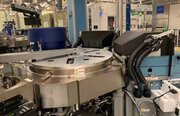

Wafer Size: 12"

Vintage: 2006

Etcher, 12"

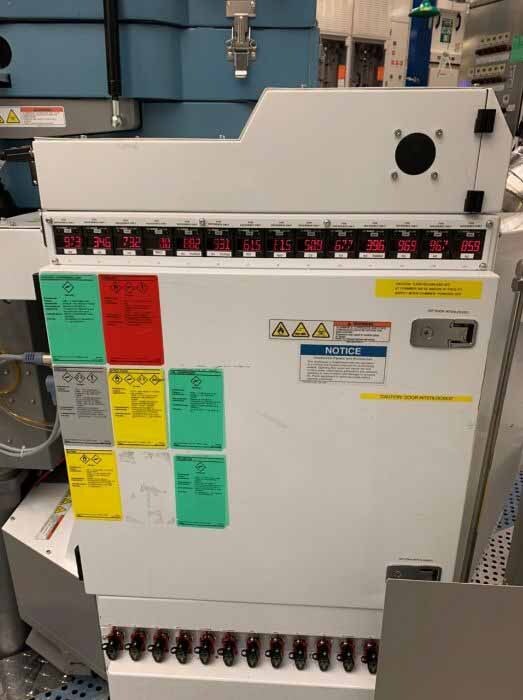

CIM: SECS / GEM

Process: RTP

Factory interface: (3) FOUPs

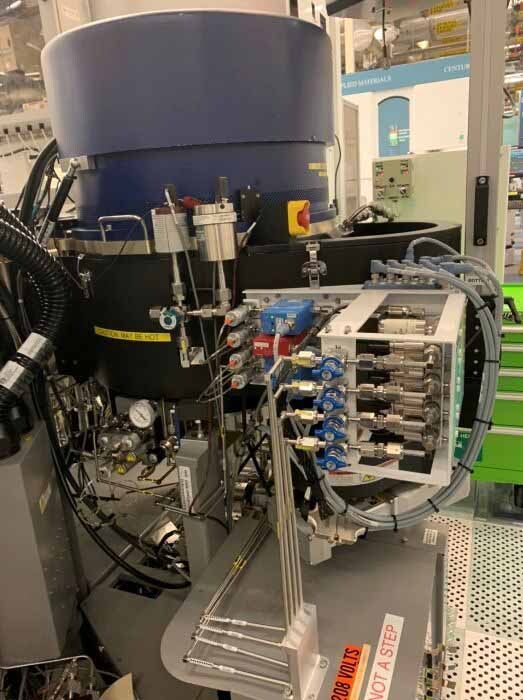

(3) Vacuum pumps

2006 vintage.

AMAT / APPLIED MATERIALS CENTURA is an advanced system used in semiconductor fabrication and thin film deposition processes. It consists of an integrated reactor and integrated process controller, providing precise control of temperatures, pressures, rates of deposition, and other related parameters. AMAT CENTURA can be used for the manufacturing of small molecules, large molecules, and thin films. The reactor consists of a quartz cylinder, enclosed within a cylindrical vacuum chamber. The quartz cylinder contains a number of independent burroholes that are aligned with a single central cathode. This arrangement allows the formation of a uniform electric field between the central cathode and the burr holes, facilitating precise control over the deposition process. The vacuum chamber is where the process gas is introduced and the reaction takes place. The top of the chamber has a window through which various optical probing techniques can be used to observe and control the process. The bottom of the chamber has an electrostatic chuck, which is used to hold substrate wafers during processing. APPLIED MATERIALS CENTURA has a powerful integrated process controller that allows for precise control of temperatures, pressures, RF powers, and other related parameters. A graphical user interface can be used for setting up the process parameters, as well as for viewing the experimental data generated. The process controller also includes an automatic process tuning system, which enables CENTURA to automatically adjust the parameters to achieve the optimal process performance. The process gas is introduced into the vacuum chamber through a set of piping and valves, depending on the type of process being used. For example, in the deposition of silicon oxide, silane and nitrogen are usually used. Pressure controllers are used to regulate the amount of process gas that is introduced into the chamber, which can range from a few millibars to several hundred millibars. In the deposition process, two types of chamber sputter sources are used - inductively coupled plasma (ICP) and direct current (DC) magnetron sputtering. An RF or DC power supply is used to create an electric field between the target material and the substrate. This electric field produces ions, which then transfer the material to the substrate surface. Once the process is complete, the substrate is then unloaded from AMAT / APPLIED MATERIALS CENTURA and the process automatically reverts to the standby mode. AMAT CENTURA is a versatile and highly reliable system widely employed in semiconductor fabrication and thin film deposition processes. Its integrated process controller provides precise control of temperatures, pressures, rates of deposition, and other related parameters. It is widely used in the manufacturing of small molecules, large molecules, and thin films for various industrial applications.

There are no reviews yet