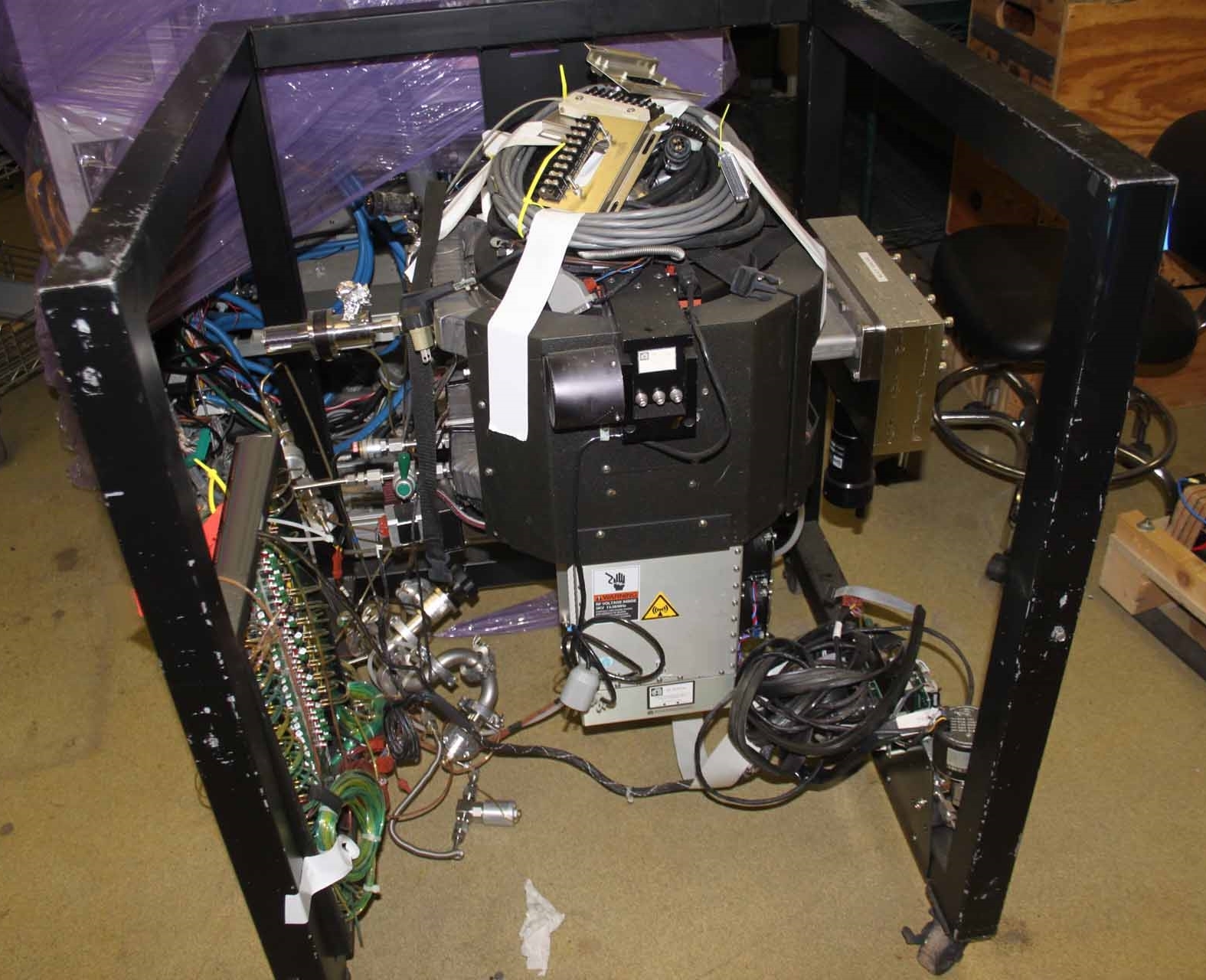

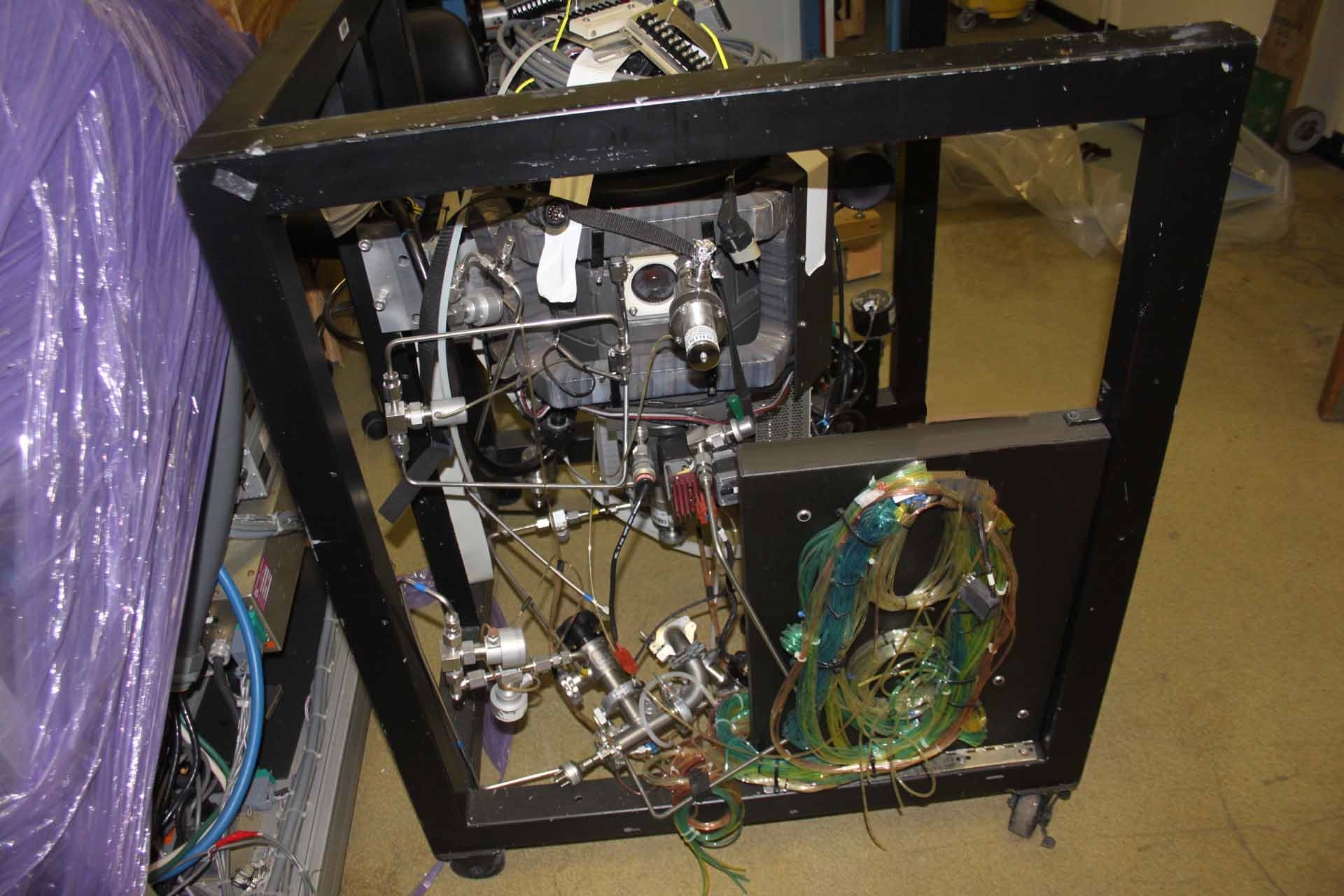

Used AMAT / APPLIED MATERIALS Chamber for P5000 #9204032 for sale

URL successfully copied!

Tap to zoom

ID: 9204032

Wafer Size: 6"

6"

Stand-alone

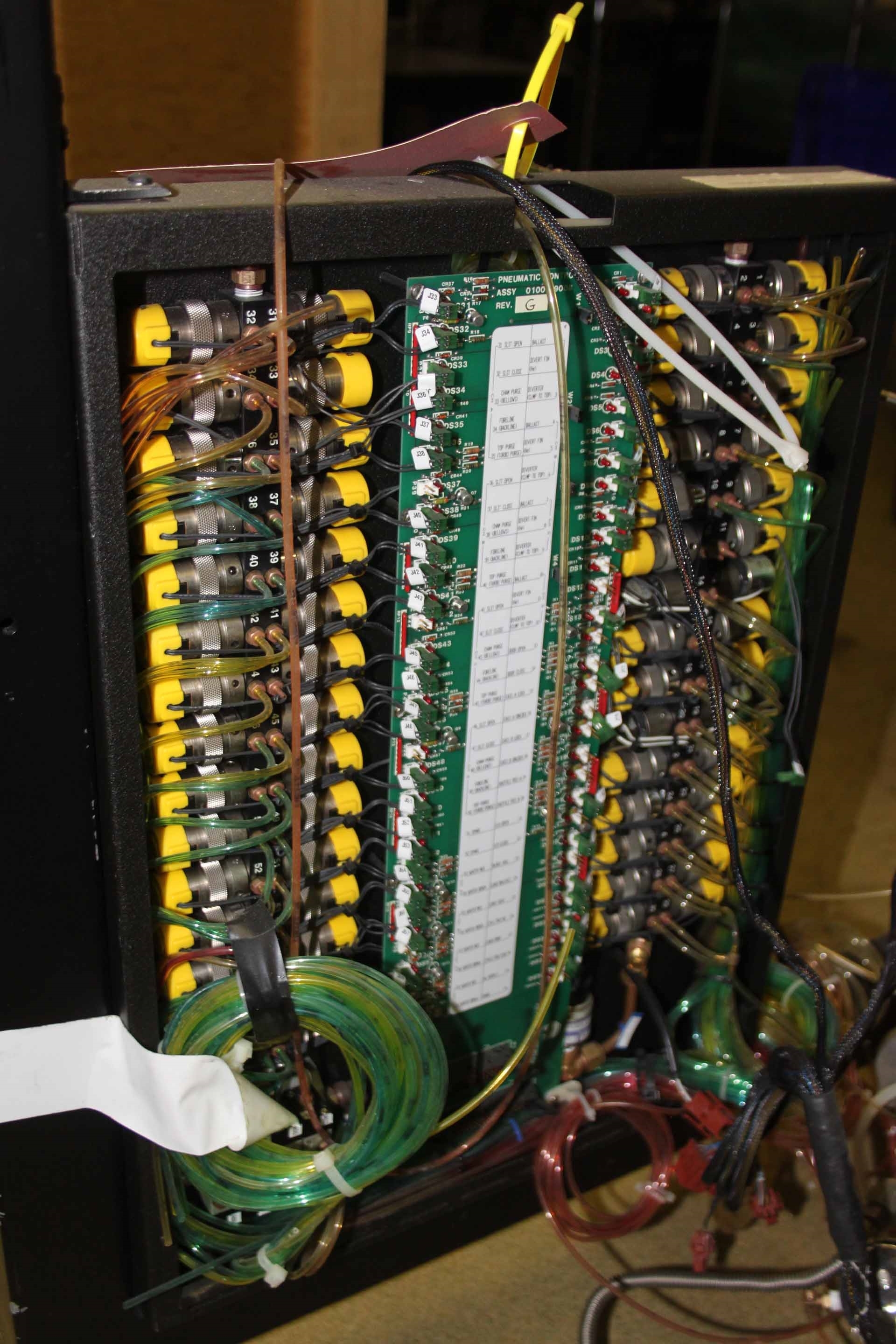

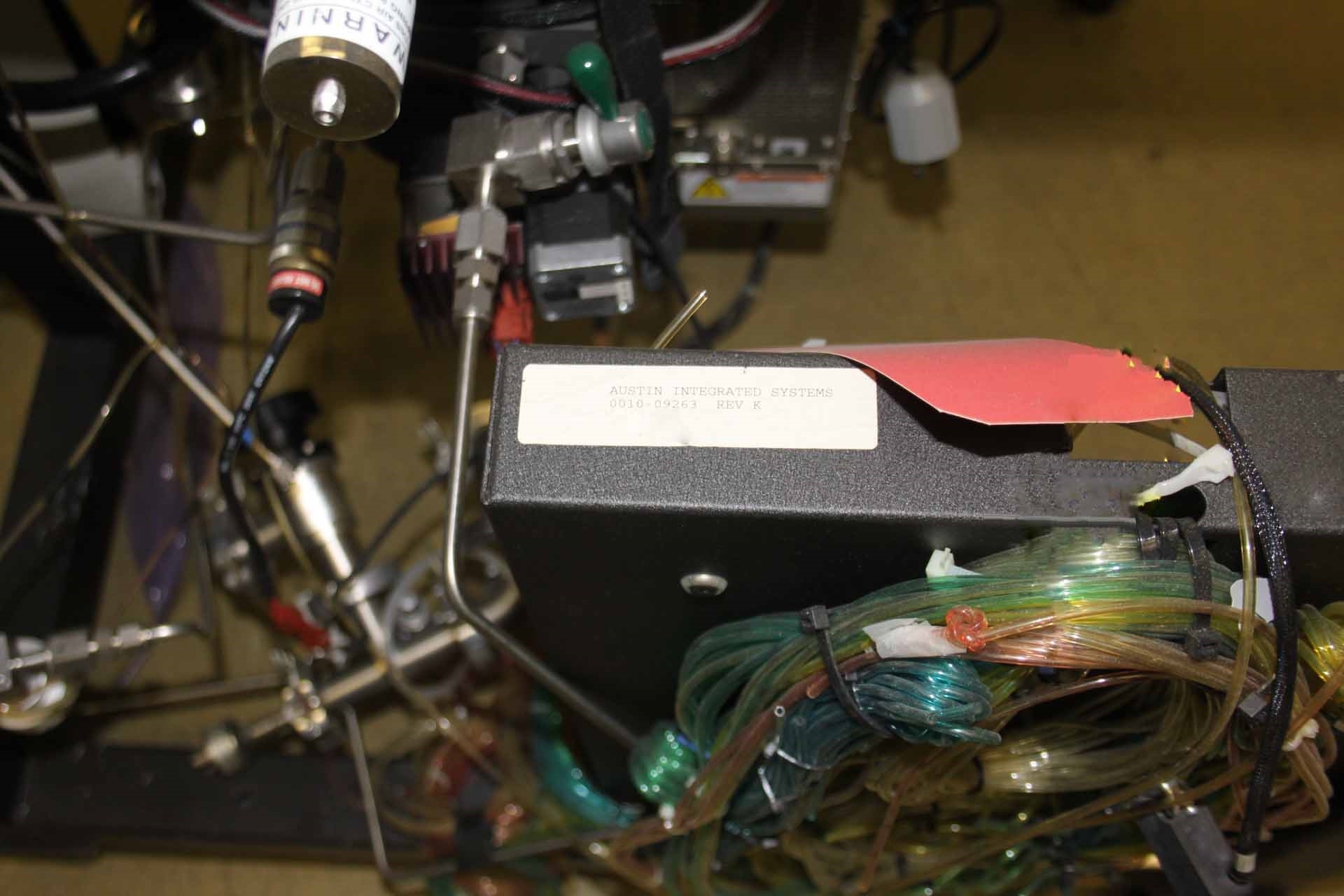

Pneumatic manifold P/N: 0010-09263

Process: Oxide etch (CF4 / C2F6).

AMAT P5000 reactor is a source deposition chamber used in various semiconductor deposition processes. It is one of the most versatile and user-friendly deposition chambers in the market. The P5000 is a great choice when looking for a reliable and efficient machine to optimize thickness, uniformity and control of film properties. The P5000's advanced process control provides superior process stability, process repeatability, and exceptional control of structural and compositional film properties. It features a Direct Drive Throttle (DDT) process head, allowing for precise movement of the substrate back-and-forth during the deposition process. This ensures uniformity and a consistent film thickness over the entire wafer. The P5000 has a built-in gas delivery equipment that is capable of supporting up to 3 different gases, each with its own dedicated flow meter. This system allows for precise control and mixing of gases, enabling precise process control that leads to high quality films. Additionally, the P5000 is designed to ensure that the contamination levels in the chamber are kept at a minimum through its self- contained filtration unit, which filters out any potential particles within the chamber before they reach the substrate. The P5000 also offers a number of advanced safety features, including a unique on-board diagnostics (OBD) machine. This tool monitors both chamber and electrical components on an ongoing basis and provides detailed feedback and real-time process data, alarms, and reports. The P5000 has become a top of the line reactor due to its performance, reliability, and user-friendly interface. Not only is the P5000 compliant with process requirements, but also it can be used to grow films to meet a variety of applications, which make it a great choice for a wide variety of users. It should be noted that the P5000 should be used in areas with good ventilation as the improved efficiency of the process may result in generating more byproducts and emissions.

There are no reviews yet