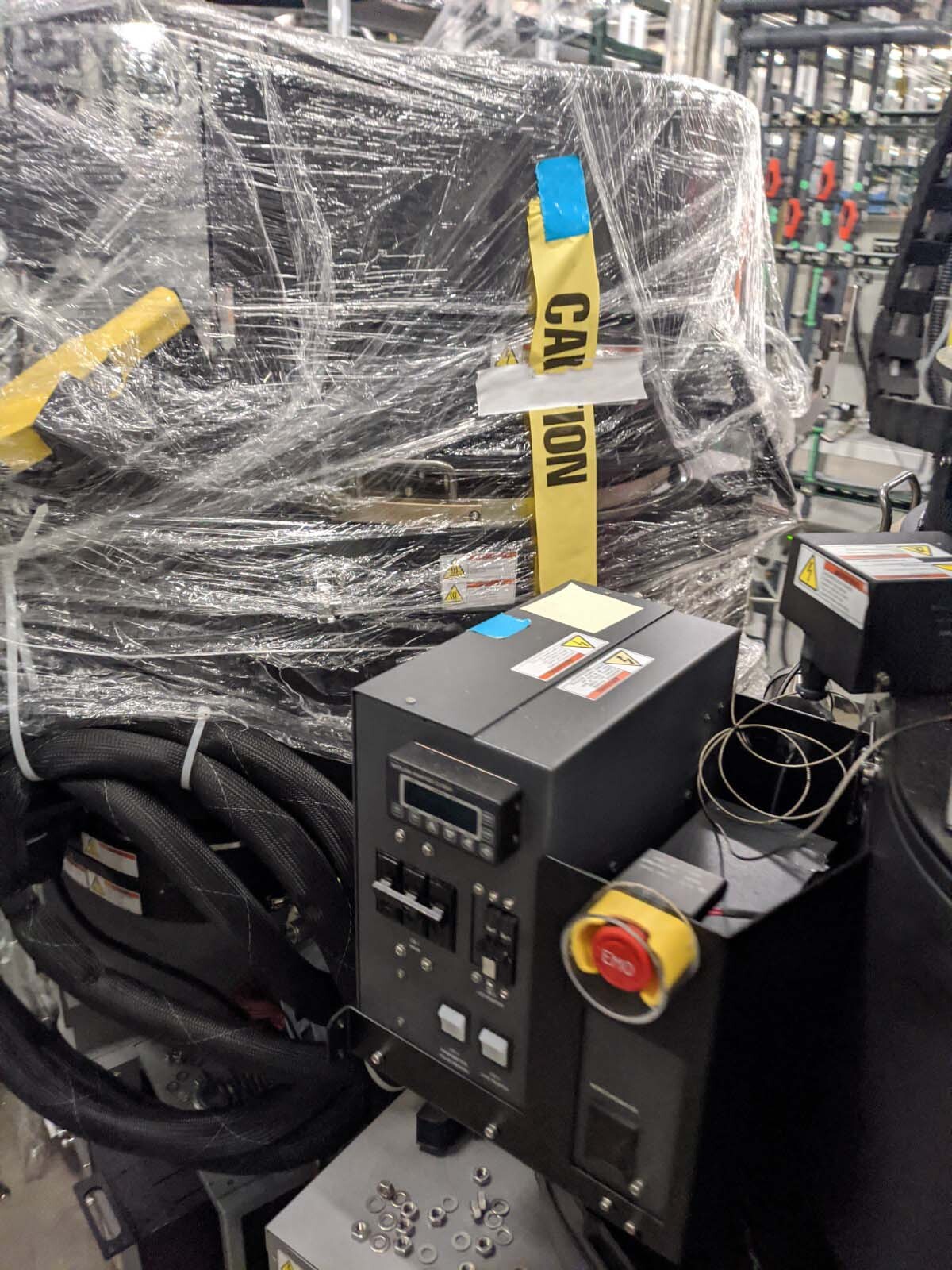

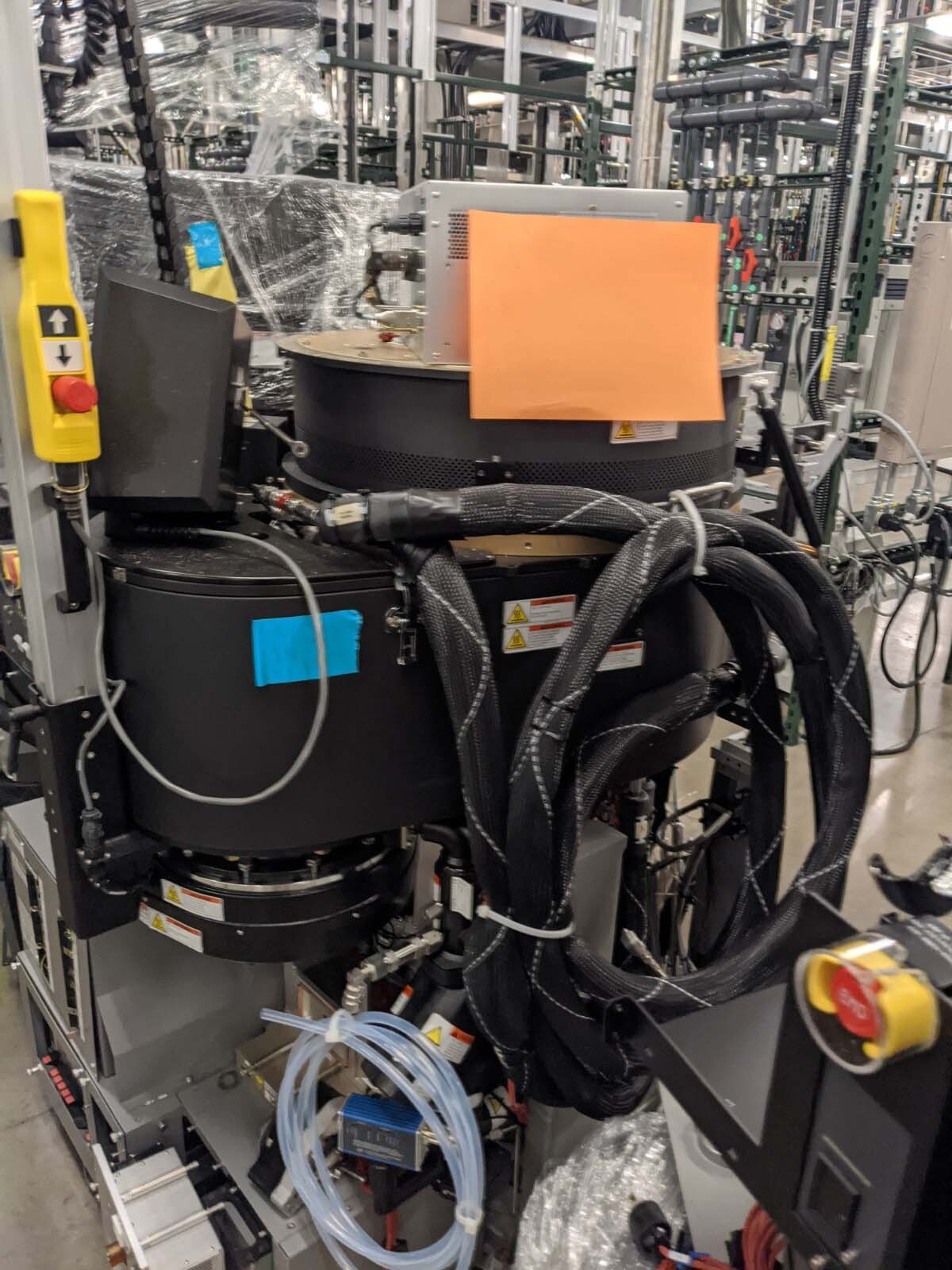

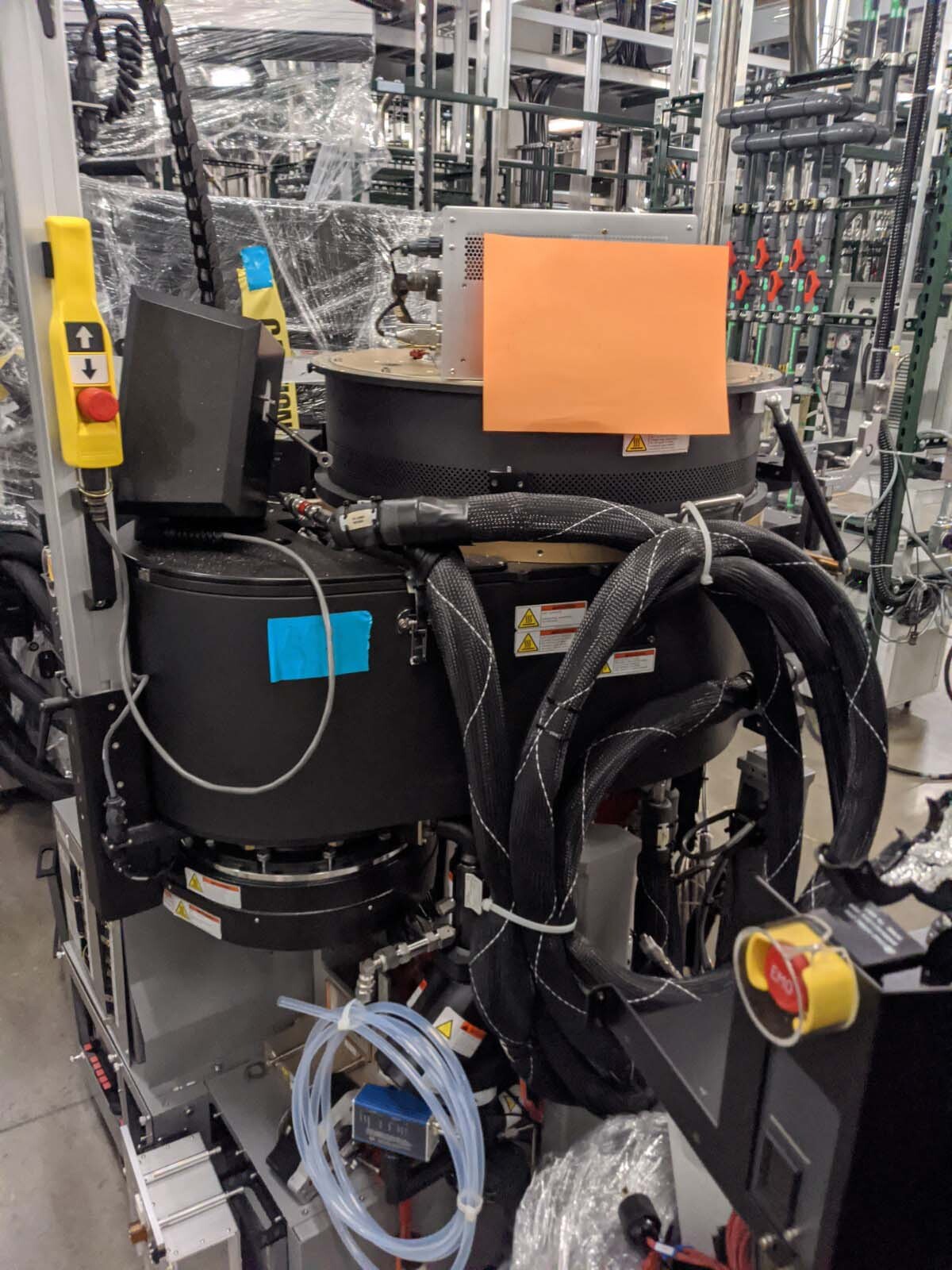

Used AMAT / APPLIED MATERIALS Chambers for Centura DPS II #293664214 for sale

URL successfully copied!

Tap to zoom

ID: 293664214

Parts to be removed:

P/N / Description

4746896-0001-REF / Turbo pump

4715467-0001-REF / Bias match

4744307-0001-REF / Source match

4742800-0001-REF / Bias generator

4742799-0001-REF / Source generator

4744329-0001-REF / Helium controllers

4678617-0001 / Process manometer

1021020-0405 / Service manometer

Various / Chamber boards

4746946-0001-REF / Turbo pump controller

4650875-0001-REF / High voltage module

4733410-0001 / TGV

4744185-0001 / End point AMAT DPS II Spectrograph SD1024 (0190-42853)

0190-29887 / Eyed IEP flash lamp, ROHS.

AMAT Centura DPS II is an advanced high-performance single-wafer reactor that provides users with high throughput and maximum uptime. It is ideal for producing high-quality silicon wafers for use in the electronics industry. The machine features a patented Dual Process, Single-Wafer Equipment (DPS) technology, which allows it to perform a variety of process functions on one reactor chamber. It is equipped with two sets of cylindrical chambers, each chamber capable of processing up to 24 wafers. The chambers feature robust free-floating, double-sealed design, which prevents contamination and high stray magnetic fields. APPLIED MATERIALS Centura DPS II comprises of four separate chambers, namely the Load Lock, Process, Purge, and Exit chambers. The Load Lock chamber is the first chamber that a silicon wafer is loaded into. This chamber is equipped with antimicrobial contamination protection technology, which prevents contaminates from entering the system. The Process chamber houses the precisely controlled RF heating unit with adjustable power levels and is designed for maximum yield with a uniform substrate temperature throughout the chamber. This chamber is also equipped with a on-board process controller that can be used to configure and control the process parameters. The Purge chamber is designed to safely remove any remaining reaction gases and particles, helping to ensure clean process results. The Exit chamber is designed to ensure the safe removal of wafers from the machine. AMAT / APPLIED MATERIALS Centura DPS II is designed with advanced diagnostic and monitoring capabilities. This reactor is equipped with a Process Control Computer (PCC), a main control computer that governs its operations. The PCC also features remote monitoring capabilities, which allow users to monitor the reactor's performance from virtually anywhere in the world. The tool also offers detailed diagnostics and alarm functions that ensure optimal performance of the asset. In conclusion, AMAT Centura DPS II is an advanced single-wafer reactor that is designed to produce high-quality silicon wafers for the electronics industry. It is equipped with four separate chambers, each designed for a specific purpose and with advanced diagnostic and monitoring capabilities. It is designed with the latest process control technology and has the ability to perform a variety of process functions on one reactor chamber.

There are no reviews yet