Used AMAT / APPLIED MATERIALS ECP SlimCell #9031142 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9031142

System, 12"

Factory interface: 3 FOUP stage

Anneal module: Anneal – A

SRD module: SRD – B

SLIM CELL module: CELL – B, CELL – D

IBC module: IBC – B

(16) Units:

1. EFEM

2. Buffer Unit

3. Annel Unit

4. Main System

5. Chemical Supplier #1

6. Chemical Supplier #2

7. Chemical Drain Unit

8. Chiller

9. Monitor Stand #1

10. Monitor Stand #2

11. Parts Box #1

12. Parts Box #2

13. Parts Box #3,

14. Parts Box #4

15. Lifter #1

16. Lifter #2

System Configuration:

Mainframe:

- Wafer Transfer Robot with two Blades x 1

- SLIM CELL TM Module x 2 (Cell - B, Cell - D)

- SRD (Spin Rinse Dry) x 1 (SRD - B),

- IBC (Integrated Bevel Cleaner) x 1 (IBC - B)

- In-Station (Pass Stage) under SRD x 4

- Independent Plating-solution Circulation System x 4

(for Anode and Cathode in each SLIM CELL TM Module)

- Mixing Unit for Plating-solution and Cleaning Fluid

- Fan Filter Unit (FFU)

Factory Interface (FI):

- Two Blade Robot

- FOUP Stage (ADO) x 3

- Aligner

- Fan Filter Unit

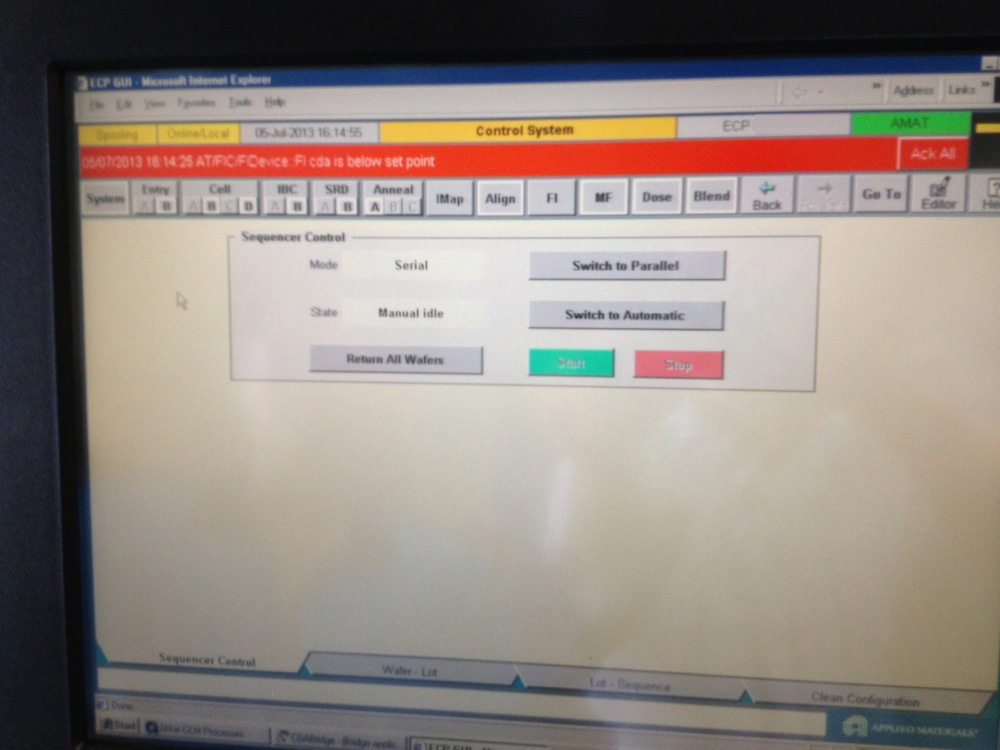

- GUI Computer controlling FI and Mainframe control systems

Heater / Chiller

Operator Interface x 2 (Main & Sub)

Anneal Chamber Module:

- Anneal Chamber x 1 (Anneal - A)

- Movement and Temperature Control, Gas Box

* Mainframes consist of 1) Mainframe, 2) FI and 5) Anneal Chamber Module

* Anneal Chamber is middle of Anneal Chamber Module and Anneal - A is above

the Anneal Chamber

Mainframe Details:

Frame

Fan Filter Unit: ULPA Filter (>0.12 μm, >99.999%)

Plating-solution Supply Unit

SLIM CELLTM Module

- Plating Head: 5 RPM to 400 RPM

- Plating Cell

- Plating-solution circulation system

Filter (Millipore, 0.05 μ, 20")

Temperature Control ± 1.5 deg C

SRD (Spin Rinse Dry): 50 ~ 2500 RPM

- Lower Cleaning Nozzle (one for DI and Chemical)

- Upper Cleaning Nozzle (one for DI)

IBC (Integrated Bevel Cleaner): 50 ~ 2500 RPM ± 20%

- Lower Cleaning Nozzle (three for each DI and Chemical)

- Upper Cleaning Nozzle (one for each DI and Chemical)I)

LBDU (Liquid Blend Dose Unit): ± 5 %

AC Box

- 208 VAC, 3 Phase, 175 A

Mainframe ROBOT

- Dual Arm Robot made by Roze, RS-485 (Ethernet) serial interface

Factory Interface (FI) Details:

FOUP Stage (ADO: Auto Door Opener)

- TDK for AMAT Specification

Link Tunnel

- Dual Blade Robot made by Yaskawa

Align Stage detecting Wafer Notch

Fan Filter unit: (>0.12 μm, >99.999%)

FI / Mainframe Control Unit with UPS (Window NT 4.0)

GUI (Graphic-User-Interface) Computer with UPS (Window NT 4.0)

Chiller Details

- Daiken for AMAT Specification

- Temperature Control Range: 5 ~ 22 deg C

Operator Interface Details

- LCD Touch Panel, Keyboard with Track Ball

- Desk Type or Roll-Around or Wall Mount Type

Anneal Chamber Module Details:

Anneal Chamber

- Gas Box: Mixing and Control of N2 96 %, H2 4% Process Gases

MFC, Flow Switch

- Heater (150 ~ 300 deg C), Cooler Plate, Arm

MTBF

1) MTBF Target : 250 hr

2) MTBF Target for each Unit

- Slim Cell 3400 hr

- IBC 3400 hr

- SRD 4000 hr

- Anneal 4500 hr

- MF Robot 6800 hr

- FI 5000 hr.

AMAT / APPLIED MATERIALS ECP SlimCell is a reactor that utilises electron cyclotron resonance (ECR) to deposit dielectric and conductive films. The reactor includes a full-featured process chamber with an ECR microwave source, gas-bias delivery frames, additional gas inputs, combustion-assisted cleaning, a process controller, water circulation and cooling systems, and a well-designed safety equipment. The chamber of the reactor is a single-shell transparent quartz and stainless steel structure. It is designed for high-performance reactive- ion etching, plasma ablation and deposition operations. The ECR microwave source is a high-frequency generator which produces microwaves to ionise the gas mixture in the chamber. The gas-bias delivery frames are located at the lower part of the chamber, which allows precise control of the intensity of the ions. The additional gas inputs are connected to the top of the chamber to deliver inert or corrosive gases to the process chamber. The combustion-assisted cleaning system is a novel feature in which a controlled chemical reaction helps to maintain a clean chamber. It eliminates the need for complex vacuum cleaning all at once. It also reduces post-process maintenance time. The process control unit is based on a distributed equipment machine which is interfaced with a Windows transport architecture. It is designed to handle multiple applications and recipes simultaneously and operate with all the peripheral processing components. This tool is also capable of real-time feedback control of all process parameters. The water circulation and cooling systems are designed to provide uniform, temperature-controlled cooling of all critical components of the reaction chamber. Passivated plates design is utilised in the reactor to maximise water velocity and heat dissipation. The safety asset of AMAT ECP SlimCell reactor includes various safety features to prevent accidents and protect personnel against excessive radiation and/or overheating. APPLIED MATERIALS ECP SlimCell provides excellent uniformity and scalability for deposition processes, while its superior safety systems makes it ideal for use in critical operations. A comprehensive maintenance process helps to keep the device in excellent working condition and ensure consistent performance. The use of a modern, integrated control model allows for easy and precise process control, making it an optimal choice for research and production.

There are no reviews yet