Used AMAT / APPLIED MATERIALS Enabler #293600548 for sale

URL successfully copied!

Tap to zoom

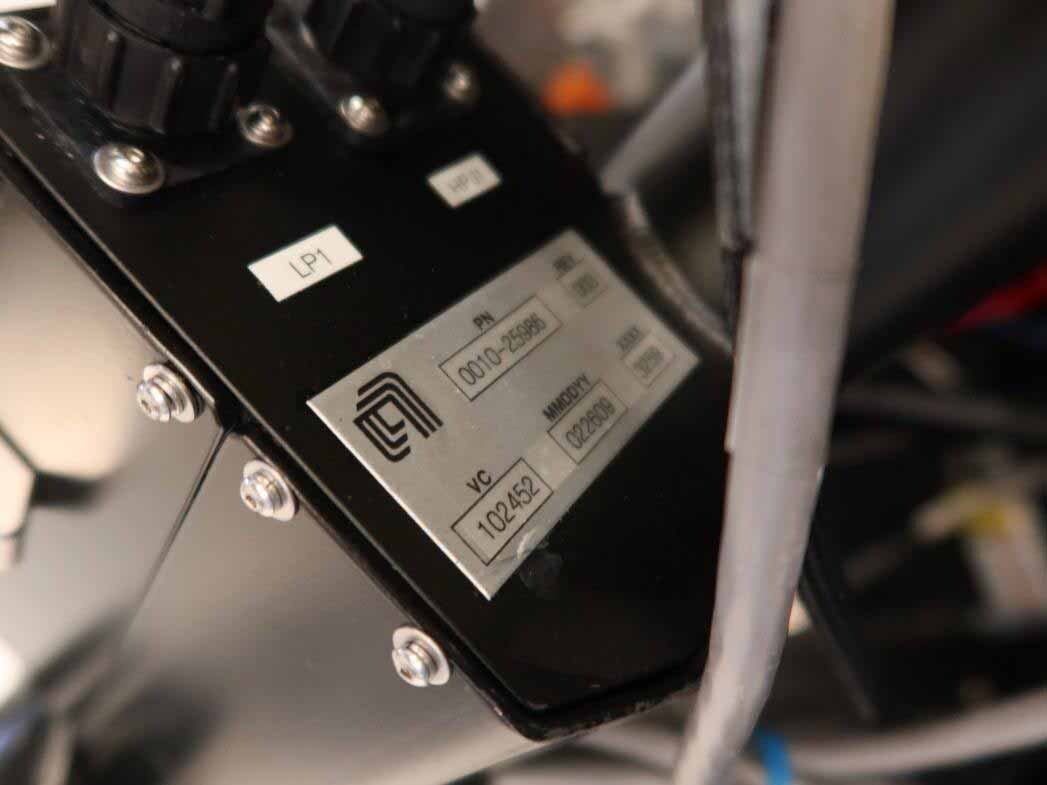

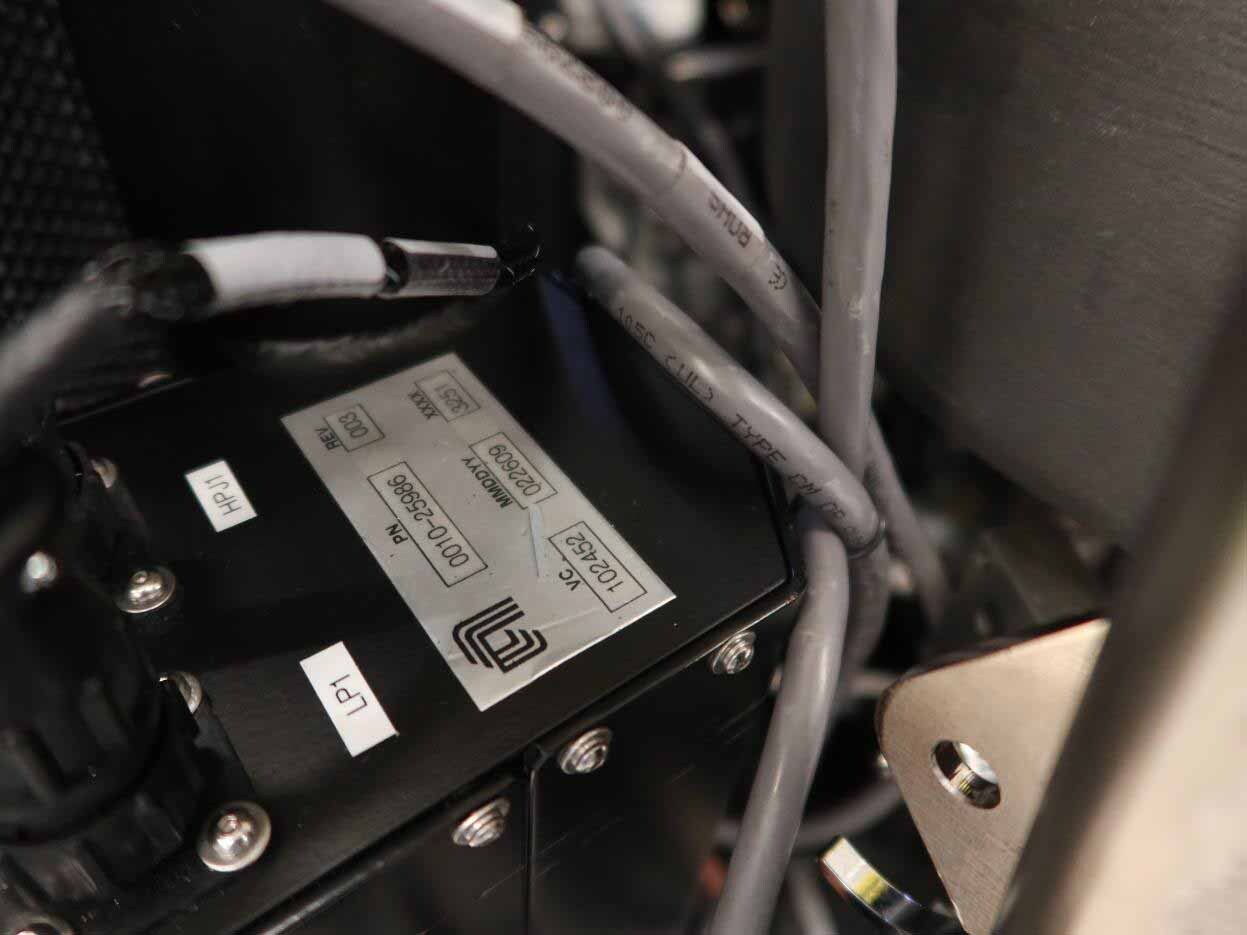

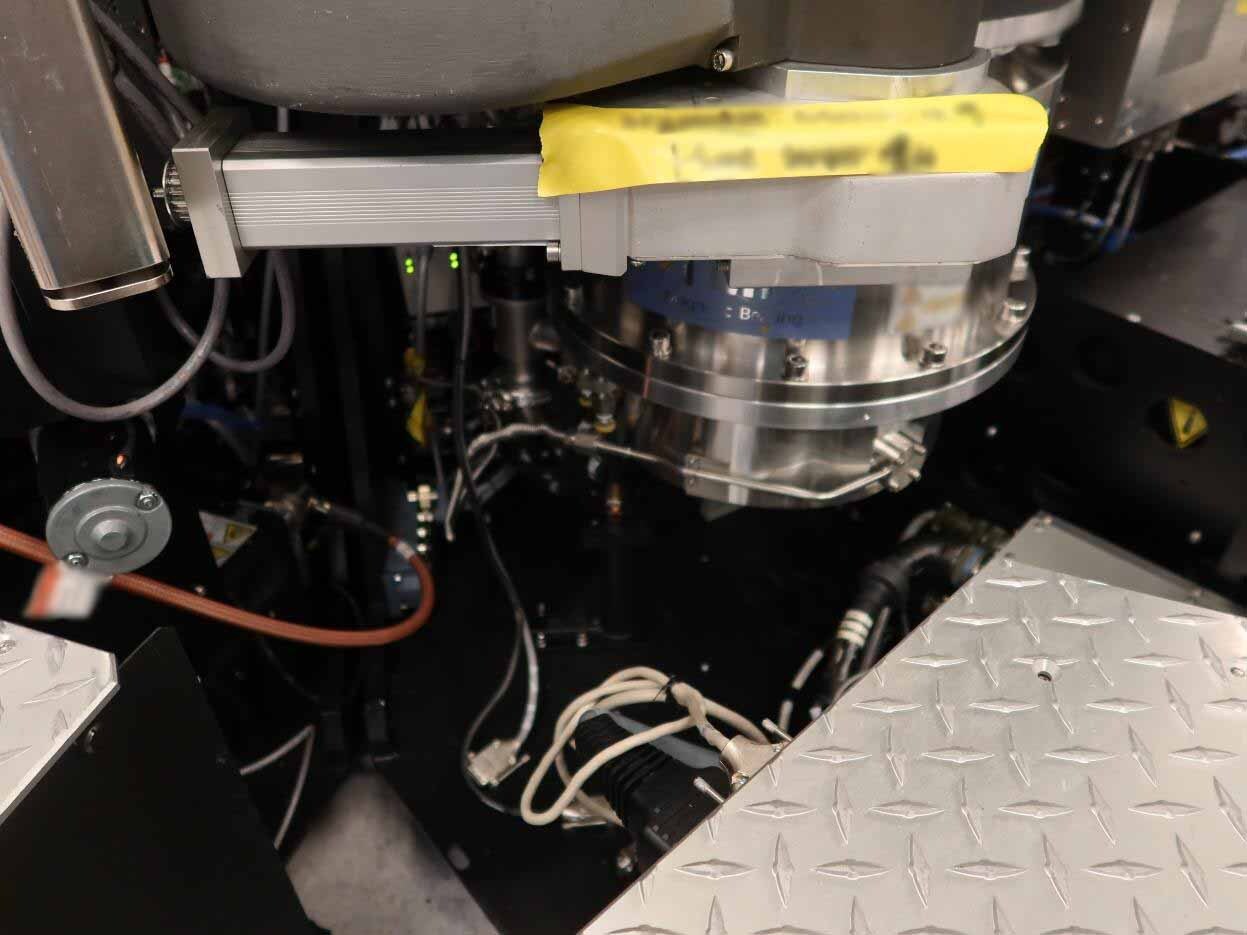

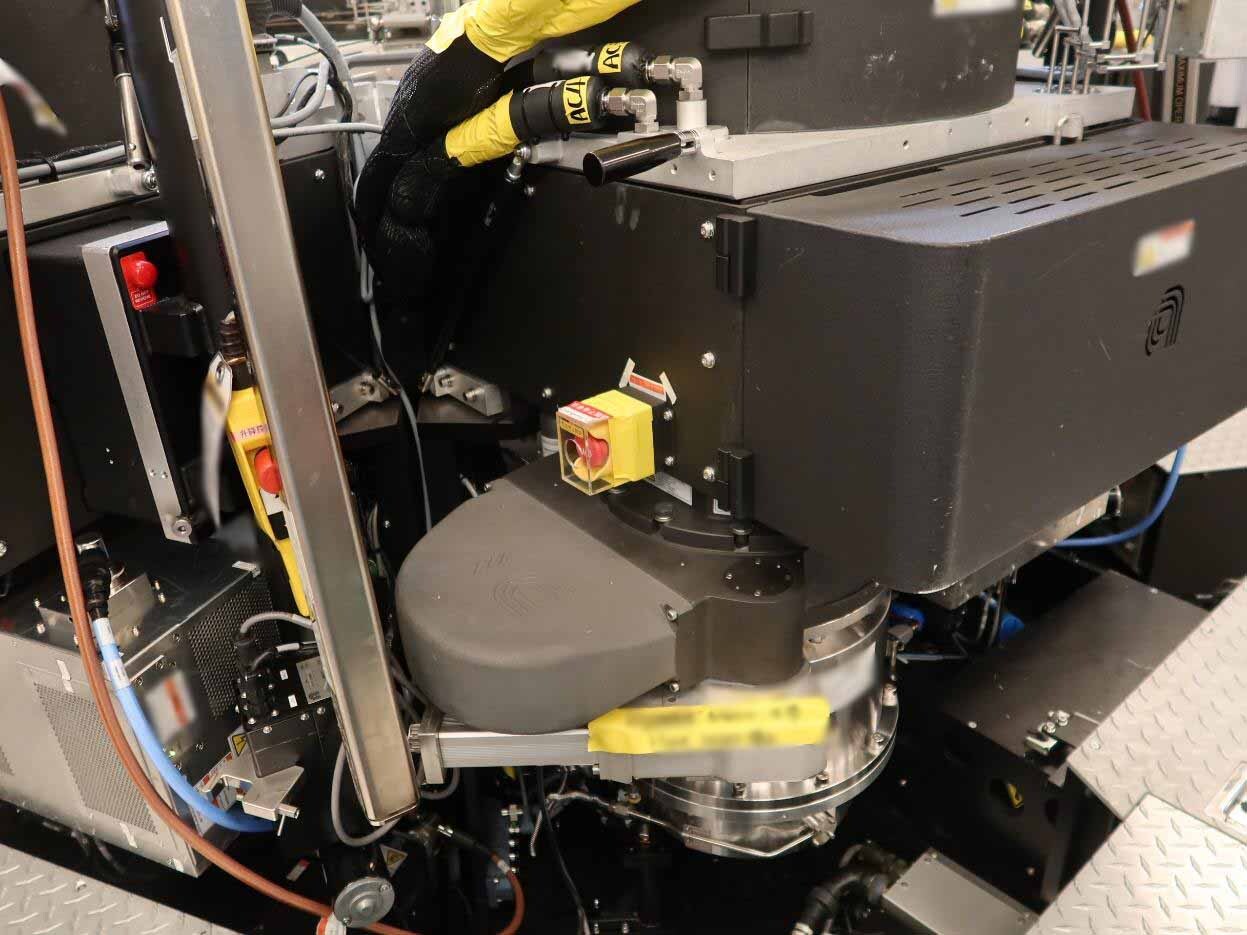

ID: 293600548

Wafer Size: 12"

Vintage: 2008

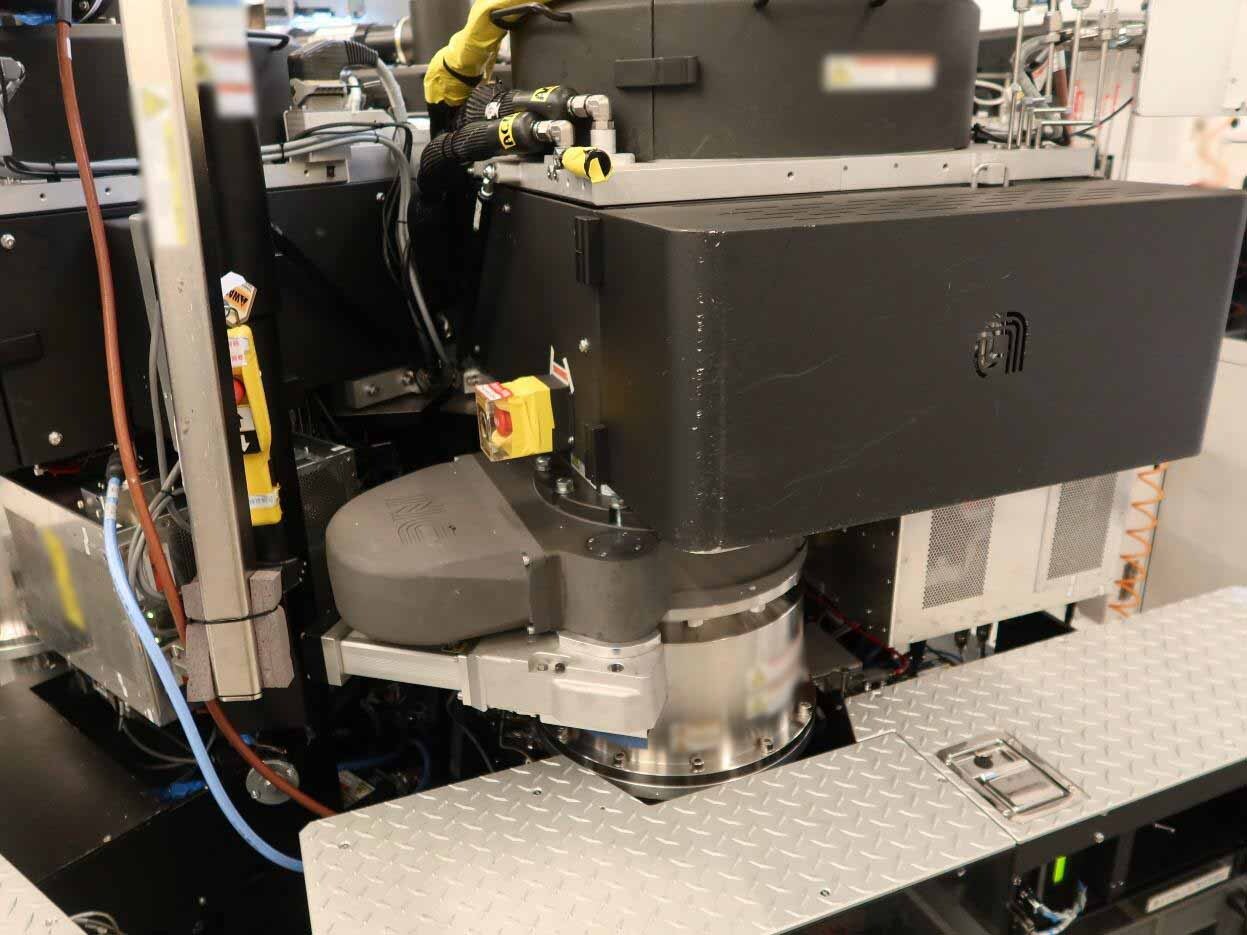

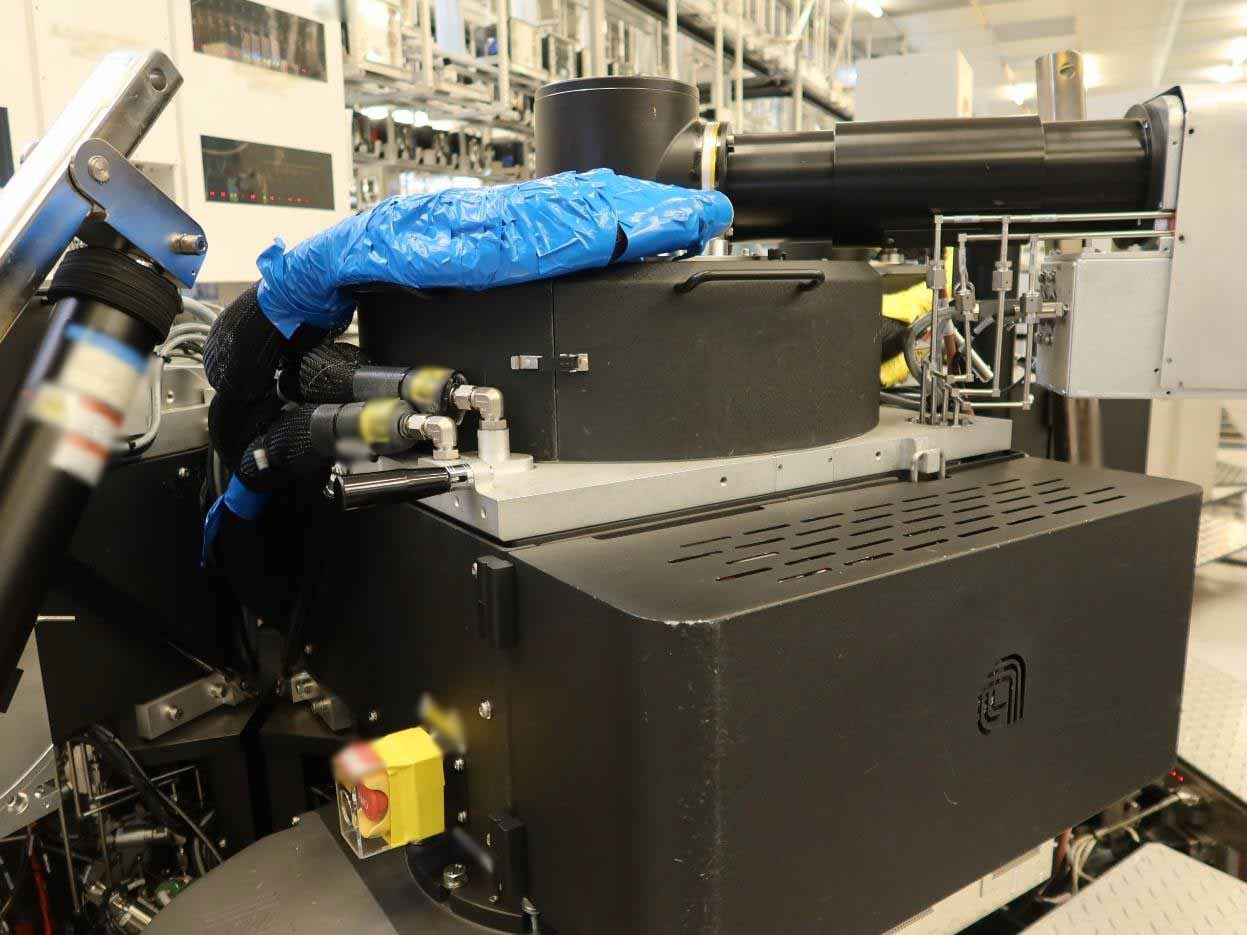

Etcher, 12"

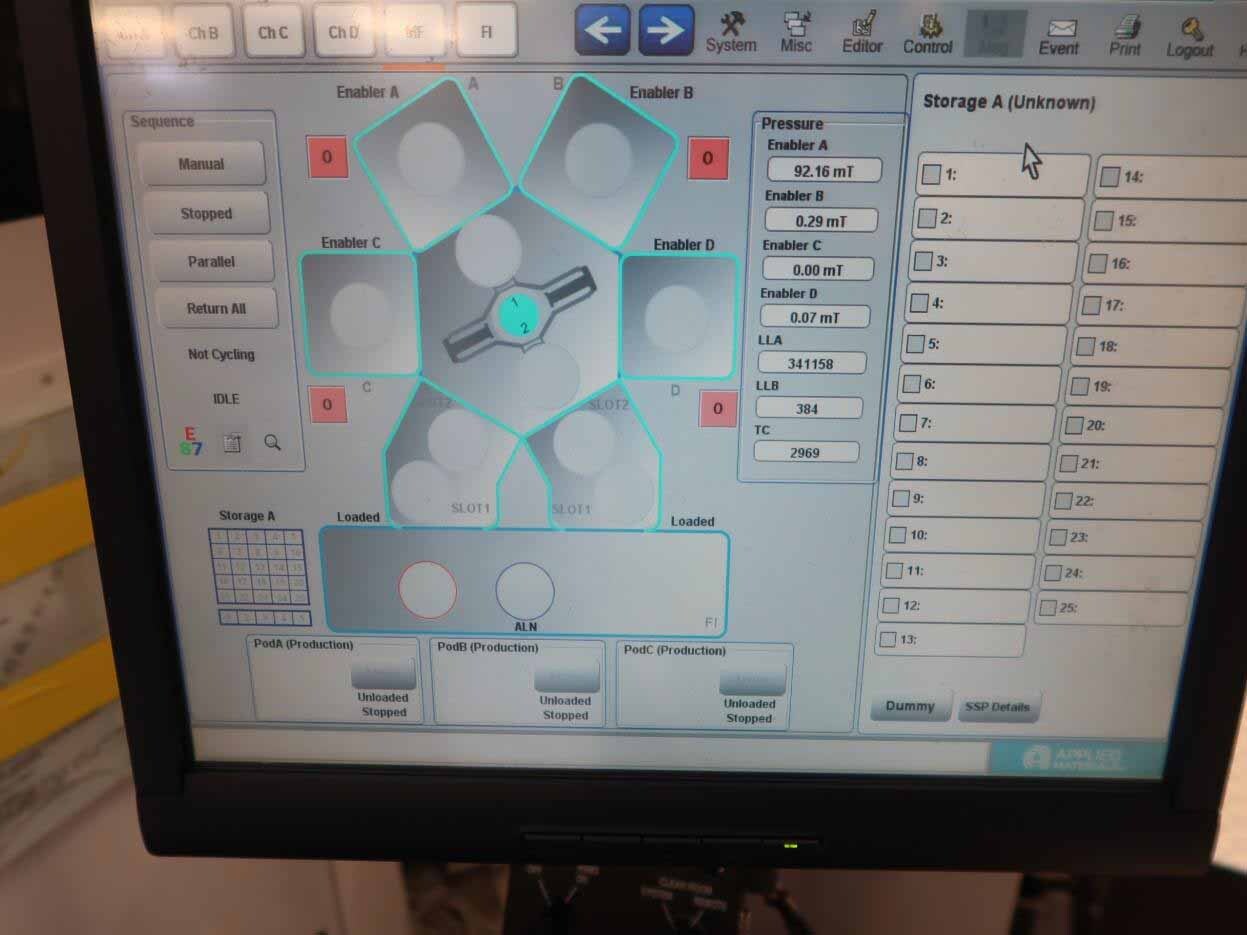

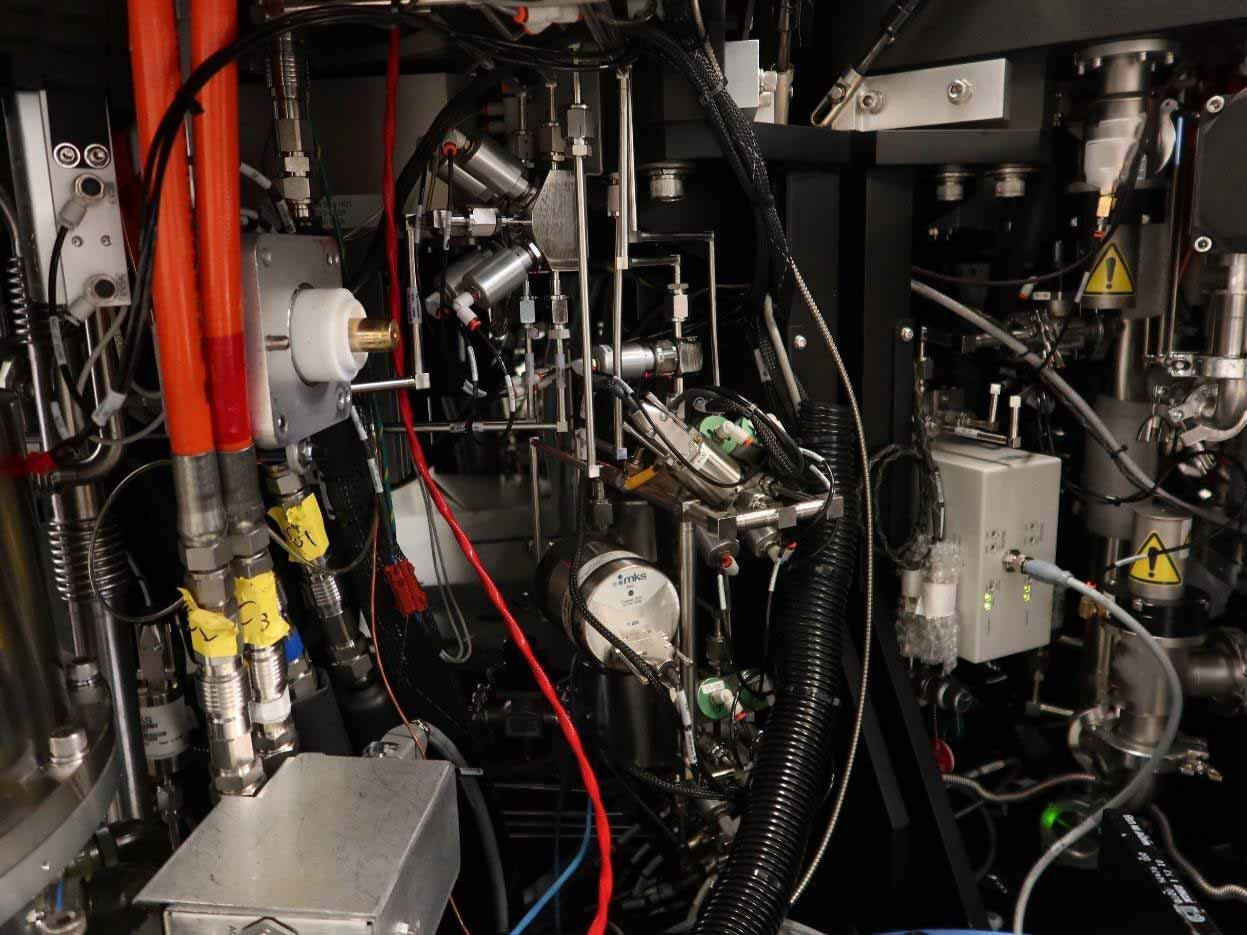

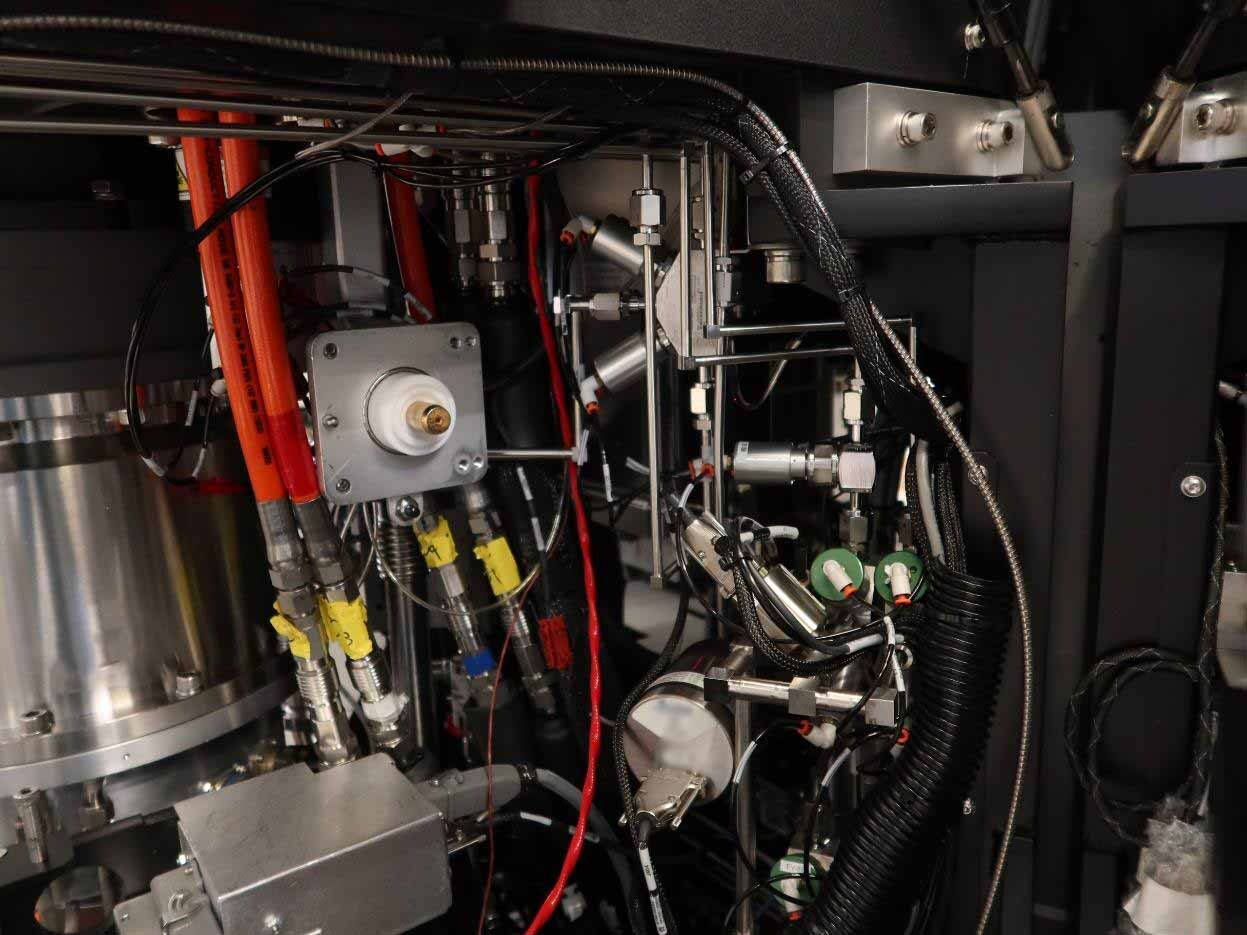

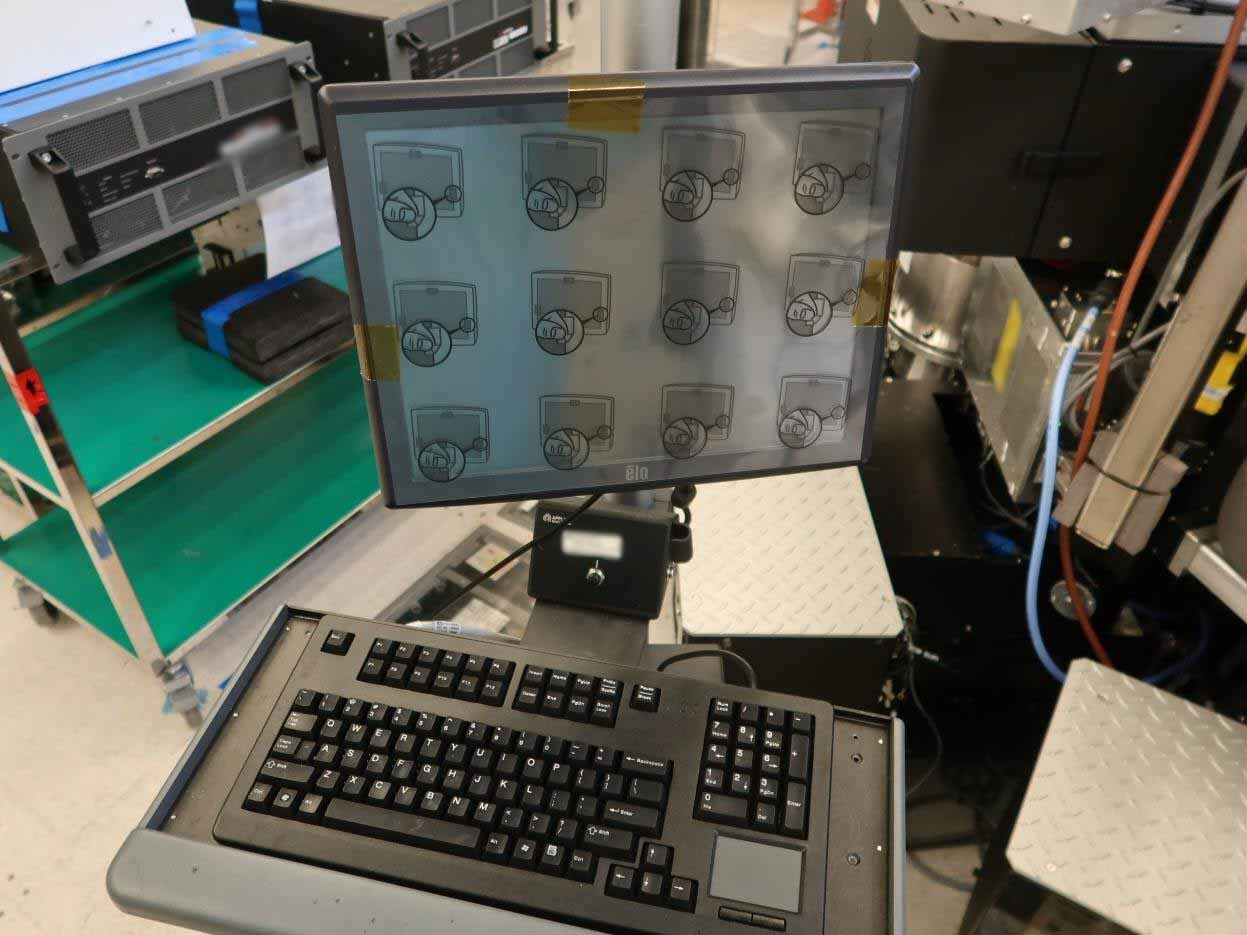

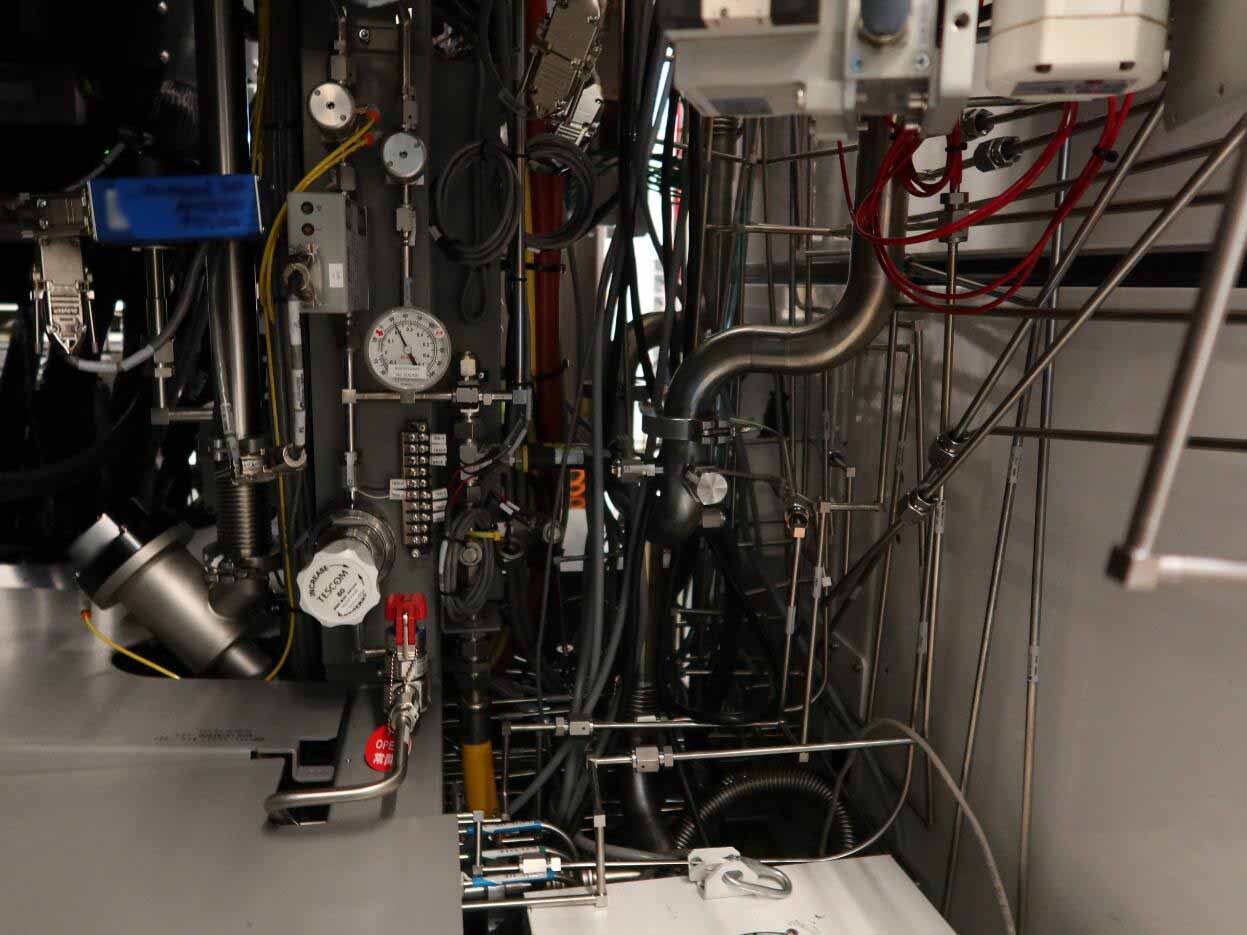

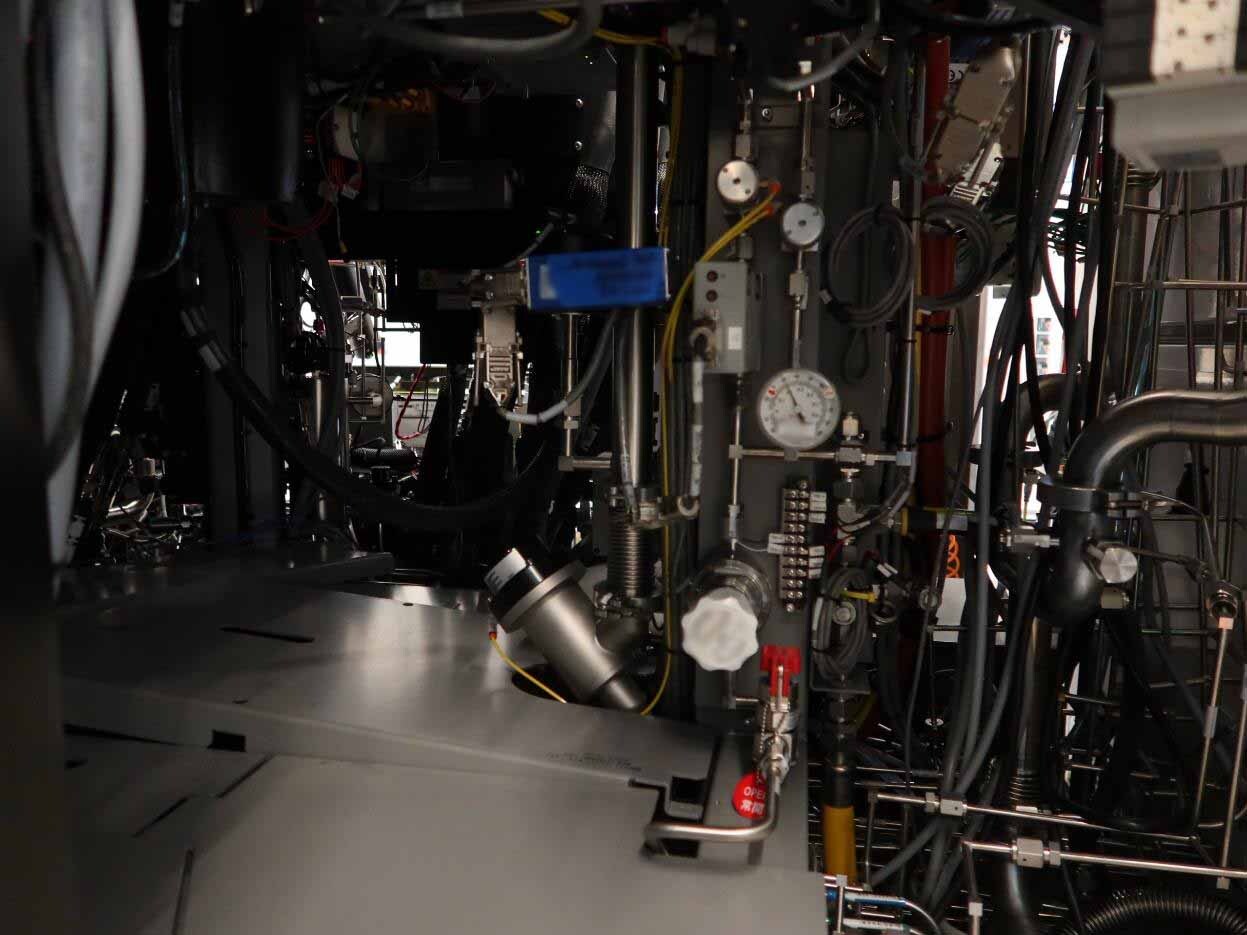

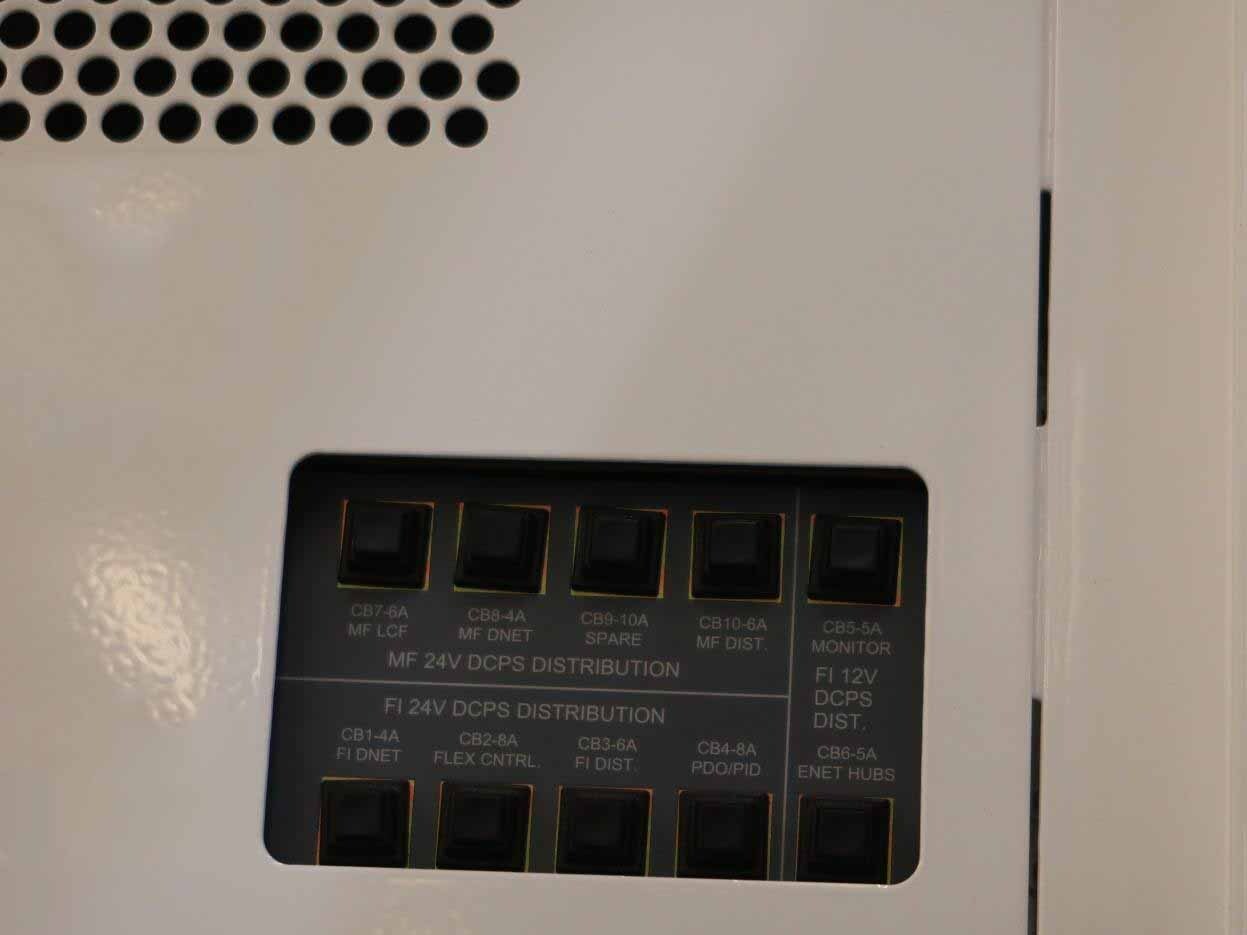

Factory interface: FI 5.3

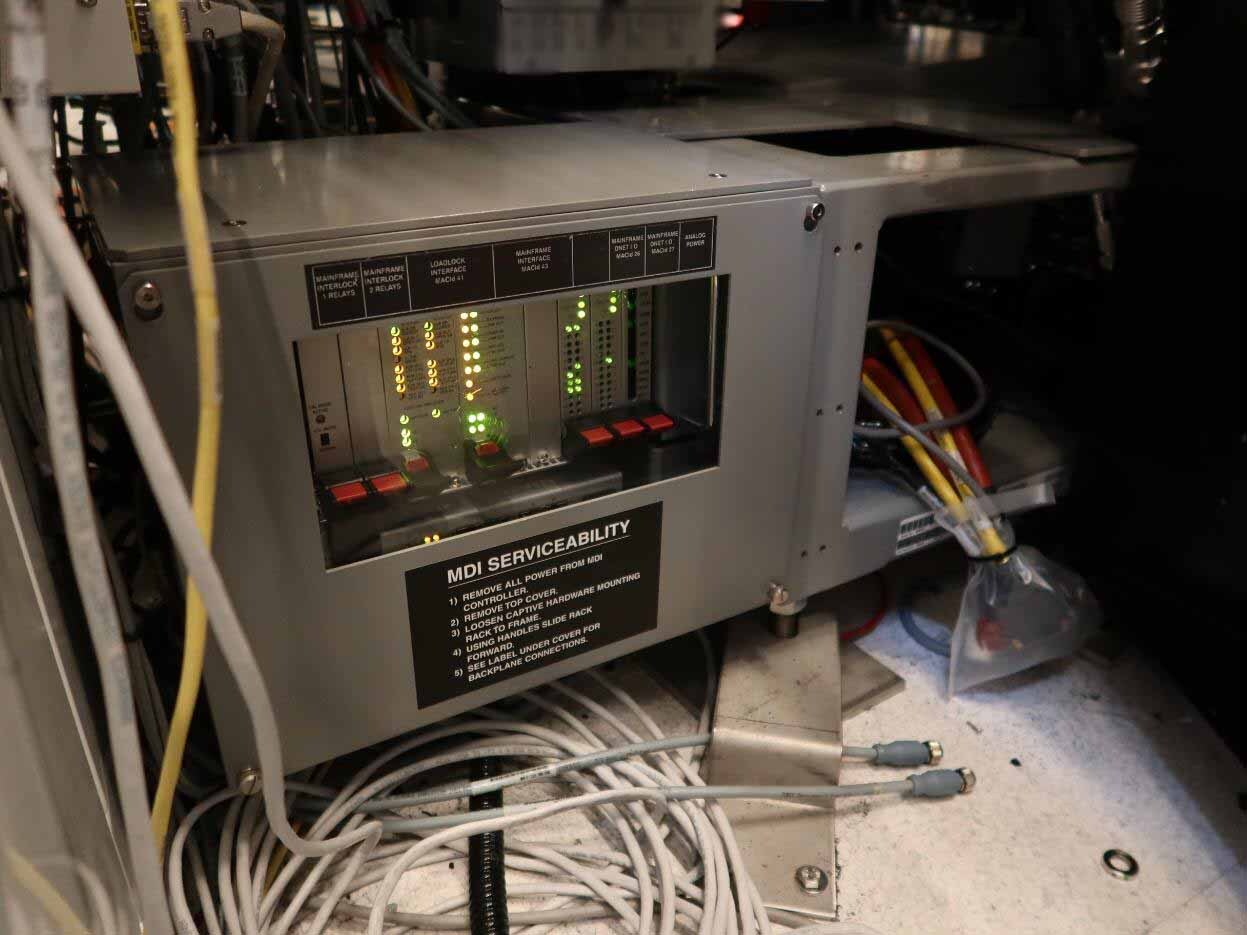

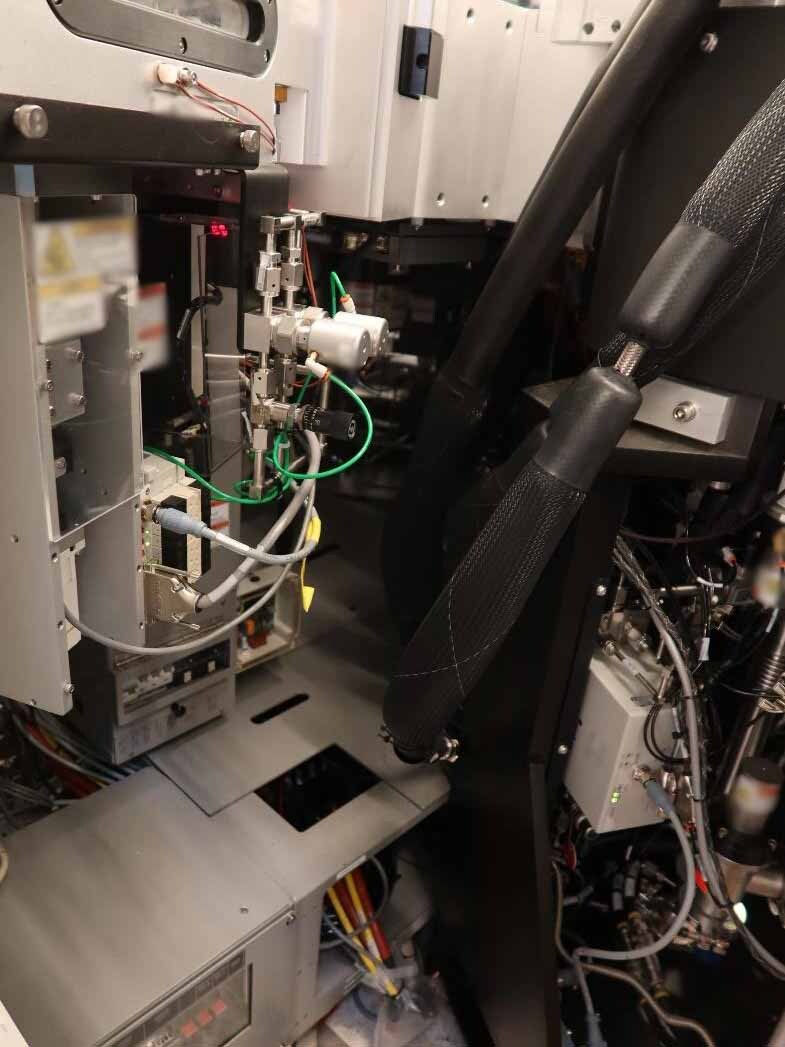

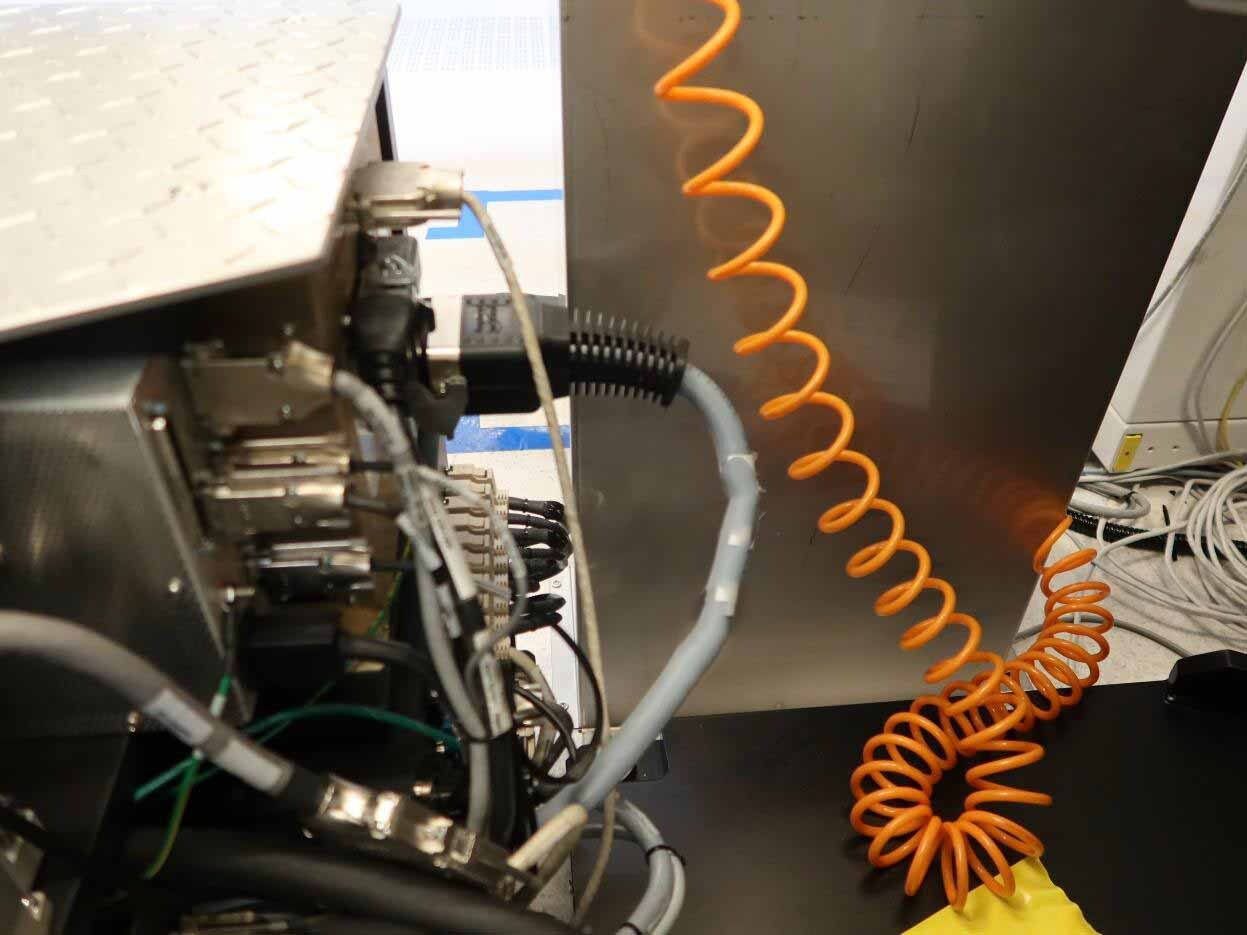

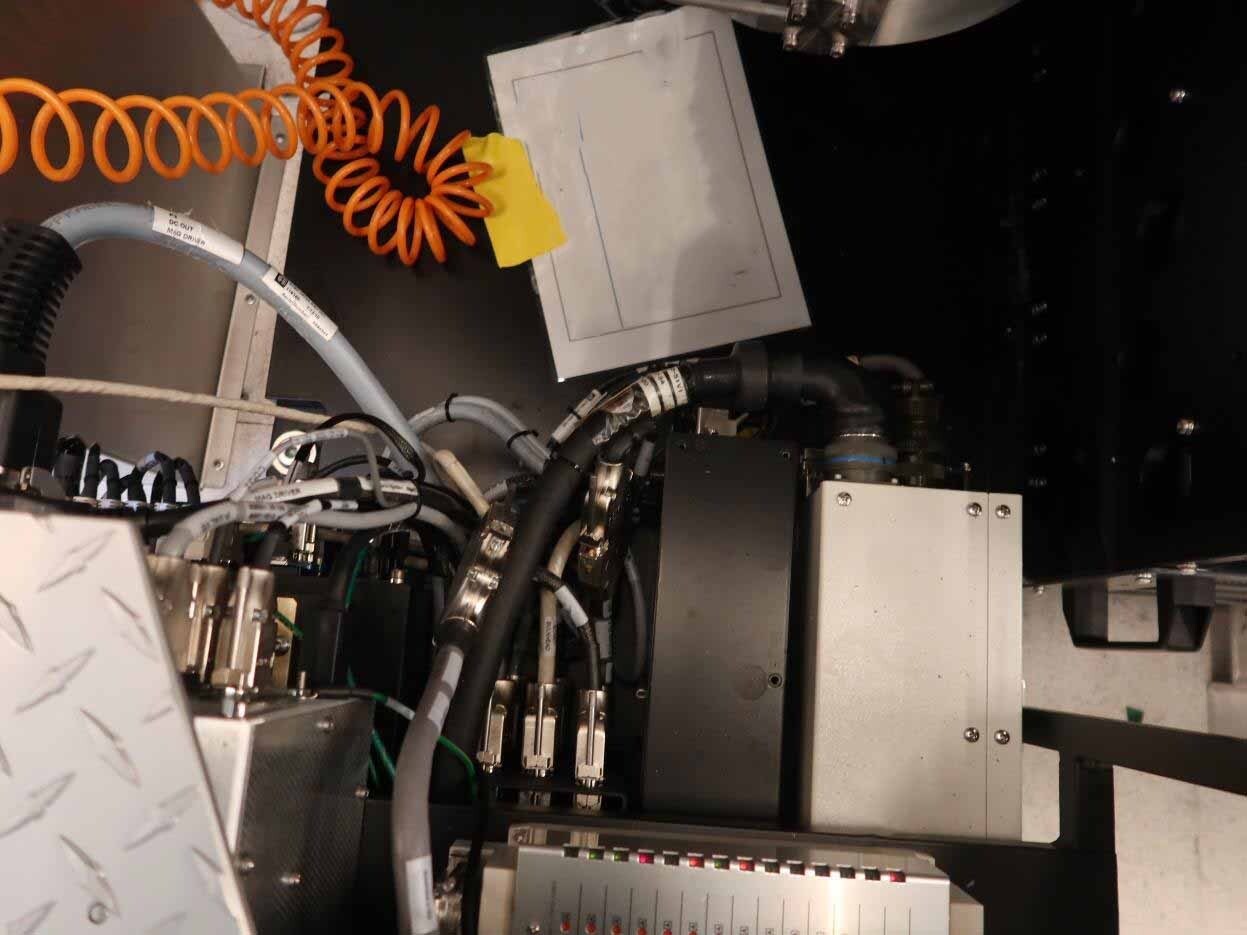

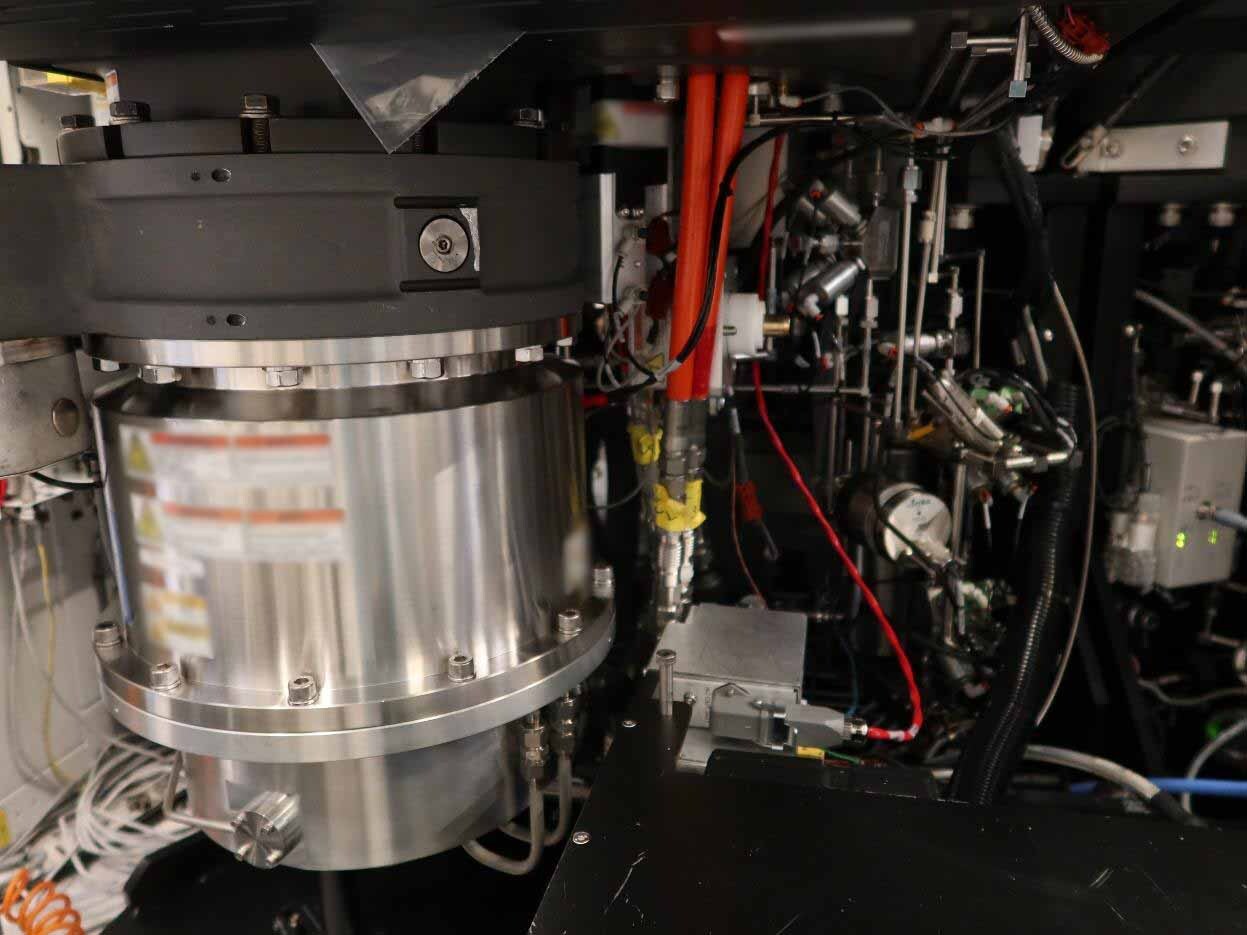

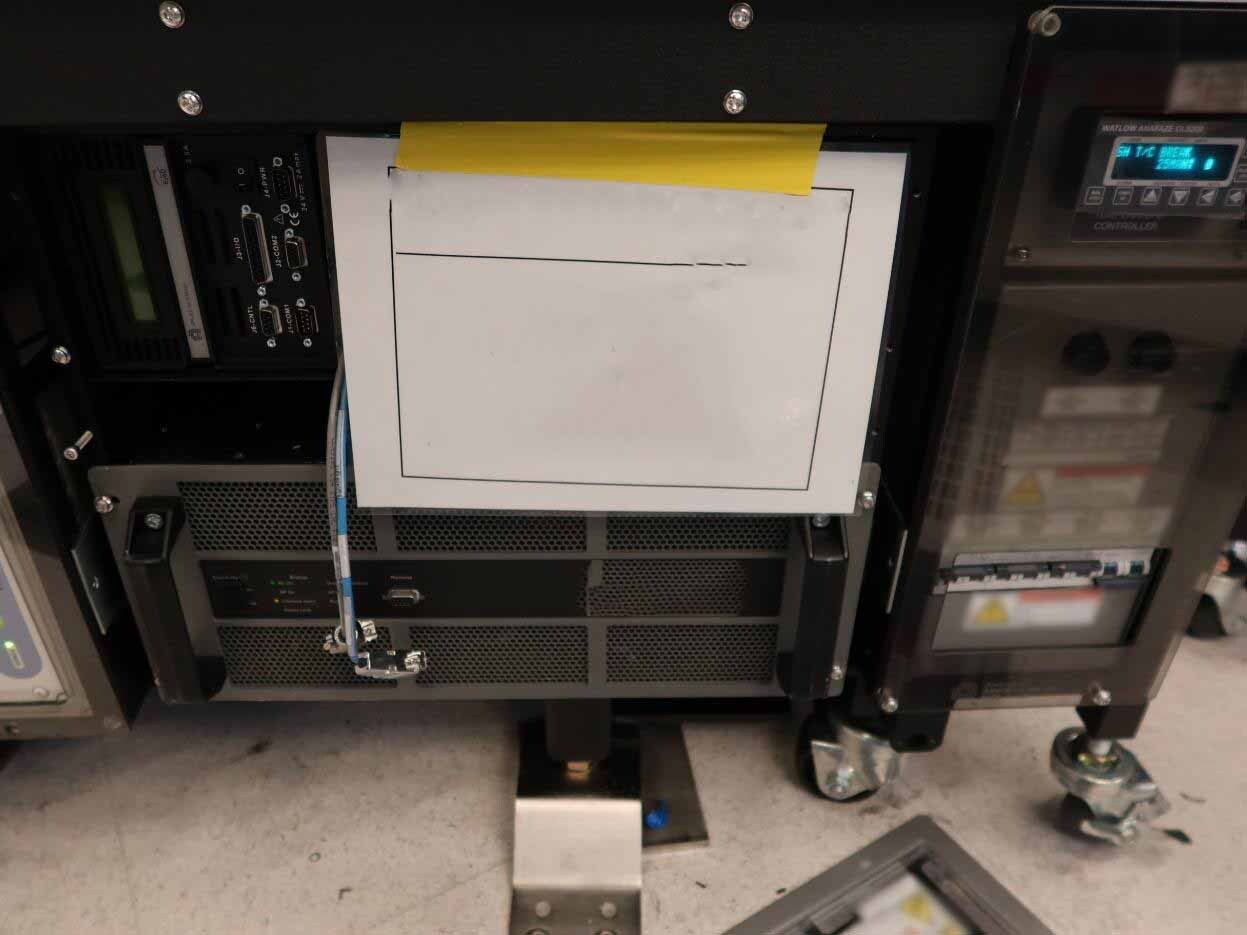

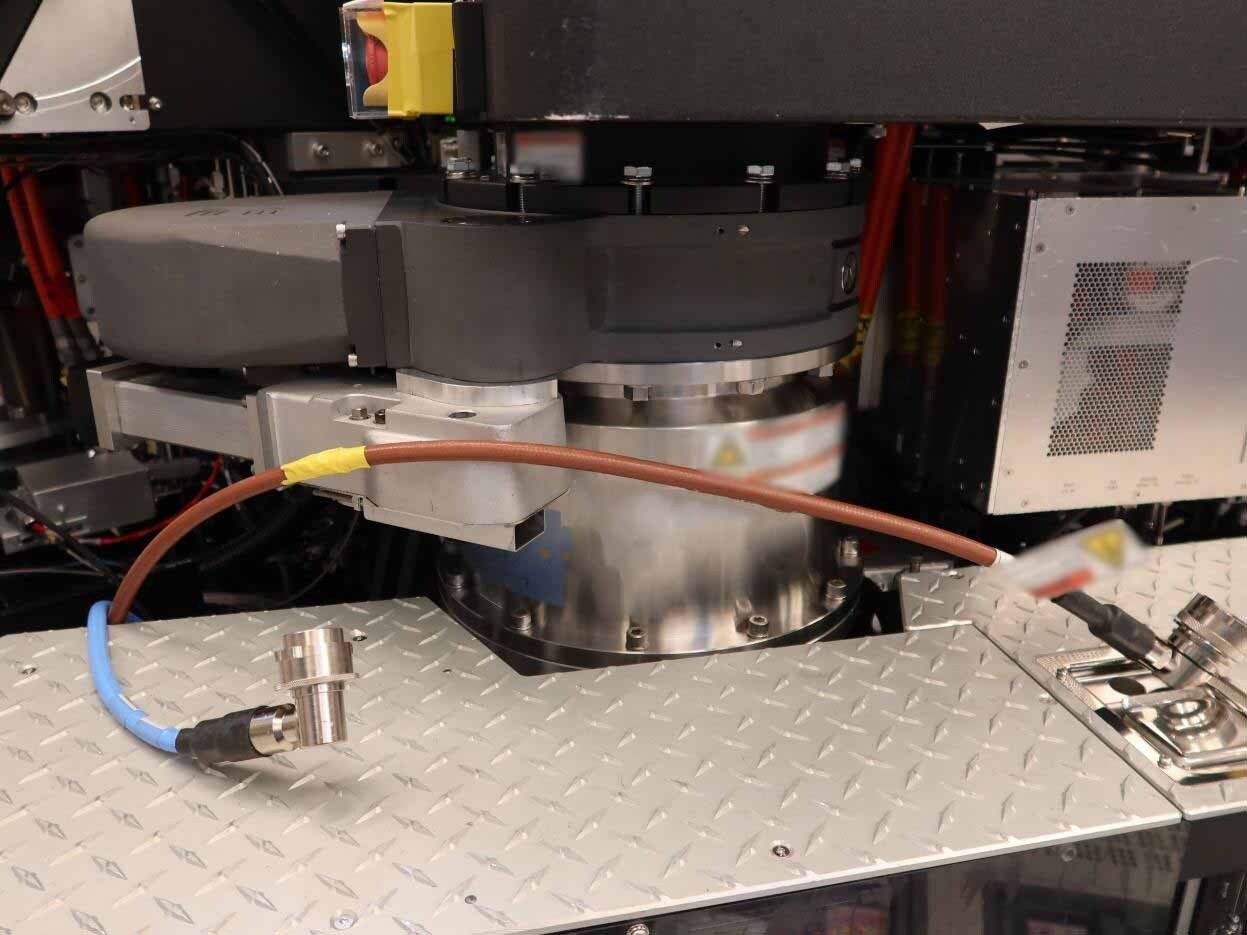

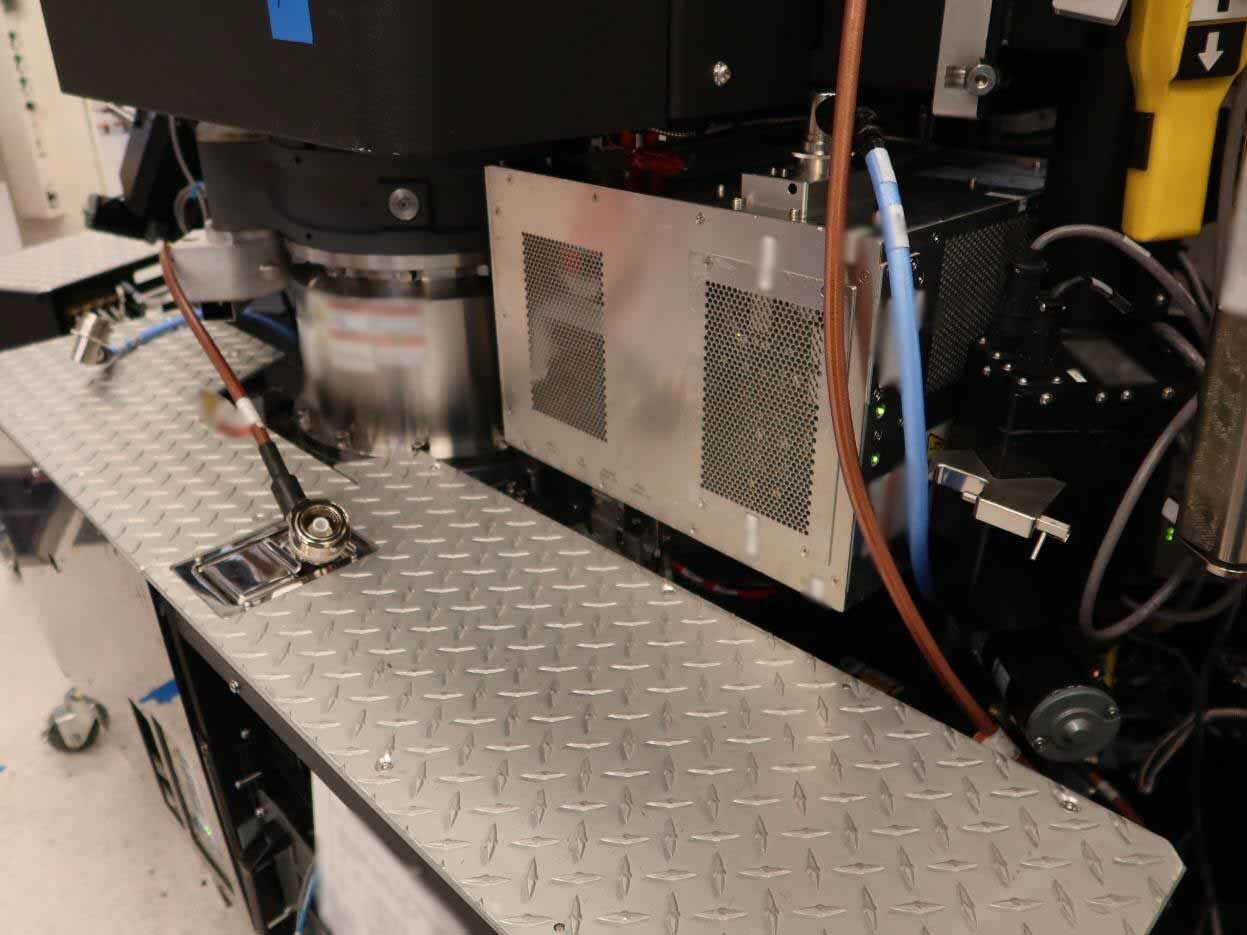

Centura AP Mainframe

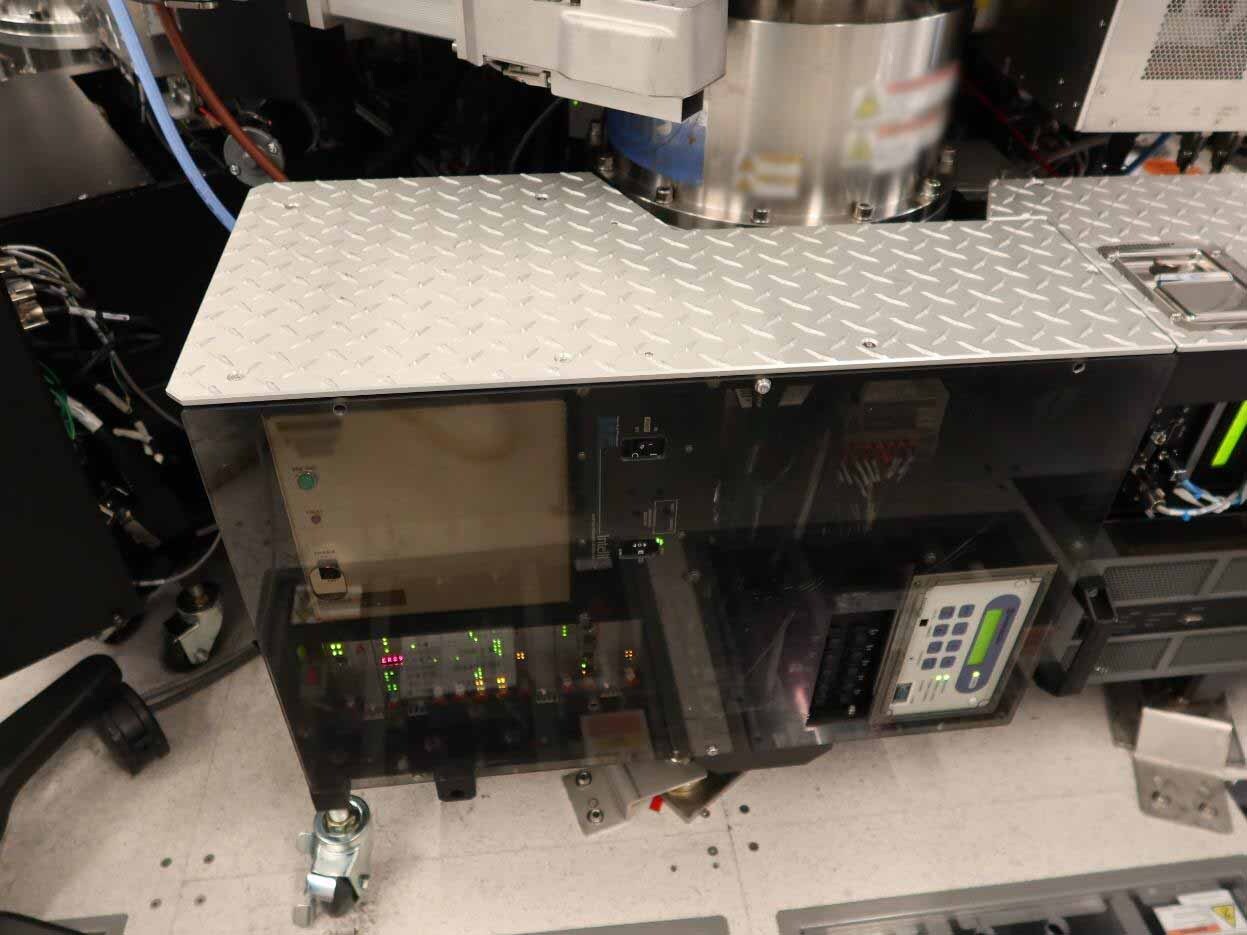

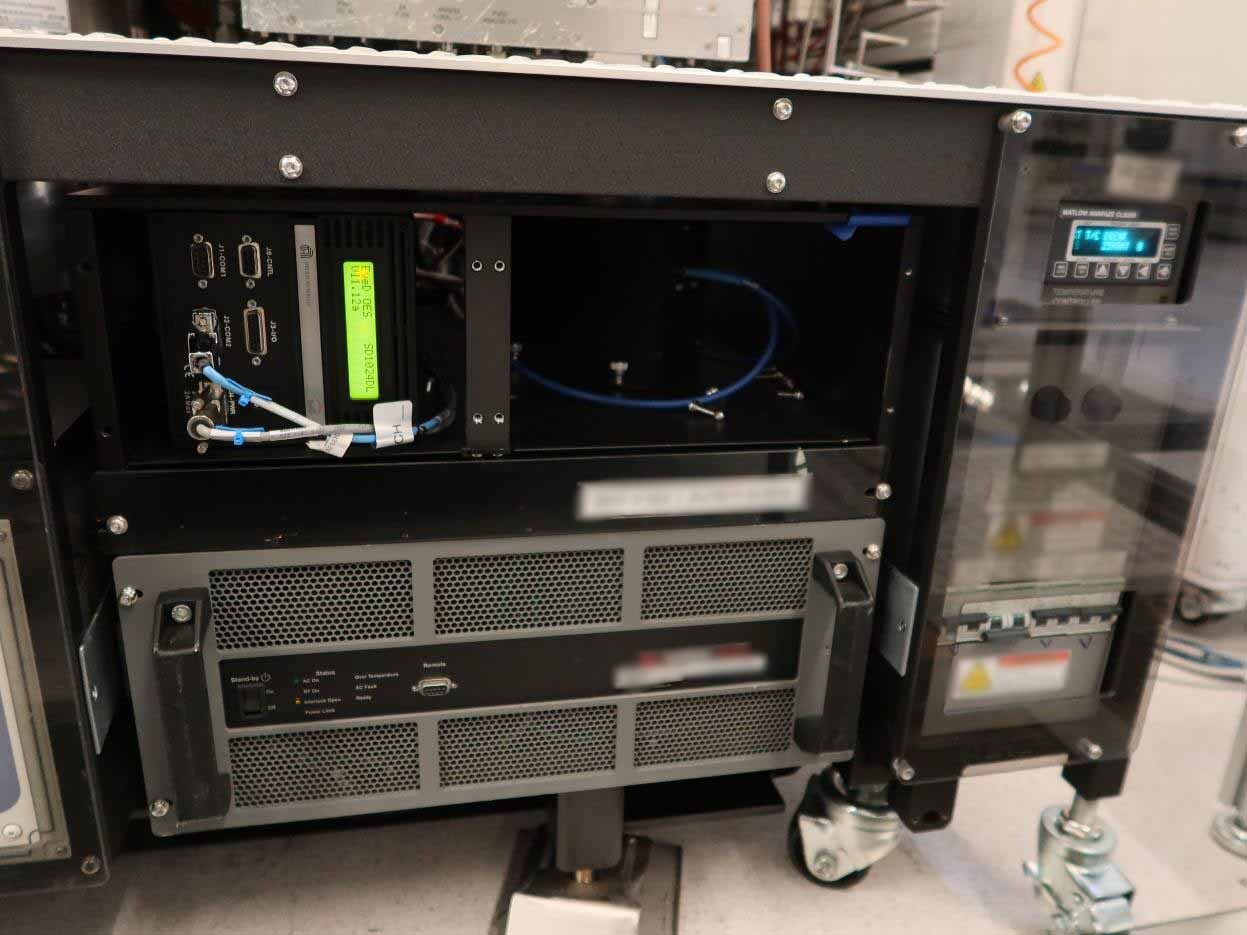

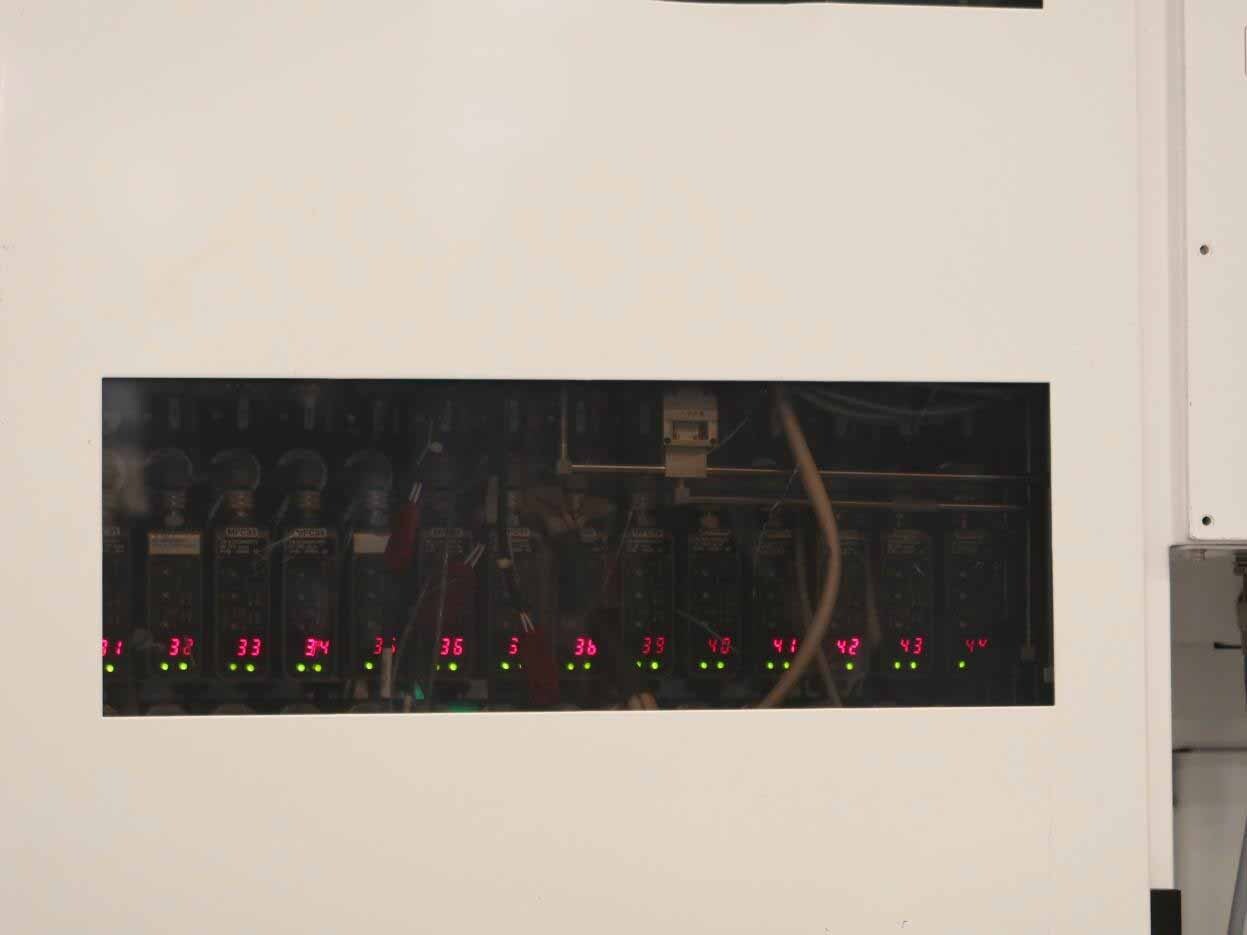

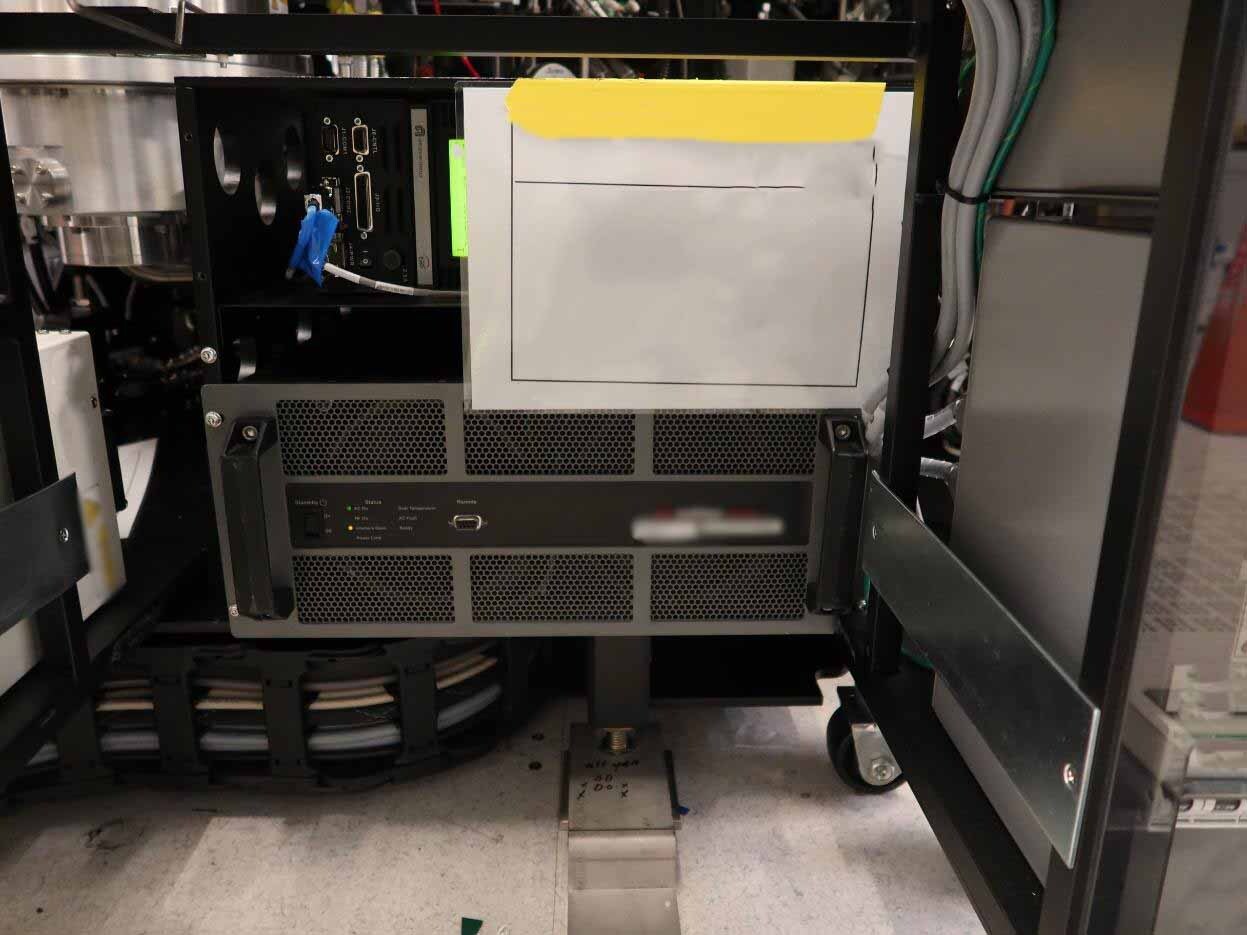

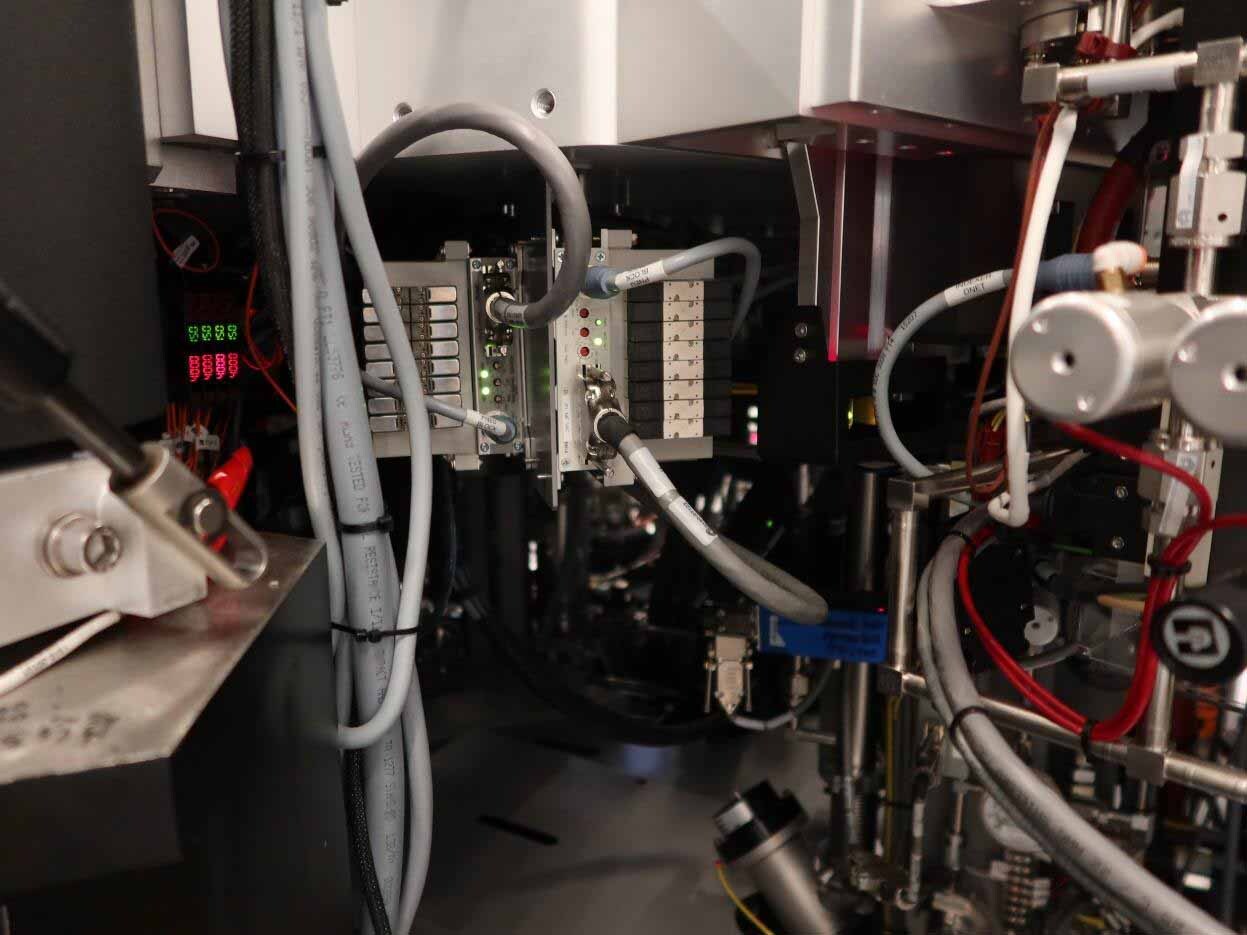

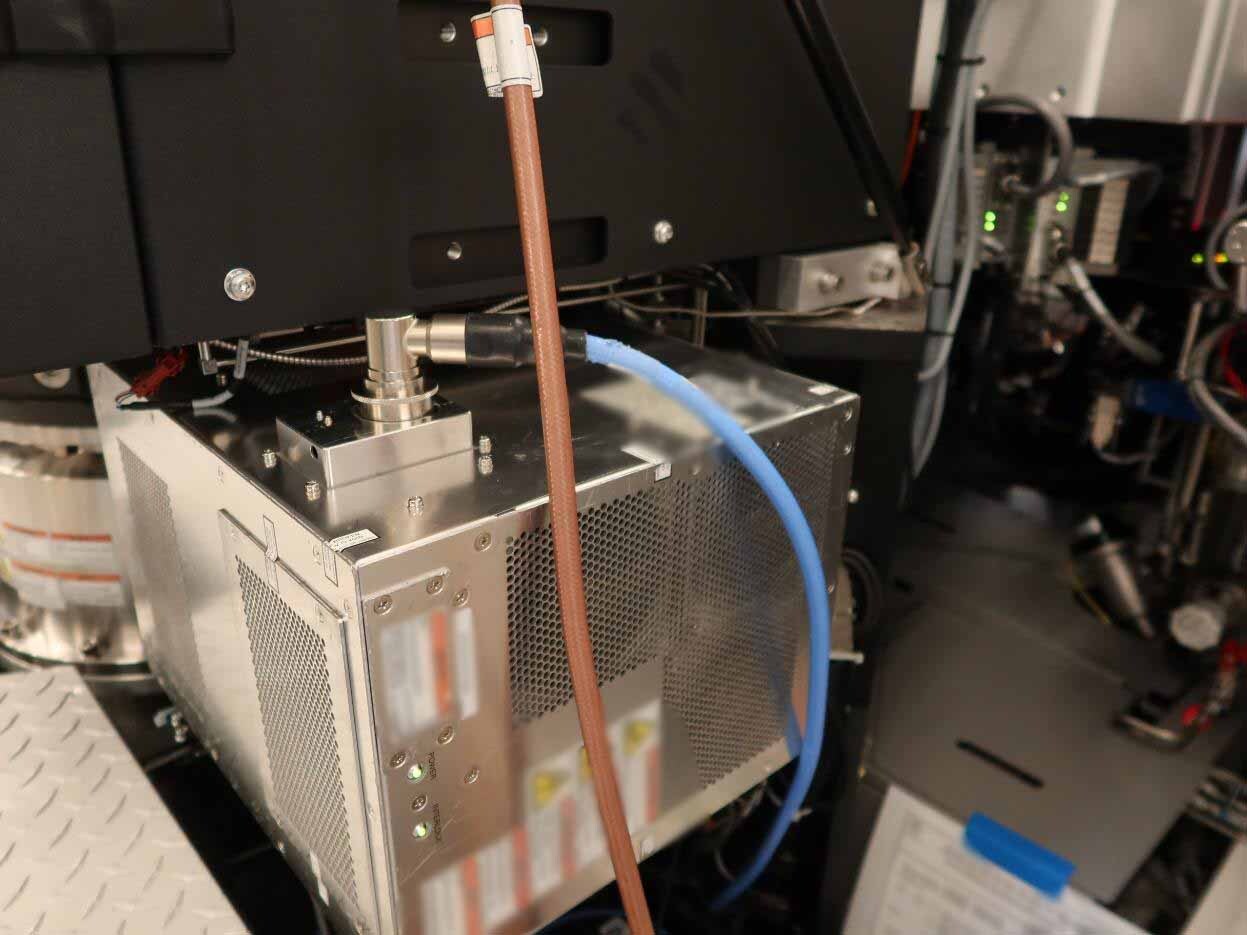

RF Rack, 12"

Bias 2 RF generator rack

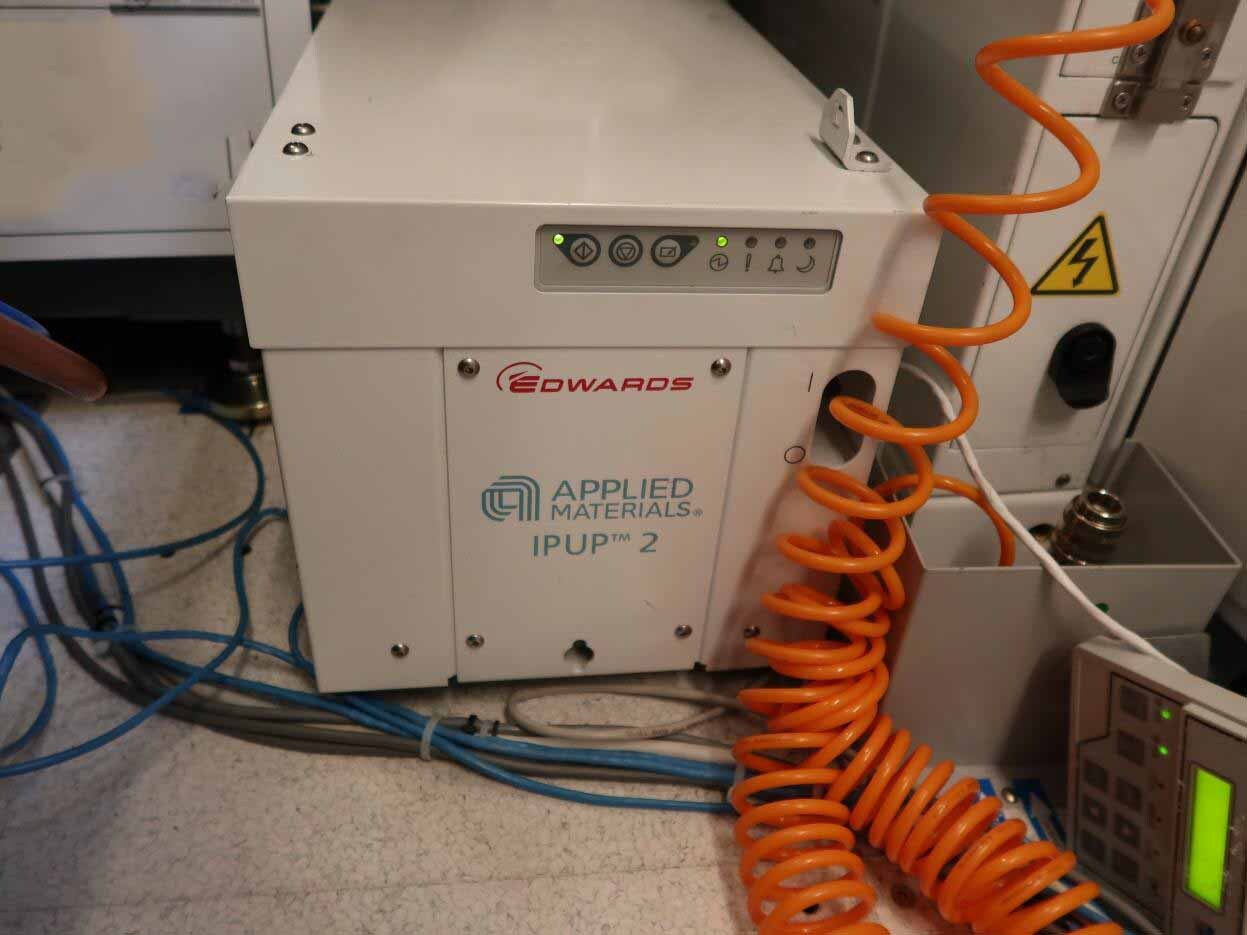

TOYOTA T100L LL/MF Dry pump

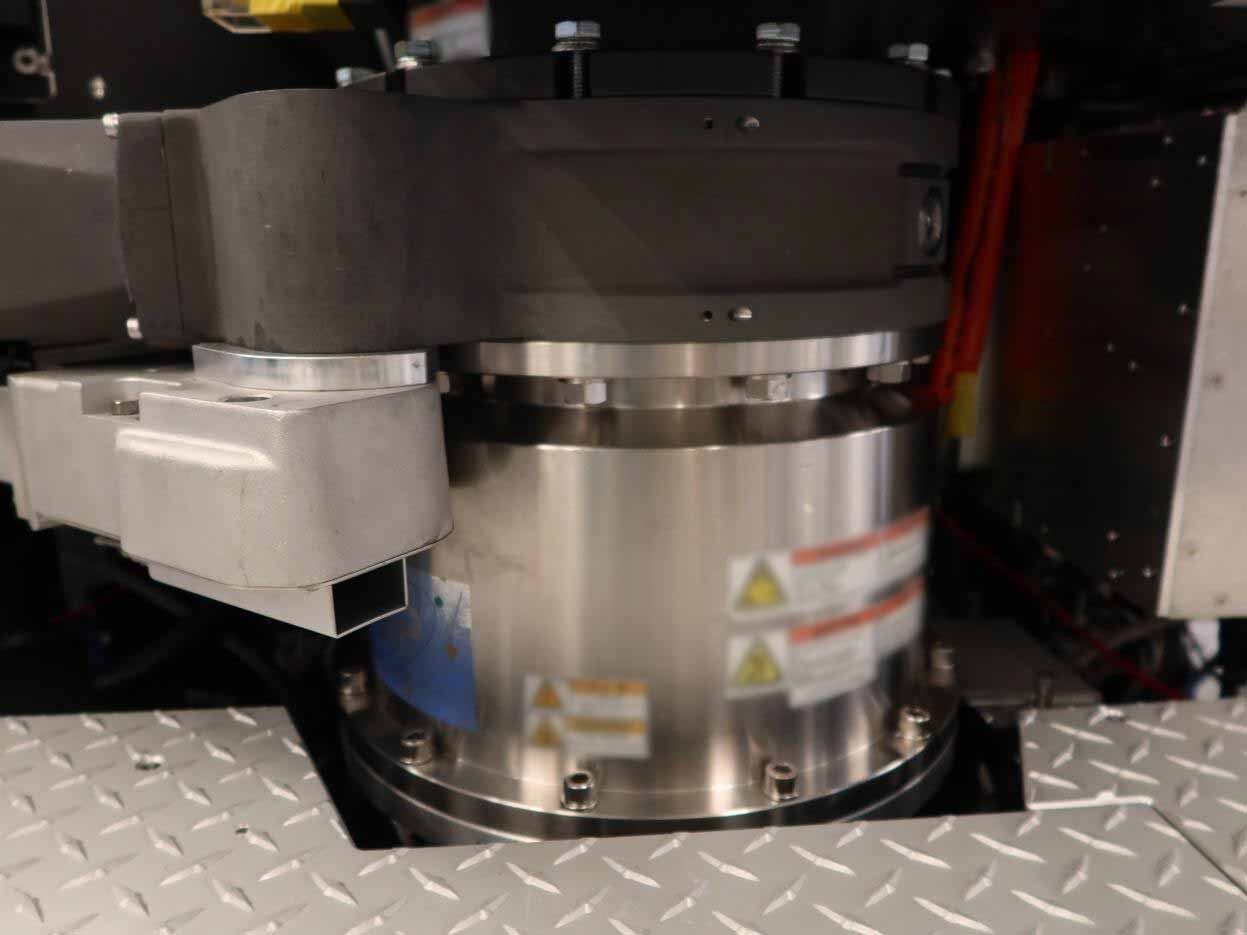

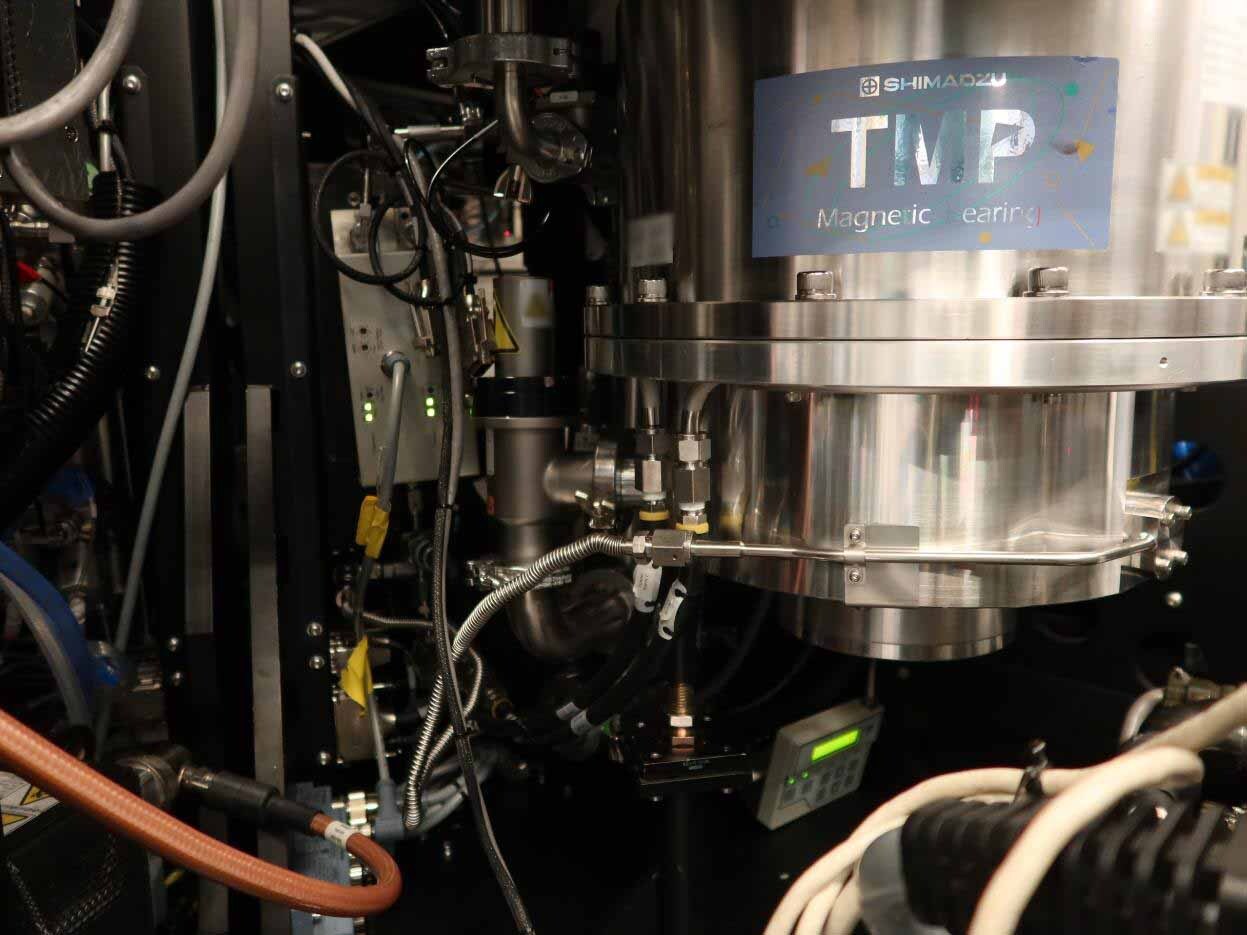

SHIMADZU TMP-3403LMC Turbo pump

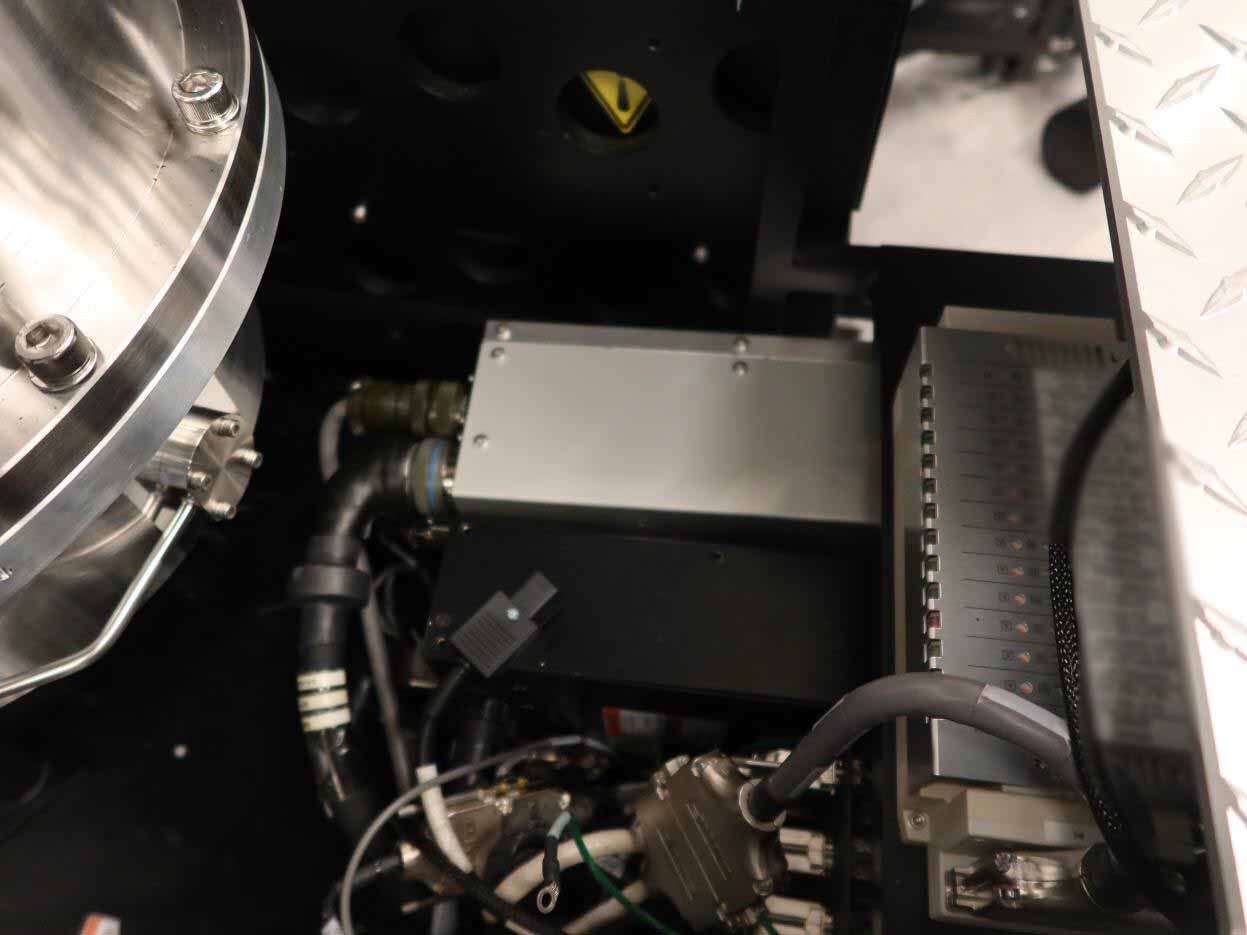

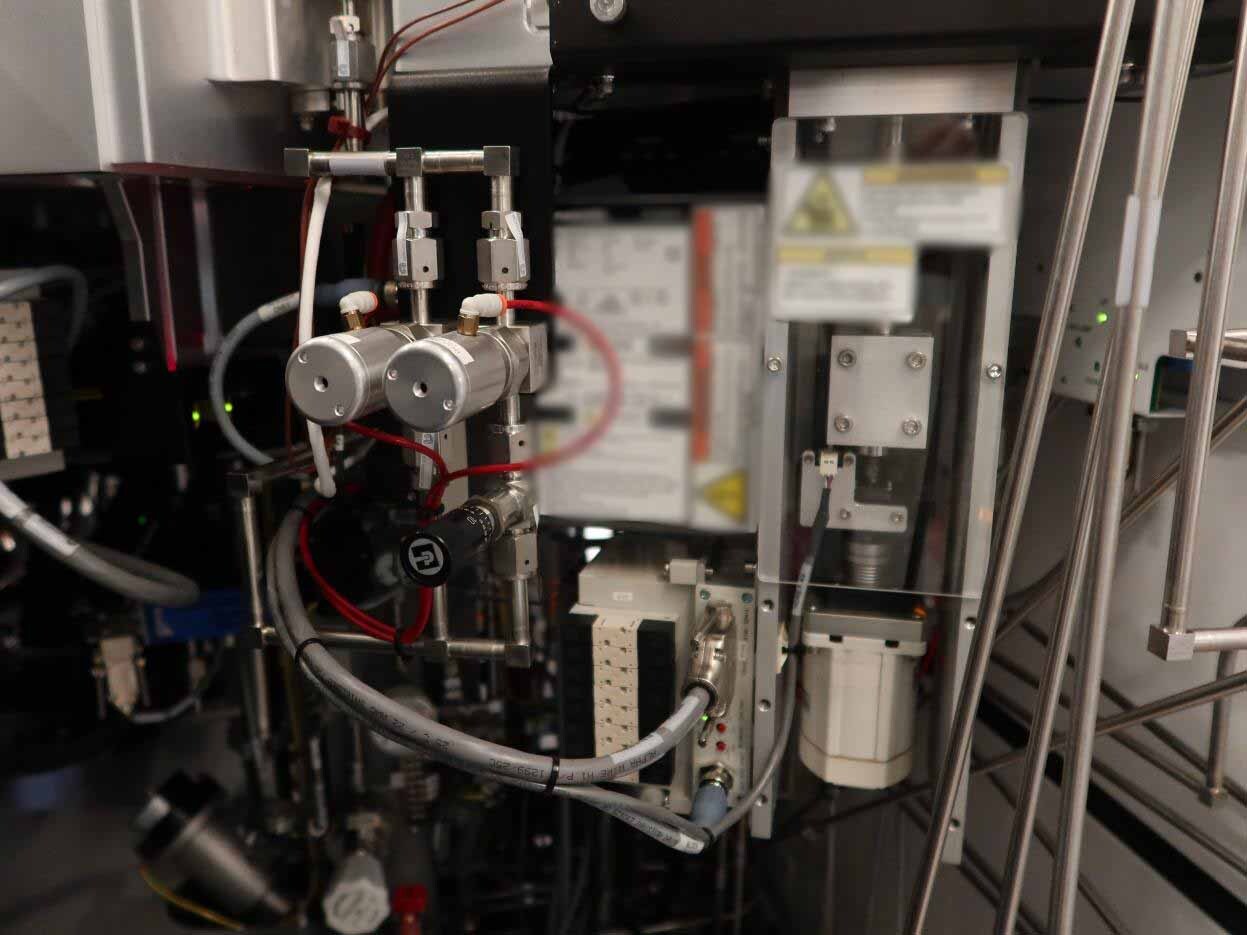

DAIHEN RMN-50N6 matcher

Shower head assy, TKI SIC SGD, With Alum Plug, E5

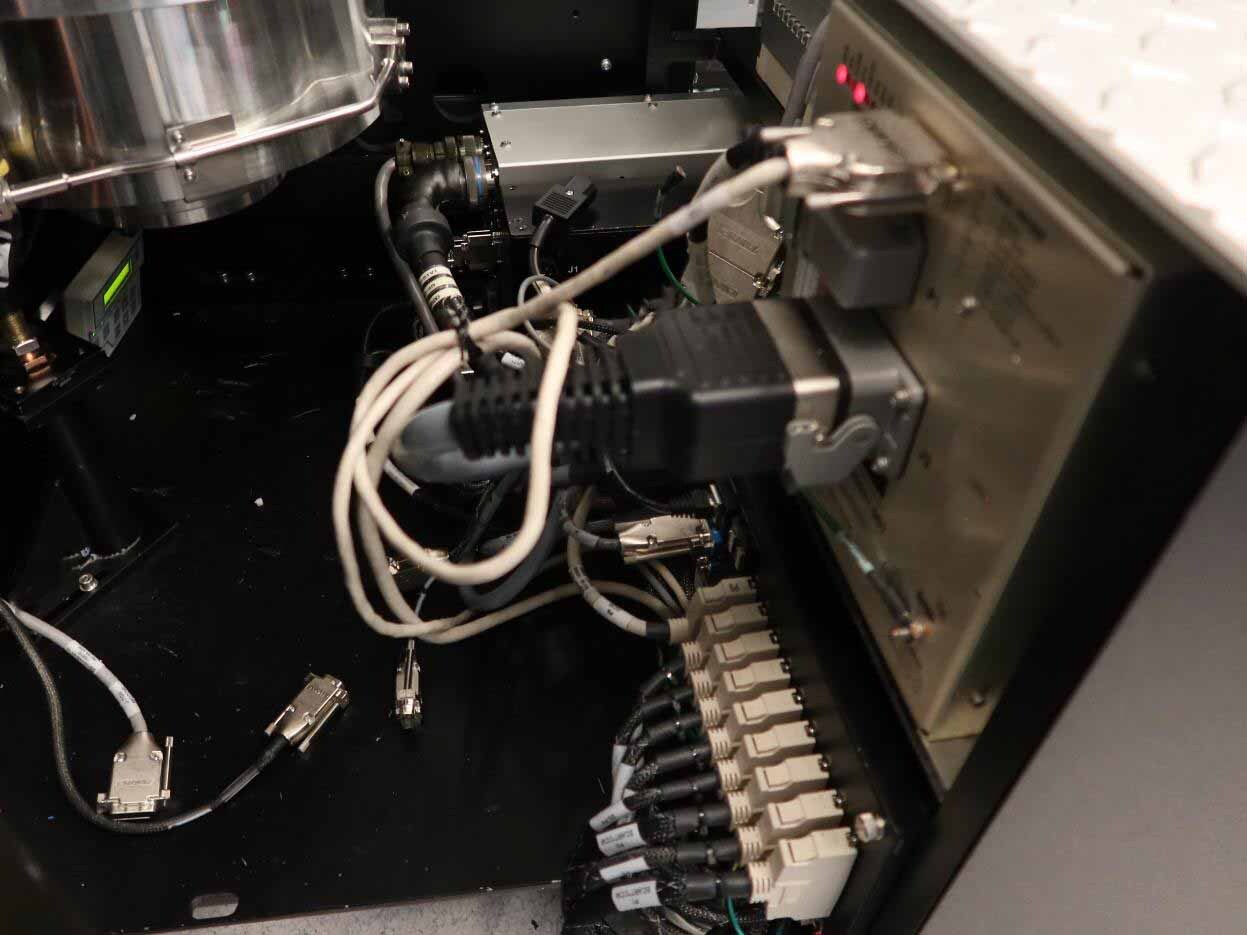

12" Facilities interface box: wFIB, eFIB

Inner/Outer independent temperature control

Independent Gas injection: 2 gases for each step

Closer cooling and heating showerhead design

Power supply:

High bias RF power capacity: 7.5 kW (max combined power)

RF Frequency: 162 MHz Source, 13.56/2 MHz Bias

2008 vintage.

AMAT / APPLIED MATERIALS Enabler is a high-performance gas-phase reactor used for the production of components used in the semiconductor industry. AMAT Enabler has a unique design that uses a patented gas-flow-based process to provide an efficient and reliable method for the deposition of thin films. APPLIED MATERIALS Enabler's chamber is sealed off from the atmosphere and filled with a silicon-based gas, typically composed of silane or disilane, which is transferred into the substrate chamber. Enabler is then able to control the thermal conductivity and etching temperature of the substrate using a built-in thermal management equipment. This system allows precision control over the amount of heat energy used to create the desired film thickness and etch characteristics. AMAT / APPLIED MATERIALS Enabler utilizes an ohmic current injected into a heated plasma discharge region to achieve the desired process. This two-in-one approach helps to improve the speed of deposition as well as minimize film contamination. Additionally, AMAT Enabler is equipped with a fast-fill unit, allowing for an efficient switching between process gases. This feature helps to optimize the process by reducing film non-uniformity, improving uniformity, and producing better process performance. APPLIED MATERIALS Enabler is also equipped with a closed-loop control machine to maintain equipment performance, temperature uniformity, and long-term film quality. This state-of-the-art tool monitors each process stage including plasma generation, ion impact, and sputtering. This asset also helps to ensure accurate temperature control across the entire processing chamber, which is crucial for producing high-quality components. In summary, Enabler is a high-performance gas-phase plasma reactor designed to produce semiconductor components with greater speed and efficiency. AMAT / APPLIED MATERIALS Enabler features a unique process that combines ohmic current injection with thermal management to improve process performance and reduce contamination. Additionally, it utilizes an advanced control model that helps maintain temperature uniformity across the processing chamber during production. Through its advanced features and reliable performance, AMAT Enabler offers a highly efficient and reliable method for producing some of the most advanced semiconductors components in production today.

There are no reviews yet