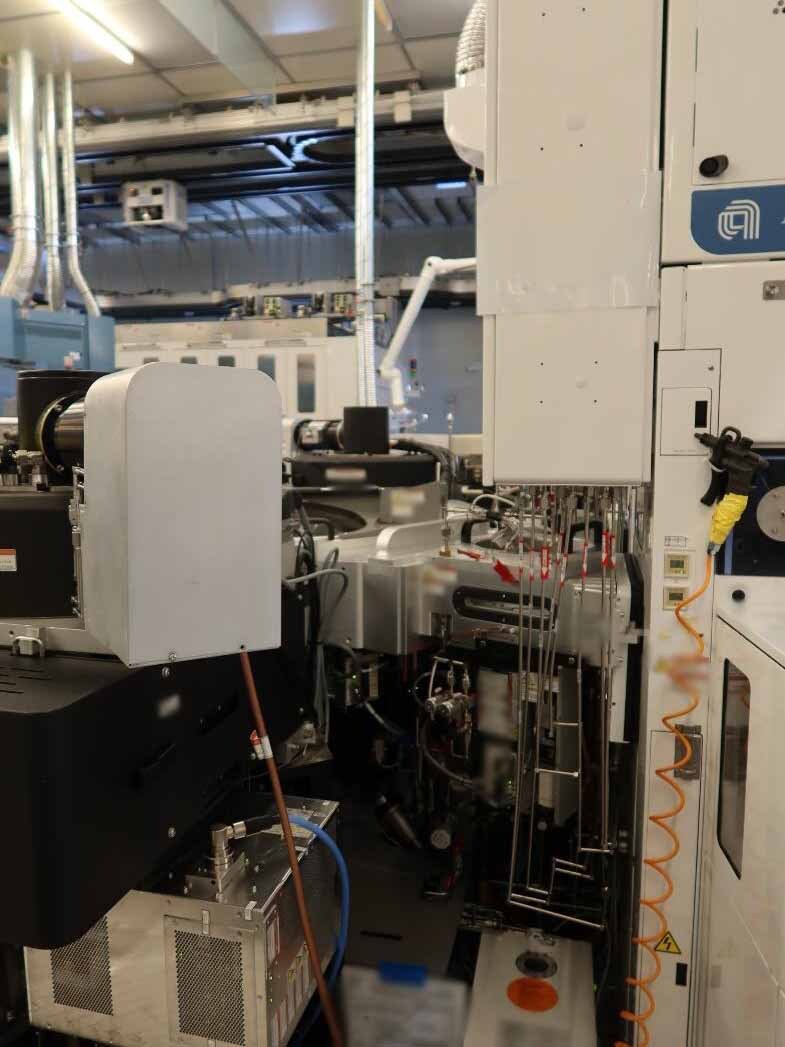

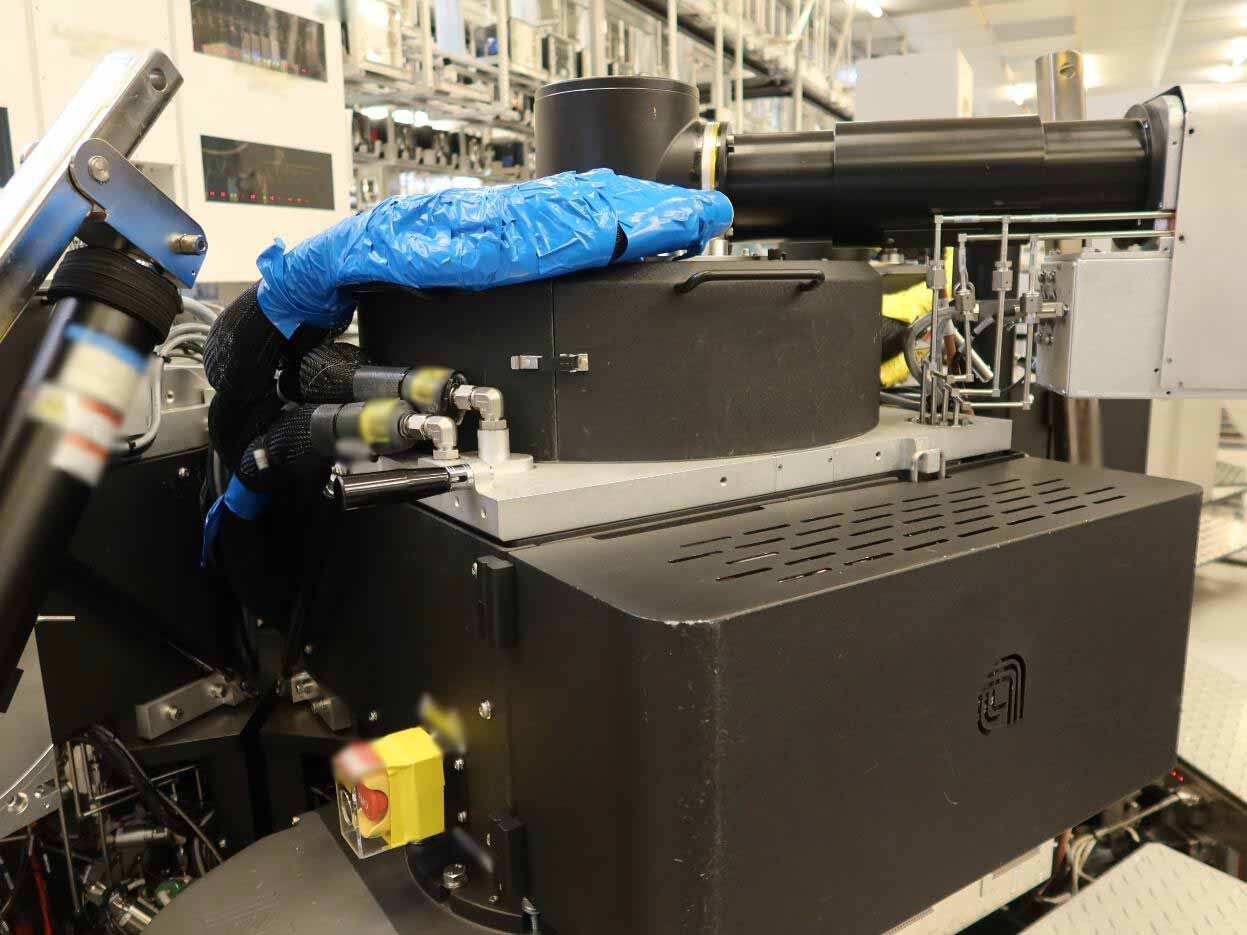

Used AMAT / APPLIED MATERIALS Enabler #293600549 for sale

URL successfully copied!

Tap to zoom

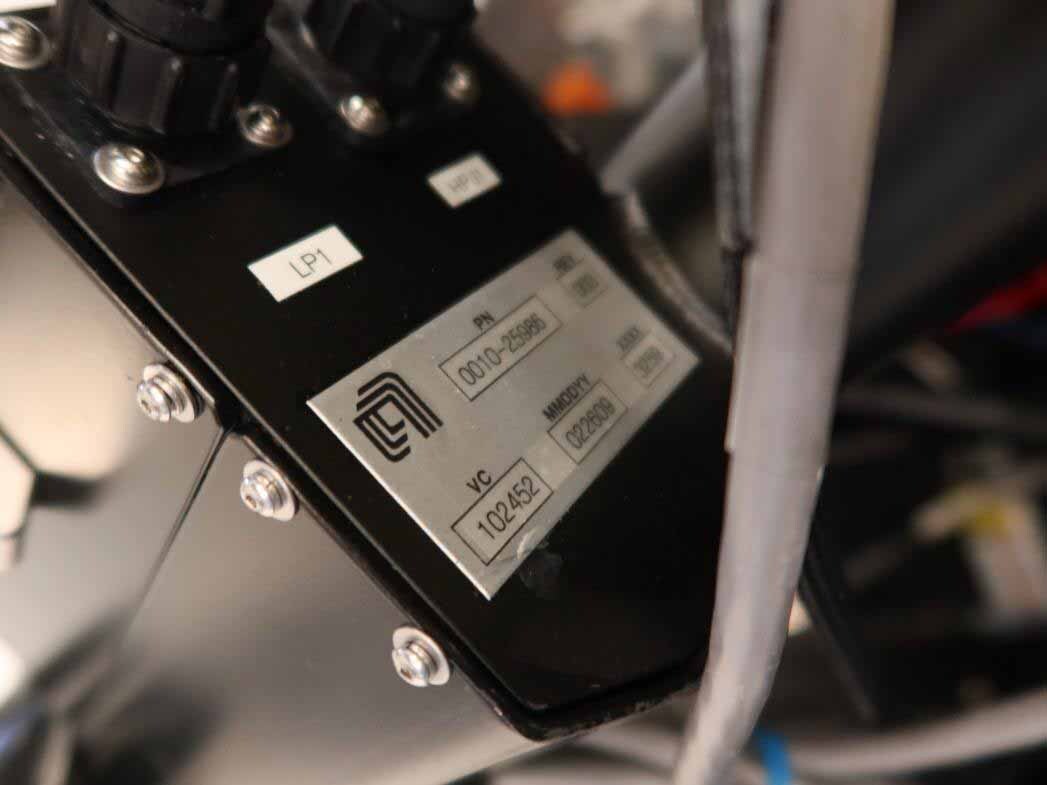

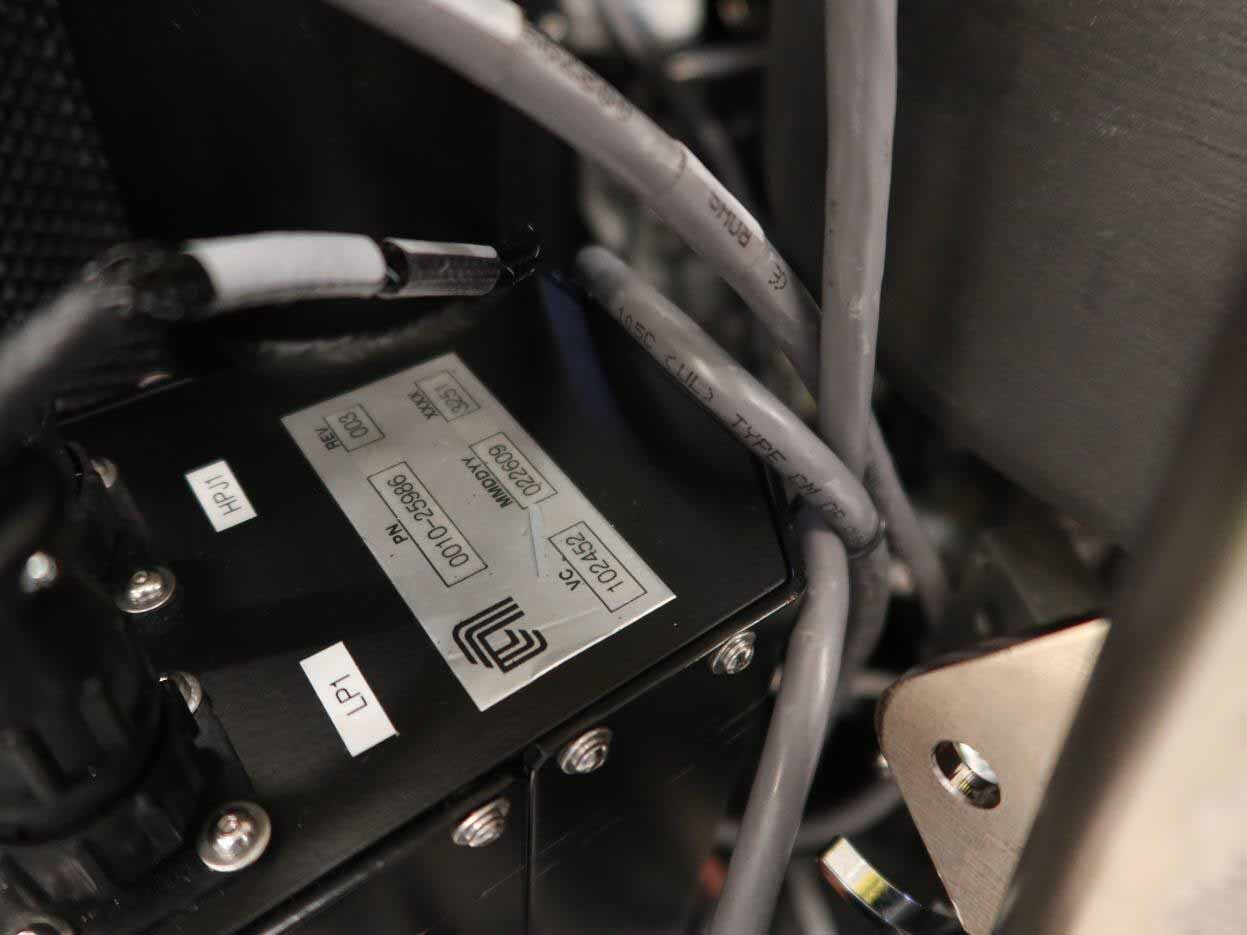

ID: 293600549

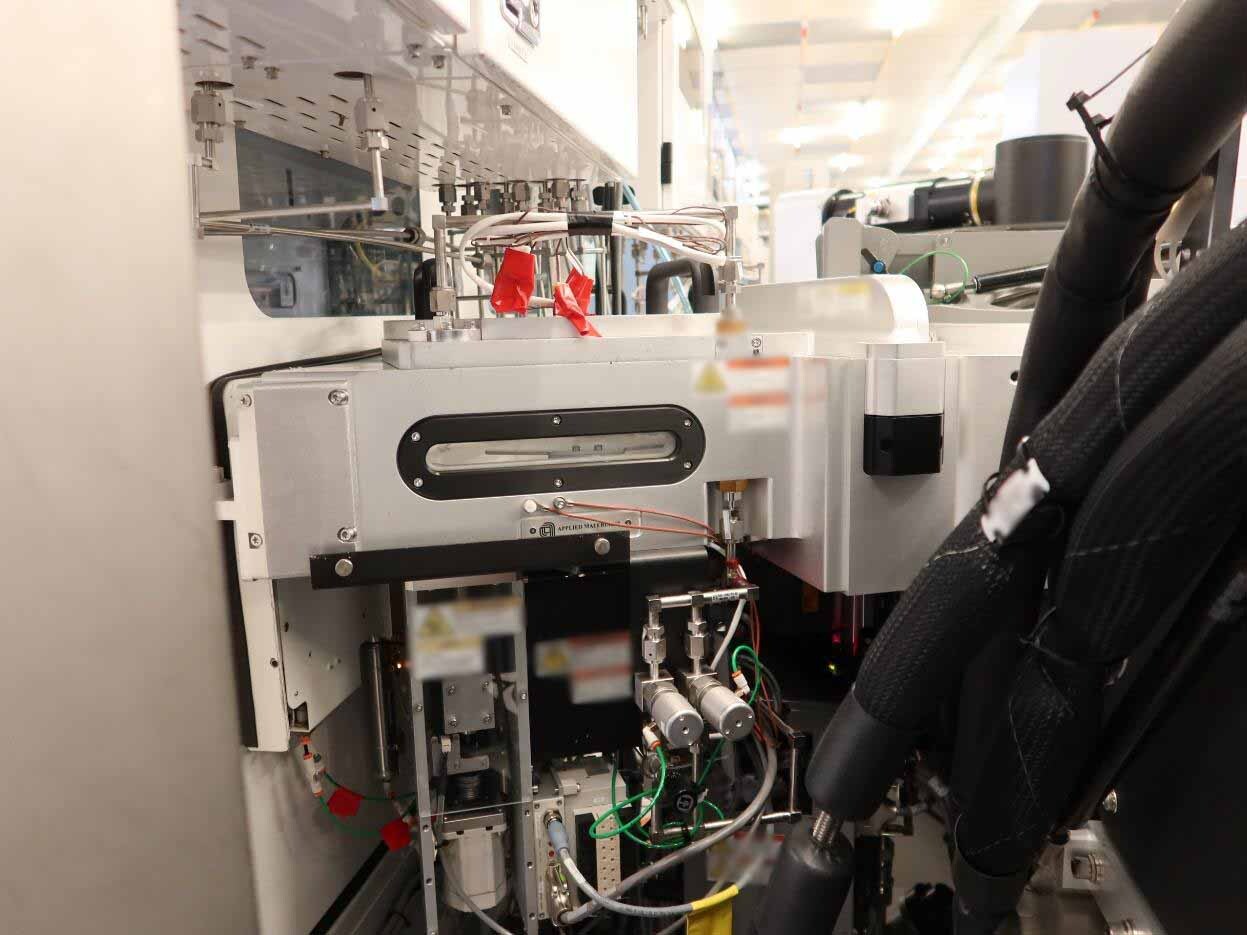

Wafer Size: 12"

Vintage: 2008

Etcher, 12"

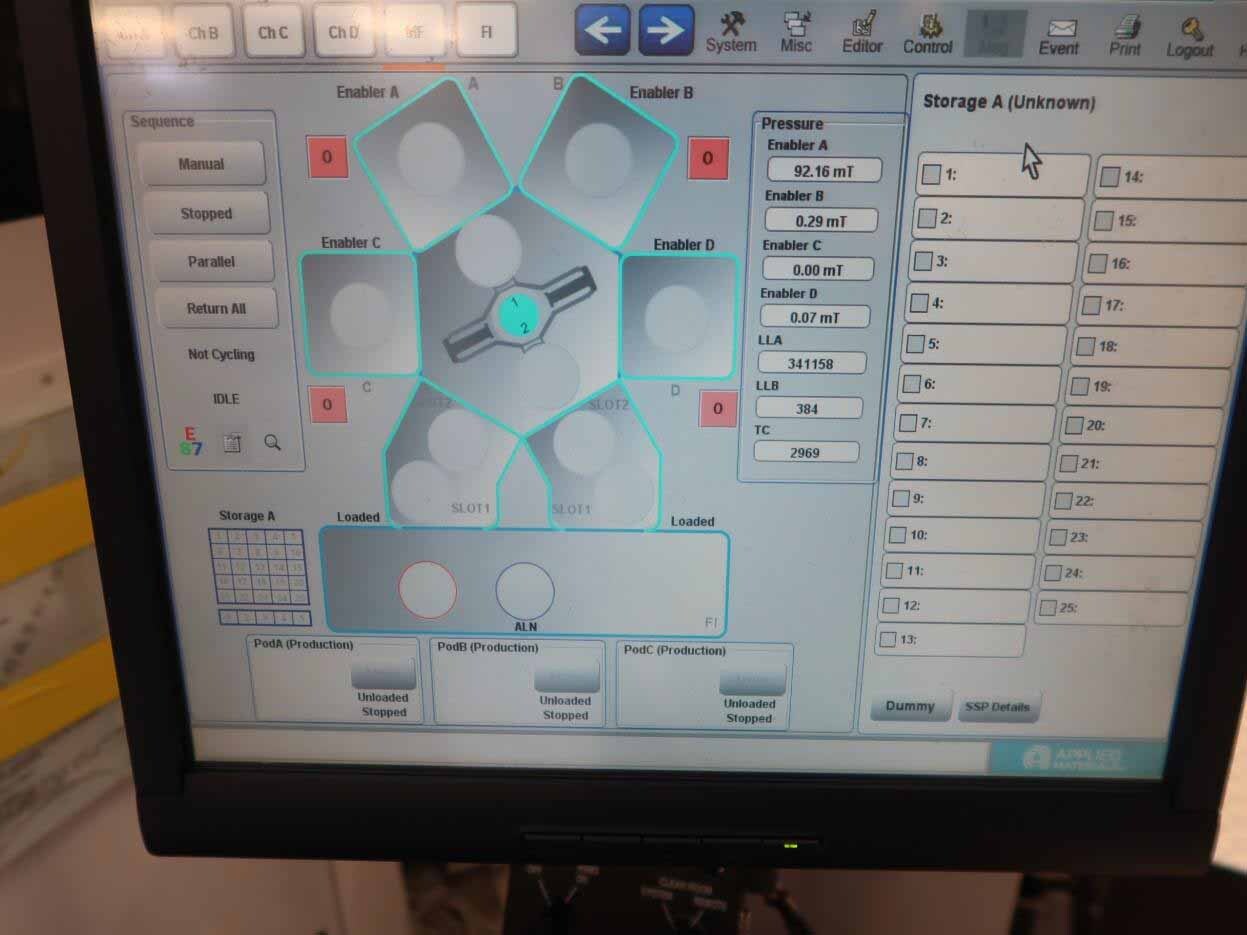

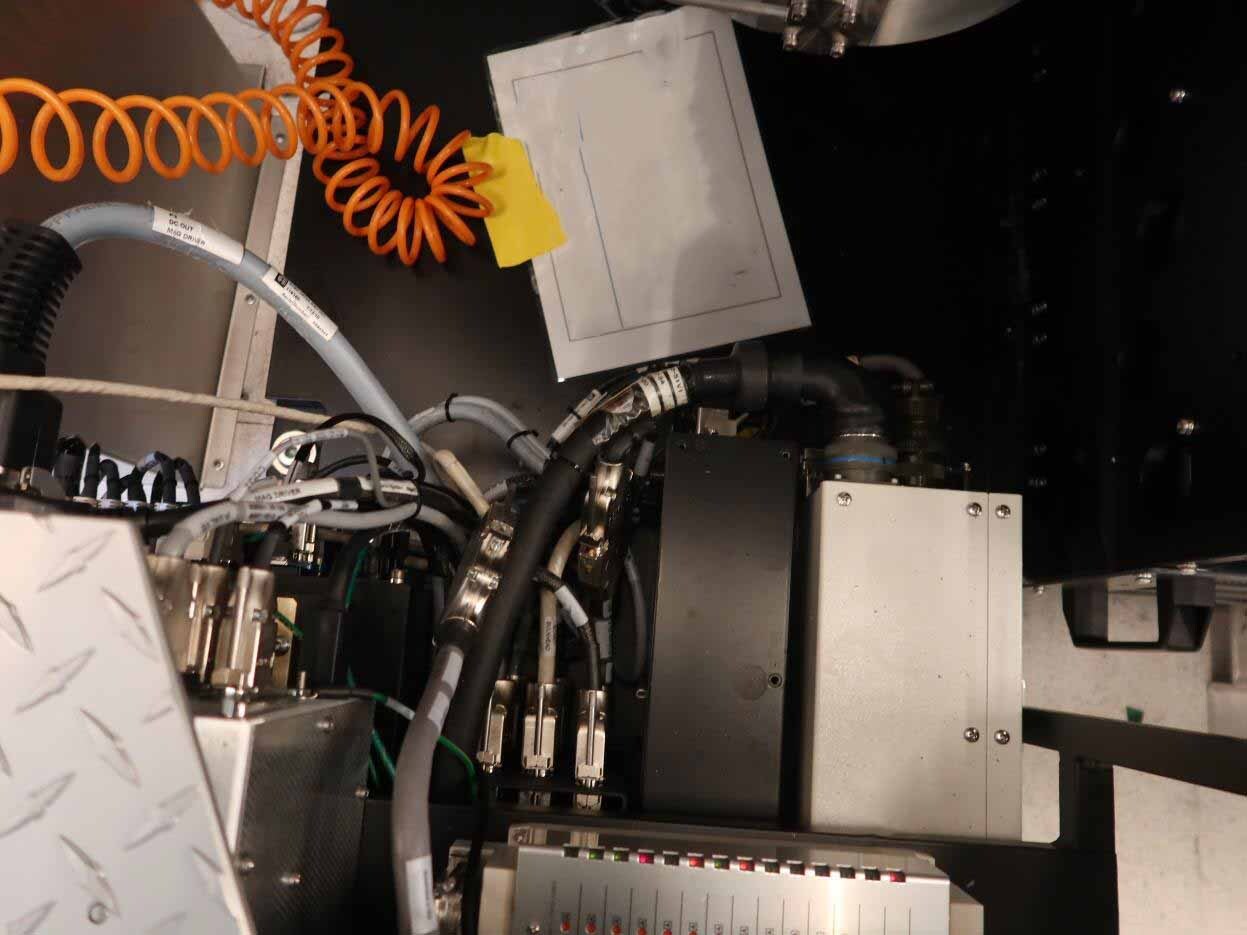

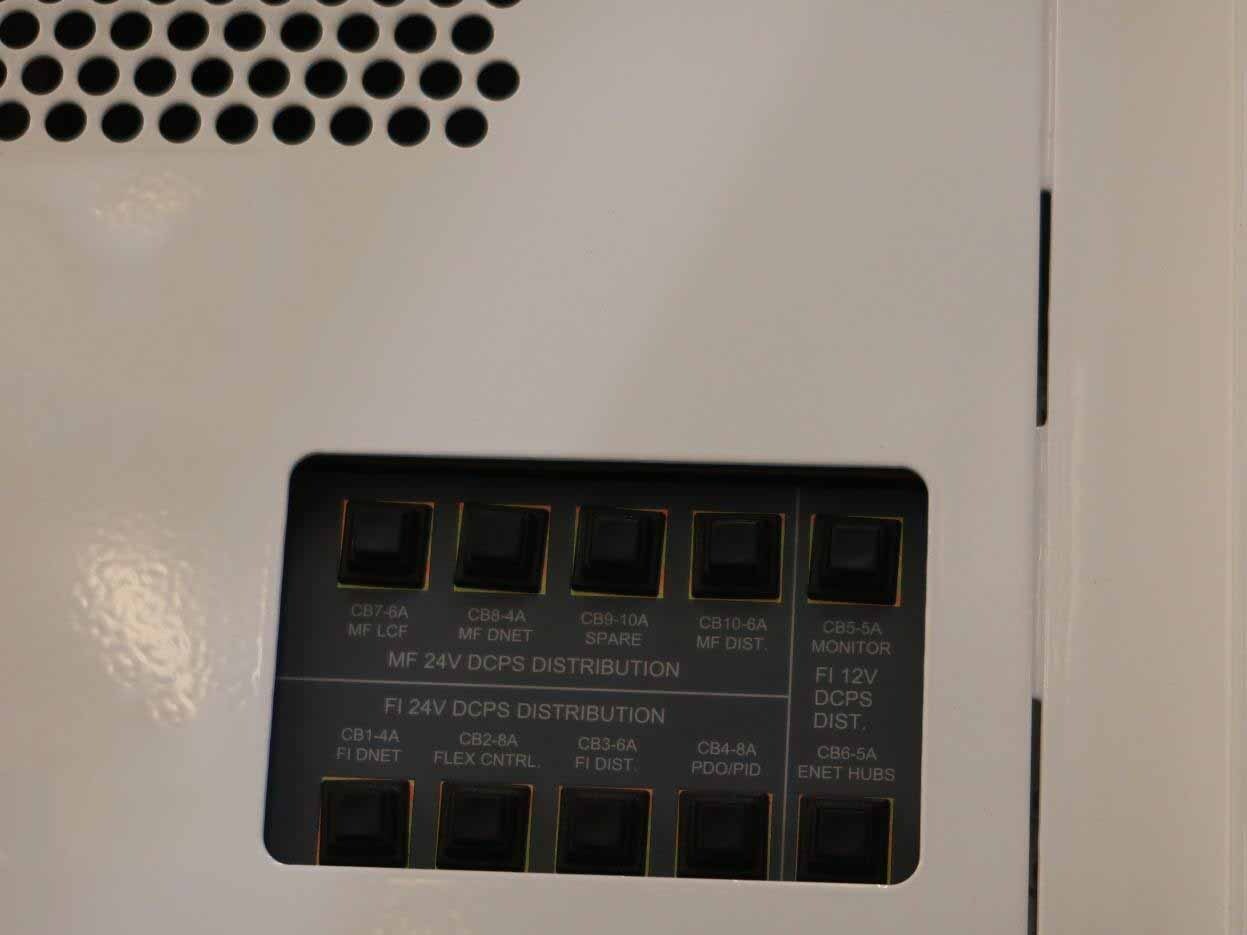

Factory interface: FI 5.3

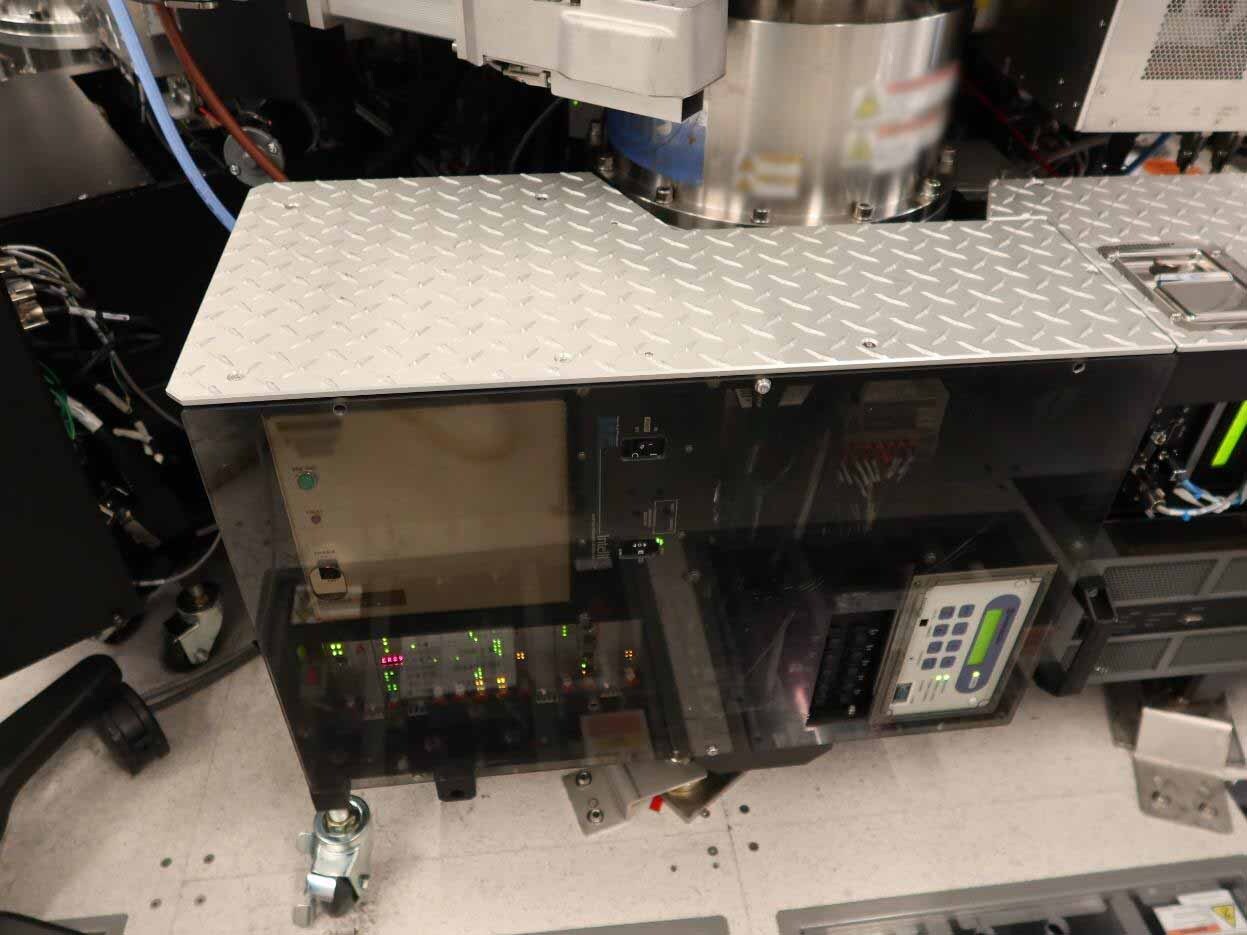

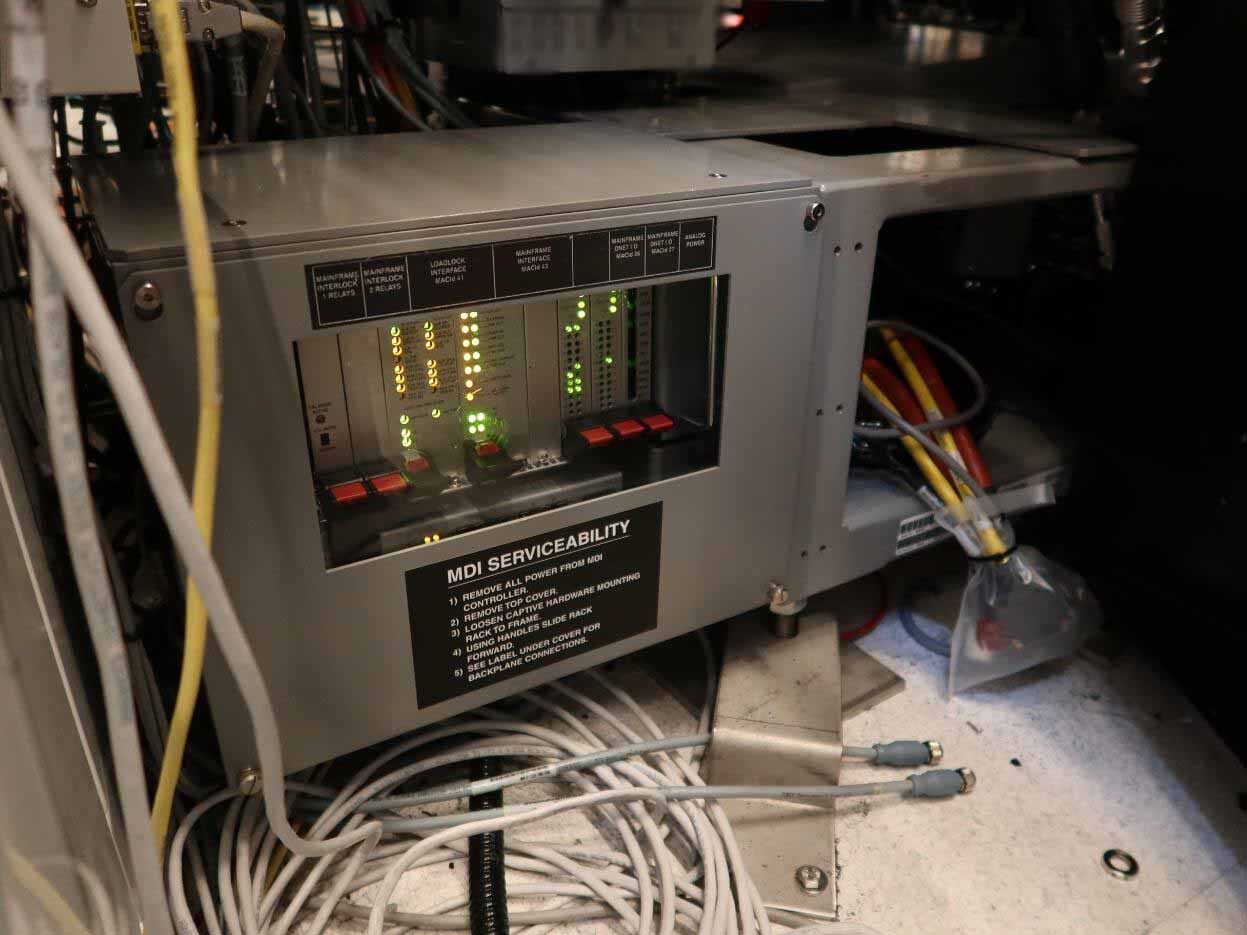

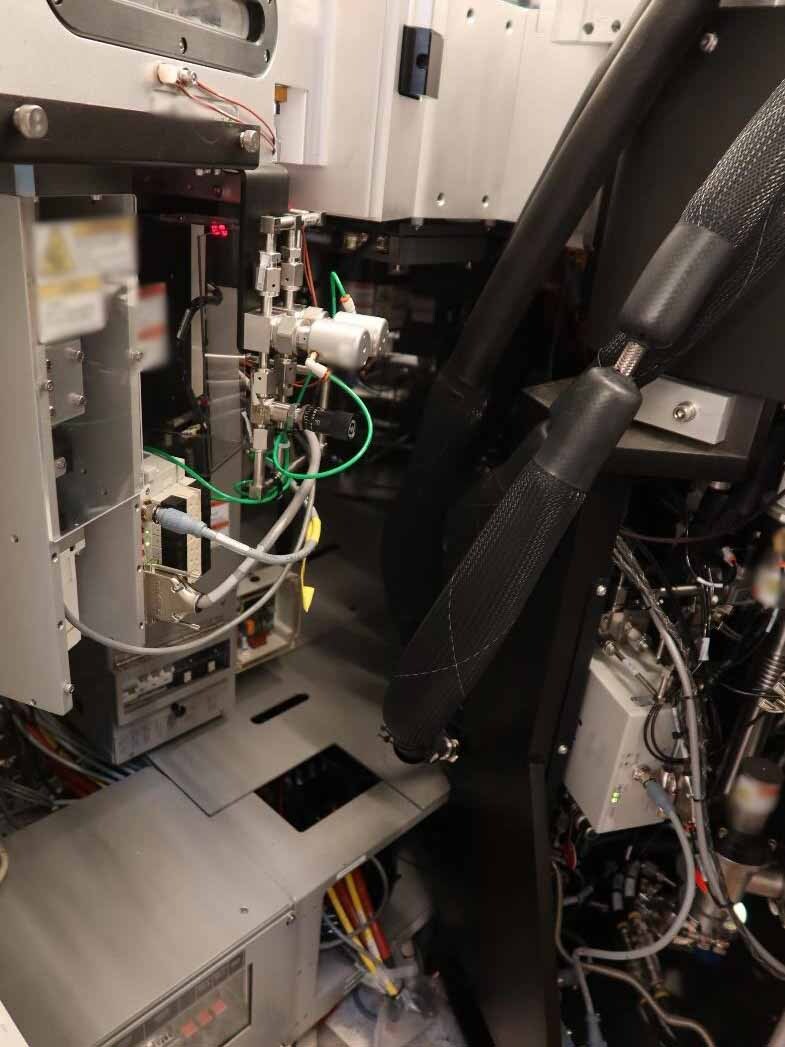

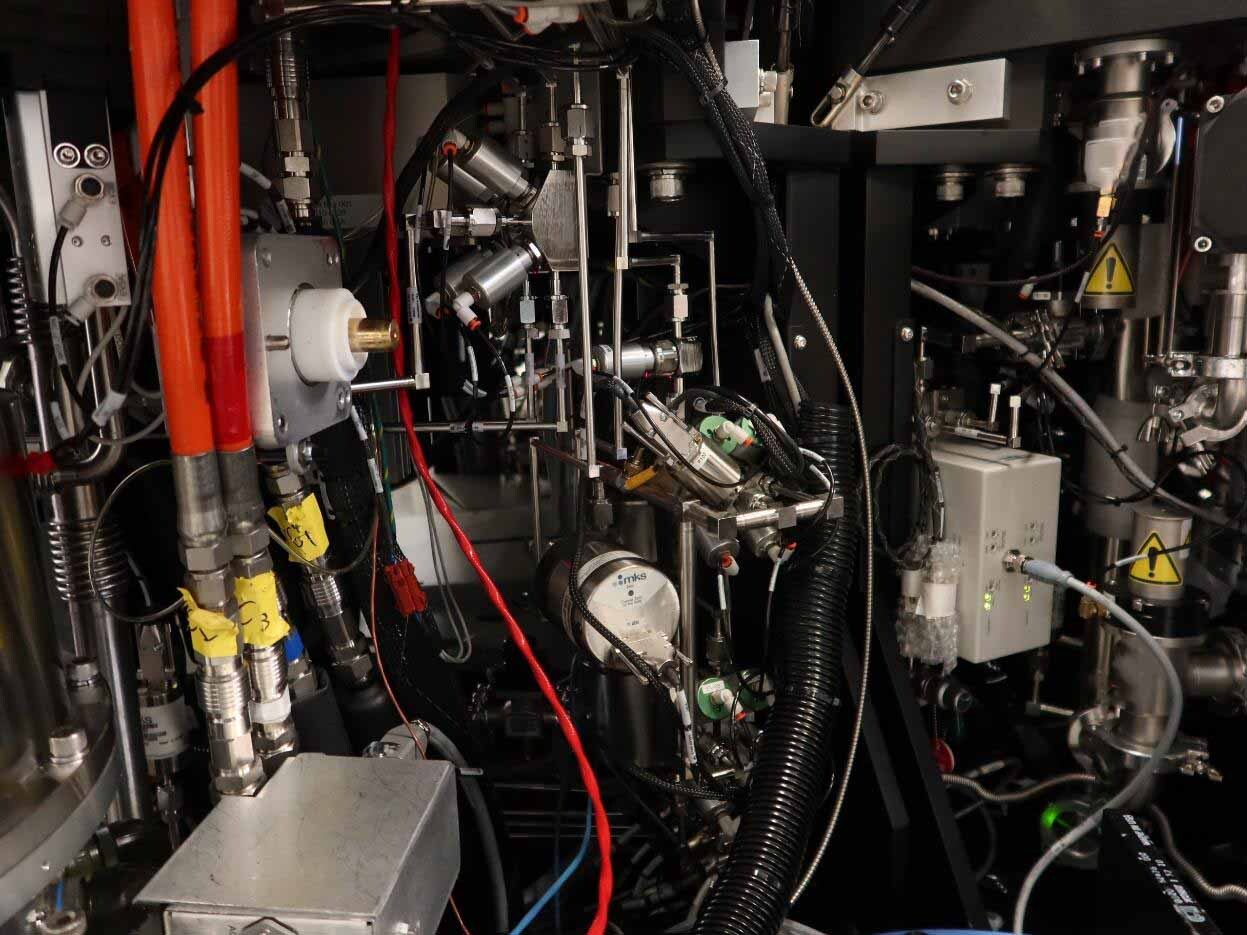

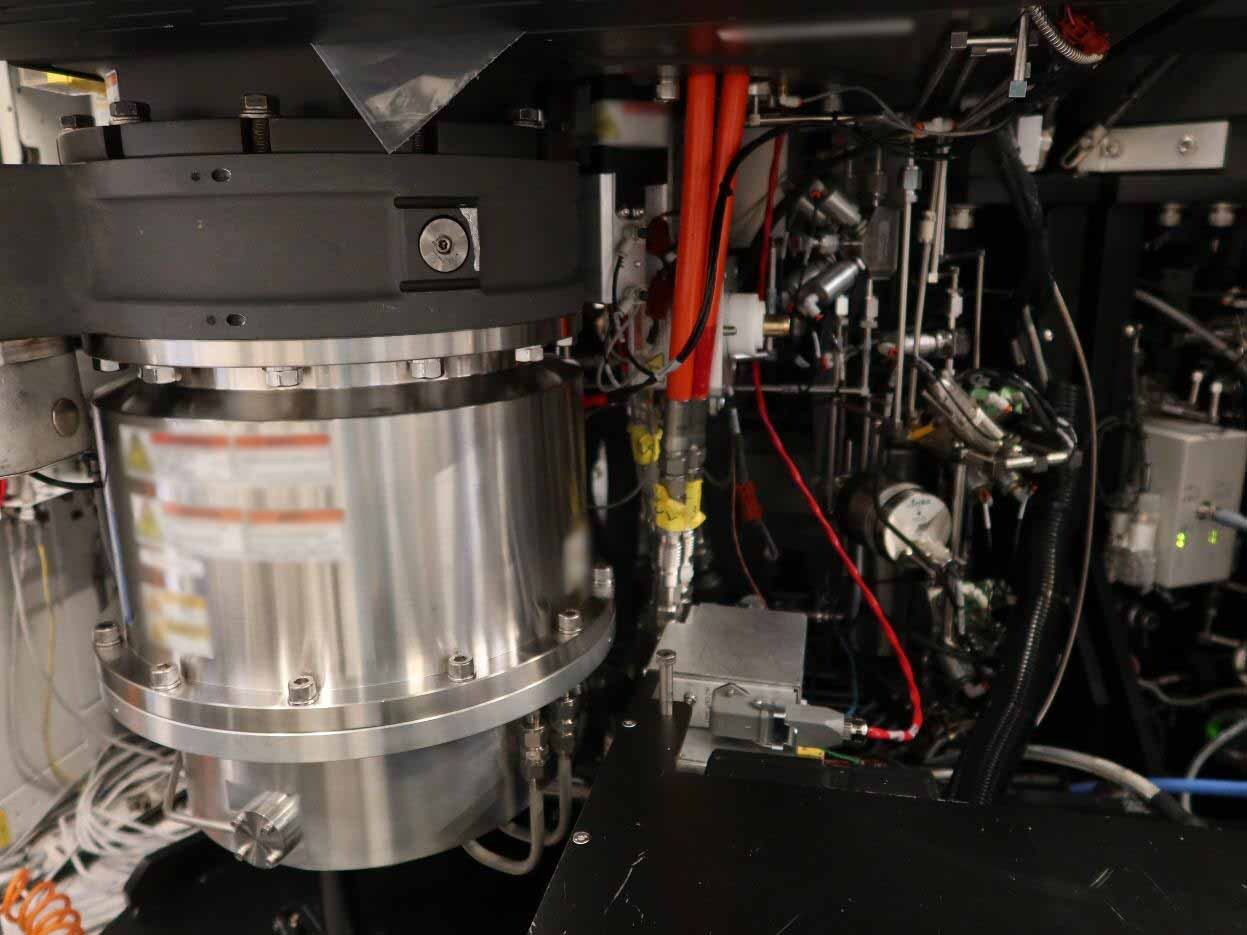

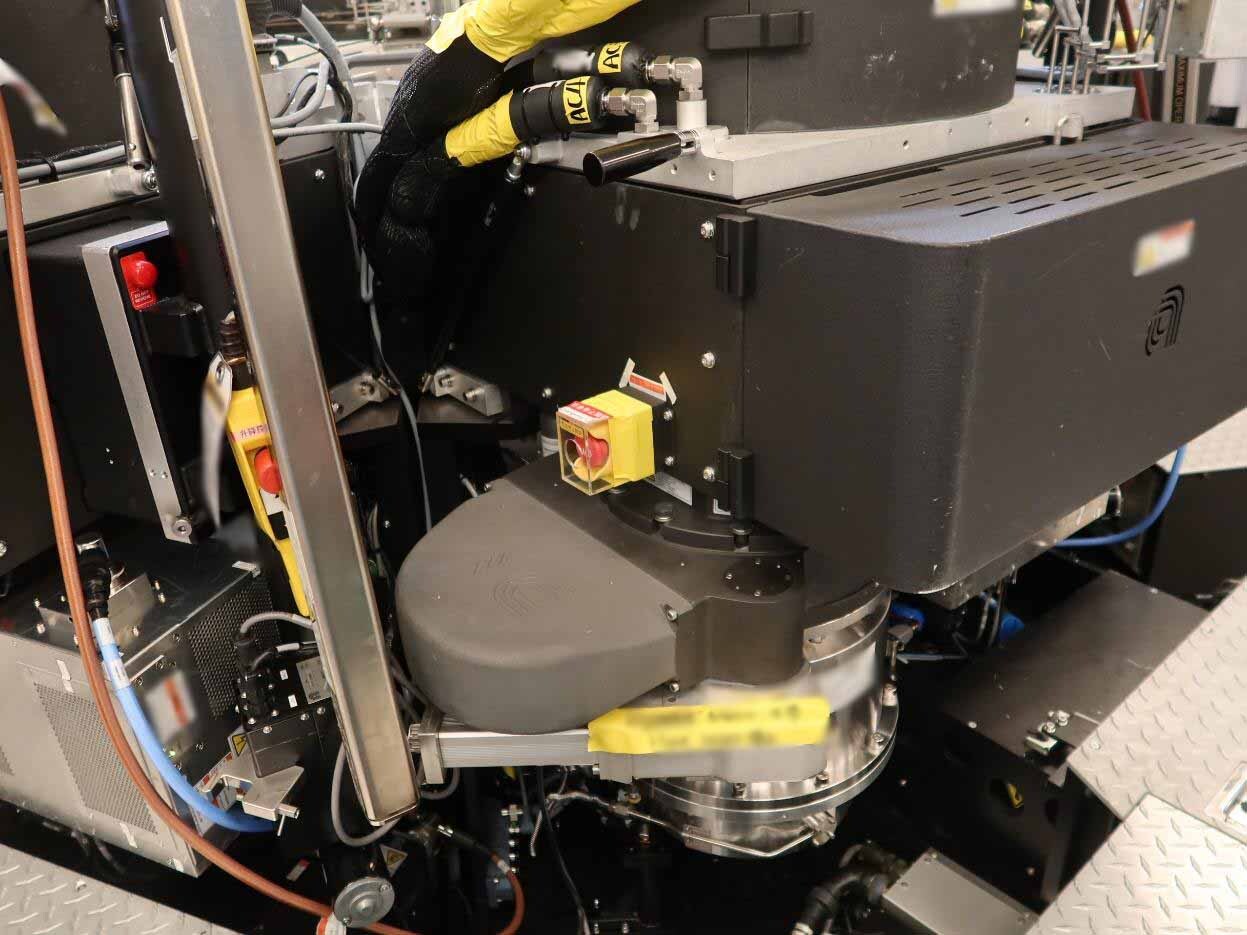

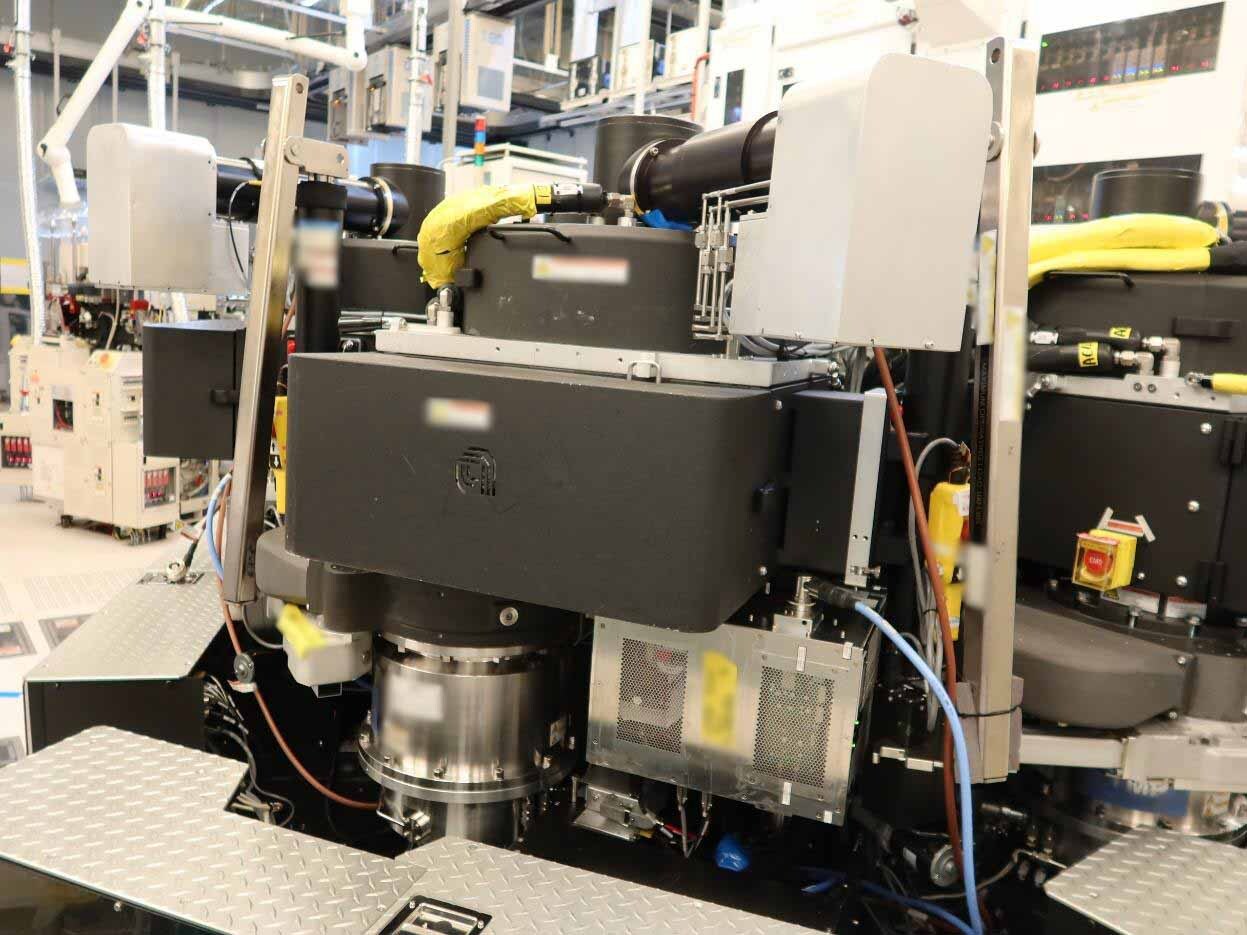

Centura AP Mainframe

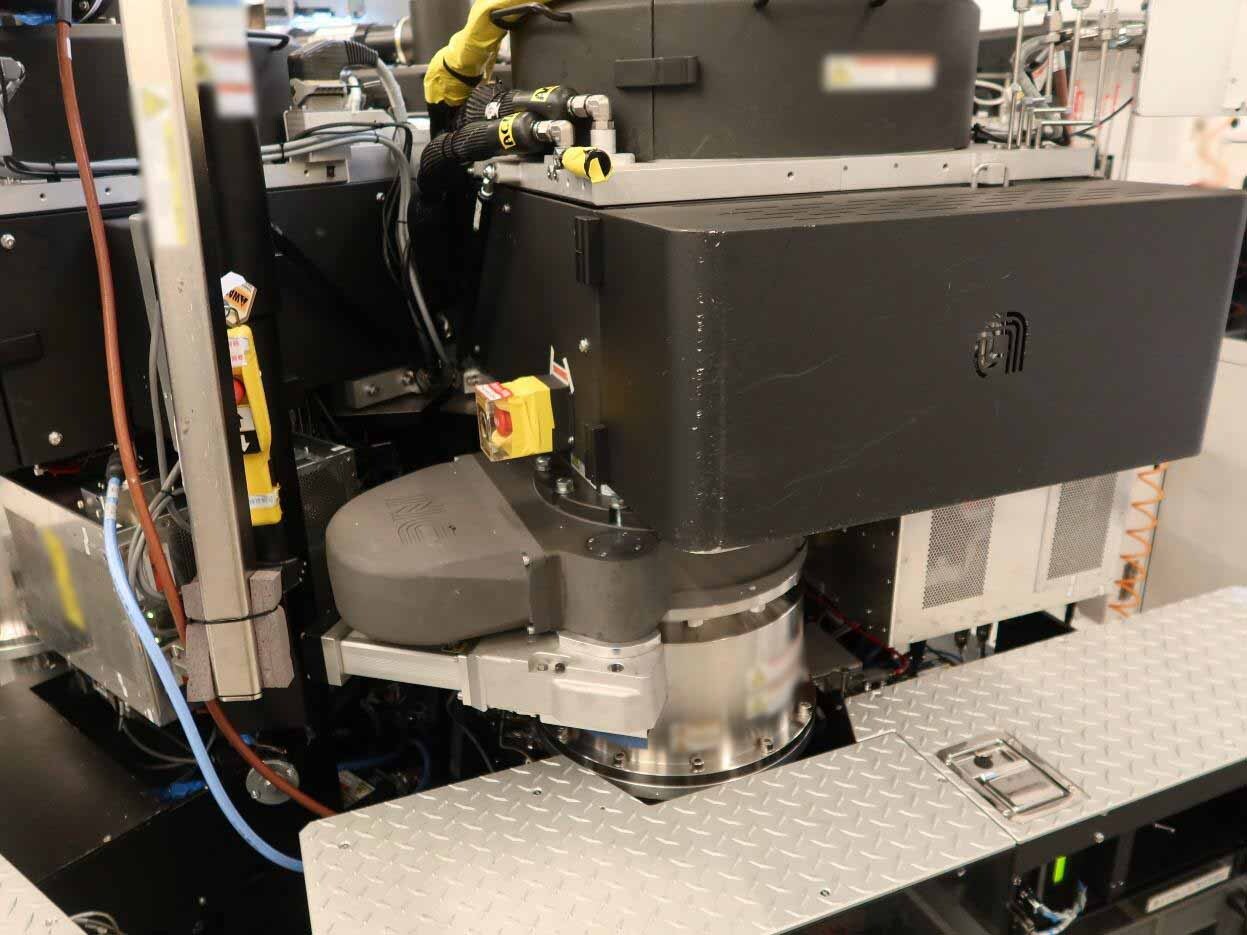

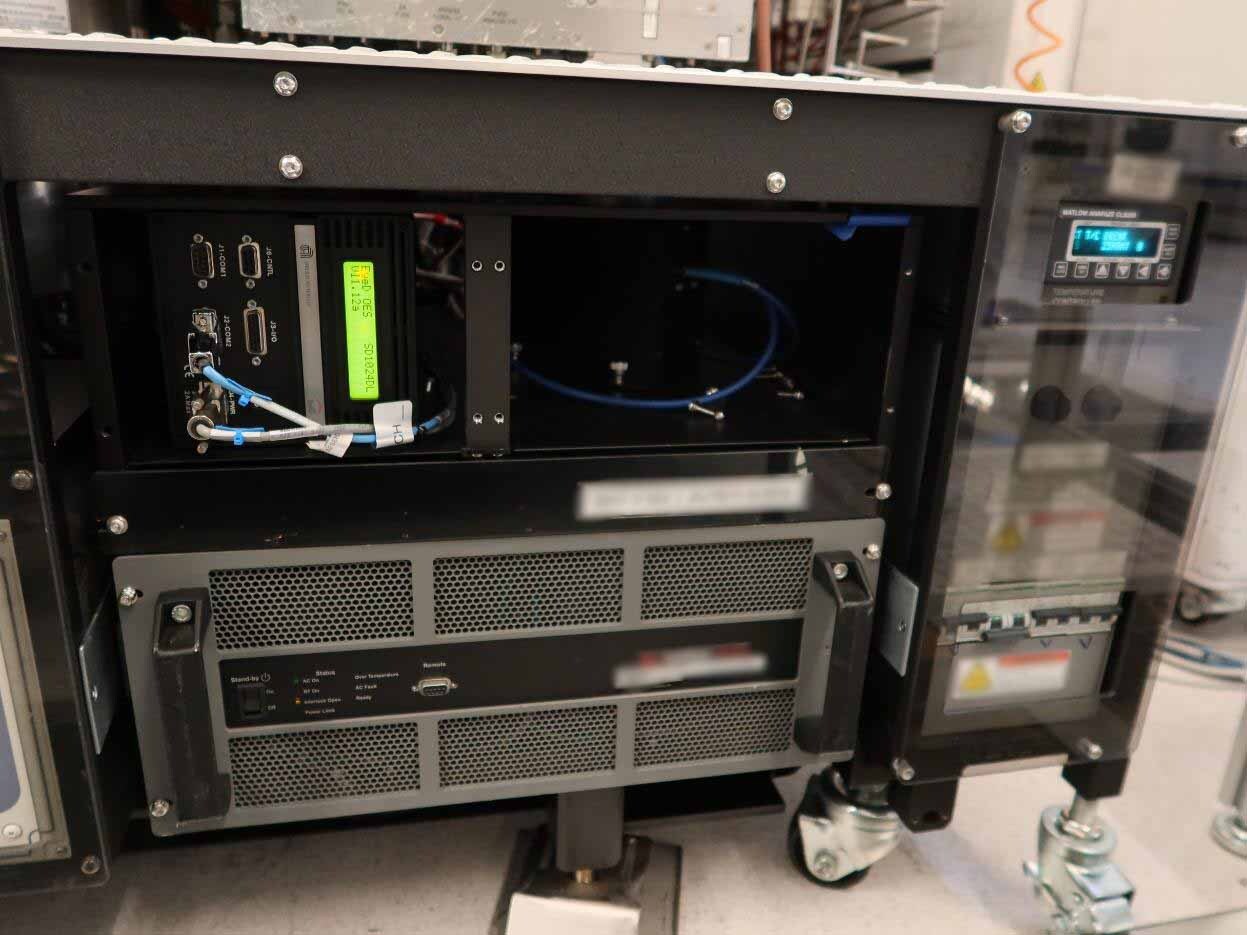

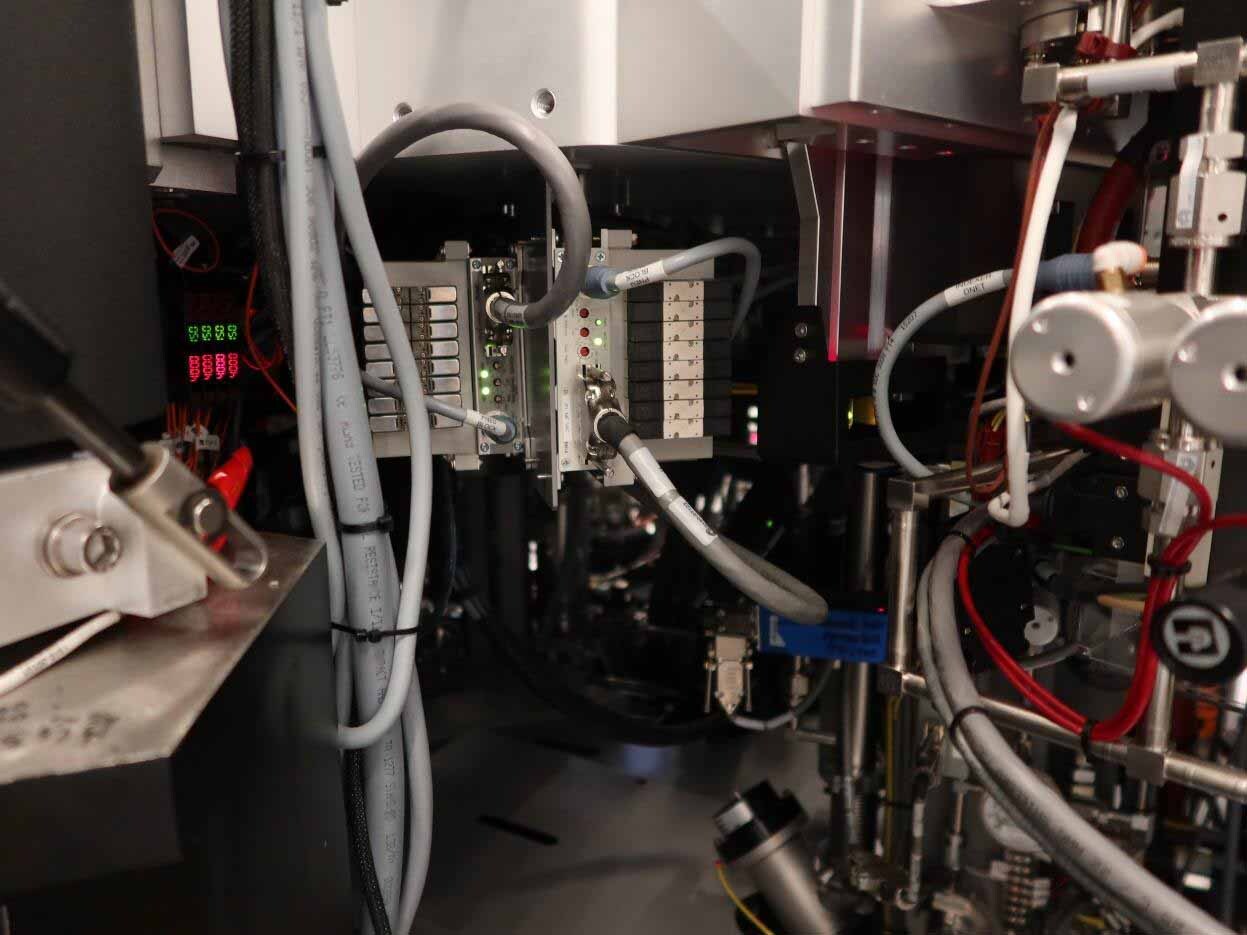

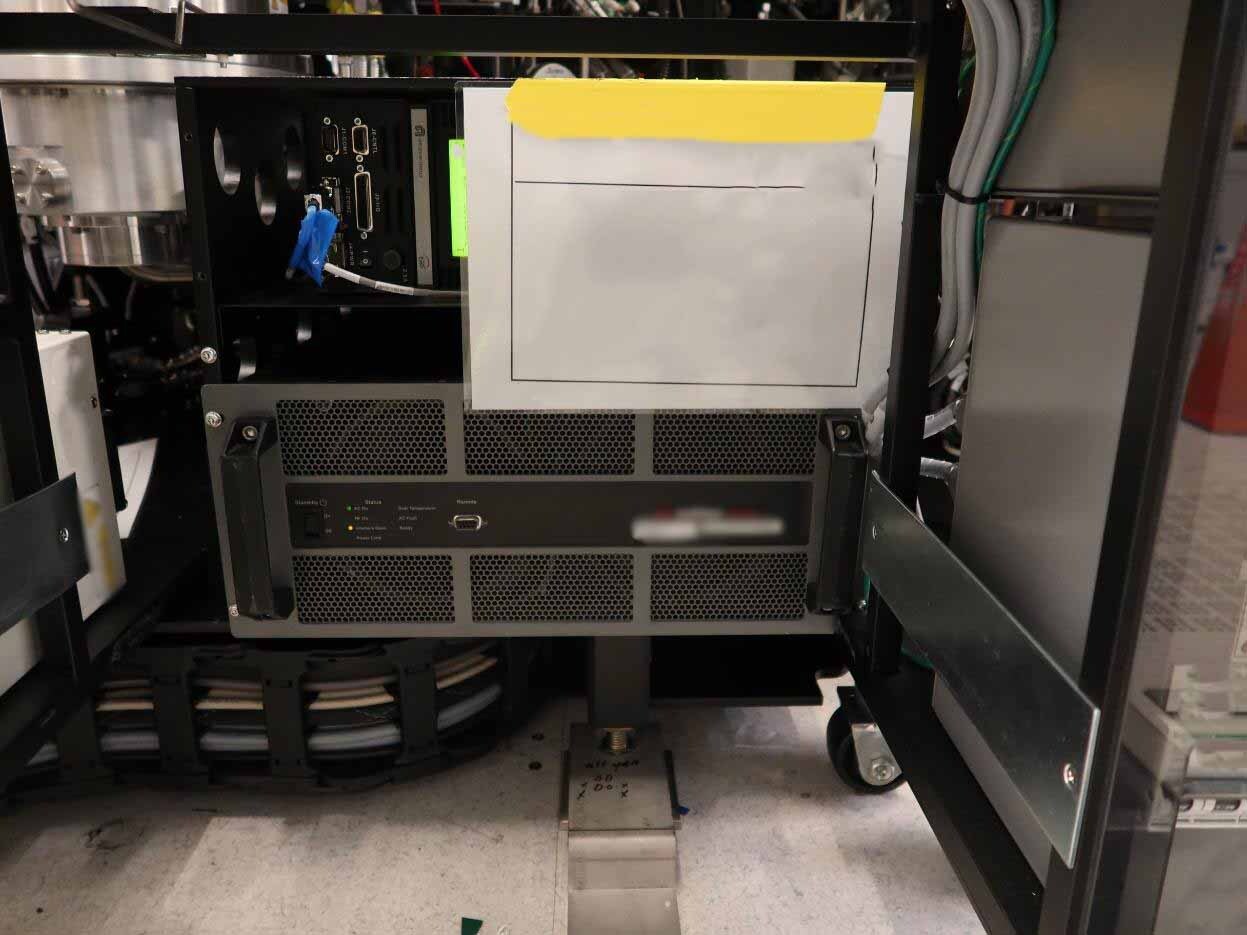

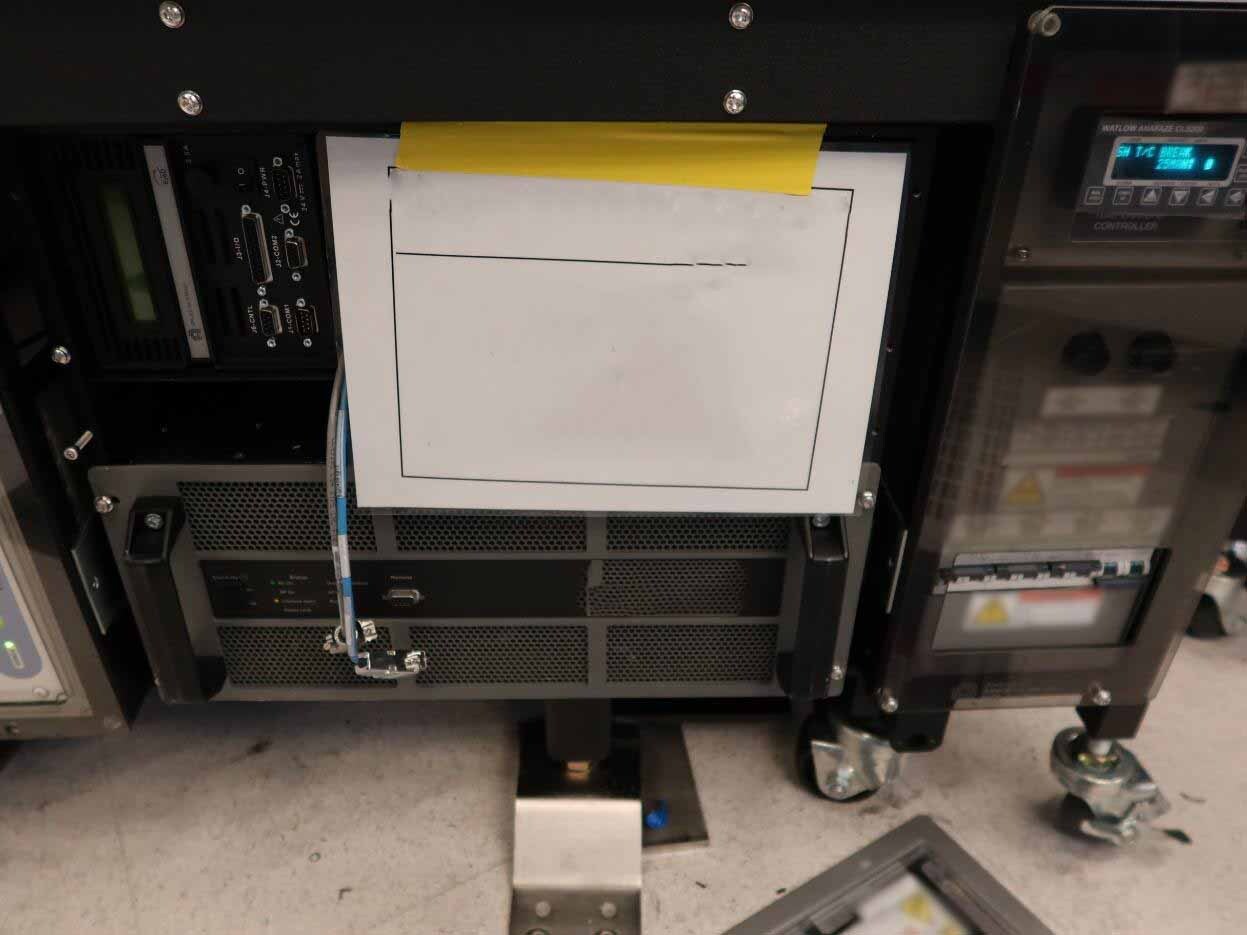

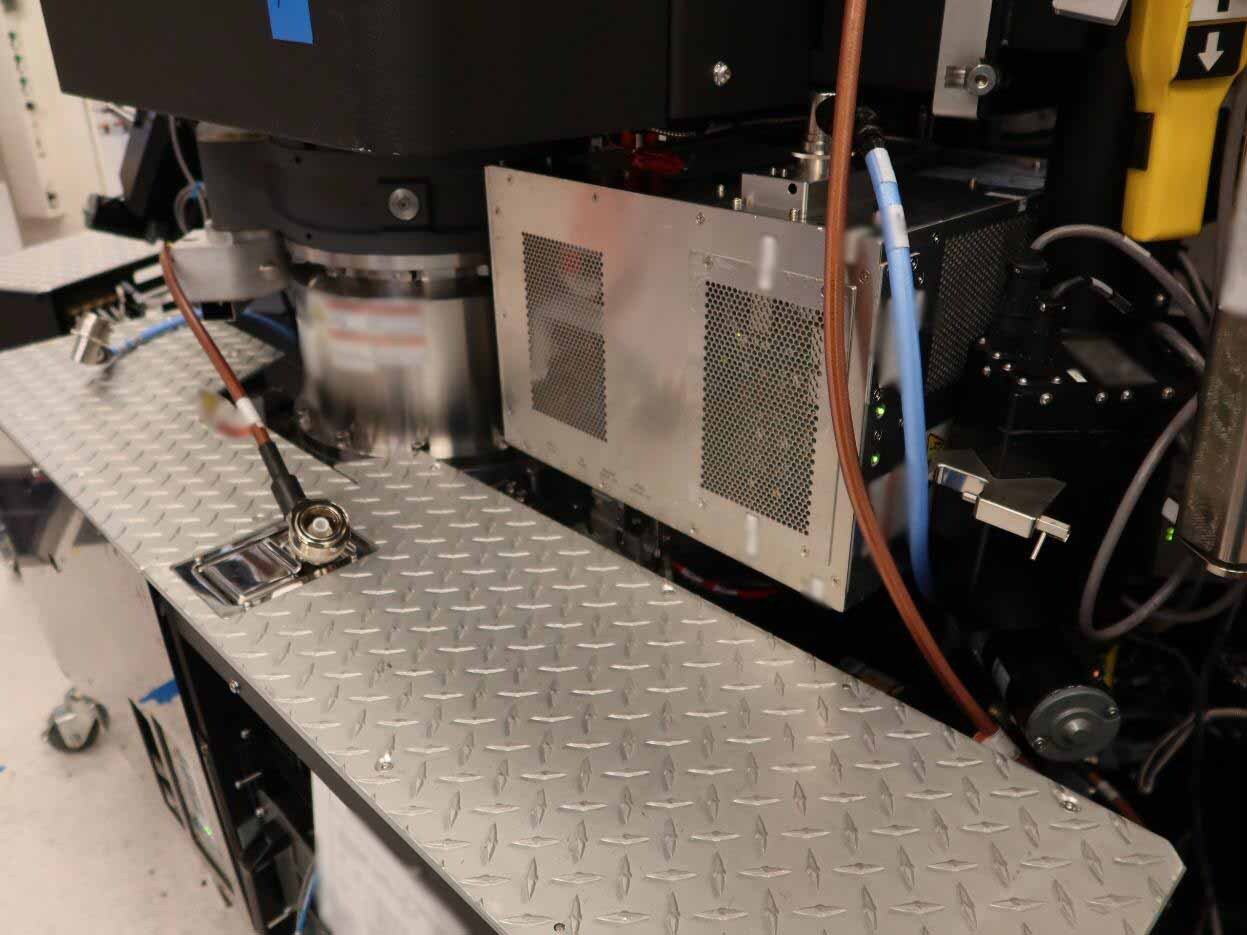

RF Rack, 12"

Bias 2 RF generator rack

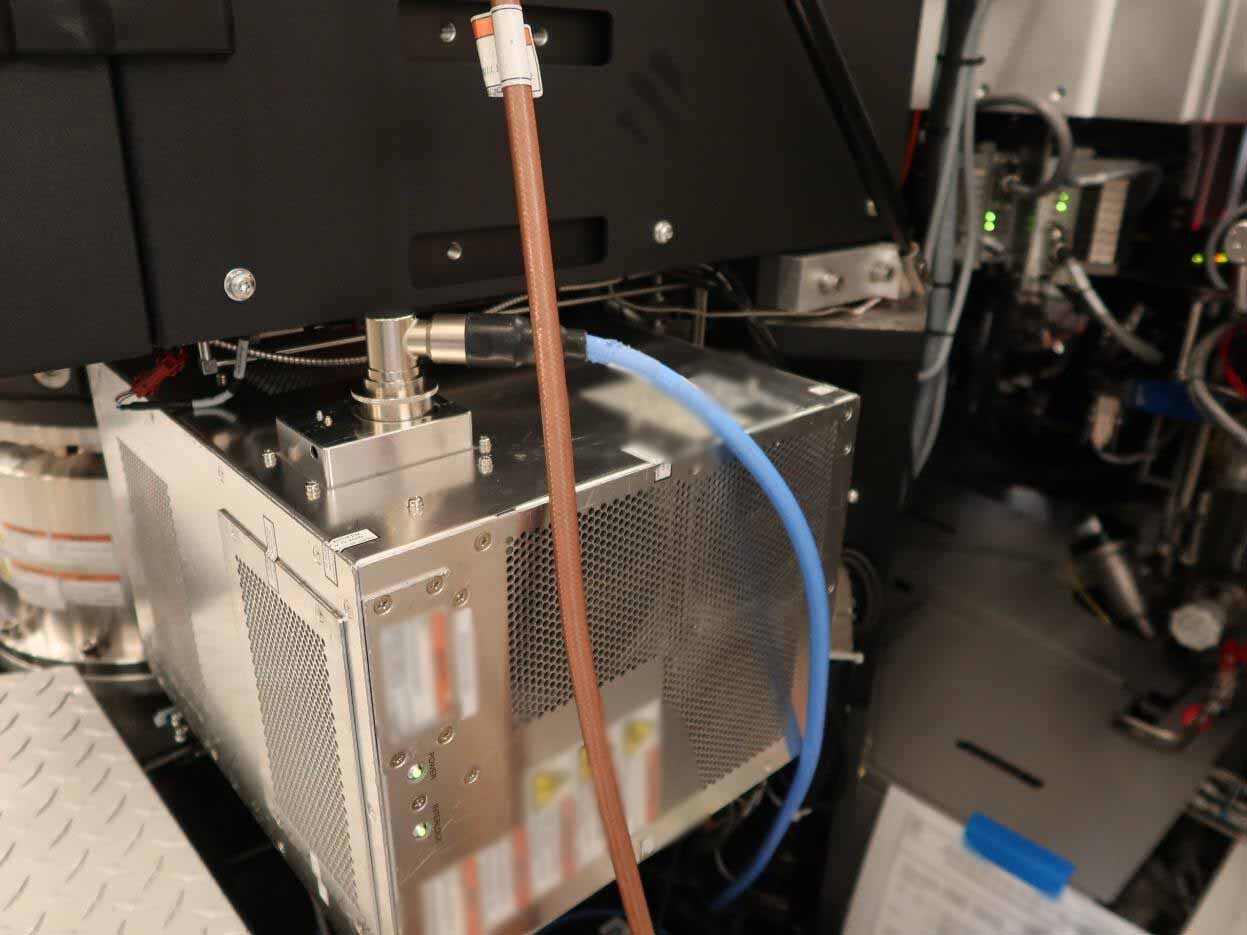

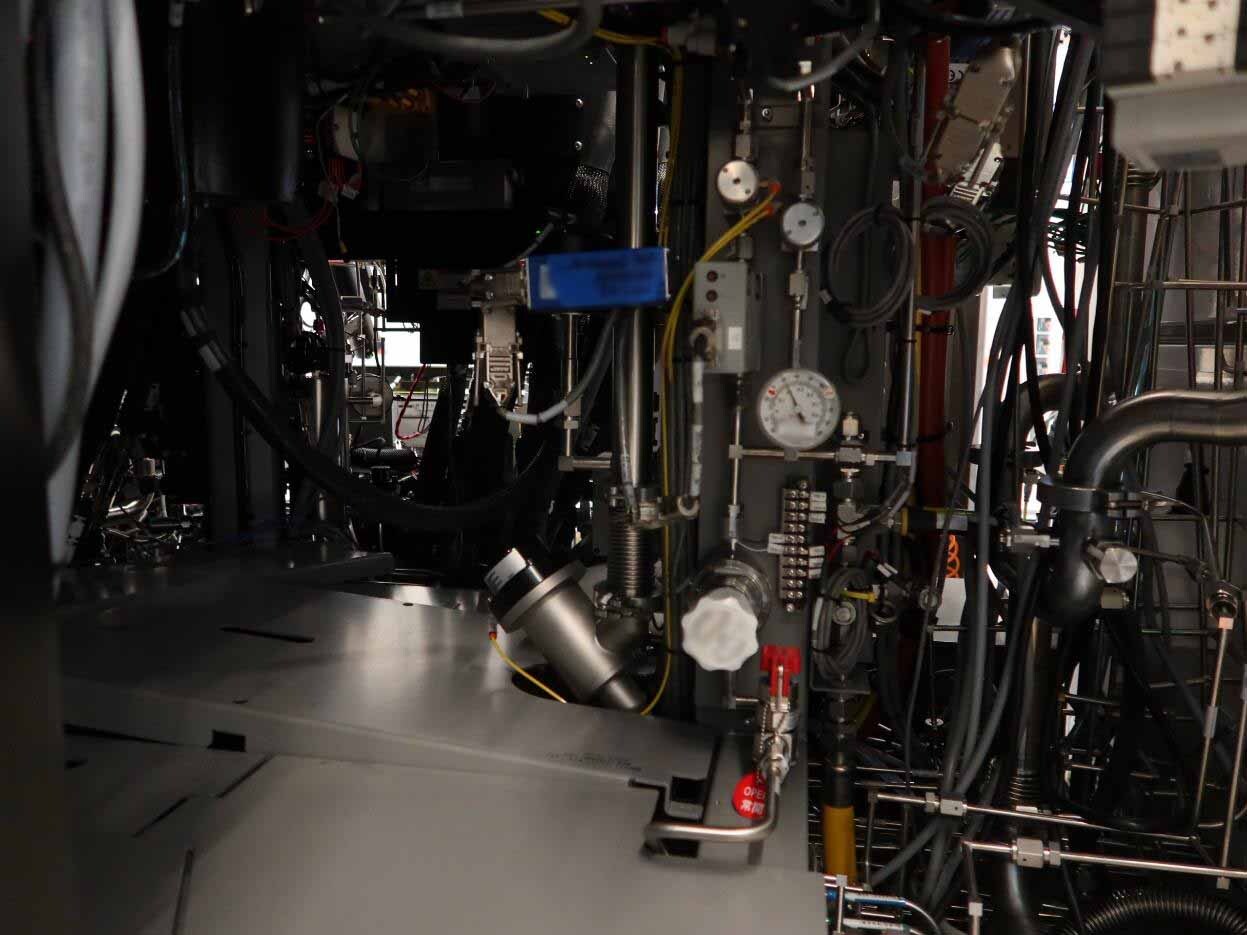

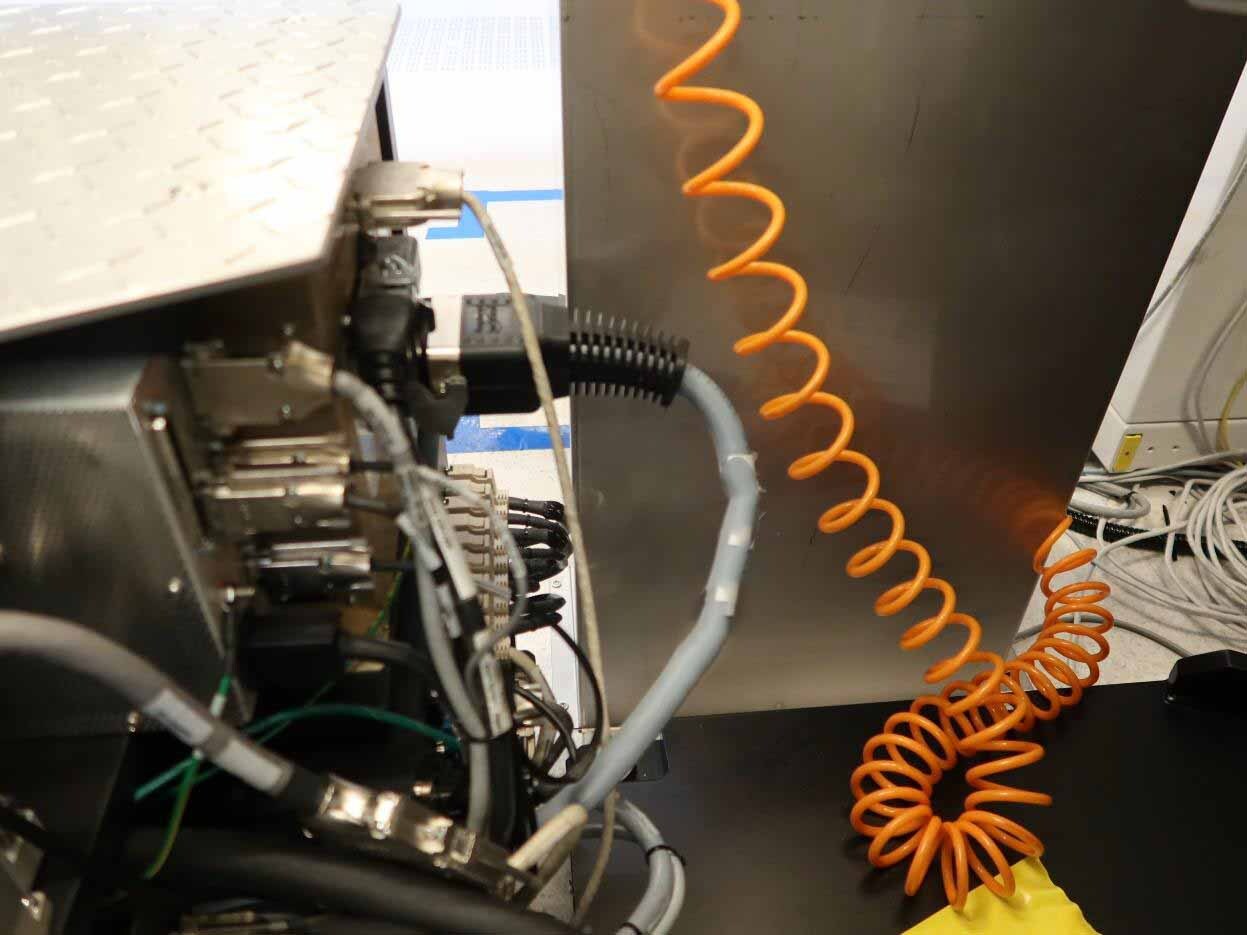

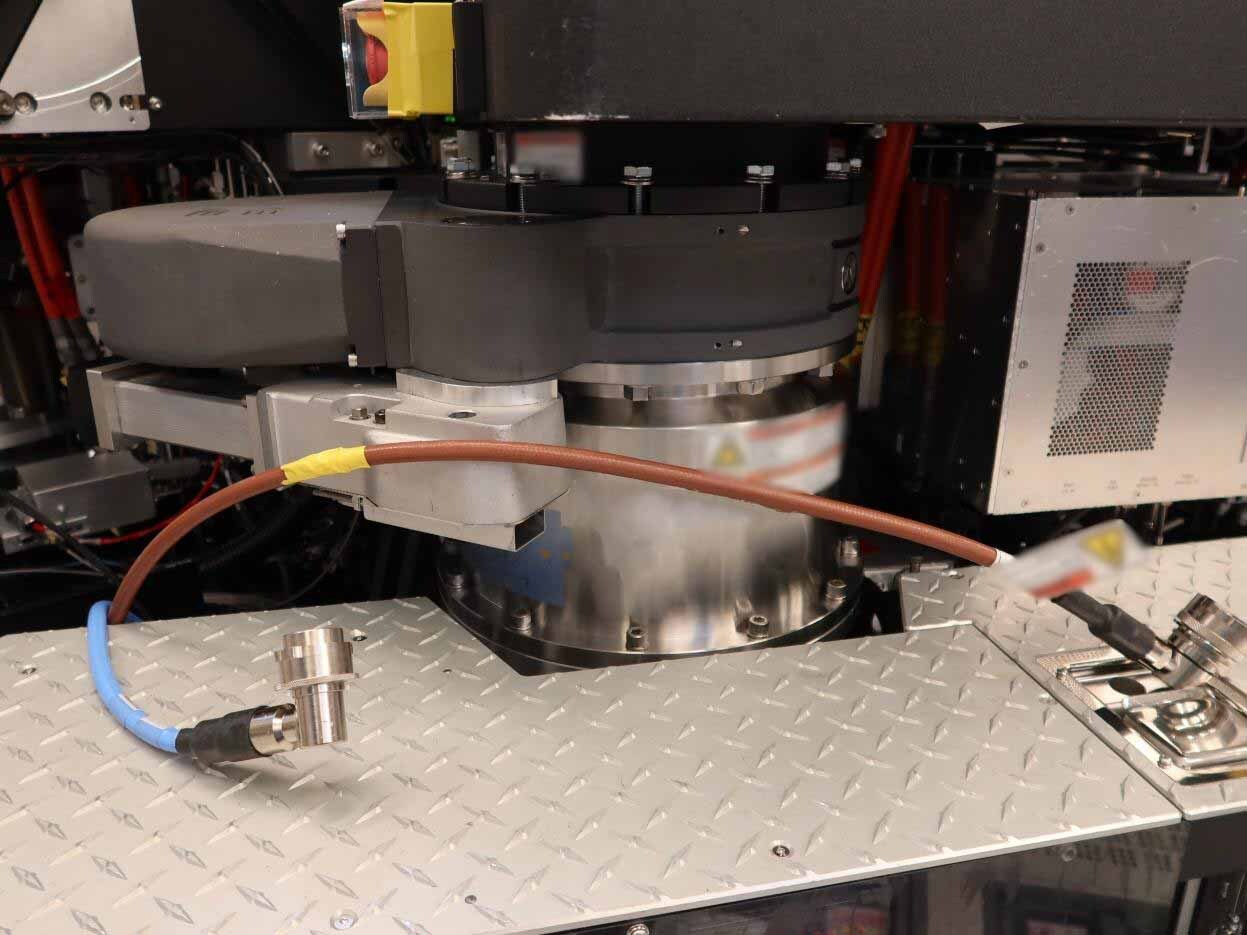

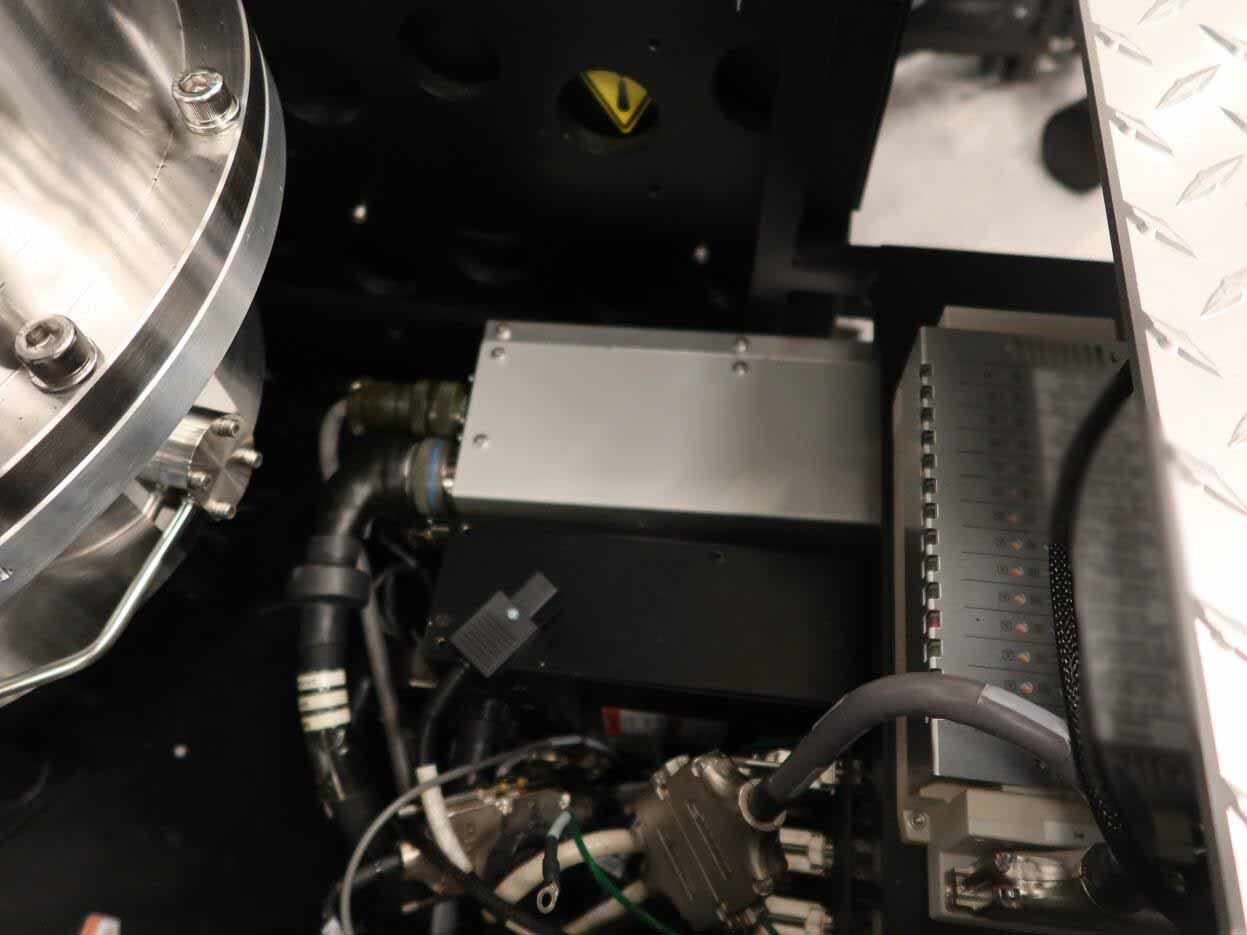

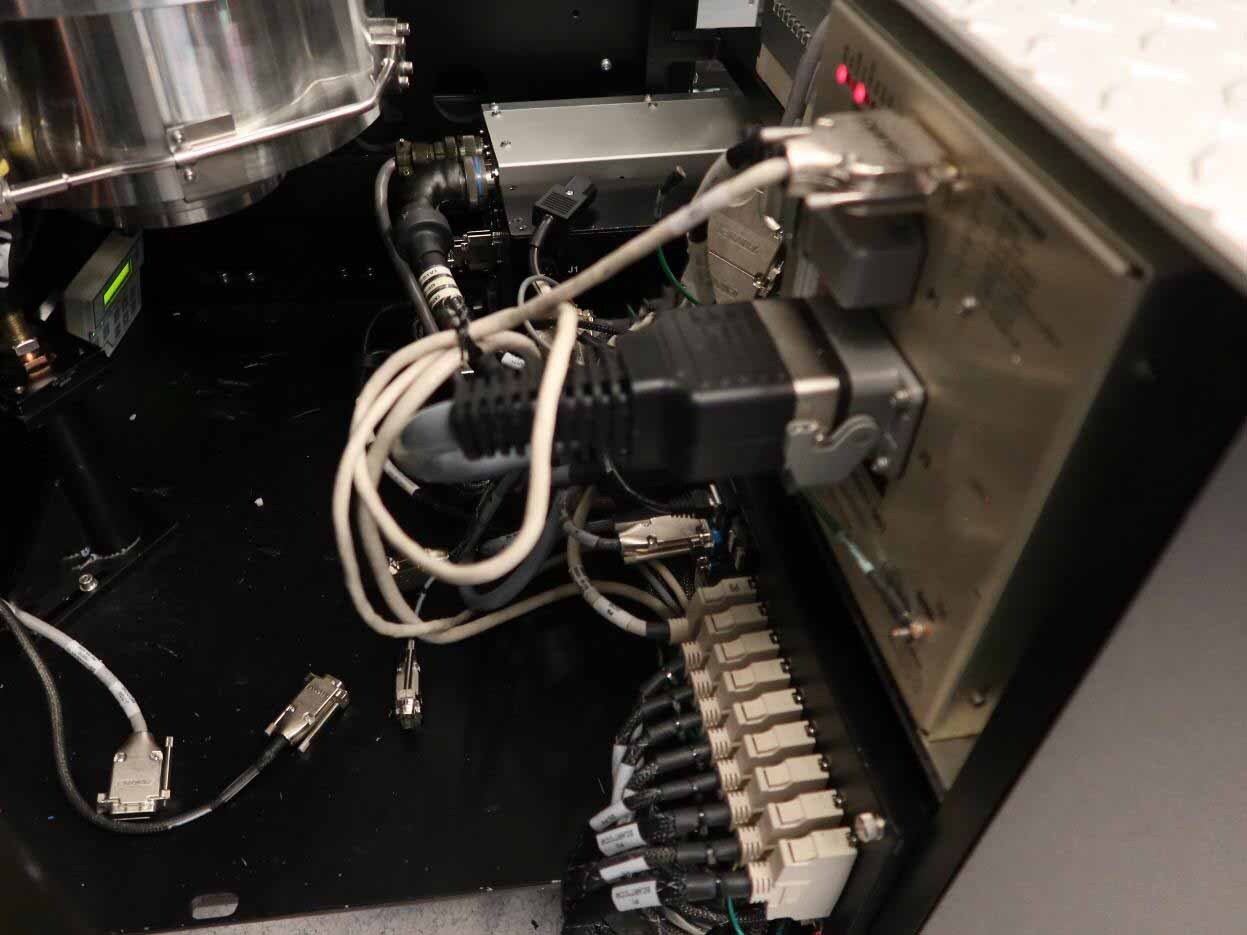

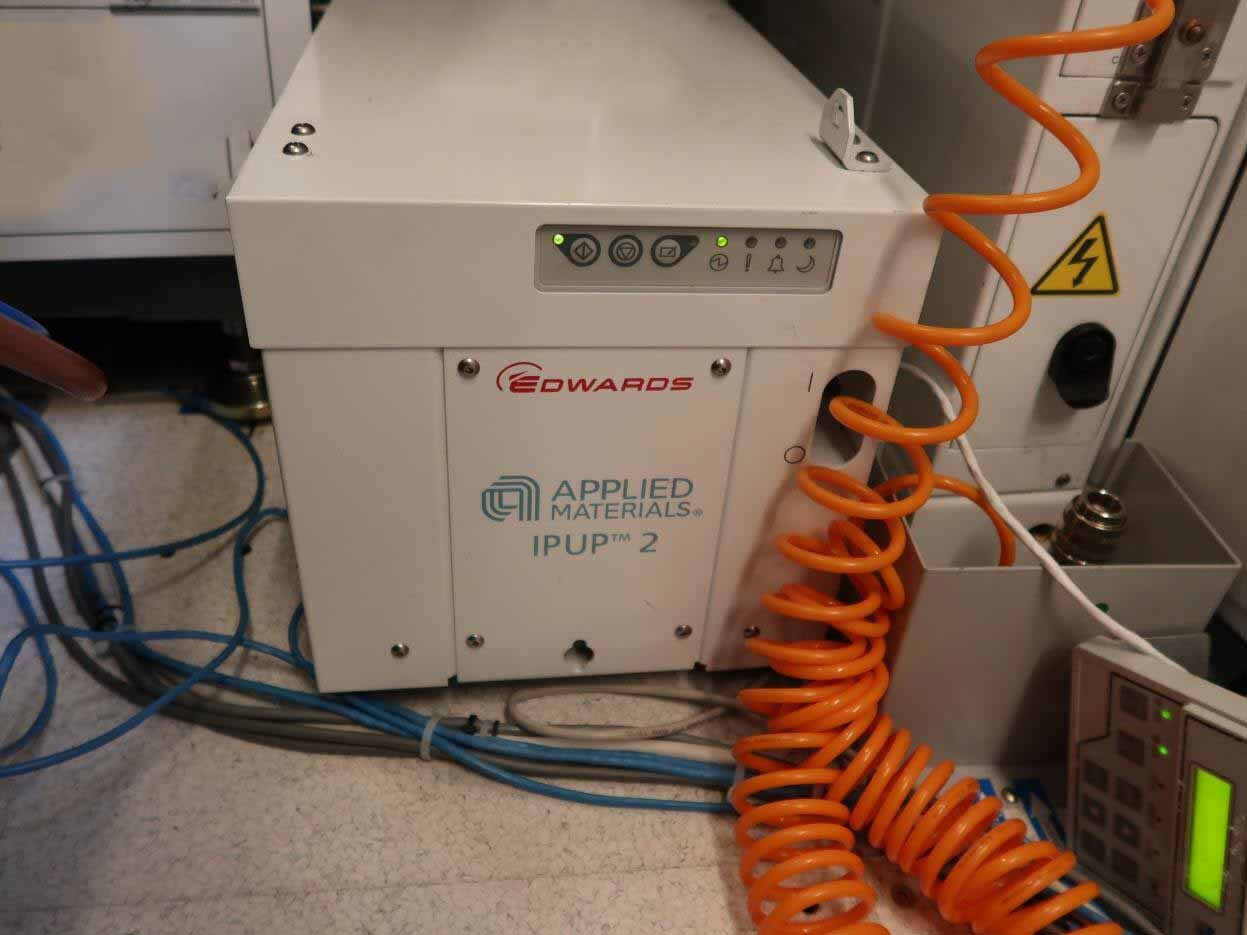

TOYOTA T100L LL/MF Dry pump

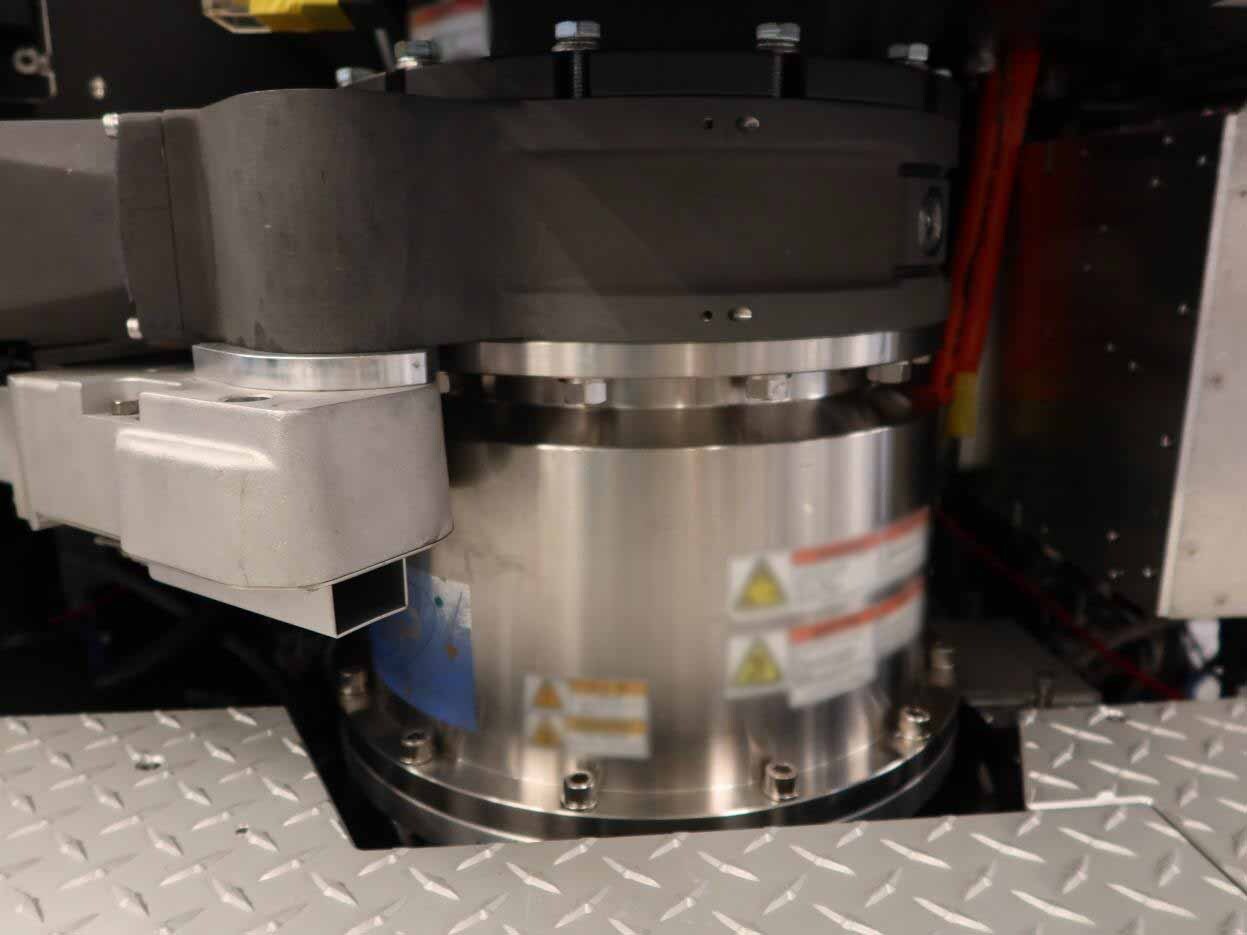

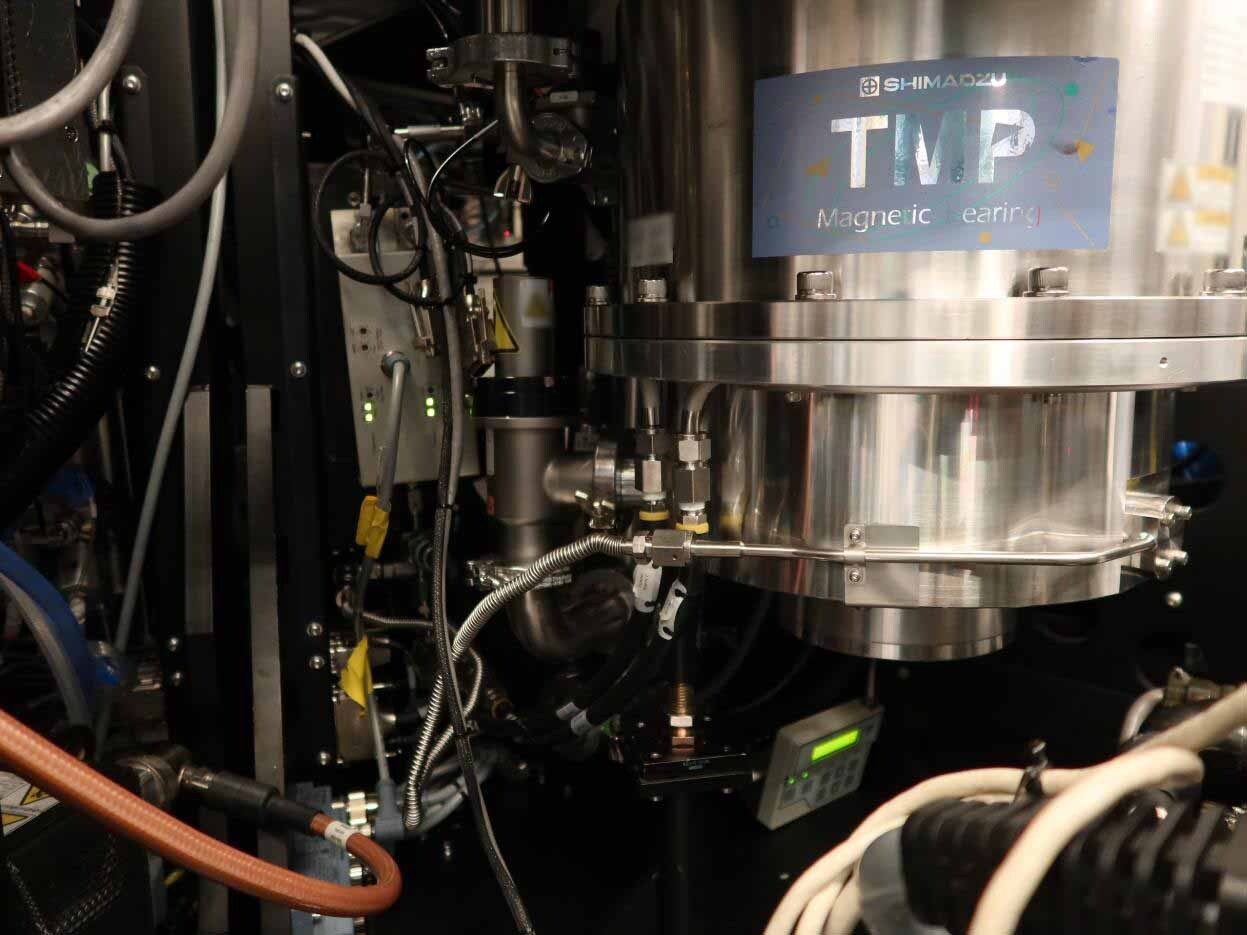

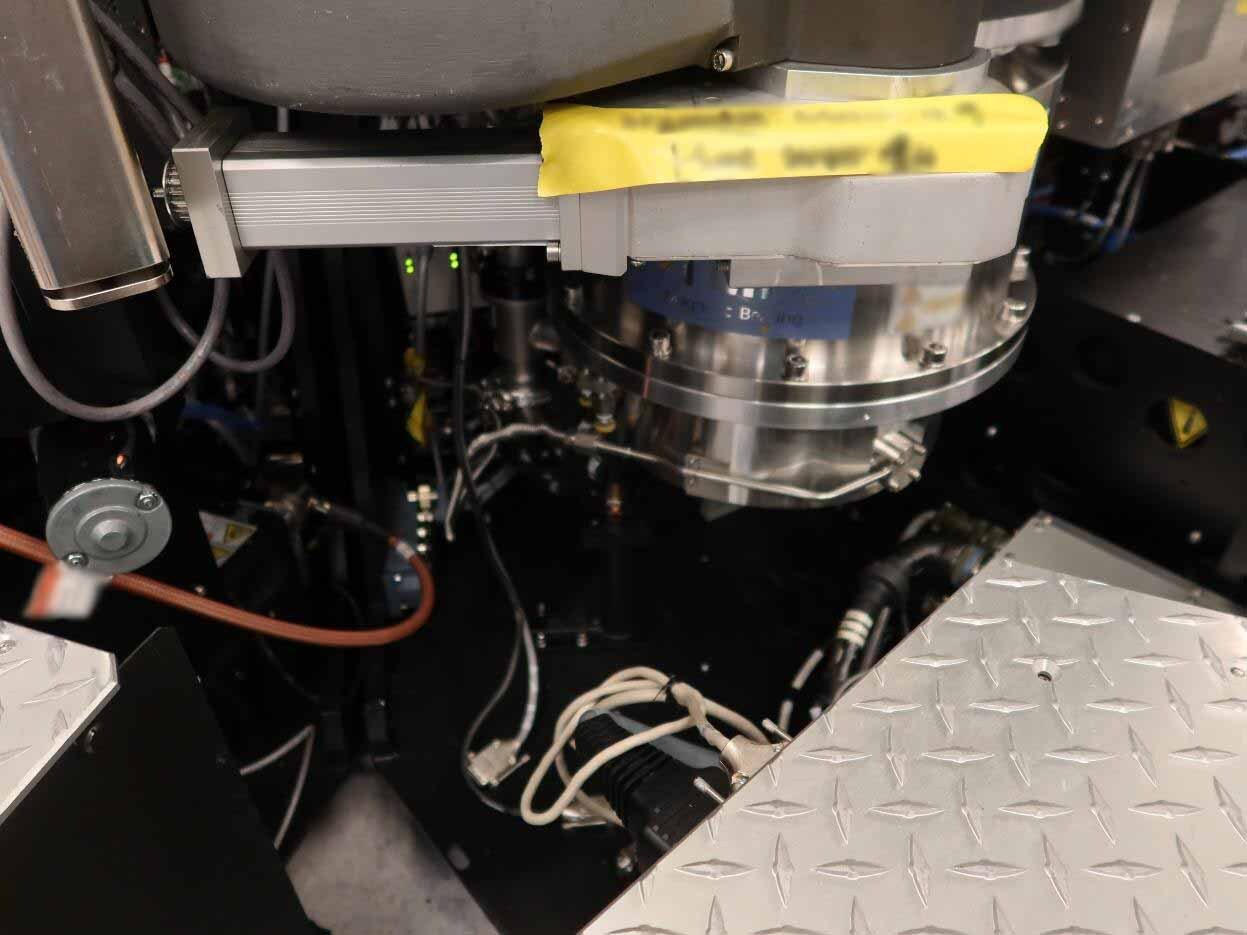

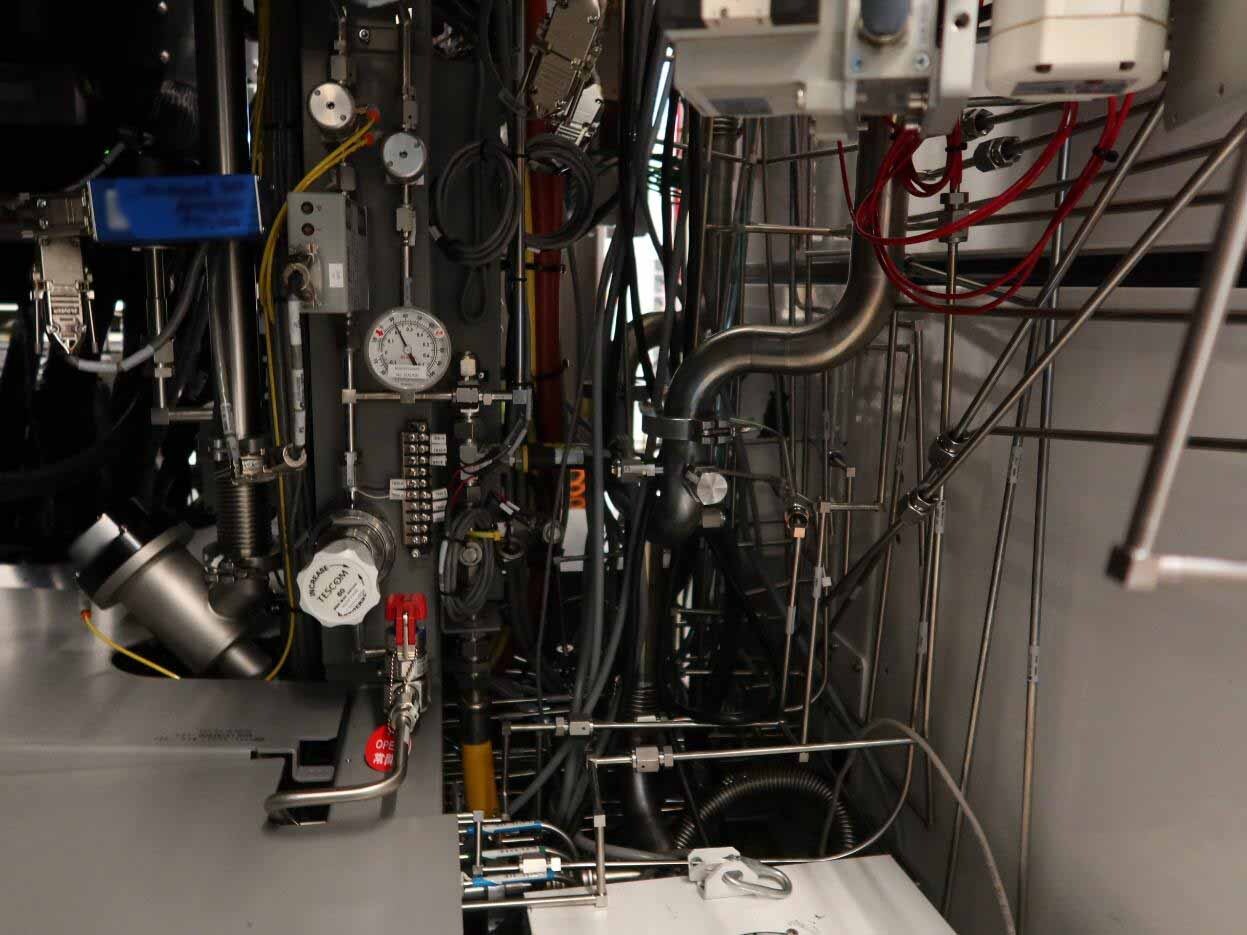

SHIMADZU TMP-3403LMC Turbo pump

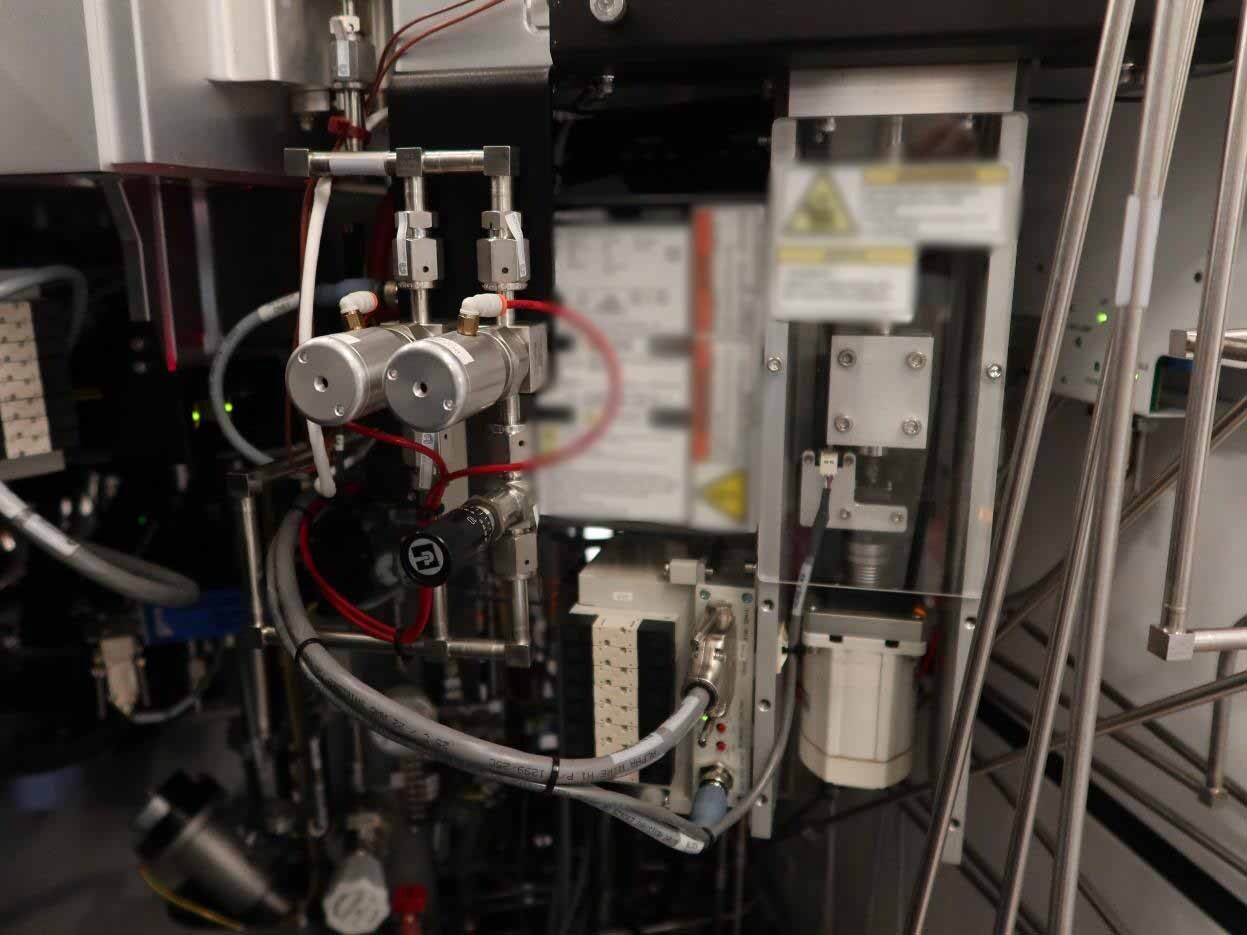

DAIHEN RMN-50N6 matcher

Shower head assy, TKI SIC SGD, With Alum Plug, E5

12" Facilities interface box: wFIB, eFIB

Inner/Outer independent temperature control

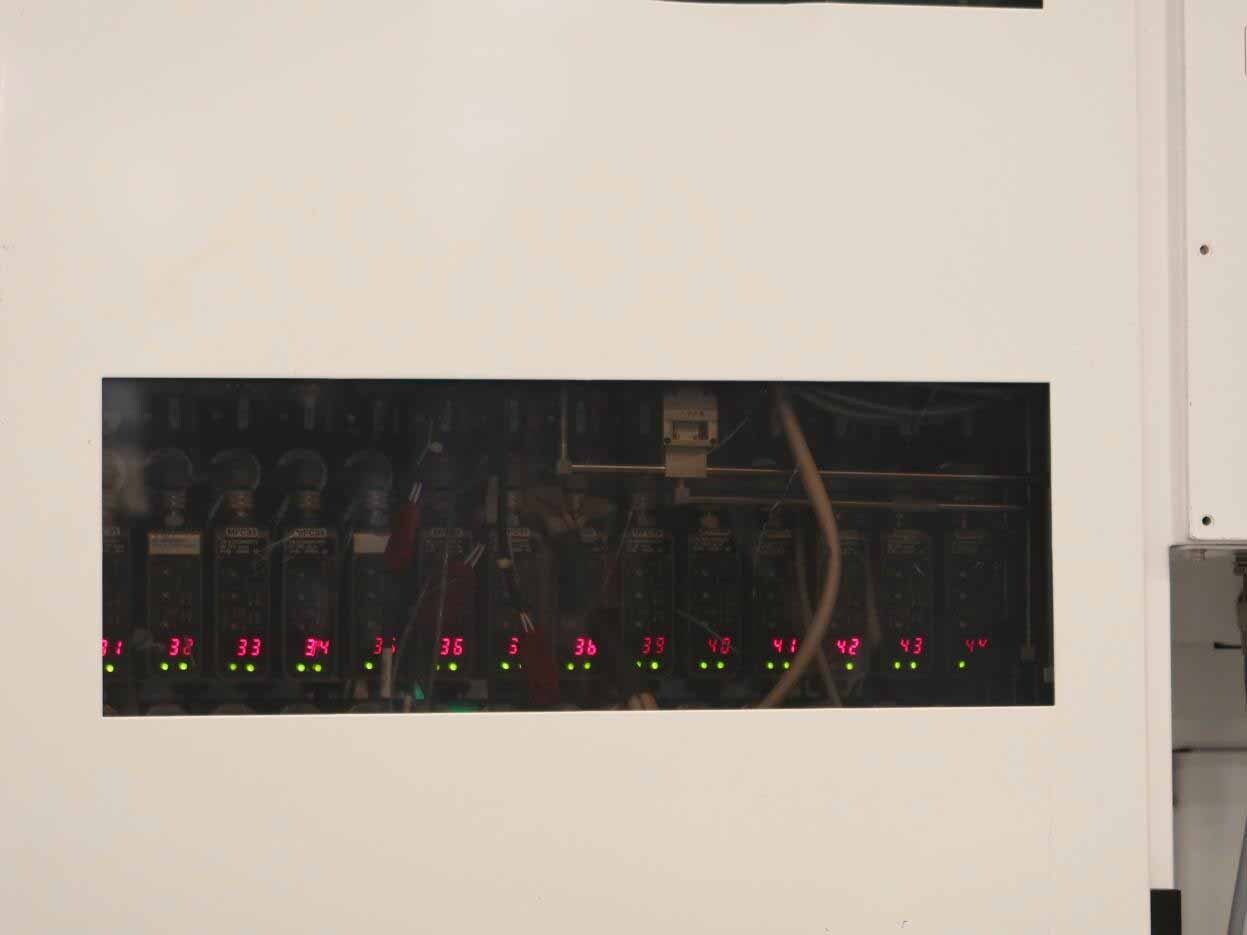

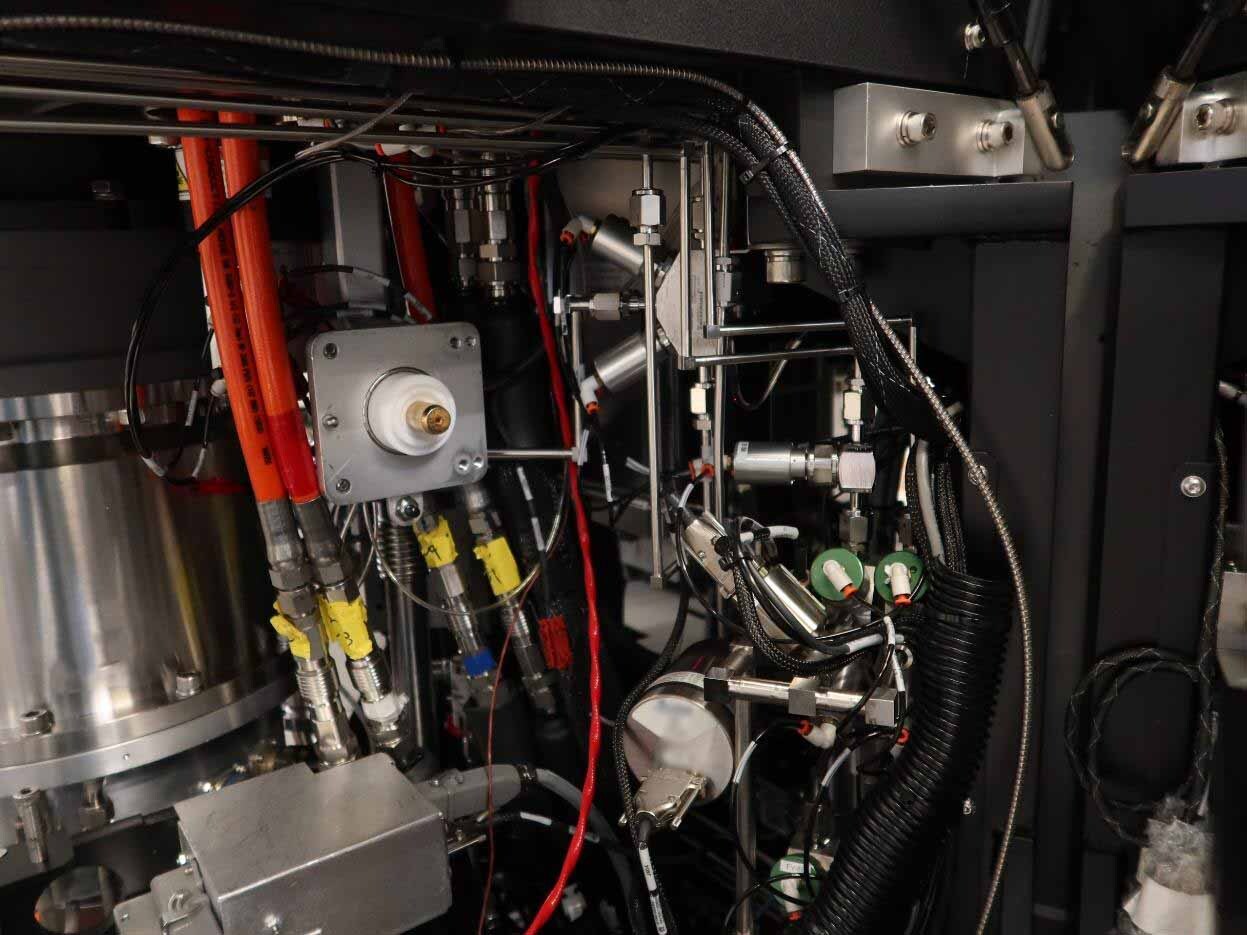

Independent Gas injection: 2 gases for each step

Closer cooling and heating showerhead design

Power supply:

High bias RF power capacity: 7.5 kW (max combined power)

RF Frequency: 162 MHz Source, 13.56/2 MHz Bias

2008 vintage.

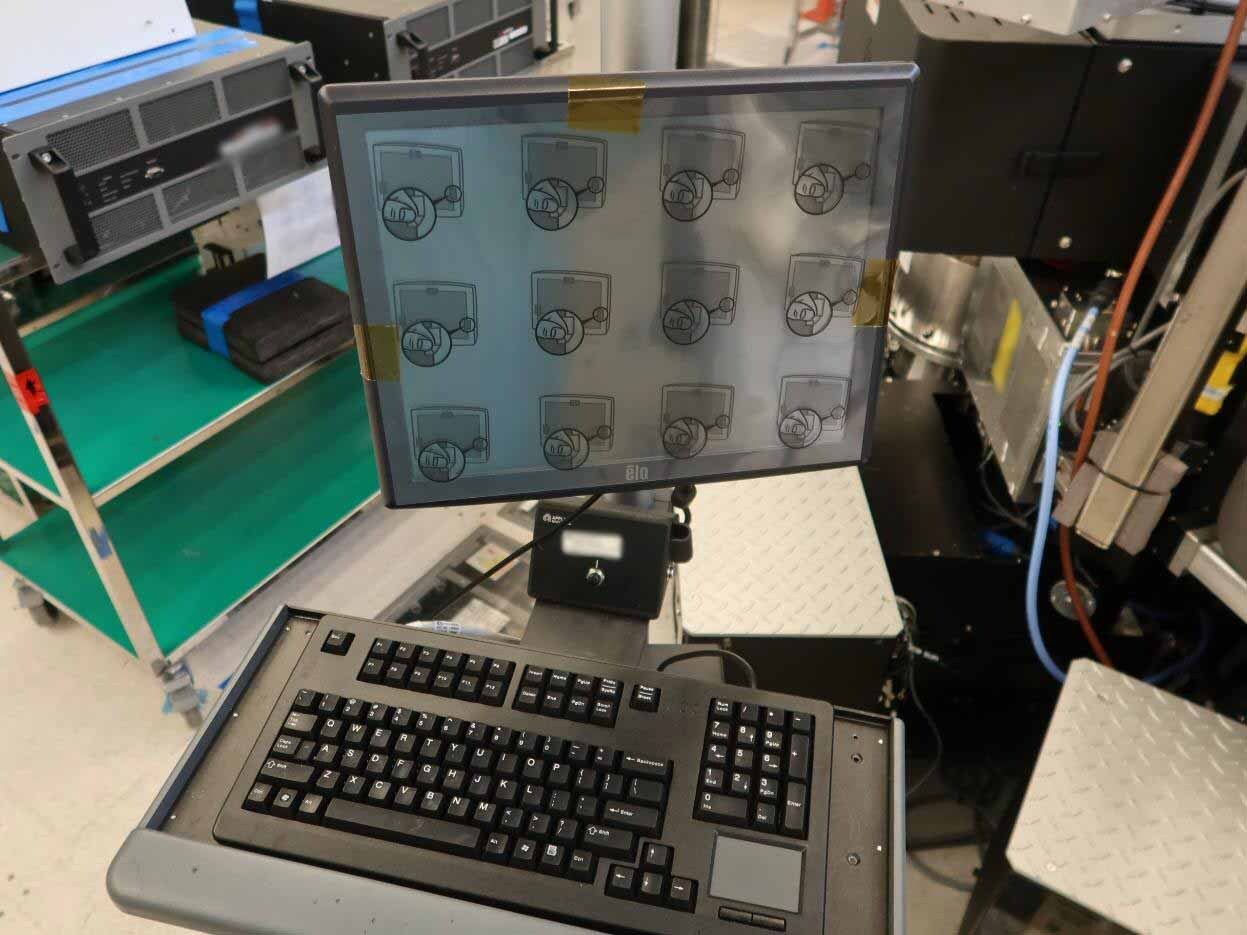

AMAT / APPLIED MATERIALS Enabler reactor is an advanced chemical vapor deposition (CVD) equipment designed for the production of semiconductor materials. This single-wafer reactor provides robust, reliable and repeatable process performance using ultra-low pressure CVD chamber and a patented Homura cooling system. AMAT Enabler reactor offers high-quality thin film deposition at temperatures up to 850°C and is well-suited for the production of compounds such as silicon dioxide (SiO2), silicon nitride (SiNx) and silicon carbide (SiCX). APPLIED MATERIALS Enabler reactor's unique and patented Homura cooling unit greatly reduces process cycle times by utilizing an innovative arrangement of gas pulses to extract heat from the wafers. This allows for thinner film deposition and faster growth rates over traditional, non-Homura-cooled reactors. Enabler also features user-friendly design, intuitive control machine and a graphical user interface. AMAT / APPLIED MATERIALS Enabler reactor utilizes the CVD process to deposit thin films of specific semiconductor materials with precision and allows optimizing the semiconductor material properties (such as compressive or tensile stress, porosity, grain size, composition homogeneity) with great accuracy. The tool also ensures uniformity of film deposition for wafers with different sizes, levels, and multiple deposition operations with rapid cooldown and excellent uniformity. The homogenous gas flows, pre-defined process parameters and advanced sheath heating method provide reliable and repeatable process outcomes and excellent uniformity. Additionally, AMAT Enabler reactor features advanced thermal management asset (TMS) with variable cooling rates and low temperature zones to prevent damage or oversaturation of materials. This is possible due to the power of the reactor's TMS, which provides exact control over the rate of cooling. APPLIED MATERIALS Enabler reactor is a robust, reliable and repeatable tool for producing semiconductor materials and it is highly regarded in the industry for its superior performance and repeatability. This advanced reactor provides a lot of flexibility to the user, who can customize and profile the deposition according to their needs. The ability to obtain exact control over the deposition process and obtain total uniformity is one of the biggest advantages of Enabler reactor and makes the reactor suitable for various semiconductor application.

There are no reviews yet