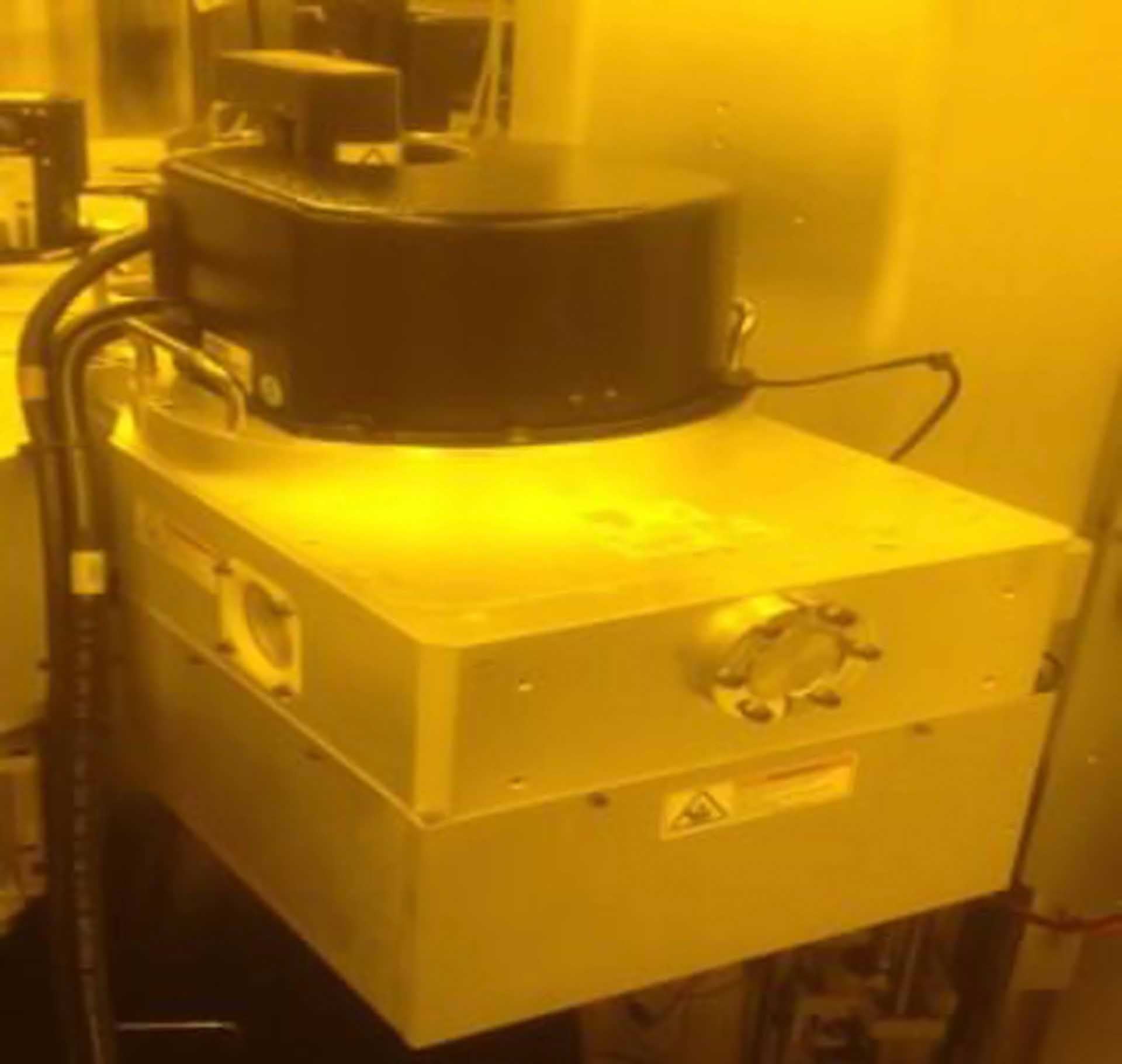

Used AMAT / APPLIED MATERIALS Endura 5500 HP #9223524 for sale

URL successfully copied!

Tap to zoom

ID: 9223524

Wafer Size: 8"

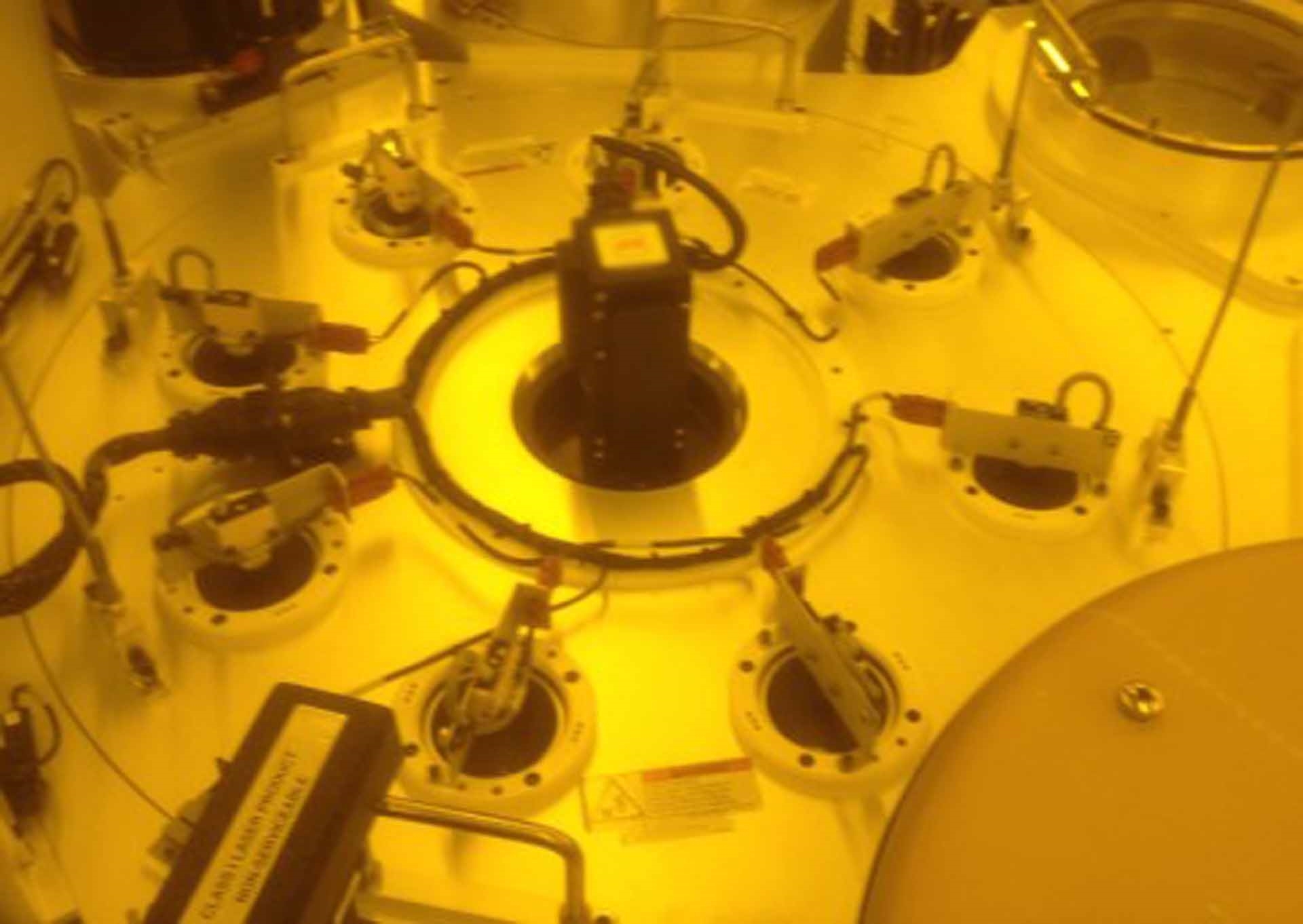

PVD System, 8"

Multi-chamber sputtering system

Process: Copper

Dry pump type: EBARA AA40W (System)

LLA

LLB

(2) Al

(2) Ta PVD

(2) PCII

(2) DG

System controller

SMIF System:

(2) LPT 2200

(2) Load locks

Handler system:

Buffer Hp

Transfer VHp

(2) Hoisters

Process chambers:

(2) ImpTa

(2) ClampAl

(2) PcII

(2) Degas

Main AC

NESLAB Chiller

(3) General racks

(2) Compressors

(4) EBARA Pumps

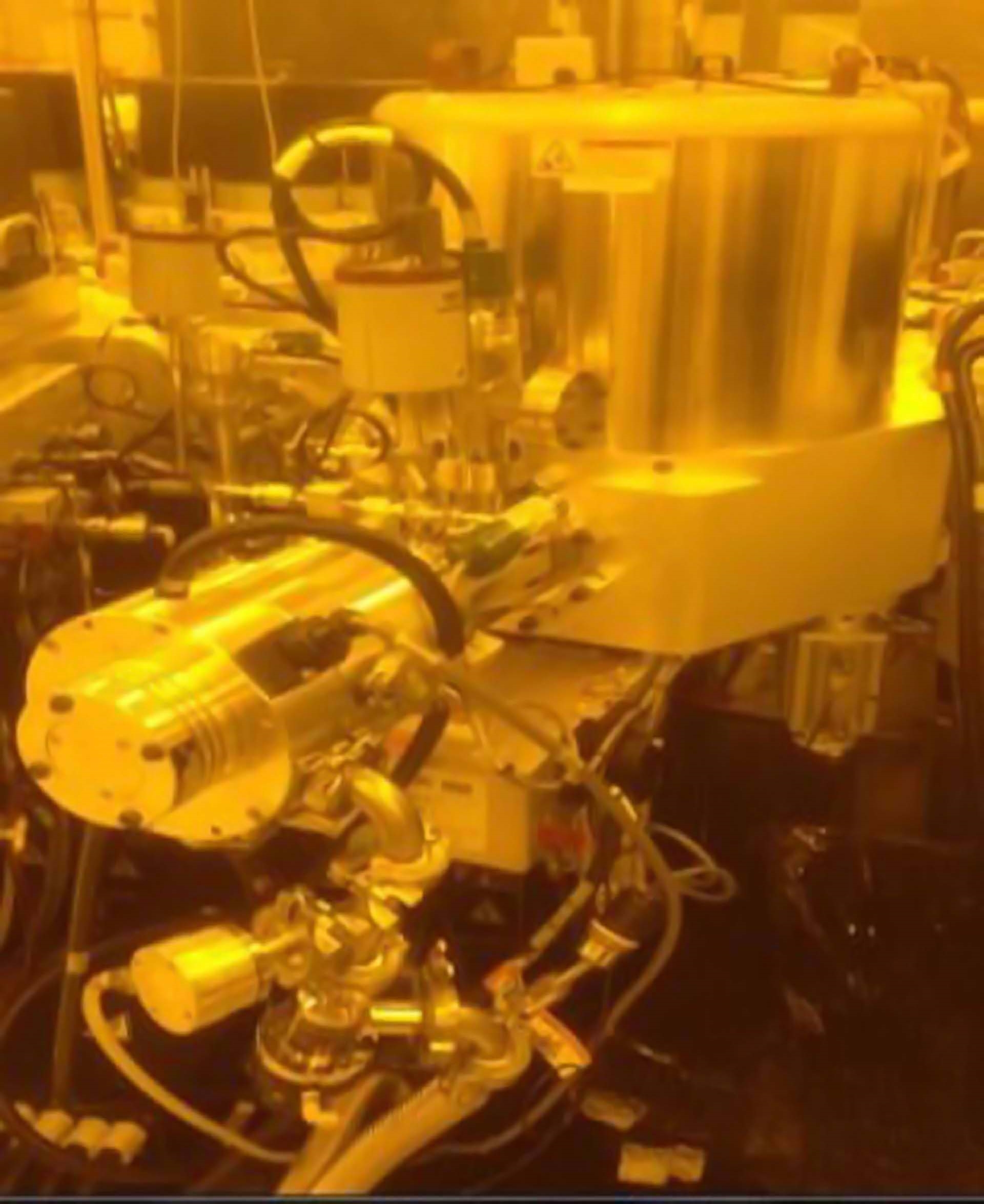

Chamber 1: B101 IMP Ta

Shutter disk

Body type: WB

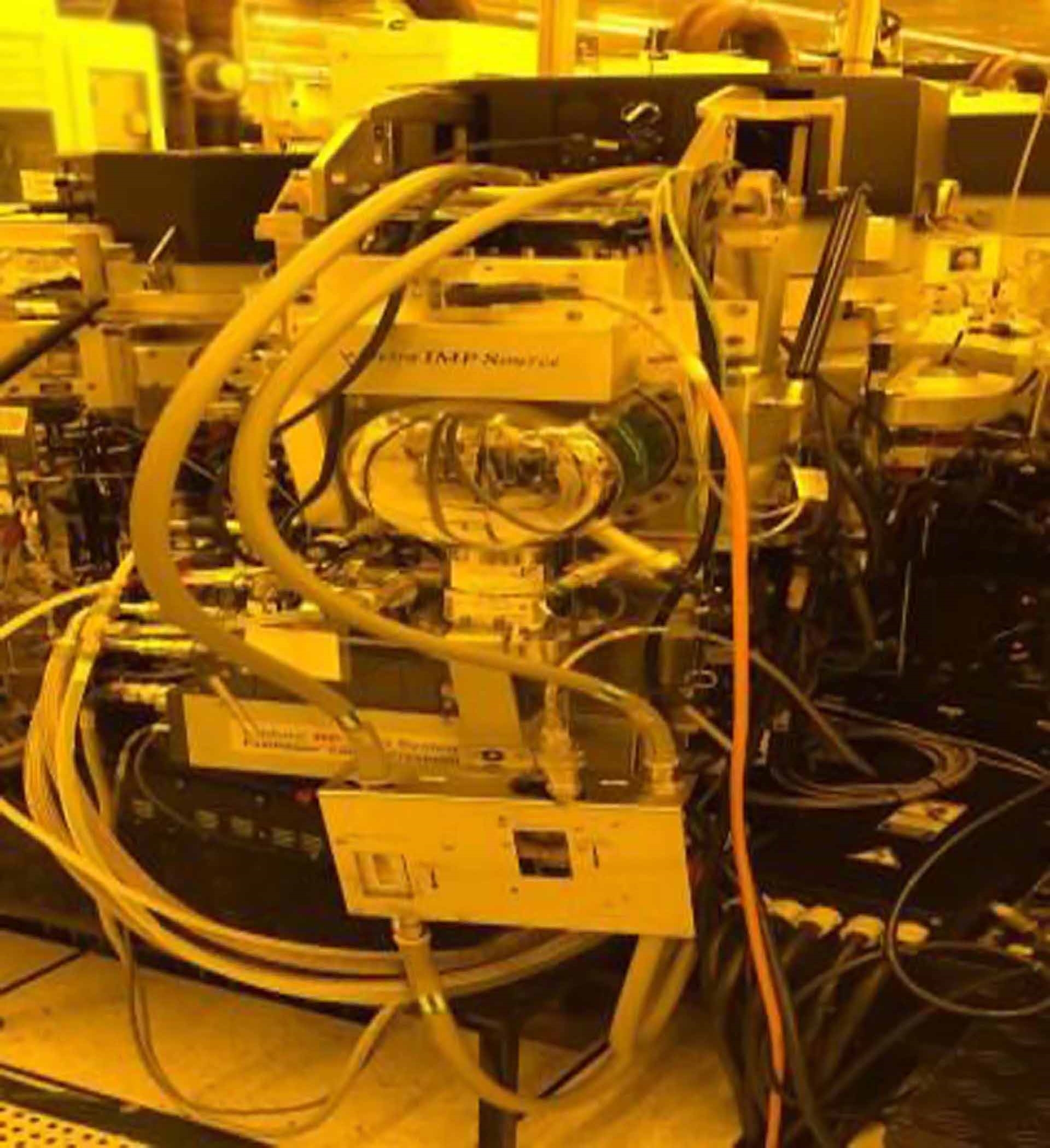

Source type: Vectra IMP

Magnet type: RH-2

MFCs: Ar 140sccm

DC Generator: ADVANCED ENERGY MDX-L6

RF Generator:

ADVANCED ENERGY HFV8000 (RF Coil)

COMDEL CX-600S (AC Bias)

RF Match:

HE

BIAS

Vectra IMP

010CAP 2MHz (RF Coil)

13.56 MHz (AC Bias)

Cryo Pump: CTI On-Board 8F

No turbo pump

Chamber 2 & 3: Clamp Al

Body type: WB

Source type: 12.9''

Magnet type: Al A, 12.9''

DC Generator: ADVANCED ENERGY MDX-L12M

MFCs:

Ar 140sccm

Ar-H 70sccm

Cryo pump: CTI On-board 8F

No shutter disk

No RF Generator

No RF Match

No turbo pump

Chamber: 4 B101 IMP Ta

Shutter disk

Body type: WB

Source type: Vectra IMP

Magnet type: RH-2

MFCs: Ar 140 sccm

ADVANCED ENERGY MDX-L6 DC Generator

RF Generator:

ADVANCED ENERGY HFV8000 RF Coil

COMDEL CX-600S AC Bias

RF Match:

HE

BIAS

Vectra IMP

010CAP 2MHz (RF Coil)

13.56MHz (AC Bias)

Cryo pump: CTI On-board 8F

No turbo pump

Chamber A & B: Cool down

Dry pump: EBARA AA20N

Pedestal type: Clncool

Chamber C & D: PCII

Process: Etch

PK Type: PIKII Pinless

Dry pump: EBARA AA20N

Turbo pump: LEYBOLD TMP

RF Generator:

COMDEL CPS1001S 13.56MHz

RFPP LF10A 400KHz

RF Match: PC II 13.56MHz

MFCs:

Ar 28sccm

Ar 420sccm

No DC Generator

No cryo pump

Chamber E & F: O/D

Degas type: Standard

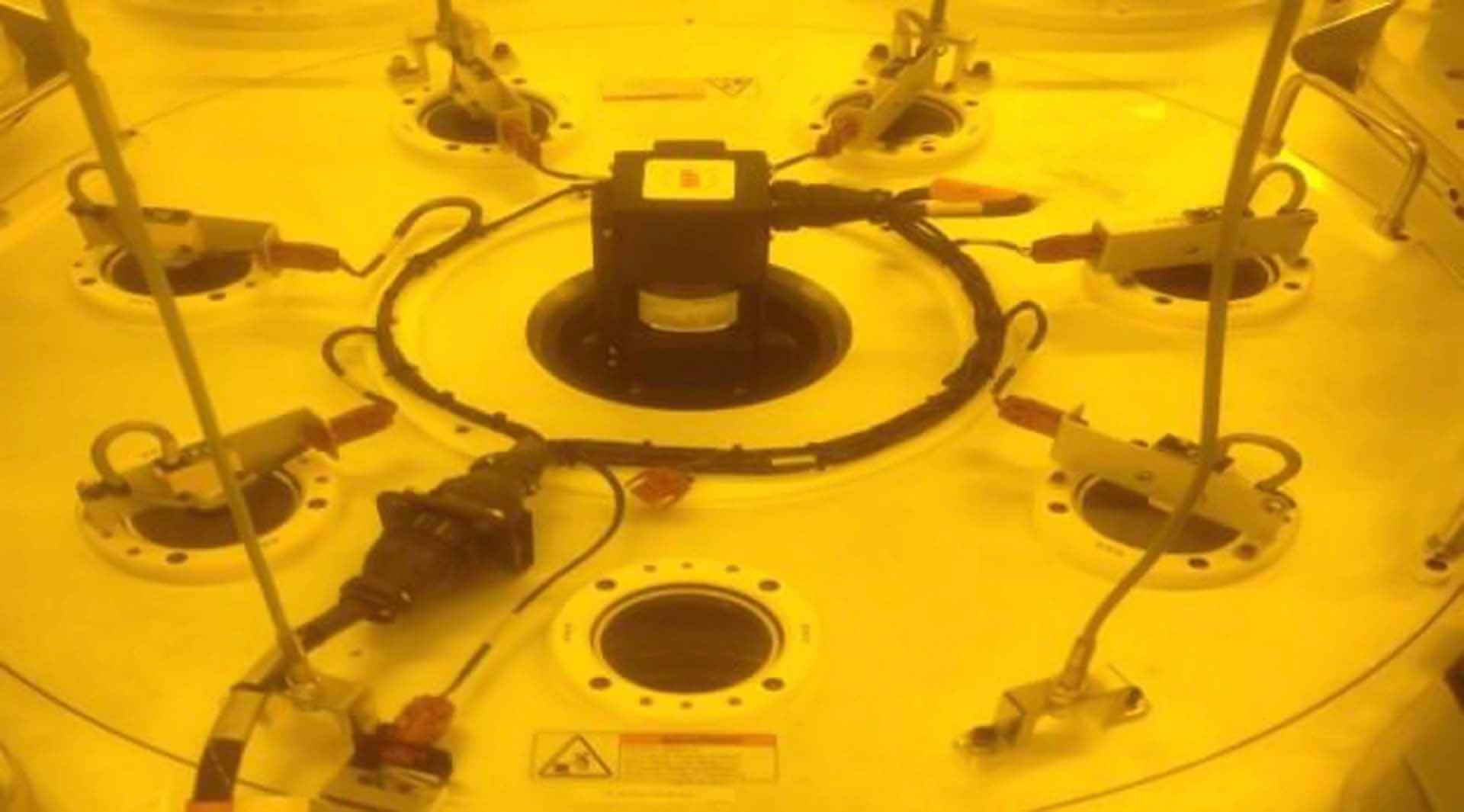

Buffer & Transfer:

Cryo pump: CTI On-board 8F

Robot type: HP

Load lock:

Body type WB

Venting & pumping mode:

Soft slow

Fast

Wafer mapping: Standard

No scrubber / CDO

Heat exchanger: NESLAB III (PVD Chm)

Cryo compressor: Water cooled 9600

CIM Linked.

AMAT / APPLIED MATERIALS Endura 5500 HP Reactor is a compact, automated CVD tool designed to reliably do high-precision processing for advanced materials applications. This reactor boasts unparalleled speed and accuracy capabilities with its micron-level accuracy and vertical scanning time of up to 10 minutes. AMAT Endura 5500 HP is equipped with a robustly designed chamber that is well-suited for large batch jobs as well as the most complex assignments. It utilizes dual-frequency plasma to enable optimized deposition capabilities under a wide range of process conditions. The dual-engines, the high-performance RF power modules, the multiple independent deposition sources and the adjustable chamber temperature provide a highly repeatable suite of process parameters for the most advanced applications. The Endura's stand-out features include its powerful control and automation capabilities. It has an advanced robot arm with integrated end-effectors that allows it to precisely control the trajectory of the wafer carrier through the chamber. The Endura also offers a user-friendly Graphical User Interface system that allows for quick parameter changes and the ability to monitor the process in real-time. The motorized chamber elements, such as the robot arm, the quartz chamber and the gas delivery systems, enable APPLIED MATERIALS Endura 5500 HP to be infinitely adjusted for ultra-precise thin film functions. This reactor can be used for deposition processes using organo-metallic reagents, such as ozone based processes, as well as deposition processes using solid phase precursors. Endura 5500 HP is designed to provide outstanding reliability and performance. Its advanced features provide flexible process development capabilities, including process profiling, diagnostics, remote monitoring and data logging. The reactor also has various safety features to protect the operators and the system itself from potential hazards. AMAT / APPLIED MATERIALS Endura 5500 HP is an efficient and reliable reactor that can handle the most challenging deposition applications. It is an ideal choice for advanced materials applications, allowing for the production of high-quality films and surfaces at unprecedented yields.

There are no reviews yet