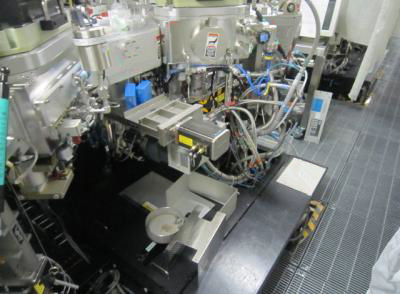

Used AMAT / APPLIED MATERIALS Endura 5500 #190624 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 190624

Wafer Size: 6"

Vintage: 1991

PVD Sputtering system, 6"

Chamber Type: 4 Chamber (1 Standard Body, 3 Wide Body), Pre-Clean 1 Type

Process: Al, Ti, TiN

No missing parts

1 STD-Ti (clamp)

2 Wide-AL (A101)

3 Wide-AL (A101)

4 STD-Ti (clamp)

5 -

A pass

B cool

C PC2

D PC2

E orienter-degas

F orienter-degas

Buffer HP

Xfer HP

LL narrow

Magnet dura and G12

1991 vintage.

AMAT / APPLIED MATERIALS / AKT Endura 5500 is a versatile reactor designed for a wide range of applications in the semiconductor market. It is used in a variety of processes such as chemical vapor deposition (CVD), etching, oxidation, and diffusion. AKT Endura 5500 is a thermal processing equipment with in-situ rapid thermal processing capability and unparalleled temperature uniformity. It has a high temperature range of up to 1700°C (3100°F), making it suitable for a range of advanced semiconductor materials. The reactor is designed with a dual plasma operation capability for improved material deposition process control. This reactor also features ion beam deposition technology for precise deposition uniformity on the wafer. AMAT ENDURA 5500 has a 5.7" wafer capacity and is equipped with two independent heating zones. This allows for better chances of achieving a uniform thermal profile across the wafer. AMAT Endura 5500 is also equipped with a graphite susceptor, which provides excellent thermal management and uniformity. AKT ENDURA 5500 also features automated process control with a computerized system and dedicated, easy-to-use software. This unit provides consistent process performance and faster process time, while its electrostatic chuck wafer holders provide a high level of wafer flatness and excellent uniformity. Other key features of Endura 5500 include a cassette-to-cassette transfer machine and an integrated wafer mapping feature for precise wafer mapping. In addition, the reactor features a conformal coating chamber which provides improved conformal coating quality for low-k materials. APPLIED MATERIALS ENDURA 5500 reactor has an industry-leading, unsurpassed level of temperature control and uniformity that offers optimal process performance for a variety of applications. It is ideal for processing a variety of materials, including advanced materials for next-generation semiconductor devices. Its robust design and leading-edge technology, along with its ease of use, make it a preferred choice for semiconductor applications.

There are no reviews yet