Used AMAT / APPLIED MATERIALS Endura 5500 #9030866 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9030866

PVD system, 8"

System software ver: C8.622

System Platform: Endura

Wafer Shape: SNNF

EMO Type: Turn to Release

CE Safety Mark: English

CIM Configuration: SECS

SBC Version: V452

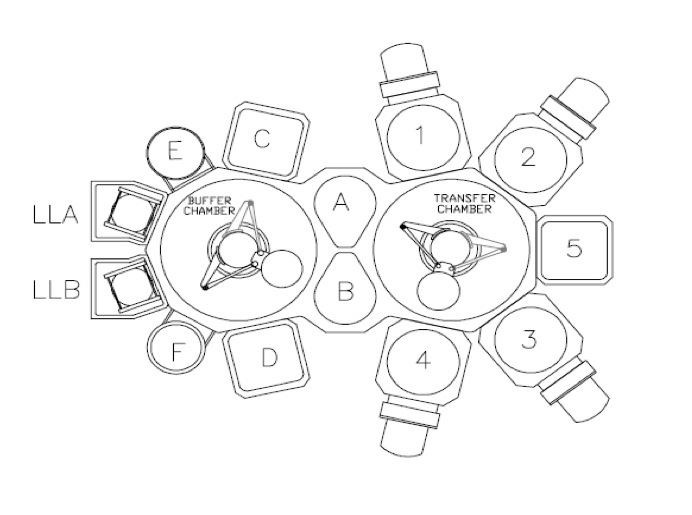

Mainframe Configuration:

Buffer Robot Type: HP

Buffer Robot Blade: Thin Metal

XFER Robot Type: VHP

XFER Robot Blade: Original Metal

Lid Hoist: Yes

Status Light Tower: RYG

Remote Monitor: Table Mount

Sub-System Configuration:

(1) Chiller: Model: None

Cryo Pump Type: CTI Cryo- on board 8F

Cryo Pump Power: 3 Phase

(2) CompressorS

Compressor Type: 9600

Loadlock Configuration:

Loadlock Type: Narrow body

Auto Rotation: Yes

Cassette Type: 8"

Mapping Function: WFM

Vent Type: Variable Speed

Fast Vent Option: Yes

LLKs NB w/Auto Tilt

A Pass-thru

B Cool Down

E O/D (Std)

F O/D (Std)

C PCII w/Cryo Std

D PVD TiN 101

1 PVD Tungsten (W) HT-ESC - Chamber has UV Flash for ESC E-Clean

2 PVD Hot-Al HT-ESC - Source Assy missing, Process kit still intact.

3 PVD Hot-Al HT-ESC - Source Assy missing, Process kit still intact

4 PVD Al/Cu SLT-ESC Complete

5 Iso-Valve (Manual) -

Bfr HP

Txfr VHP (Style Lid)

PVD Hot-Al Chambers: These are Water-Cooled Chamber bodies (can't use for other processes which use Wide-Body Chambers

Gas Information:

Gas Box Pneumatic Valve: Single

Pneumatic Valve Type: Veriflo

Manual Valve Type: Veriflo

MFC Type: FC-780C

Gas Line Out: Out The Back

Modules:

M/F Yes

Sys/AC Yes

EQ1 Yes

EQ2 Yes

Main/AC Yes

AC Dist Box Yes

Cryo Comp 3 - 9600

Heat Ex Yes, Neslab III

Pumps No Pumps included with any tools

Lift Hoist non-AMAT, Gantry & 250lb hoist

Umbilical Configuration:

Controller to Main AC: 50 Feet

Controller to Mainframe: 50 Feet

Mainframe to Generator: 50 Feet

Remote Monitor: 50 Feet

Mainframe to Compressor: 50 Feet

Main AC to pump: 50 Feet

AC Box to Heat Exchanger: 50 Feet

Controller to Gen Rack: 50 Feet

Gen Rack to Gen Rack#2: 50 Feet

Electrical Configuration:

Line Voltage: 200V

Full Load Current: 487A

Remote Transformer: No

Frequency: 60Hz

Missing Parts:

Chamber E: Orientor PCB

Chamber F: Orientor PCB

Chamber 2: Missing upper chamber lid

Chamber 3: Missing upper chamber lid

Chamber C: Missing upper chamber lid

1995 vintage.

AMAT / APPLIED MATERIALS / AKT Endura 5500 is a single wafer processing reactor with advanced functionality for a wide range of semiconductor-processing applications. This intuitively designed reactor is designed to maximize productivity and process flexibility, enabling users to perform non-planar, planar, and complex device structures with superior process capabilities. AKT Endura 5500 is equipped with unmatched thermal capability powered by its advanced tri-zone heating and cooling technology, allowing users to accurately control temperatures for uniform reaction across the entire wafer face. This thermal performance is further equipped by the uniform-flow media injection technology, which provides precise control and homogenous distribution of process gases. As a result, users are able to achieve optimal film profiles with repeatable and consistent performance. Additional features of the reactor include high availability, reduced downtime, and excellent process control. In terms of safety and environmental protection, AMAT ENDURA 5500 meets safety standards such as UL/CSA, with features like the hermetic enclosures to protect personnel from potential exposure to hazardous process materials. Furthermore, the reactor is equipped with advanced diagnostics tools that allow for easy and efficient monitoring, as well as for additional process validation. The reactor also offers improved process uniformity combined with an extended process window compared to conventional thermal processes, allowing for increased flexibility and throughput. Apart from its superior thermal performance, APPLIED MATERIALS ENDURA 5500 provides users with flexible control options, with programmable feed/vent options and advanced I/O configurations that support efficient in-situ process control. Additionally, the reactor utilizes chemical containment and low-flow modes, to enable efficient operation and optimized yields. With its precision motion controllers, users are able to achieve small, but precise motion control with quick calibration, and integration into third party systems is also available. In summary, AMAT / APPLIED MATERIALS / AKT ENDURA 5500 is a powerful, user-friendly, and safe reactor that minimizes waste and overall costs. It offers energy-saving technology, superior thermal performance, reduced downtime and excellent process control, making it an excellent choice for those in the semiconductor industry.

There are no reviews yet