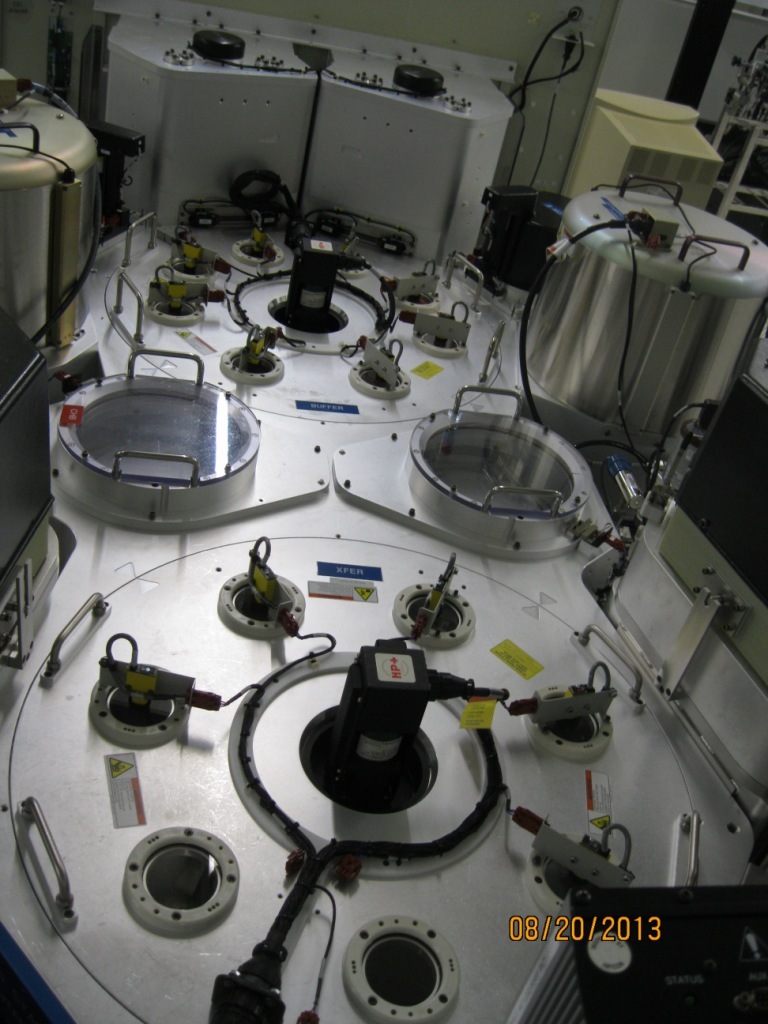

Used AMAT / APPLIED MATERIALS Endura 5500 #9036092 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9036092

PVD System, 8"

Wafer handling: SMIF

Front panel type: wide body

Software version: B88810

Single board computer in controller: Yes

Ion gauges: Yes

Robots (standard, HP, HP+, VHP, etc):

Buffer robot: HP+

Transfer robot:HP+

Blade material: Metal

Blade material: Metal

Load Lock: Wide Body

Narrow Body: tilt-out

Index handler type:

Loadlock vents: N2 vent

Basic Chamber setup: (PC II, Cooldown, O/D, pass through, CVD, other - w/o details)

A: Cool down

B: Cool down

C: Pre clean II

D: Pre clean II

E: Orient / Enhanced degas

F: Orient / Enhanced degas

Process: VECTRA IMP Ti

Platform: Endura

RF coil power supply: Advance Energy HFV 8000

Chamber temperature: Heater 100°C - Bake 30%

Pump Type: CTI 8F Enhanced Fast Regen Low Vib

MFC #1: Argon Heater

MFC #1 type / size: Stec SEC-4400M 50 Sccm

MFC #2: Argon Final

MFC #2 type / size: Stec SEC-4400M 100 Sccm

Source type: Vectra IMP

Target type / vendor: D-Bond 0.25" - Honeywell

Target part # 7VX00236

Coil part # 7VX20266

Magnet type / part number: Type RH-2 P/N 0010-21676

Ar Psi: 20 PSI

Power supply: MDX 12KW

Shutter: Linkage

Heater: Original 4F

Process Kit (type/desc): IMP Process Kit Version 4.5

Upper Shield Part No: 0020-22498

Lower Shield Part No: 0020-22499

Shield Clamp Kit Part No: 0240-25440

DC Bias Hardware Kit PN: 0240-20021

Process: CVD TiN

Platform: ENDURA

Chamber temperature: 400°C

Chamber type: TxZ HP+

Heater: AMAT P/N 0010-03244

Pump Type: ALCATEL 602 P

HX: AMAT 1

HX temperature: 60°C

MFC #1: Argon Edge Purge

MFC #1 type / size: Stec SEC-4400M 3000 Sccm

MFC #2: Argon BTPur

MFC #2 type / size: Stec SEC-4400M 2000 Sccm

MFC #3: He Carrier

MFC #3 type / size: Stec SEC-4400M 500 Sccm

MFC #4: N2 Dil

MFC #4 type / size: Stec SEC-4400M 1000 Sccm

MFC #5: He Dil

MFC #5 type / size: Stec SEC-4400M 1000 Sccm

MFC #6: N2

MFC #6 type / size: Stec SEC-4400M 1000 Sccm

RF Power supply: ADVANCE ENERGY PDX 900-2V

HE carrier pressure: 18 PSI

HE DIL pressure: 30 PSI

Ampole temperature: 50°C

Gas line temperature: 60°C

Hot Box: 70°C

CVD Ion gauge: Absent

Process Kit (type/desc)

INSERT LINER EXHAUST TXZ 200MM: 0021-02469

RING, LOWER, ISOLATOR: 0021-02155

RING, MIDDLE, ISOLATOR: 0021-02156

EDGE RING, PURGE HEATER, 200MM TXZ: 0021-03094

SCREW, CENTERING PURGE HEATER 200MM TXZ: 0021-07418

OUTER SHIELD W/O WINDOW, TXZ CHAMBER: 0021-03980

INNER SHIELD HP TXZ IMP. UNIF.: 0040-06127

PIN, LIFT, TXZ HEATER: 0200-01798

PLATE,BLOCKER,TXZ 200MM: 0021-35744

FACE PLATE, BKM3 TXZ 200MM: 0040-01878

CHAMBER INSERT 200MM TXZ CIP: 0200-00261

ISOLATOR, SIN, ENH, PUMPING LID, DXZ GECO: 0200-10163

TUBE GAS FEED: 0020-31425

LID LINER, HPTXZ: 0200-00689

Process: PVD TiN

Platform: ENDURA

Ch temp control: Without temp control

Chamber type: WB

Pump Type: CTI 8F Enhanced Fast Regen Low Vib

MFC #1: Argon

MFC #1 type / size: Stec SEC-4400M 100 Sccm

MFC #2: N2

MFC #2 type / size: Stec SEC-4400M 200 Sccm

Source type: G-12

Target type / vendor: D-Bond 0.35" - Praxair

Target part #: 7VX00135

Magnet type / part number: Type G-12 P/N 0010-20768

N2 Psi: 20 PSI

Ar Psi: 20 PSI

Power supply: MDX - L12M - 650

Shutter: Linkage

Heater: SST Pedestal Unclamped 101

Process Kit (type/desc): Shield Mounting G12 btn hd

Upper Shield Part No: 0020-25730

Lower Shield Part No: 0020-25077

Pedestal Part No: 0021-22028

Cover Ring Part No: 0020-24914

Process: Pre-clean

Pedestal type: Preclean II Pik1

Power supply 1: 400 KHz

Power supply 2: 13.56 MHz

Gasline fittings: VCR

Loadlock fittings: VCR

MFC type: Millipore / STEC

Paste chamber: NA

Chamber cryo pump type: CTI 8F Enhanced Fast Regen Low Vib

Umbilicals:

Mainframe to controller: ~25 ft

Mainframe to generator racks: ~25 ft

Mainframe to cryo compressor: ~25 ft

Main AC to system controller/sys. AC: ~25 ft

Syst cont/sys AC to primary Gen rack: ~25 ft

Main AC to primary generator rack: ~25 ft

Main AC to pump frame: ~25 ft

Main AC to Neslab heat exchanger: ~25 ft

Monitor cable: ~25 ft

Monitor2 cable: ~25 ft

Monitor3 cable: ~15 ft

EMO button guard ring: Yes

Water leak detector: yes

Buffer and transfer lid hoist: Yes

Support Equipment:

AMAT 0 Heat exchanger 0010-76467

Cryo compressors:

(2) CTI Cryo pump 1 8135900G001

Neslab with resistivity meter

Soft copy pdf manuals

Currently in a fab

2003 vintage.

AMAT / APPLIED MATERIALS / AKT Endura 5500 Reactor is an advanced, cost-effective multipurpose cluster tools that provide improved performance requirements for demanding wafer fabrication processes. This reactor is capable of providing a reliable and uniform environment during the etching and deposition processes. AKT Endura 5500 Reactor is specifically designed for singles, dual and multi-chamber operations, using an advanced vacuum equipment with superior gas distribution and a variety of options. AMAT ENDURA 5500 is built with a compact design that requires minimal space and takes up less than 3 cubic meters, allowing it to fit into any production process with ease. AKT ENDURA 5500 allows for easy positioning in three dimensional directions, making it more efficient and easier to set up and run. APPLIED MATERIALS Endura 5500 also has a unique cooling system that allows for faster throughput and cooling between runs. This multi-purpose cluster tool also provides options for etching and deposition processes. Endura 5500 includes a modular etch and deposition chamber design that allows for deposition to be performed as etching takes place in the same space. This multipurpose feature ensures that a wide variety of processes are able to be completed within the one reactor. The Endura 5500Reactor provides low cost and low maintenance with excellent performance and durability. Its gas delivery unit lends itself to increased throughput and improved product yield. AMAT / APPLIED MATERIALS / AKT ENDURA 5500's high vacuum capabilities improve quality and repeatability while eliminating wafer edge effects. ENDURA 5500 comes with a wide range of control options which provides a high level of control and accuracy for both etching and deposition processes. The reactor includes both a process control machine and an operator panel for greater operator convenience. The control tool can manage multiple process parameters with quick process development, high performance and accuracy. APPLIED MATERIALS ENDURA 5500's advanced features and compact design make it the perfect choice for a number of applications. Its flexibility and easy installation allow it to be integrated into any process while providing optimized results and exceptional performance. The reactor can handle any process from etching to deposition with low cost, high repeatability, and improved throughput.

There are no reviews yet