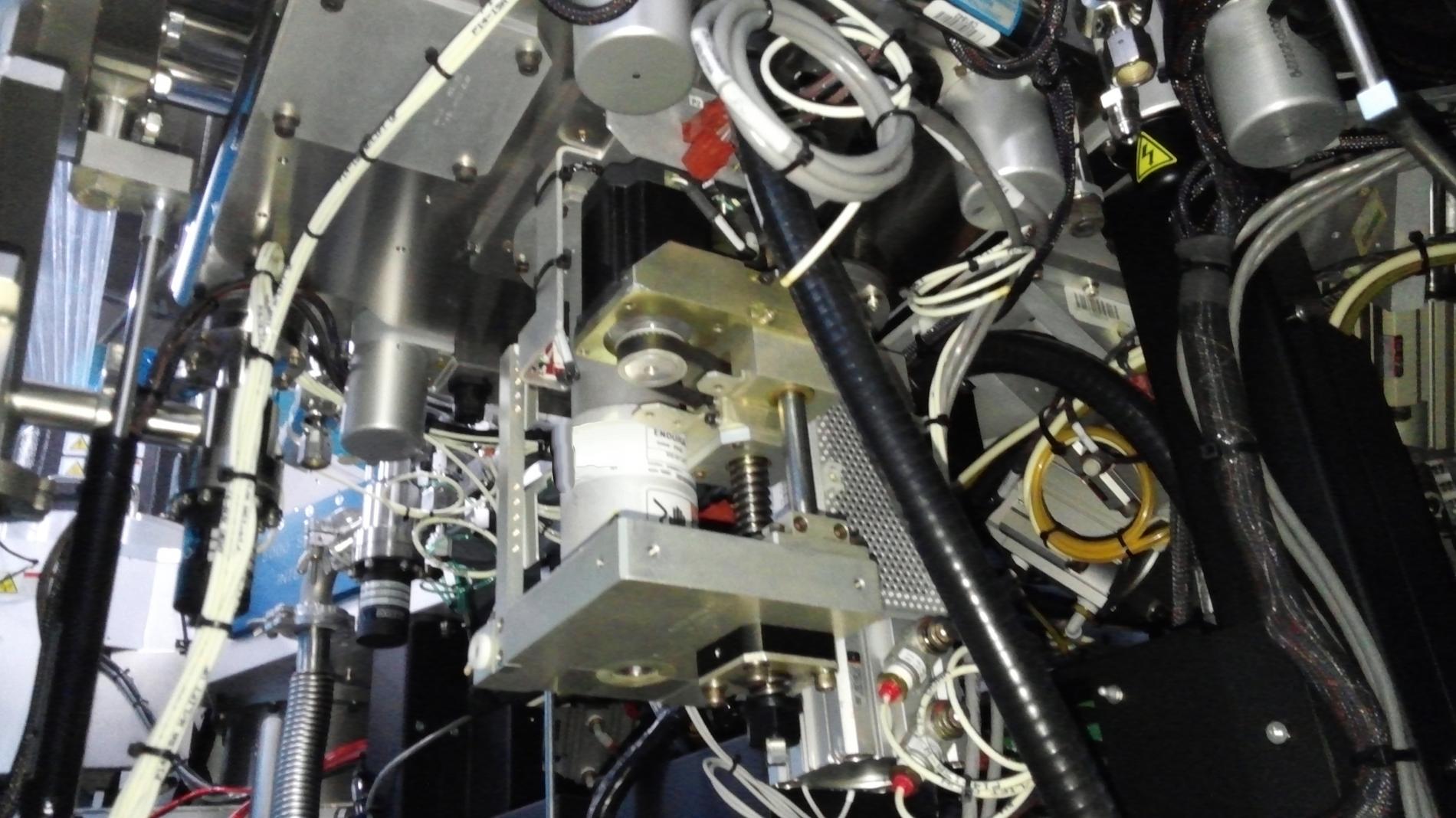

Used AMAT / APPLIED MATERIALS Endura 5500 #9134838 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9134838

Vintage: 1999

Frame,

AL sputter

Chamber information

a) Chamber A

- Chamber type: pass thru

- Chamber lid: metal lid

b) Chamber B

- Chamber type: cool down

- Chamber lid: metal lid

- Cooling method: By PCW / by gas

c) Chamber C

- Chamber type:

- Chamber process: PC II

- RF gen/DC power supply 1: Preclean

- RF gen/DC power supply 2: CPS-1001

- Turbo/cryo pump type: LF-10

- Turbo/cryo pump Type: 361C

e) Chamber E

- Chamber type: orient/degas

f) Chamber F

- Chamber type: orient/degas

g) Chamber 1

- Chamber type: wide body

- Chamber process: TiN

- RF gen/DC power supply 1: MDX-L12

- Turbo/cryo pump type: CTI OB-8F

- Gate Valve: 2 Position

h) Chamber 2

- Chamber type: STD body

- Chamber process: AL

- RF gen/DC power supply 1: MDX-L12

- Turbo/cryo pump type: CTI OB-8F

- Gate Valve: 2 position

i) Chamber 3

- Chamber type: STD body

- Chamber process: AL

- RF gen/DC power supply 1: MDX-L12

- Turbo/cryo pump type: CTI OB-8F

- Gate Valve: 2 position

j) Chamber 4

- Chamber type: STD body

- Chamber process: AL

- RF gen/DC power supply 1: MDX-L12

- Turbo/cryo pump type: CTI OB-8F

- Gate Valve: 2 position

j) System component

System Controller

- V440 SBC

- Ion gauge controller

- 15V, 24V DC power supply

- 5Ph driver

- 2Ph driver

Generator rack#1

- MDX-L12 3ea , MDX-L18 1ea

- Turbo controller 1ea

Generator rack#2

- CPS-1001 , LF-10

Cryo compressor

- 9600 comp 2ea

AC rack

- Short body

Cryo Pump

- 2Ph cryo OF-8F 6ea

1999 vintage.

AMAT / APPLIED MATERIALS / AKT Endura 5500 is a semiconductor in-line reactor that is used to deposit a wide variety of layers onto semiconductor wafers. This reactor utilizes a vapor chemical deposition (VCD) process to produce ultra-smooth, high efficiency layers. AKT Endura 5500 is designed to enable process engineers to quickly and easily setup their VCD processes. AMAT ENDURA 5500 is a production-level reactor with a short cycle time and high throughput. It can produce up to a dozen wafers per hour, with a cycle time of just 5 seconds per wafer. The reactor's adaptive control technology continuously adjusts and optimizes the process parameters, ensuring consistent, high-quality films. AMAT / APPLIED MATERIALS / AKT ENDURA 5500 offers enhanced control over the process with its in-line, closed-loop control system. This system is able to provide real-time detection and feedback of key process parameters, such as temperature, pressure, film thickness, and uniformity, allowing for the efficient control of deposition processes and guaranteeing consistent layers. In addition, AMAT Endura 5500 offers full integration with other semiconductor processing equipment and can be connected to newly-built process tools, as well as retrofitted to existing tools. The reactor offers 0.1° of repeatability in heating and cooling operations, ensuring repeatable results. APPLIED MATERIALS Endura 5500 utilizes a vapor chemical deposition process to deposit layers onto wafers with exceptional speed and characteristics. This VCD process utilizes filaments of metal-containing material, which is heated and then vaporized. When the vaporized material reaches the wafer, it is transformed into a thin film layer. This method of layer production eliminates the need for masking, allowing for the production of layers with high speed and accuracy. APPLIED MATERIALS ENDURA 5500 can generally produce low resistivity tungsten layers, as well as copper tungsten and aluminum layers with characteristics such as high electrical and thermal conductivity, and low resistivity. This makes the reactor suitable for a wide variety of semiconductor processes, such as IC devices, MEMs devices, and various types of LED and optoelectronic products. AKT ENDURA 5500 is a production-level reactor with an exemplary level of control over deposition processes, accurate and consistent results, and integration with existing processing equipment. This is an indispensable tool for any semiconductor manufacturing process.

There are no reviews yet