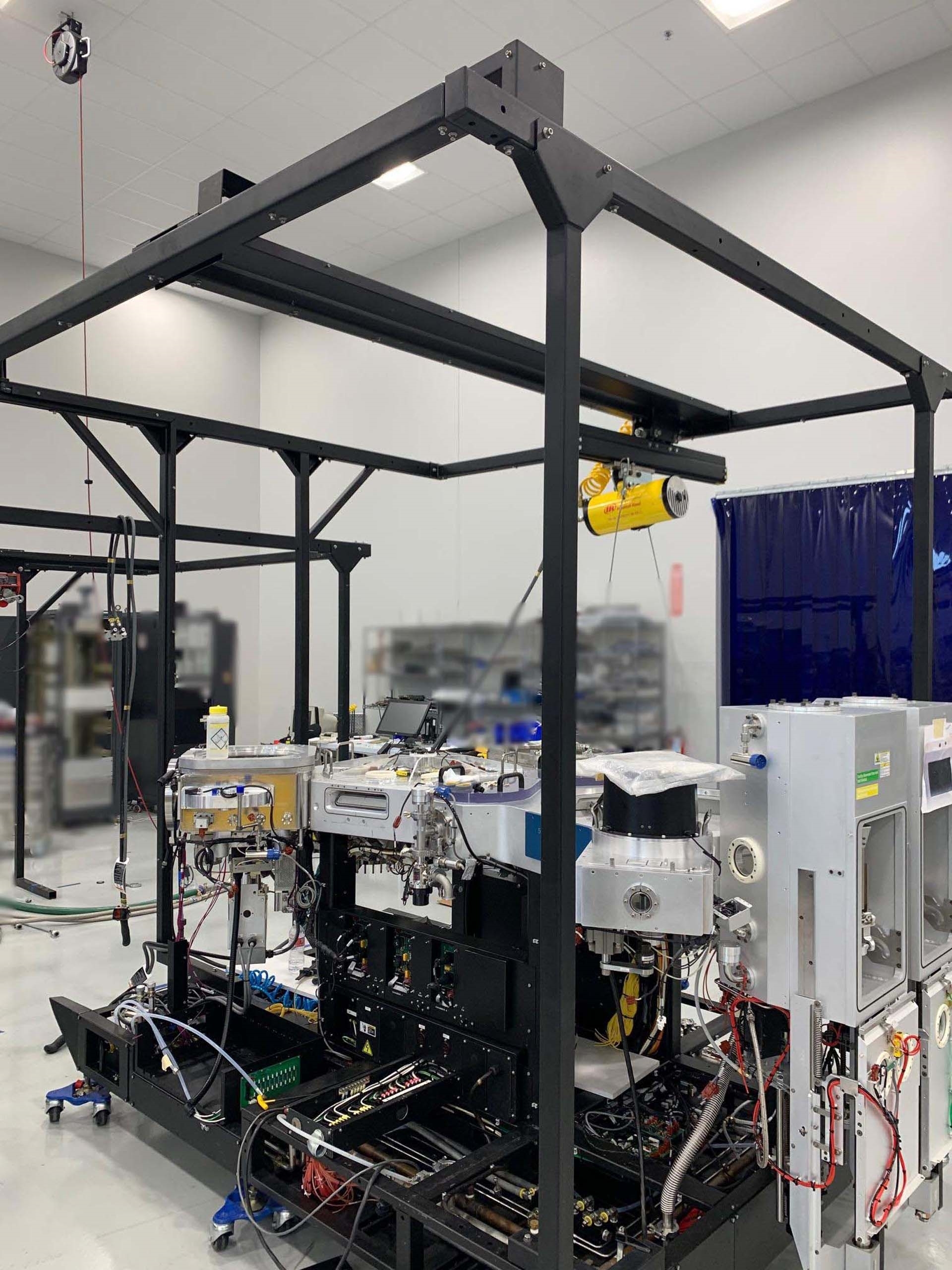

Used AMAT / APPLIED MATERIALS Endura 5500 #9177283 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9177283

Wafer Size: 8"

System, 8"

Wafer shape: SNNF

Chamber 1: SIP Cu

Process 1: Low temperature Cu

Chamber 2: Wide body

Process 2: TTN

Chamber 3: Wide body

Process 3: TTN

Chamber 4: SIP Cu

Process 4: Low temperature Cu

Chamber A: Pass through

Chamber B: Cooldown

Chamber E: Orient / Degas

Chamber F: Orient / Degas

Transfer robot type: HEWLETT-PACKARD

Transfer robot blade: Metal

Buffer robot type: HEWLETT-PACKARD

Buffer robot blade: Metal

Loadlock type: Narrow BD with tilt out

Signal tower: 4 Color R/G/Y/B

MF Facilities: Bottom

System umbilical: 25 ft

EMIs: Turn to release

No facility power (UPS)

No loadlock pump

Loadlock slit valve O-Ring: Viton (Black)

Heat exchanger 1: NESLAB

Heat exchanger 2: M-Pack

Hard drive: SCSI

(2) CRTs

No GEM

No OTF

Main AC box: 480 V type, wide type

Chamber A:

Chamber type: Pass through

Gas valves: Fujakin

Slit valve o-ring: Viton (Black)

Clear chamber lid

Chamber B:

Chamber type: Cooldown

Gas valves: Fujakin

Slit valve o-ring: Viton (Black)

Heater / Cathode cooling: PCW

Clear chamber lid

Chamber 1:

Chamber type: SIP Cu

Manometer config: Single

Manometer 1: 100 mTorr

Slit valve o-ring: Viton (Black)

Shutter option

Chamber process: Low temperature Cu

Lid type: SIP Source

RF Gen / DC Supply 1: ADVANCED ENERGY MDX-L6

Susceptor / Pedestal: Low temperature ESC

Wall cooling: PCW

Heater / Cathode cooling: M-Pack

Gate valve position: 3-Pos

Process kit type: SIP

Chamber pump: Enhanced 3 phase cryo

Magnet number: 0010-21676

Gas 1:

MFC Size: N2 100 Sccm

Gas name: AR

MFC Type: STEC 7440

MFC Number: MFC16

Gas stick configuration: Single

Chamber 2:

Chamber type: Wide body

Manometer config: Single

Manometer 1: 100 mTorr

Slit valve O-Ring: Viton (black)

Shutter option

Chamber process: TTN

Lit type: G12

RF Gen / DC Supply 1: ADVANCED ENERGY MDX-650 HiZ

Susceptor / Pedestal: A101

Heater / Cathode cooling: PCW

Gate valve position: 3-Pos

Process kit type: A101

Chamber pump: Enhanced 3 phase cryo

Magnet number: 0010-21844

Chamber 3:

Chamber type: Wide body

Manometer config: Single

Manometer 1: 100 mTorr

Slit valve o-ring: Viton (black)

Shutter option

Chamber process: TTN

Lit type: G12

RF Gen / DC Supply 1: ADVANCED ENERGY MDX-650 HiZ

Susceptor / Pedestal: A101

Heater / Cathode cooling: PCW

Gate valve position: 3-Pos

Process kit type: A101

Chamber pump: Enhanced 3 phase cryo

Magnet number: 0010-21844

Chamber 4:

Chamber type: SIP Cu

Manometer config: Single

Manometer 1: 100 mTorr

Slit valve o-ring: Viton (black)

Shutter option

Chamber process: Low temperature Cu

Lit type: G12

RF Gen / DC Supply 1: ADVANCED ENERGY MDX-L6

Susceptor / Pedestal: Low temperature ESC

Heater / Cathode cooling: NESLAB III

Process kit type: SIP

Chamber pump: Enhanced 3 phase cryo

Magnet number: 0010-21676

Power supply: 208 VAC, 3 Phase, 5 wire, 400 A.

AKT/AMAT / APPLIED MATERIALS / AKT Endura 5500 is a reactor equipment designed for advanced etching applications. This tool is capable of reaching extremely high throughputs, featuring a twin process chamber design which allows simultaneous operation of both etch and clean processes. AKT Endura 5500 has a large process window and is able to support 2.6-um devices with low temperature etch and clean. AMAT ENDURA 5500 is equipped with patent-pending DC pulsed plasma source for high selectivity etching, as well as a large area plasma that allows for higher etch rate on certain films. This system is able to achieve repeatable etch rate uniformity of <2% across wafers with a high etch uniformity over the entire substrate. APPLIED MATERIALS Endura 5500 also boasts a robust process control unit that allows for real-time recipes and monitoring of parameters such as substrate temperature, etch rate, and etch uniformity. This reactor machine also features an integrated cluster tool that provides a cluster solution for non-stop automated end-to-end processing. Endura 5500 has a broad range of flexible substrate transfer space as well as cassette to cassette, substrate to cassette, and direct cassette to cassette transfers. It also has an Advanced Process Control Module (APCM) that allows users to accurately monitor, analyze, and modify their process recipes. AMAT Endura 5500 is equipped with an on-board monitoring and control asset, making it a reliable and stable platform for demanding processes. This control model features PID control and feedback deviation monitoring. PID control allows for accurate and repeatable process stability while feedback deviation monitoring ensures the process runs in a pre-defined range. In addition, AMAT / APPLIED MATERIALS / AKT ENDURA 5500 has a low maintenance design, with over 200 points of diagnostics. This includes an integrated preventative maintenance equipment, advanced process diagnostics, and remote monitoring features. This helps reduce downtime, as it allows users to quickly identify and solve problems. Overall, AKT ENDURA 5500 is an advanced reactor system designed for etching applications. It features a twin process chamber design, a DC pulsed plasma source, a control unit for recipe adjustment, an advanced cluster machine, and low maintenance design. These features make APPLIED MATERIALS ENDURA 5500 highly efficient and reliable, making it a great choice for cutting-edge etching processes.

There are no reviews yet