Used AMAT / APPLIED MATERIALS Endura 5500 #9186543 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9186543

PVD Systems, 12"

INTEL FAB68

Intel original configuration Process group Retrofit B

(2) TTN, NiPt NISPUT (2) SiCoNi + (NiPt+NiPt) + (2) Versa TTN+Degas

(2) TTN, NiPt CUALSPUT MHM (2) TTN+TTN+Degas

CU, TTN, PCXT CUSPUT LDR PCXT + PCXT + (2) EnCoRe II TaN + Cu + Cu + Degas

Suspect CU, TTN, PCXT BSI-BATTN PCXT + PCXT + (2) IMP Ti + (2) CVD TiN + Degas

CU, TTN, PCXT BSI-PADAL PCXT + PCXT + Versa TTN + TTN+(2) HP Al + Degas.

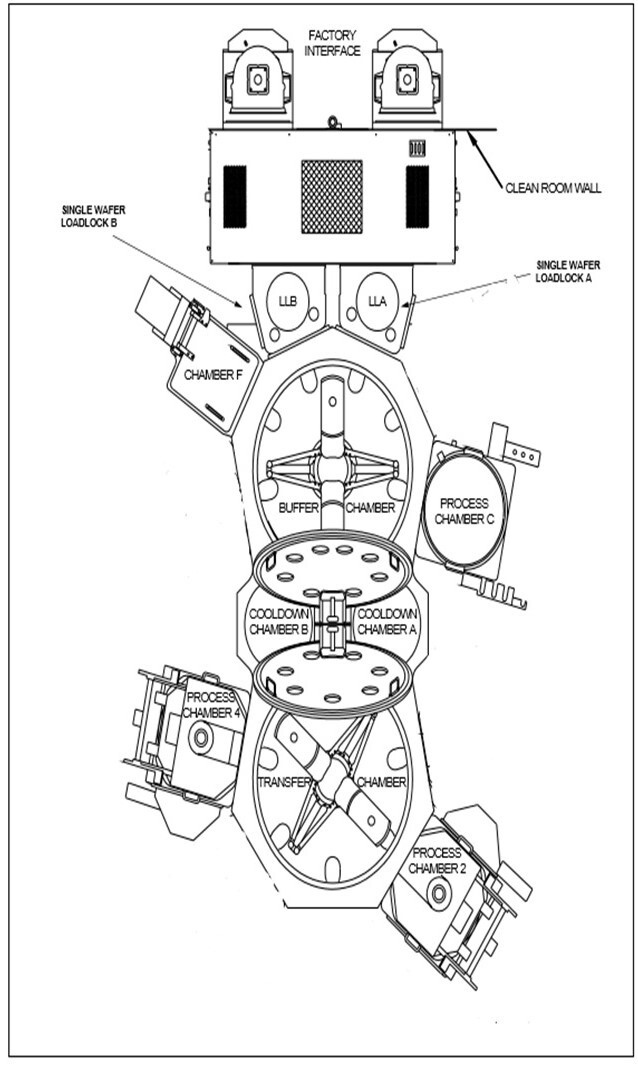

AKT/AMAT / APPLIED MATERIALS / AKT Endura 5500 is a full wafer process reactor specifically designed for advanced dielectric etching in the semiconductor industry. This reaction tool offers best-in-class etch uniformity and advanced control of pressure, temperature, and flow. It's optimal for creating high-aspect ratio dielectric features with high productivity and superior process control. AKT Endura 5500 provides exceptional performance combined with superior beam generation. It performs at process related temperatures between 25-200 degrees Celsius, with bias voltages between 0-600 VDC, and an adjustable pressure range between 0.2-1.0 torr. The reaction chamber utilizes advanced multi-chamber designs that result in improved stability and greater process flexibility. The system includes a high-performance multi-cathode design, offering superior power delivery for advanced dielectric etching. The reactor offers advanced automatic parameter control so the user to easily monitor, control, and adjust process parameters such as temperature, pressure, flow and voltage. This helps ensure processes are optimally adjusted and monitored for consistent and repeatable results. It also includes advanced feedback compensation, providing real-time pulse-width-modulated power control for improved performance and increased accuracy. AMAT ENDURA 5500 is equipped with an upgraded, nitrogen-cooled liner for use in etching high aspect ratio features, and optimized for resisting particles, protecting the process and plasma from contamination. The integrated Liner Shield increases production consistency and efficiency. It also has an advanced air-blowback cleaning system, combining high-pressure air blasts and increased plasma generation to thoroughly clean the process system. The reactor also includes advanced user-friendly software. Using high-performance modeling, the software can determine the most efficient process parameters for virtually any process application. This helps to reduce variability and optimize processes for optimal performance. In conclusion, AMAT/AMAT / APPLIED MATERIALS / AKT ENDURA 5500 is one of the premier full-wafer process reactors specifically designed for advanced dielectric etching. It's optimal for creating high-aspect ratio dielectric features with high productivity and superior process control. The reactor includes a variety of advanced features to ensure users get fast and reliable results.

There are no reviews yet