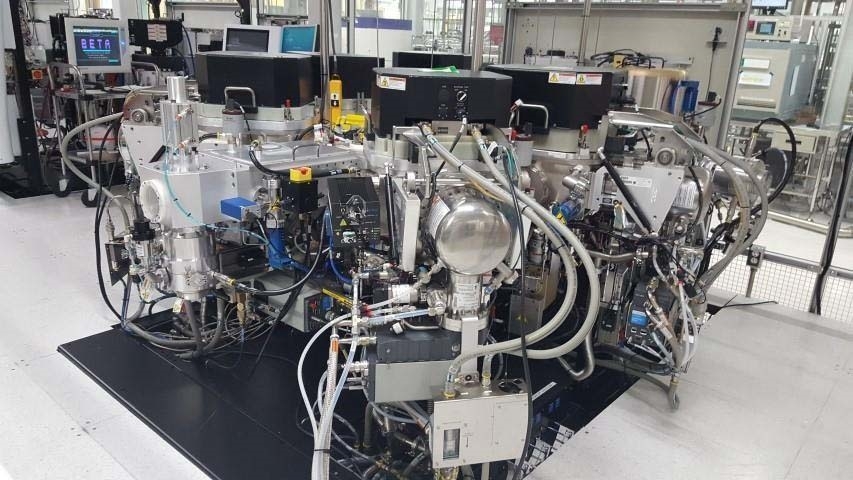

Used AMAT / APPLIED MATERIALS Endura 5500 #9193776 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9193776

PVD Metal system

Voltage: 480VAC, 30

Frequency: 60Hz

Max system rating: 150KVA

Ampere rating of largest load: 172-8A

Interruot current: 10,000 AMPS

Full load current: 172.8A

Chamber 1: MoCr

Chamber 2: AlCu

Chamber 3: AlSi

Chamber 4: AlNd

Chamber D: IGZO.

AKT/AMAT / APPLIED MATERIALS / AKT Endura 5500 is a SmartCluster deposition and etch equipment for the Advanced Packaging Interconnect (API) market. AKT Endura 5500 is engineered to deliver leading-edge device performance, quality and yields in a space-efficient and cost effective platform. AMAT ENDURA 5500 uses sophisticated material deposition technologies such as atomic layer deposition (ALD), atomic layer etch (ALE), chemical vapor deposition (CVD), plasma enhanced chemical vapor deposition (PE CVD) and plasma etch (PE). It also supports several non-volatile memory technologies that enable it to form 3D FinFET level structures. The integrated SmartCluster architecture provides a dedicated etch system for each chamber to maximize flexibility and minimize process cycle times. AMAT / APPLIED MATERIALS / AKT ENDURA 5500 has Smart Modular Cassette (SMC) technology for increased throughputs and throughput uniformity. The modular chambers are built with materials and components suitable for extreme temperatures and pressures, enabling the unit to be used in both low and high temperature processes. AKT ENDURA 5500 can be equipped with a range of ancillary equipment such as metal deposition systems, atomic layer etch (ALE), an ion implanter, and critical dimension scanning electron microscope (CD-SEM). Together these features enable ENDURA 5500 to deliver defect-critical materials deposition and etch processes. Endura 5500 provides a wide range of process capabilities due to its dual independently configurable chambers. It is capable of processing high-k materials, such as Ge, as well as lower k materials, such as SiC and SiN. AMAT Endura 5500 also supports ultra-thin film processes with thicknesses down to 2 nanometers. In addition to its etch and deposition capabilities, APPLIED MATERIALS Endura 5500 also provides advanced process control methods such as cluster temperature control, uniformity mapping and cluster fault diagnostics. Visual tracking process monitoring is enabled through an integrated web-based monitoring machine. The comprehensive material data management tool allows for easy data access and global access to process recipes. APPLIED MATERIALS ENDURA 5500 is the perfect tool for advanced interconnects manufacturing and is ideal for a range of applications, including 2.5/3D packaging, MEMS/TSV, MEMS/non-memory, integrated fan-out packaging and more. Its dual-chamber capability, modular architecture and flexible process capabilities enable customers to scale the asset to address their specific process needs.

There are no reviews yet