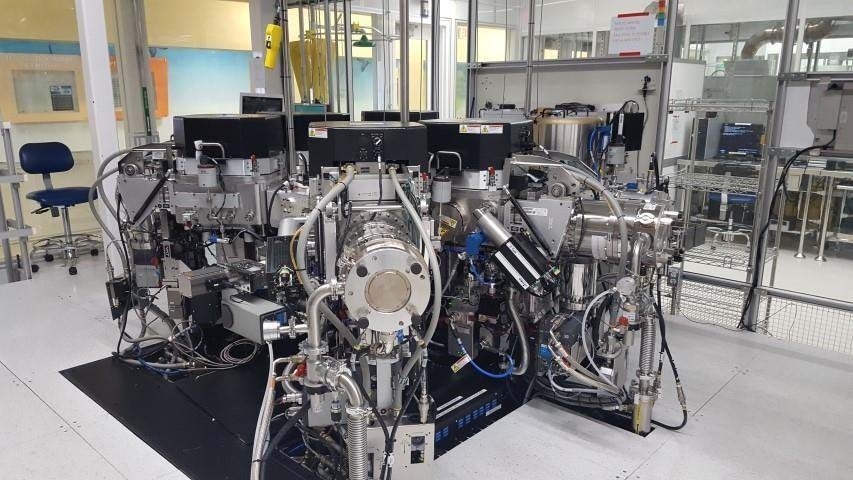

Used AMAT / APPLIED MATERIALS Endura 5500 #9193779 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9193779

Vintage: 2005

Oxide system

Voltage: 480VAC, 30

Frequency: 60Hz

(3) Wires / Ground

Max system rating: 150KVA

Ampere rating of largest load: 172-8A

Interrupt current: 10,000 AMPS

Full load current: 172.8A

(5) Chambers:

Chamber 1: Ti

Chamber 2: Zr

Chamber 3: Mo

Chamber 4: Cr

Chamber D: Ta

2005 vintage.

AMAT / APPLIED MATERIALS / AKT Endura 5500 reactor is a state-of-the-art chemical vapor deposition equipment designed for high-quality research and production needs. It features intuitive, user-friendly software, as well as precise engineering and advanced process control. AKT Endura 5500 is well-suited for a variety of applications, including deposition of ultra-thin layers of materials and precursors, inorganic and organic chemical vapor deposition (CVD) of metal oxide and metal nitride thin films, and atomic layer deposition (ALD). It is an ideal choice for large area thin film growth with its large susceptor size, quick response time, highly customizable chamber configurations, and fast ramp rates. The metal-sealed AMAT ENDURA 5500 system features automated wafer handling, programmable chamber configurations, and a modular electrical unit. For ultra-thin layer deposition, AKT ENDURA 5500's factory-tuned source configurations deliver precise control over the deposition process. These precision sources reduce substrate-substrate interference to ensure uniform deposition. APPLIED MATERIALS Endura 5500 also features dual deposition source ports, enabling the user to deposit multiple materials simultaneously. The 5500 is built on a base platform designed for easy integration in both high and medium vacuum processes, ranging from wafer-scale thin film deposition to gas-phase synthesis of nanostructures. Its stainless steel construction provides superior mechanical stability. The chamber walls feature high vacuum-compatible flex feed-throughs that provide external access to the interior of the chamber for tools and process sensors. APPLIED MATERIALS ENDURA 5500 employs an in-situ load lock machine for fast and efficient handling of up to 300mm wafers, featuring gas purging and thermal bake-out capabilities for testing process conditions prior to introduction into the main deposition chamber. This load lock tool helps minimize contamination, ensuring uniform, reproducible thin film deposition. The 5500 includes advanced temperature and pressure control systems to optimize each process. Each process is engineered to ensure precise temperature control throughout the chamber. An optional Bubbler-based humidity control asset allows the user to use various sources, such as wet precursors and reactants and humidified gases, to support deposition of material with excellent uniformity. The model has multiple safety features, including an ion gauge overpressure monitoring equipment that monitors chamber pressure at all times. An array of safety sensors is constantly monitored, and the system is equipped with a wide array of HMI and alerts to ensure unit integrity. Overall, ENDURA 5500 is a robust and reliable machine, offering a sophisticated and intuitive control platform for optimum thin film deposition. Its user-friendly software, versatile chamber configurations and load lock tool, and advanced safety features make it an ideal choice for a variety of research and production applications.

There are no reviews yet