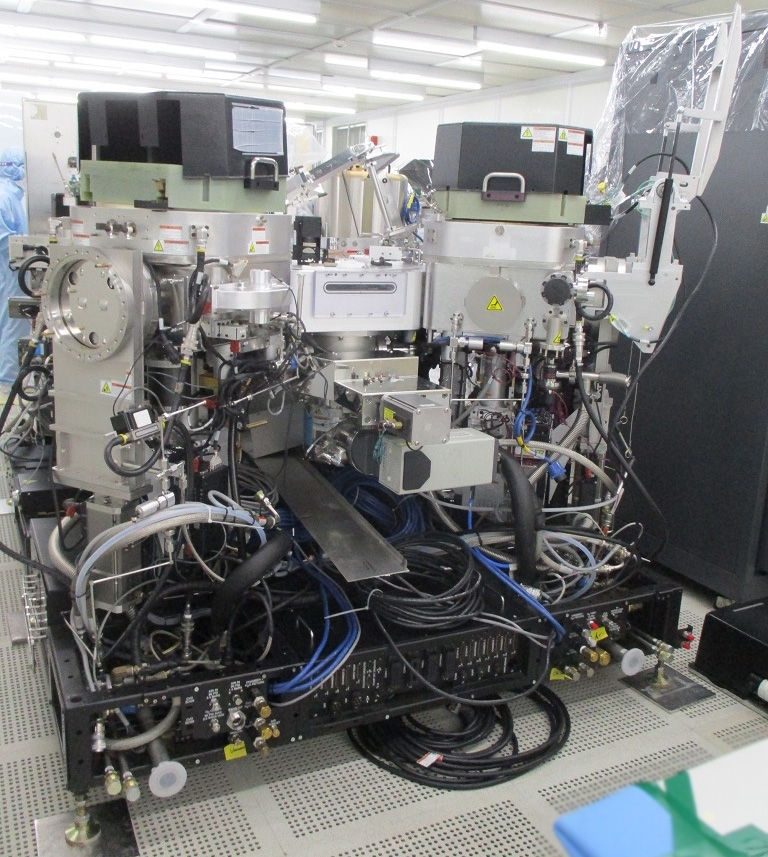

Used AMAT / APPLIED MATERIALS Endura 5500 #9208048 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9208048

Vintage: 2002

PVD System, 8"

Single board computer in controller: V452

Copper barrier / Seed

Wafer handling: SNNF

Front panel type: Light pen

Loadlock vents: Variable speed

Buffer / Transfer robot: HP

Blade material: Thin metal

Chamber A: Bypass

Chamber B: Cool

Chamber E: Degas

Chamber F: Degas

Chamber C: Pre clean

Vacuum pump type: Turbo/dry

RF Match: PVD 200

Cable length: 50 Feet

Pedestal type: Cylinder

Power supply 1: CPS-1001S

Power supply 2: RFPP LF10A

Chamber 1 / 2:

Body style: WB

Source type: VECTRA IMP

Power supply: MXD-L12M 12KW

Heater: B101

Dual TC amp kit: No

Pedestal: B101

Target: D-Bond

Magnet: RH-2

Magnet shim thx: 0.75 mm

Gasline fittings: VCR

Loadlock fittings: VCR

Process MFC-1: 1 Ar 100

Process MFC-2: 1 Ar 100

Paste chamber: No

System roughing pump type: Dry

Chamber cryo pump type: CTI OB-8F, 3 phase

Heat exchangers: 1000

Cryo compressors: 9600 X2

Umbilicals:

Mainframe to controller: 75 Feet

Mainframe to generator racks: 75 Feet

Mainframe to cryo compressor: 75 Feet

Main AC to system controller/sys AC: 75 Feet

System AC to primary generator rack: 50 Feet

Main AC to primary generator rack: 6 Feet

Main AC to pump frame: 50 Feet

Main AC to NESLAB heat exchanger: 50 Feet

Monitor cable: 50 Feet

2002 vintage.

AKT/AMAT / APPLIED MATERIALS / AKT Endura 5500 is a next-generation plasma-enhanced chemical vapor deposition (PECVD) reactor designed to provide reliable, high-performance performance deposition for wide range of thin-film applications in semiconductor device fabrication. The equipment utilizes advanced plasma technology to produce high-quality, uniform thin films with superior process control. AKT Endura 5500 reactor comes equipped with a compact, easily-serviceable design, and is well-suited for high-throughput manufacturing operations. The system allows users to set process parameters independently for each chamber, providing precise control and uniformity over the entire process. This ensures that thin film deposition is uniform and consistent, yielding high-quality results. AMAT ENDURA 5500 also utilizes a range of sophisticated plasma and gas-phase technologies to optimise process performance and enhance process reliability. By providing uniform deposition in a very consistent environment, the unit can produce thicker, thinner and multi-layer films with precise control and predictable results. Furthermore, AMAT / APPLIED MATERIALS / AKT ENDURA 5500 allows for excellent process control through its advanced integrated process monitoring, diagnostics and process optimization capabilities. Additionally, AMAT Endura 5500 also provides enhanced safety and reliability. The machine utilizes intelligent sensors to constantly monitor both plasma and temperature conditions. This provides real-time feedback on the status of the tool, allowing operators to quickly identify and address any potential performance issues. Overall, AMAT/Endura 5500 provides an easy-to-use, reliable, and efficient solution for the thin-film deposition needs of semiconductor device fabrication. With its advanced plasma technology and integrated process monitoring and optimization capabilities, APPLIED MATERIALS ENDURA 5500 provides reliable, uniform and precise deposition results that are perfect for high-volume production.

There are no reviews yet