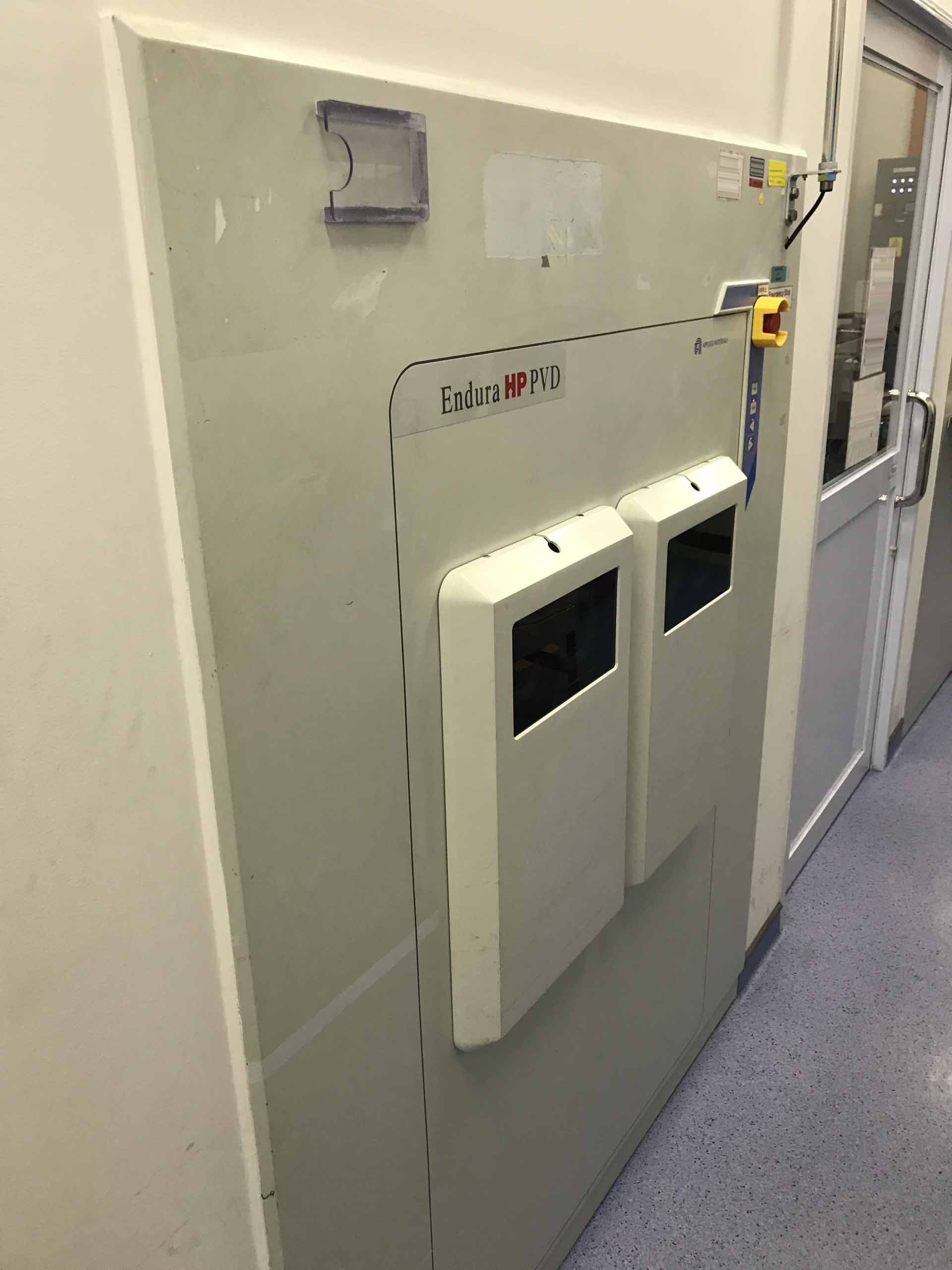

Used AMAT / APPLIED MATERIALS Endura 5500 #9221707 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9221707

Vintage: 1993

PVD System

Chambers:

(4) PVD chambers (2 TiN and 2 Al)

(2) Degas chambers

(1) Preclean chamber

CTI-CRYOGENICS / HELIX TECHNOLOGY 0120-60-4887

CTI-CRYOGENICS Roughing Valve 8112579G001

CTI-CRYOGENICS On-Board 8F Cryopump 8116142G001

CTI-CRYOGENICS Roughing Valve 8112579G001

CTI-CRYOGENICS On-Board 8F Cryopump 8116027G001

CTI-CRYOGENICS / HELIX TECHNOLOGY 0120-60-4887

CTI-CRYOGENICS SPLTR Box Tool 8135240G001

MKS Type 627 Pressure Transducer

MKS Type 627 Pressure Transducer

MKS Type 627 Pressure Transducer

CTI-CRYOGENICS Roughing Valve 8112579G001

CTI-CRYOGENICS SPLTR Box Tool 8135240G001

CTI-CRYOGENICS On-Board FastRegen Sputtering Control

CTI-CRYOGENICS On-Board 8F Cryopump 8116027G001

CTI-CRYOGENICS Roughing Valve 8112579G001

CTI-CRYOGENICS Valve 8112095

CTI-CRYOGENICS On-Board 8F Cryopump 8116027G001

CTI-CRYOGENICS On-Board FastRegen Sputtering Control

MKS Type 627 Pressure Transducer

Endura Wafer Lift Assembly 101 Rev. 003 0010-70271

8" Preclean II RF Match 0010-20524 (Label PN 0060-21140)

Endura Wafer Lift Assembly Preclean 2 Rev. 003, 21902-08

MKS Type 627 Pressure Transducer

0010-20277

8" Degas Lamp 350C 0010-20317

8" Degas Lamp 350C 0010-20317

CTI-CRYOGENICS On-Board Module 8113100G001

CTI-CRYOGENICS Roughing Valve 8112579G001

Gas Box #1 0010-20217 Rev. B

CTI-CRYOGENICS / HELIX TECHNOLOGY 0120-60-4887

CTI-CRYOGENICS On-Board 8F Cryopump 8116142G001

Loadlock A (11)

Loadlock B (0620-01049)

Operator Control Panel BD Assy. 0100-20032 Rev. D

ViewSonic E55 Monitor VCDTS21914-2M

Standalone VGA Monitor Base 0010-70386 Rev. A

Gas Box #2 0010-20218 Rev. B

Gen Rack #1

ADVANCED ENERGY MDX-L12M

ADVANCED ENERGY MDX-L12-650

ADVANCED ENERGY MDX-L12M-650

Gen Rack #2

ADVANCED ENERGY MDX-L12M

ADVANCED ENERGY MDX-L12M

Gen Rack #3

ADVANCED ENERGY LF10A

COMDEL RF Power Source CPS-1001S

GRANVILLE-PHILLIPS Ionization Gauge Supply 332102

15V PS Assembly

24V PS Assembly

CTI-CRYOGENICS On-Board 3PH MTR Control 8124063G001

CPRSR High Perf Model 9600 3620-01389 Rev. A

CTI-CRYOGENICS On-Board 3PH MTR Control 8124063G001

Thornton 200CR

CTI-CRYOGENICS 9600 Compressor 8135917G001

CTI-CRYOGENICS 9600 Compressor 8135909G001

NESLAB BOM # 327099991701

EBARA A30W

EBARA A70W

HARMONIC GEAR UGH50-28

VEXTA 5-Phase Stepping Motor A4249-9215HG

VEXTA 5-Phase Stepping Motor A4249-9215HG-A1

GEORG FISCHER V 82

Supply voltage: 480 VAC, 3 phase, 50/60 Hz

Max system rating: 150 kW

Largest load ampere rating: 42 A

Interrupt current: 10,000 Amps IC

1993 vintage.

AMAT / APPLIED MATERIALS / AKT Endura 5500 is a large-area plasma processing equipment designed for the semiconductor manufacturing industry. This system can be used to treat a variety of wafers, including silicon and sapphire, by plasma etching and deposition. It can also be used for a wide range of other purposes such as barrier layers, oxide layers, and thin film stacks. AKT Endura 5500 is a freestanding, fully-integrated unit that contains a process chamber, gas cabinets and process control modules. This allows for independent control of multiple functions including pressure, gas and power settings, making it possible to accurately tailor the process to specific applications. The machine also includes multiple shielding materials to protect users from the high voltages and temperatures present in the tool's environment. The asset is designed to control the process chamber's temperature, power, and gas flow to a high degree of accuracy. The power levels range from 300W to 5000W, which allows for a wide range of process settings. The chamber temperature is maintained between 1033 C and 1133C, while the pressure can range from 0.002 torr to 760 torr. Additionally, the chamber's flow rate can range from 0.18 liters/minute to 15 liters/minute. AMAT ENDURA 5500 also provides real-time in situ analysis with its Ion and Neutral Particle Mass Spectrometer (IPMS). This allows the operator to monitor the plasma environment and enables precise control of the process. Additionally, the model has an improved process control module that provides enhanced equipment diagnostics and process optimization. Furthermore, AKT ENDURA 5500 provides enhanced safety features, including a fault detection system and a protective gas envelope to contain any spillover. This ensures the safety of personnel and the integrity of the process. ENDURA 5500 is an efficient thermal processing unit designed to enable precise process control and repeatability. It is the ideal choice for fabrication and integration of advanced semiconductor devices. It provides a robust, cost-effective solution for processes such as etching and deposition of silicon wafers. With its real-time in situ analysis and its range of settings, the machine is ideal for a variety of applications.

There are no reviews yet