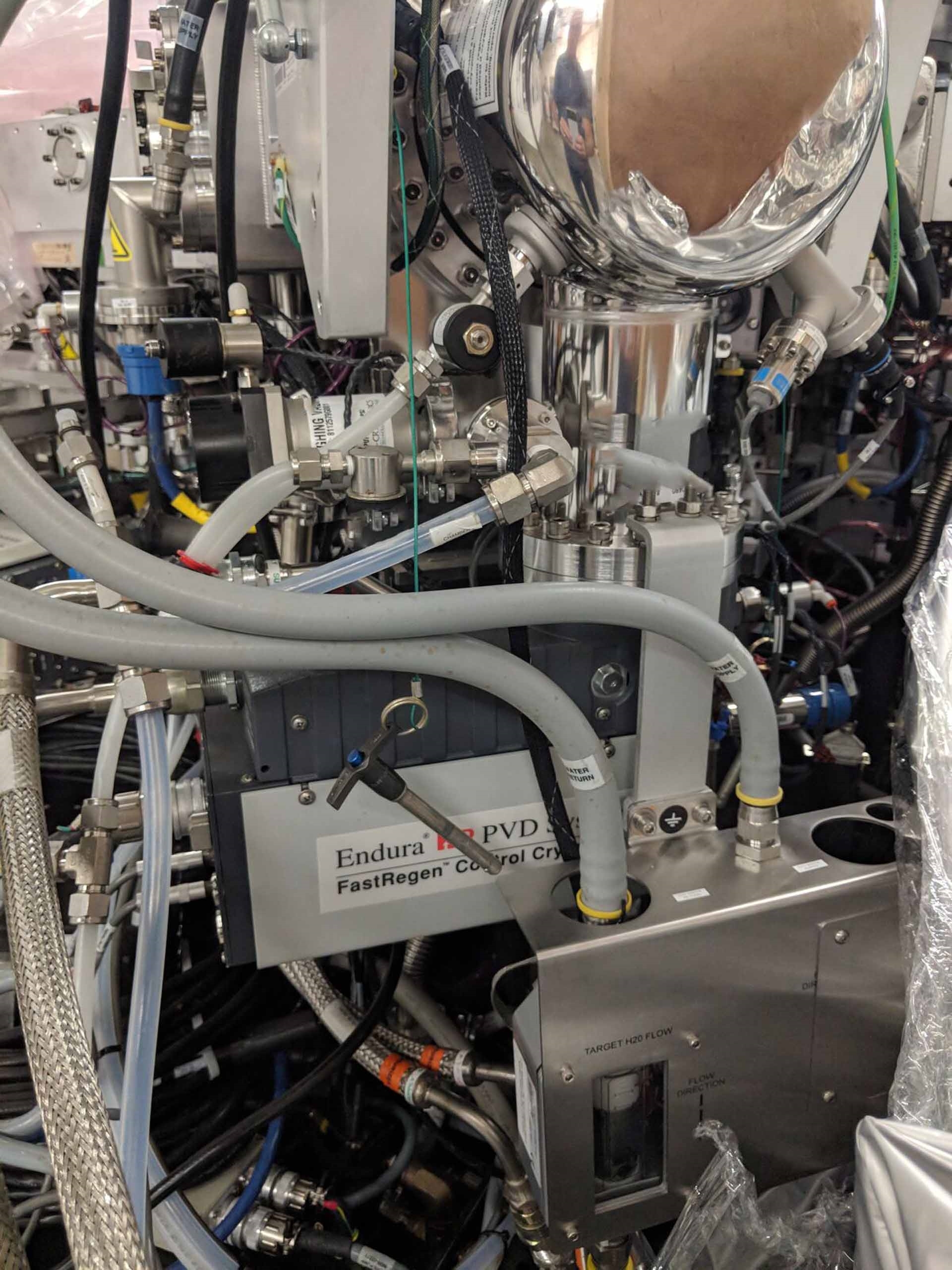

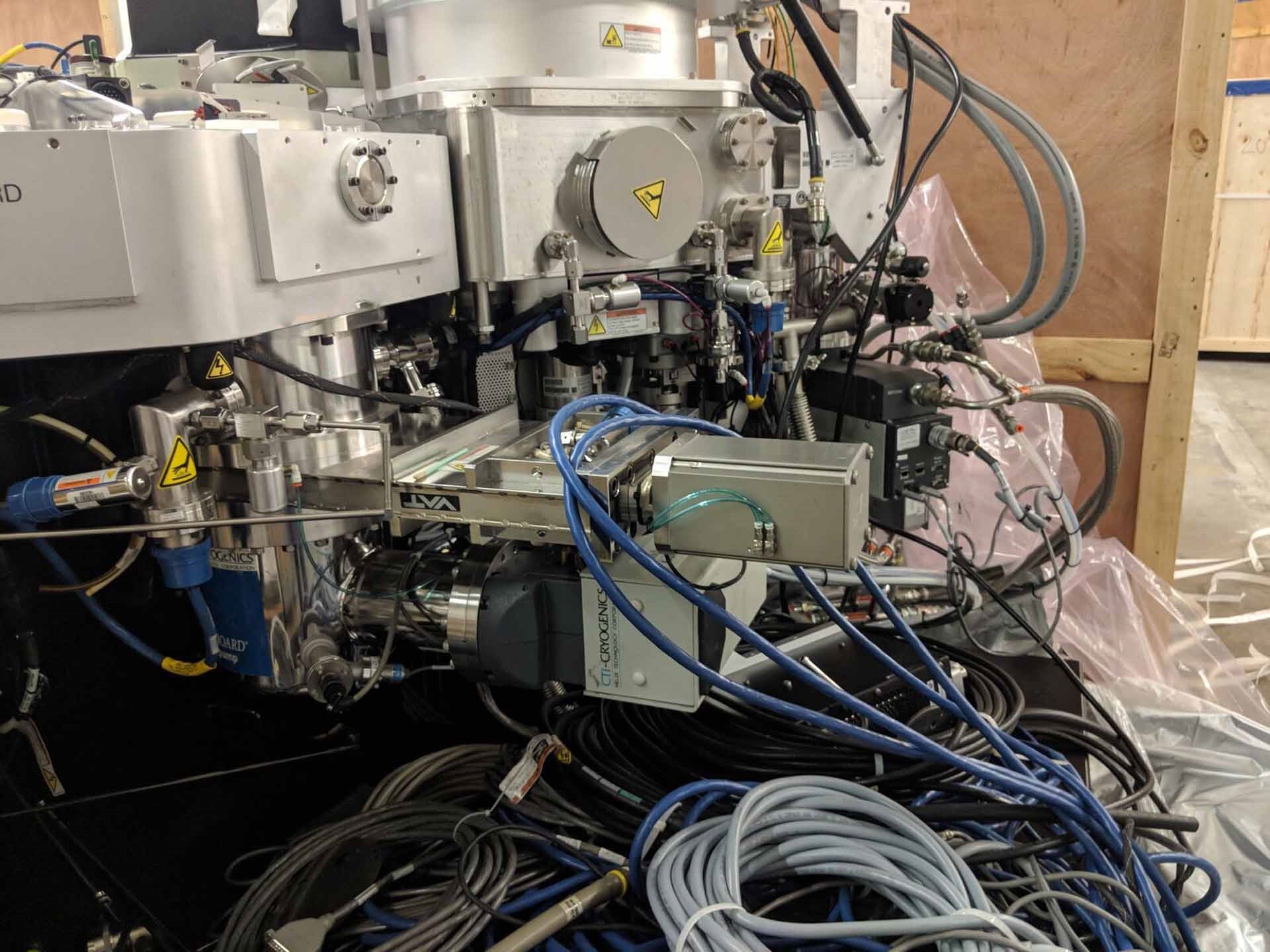

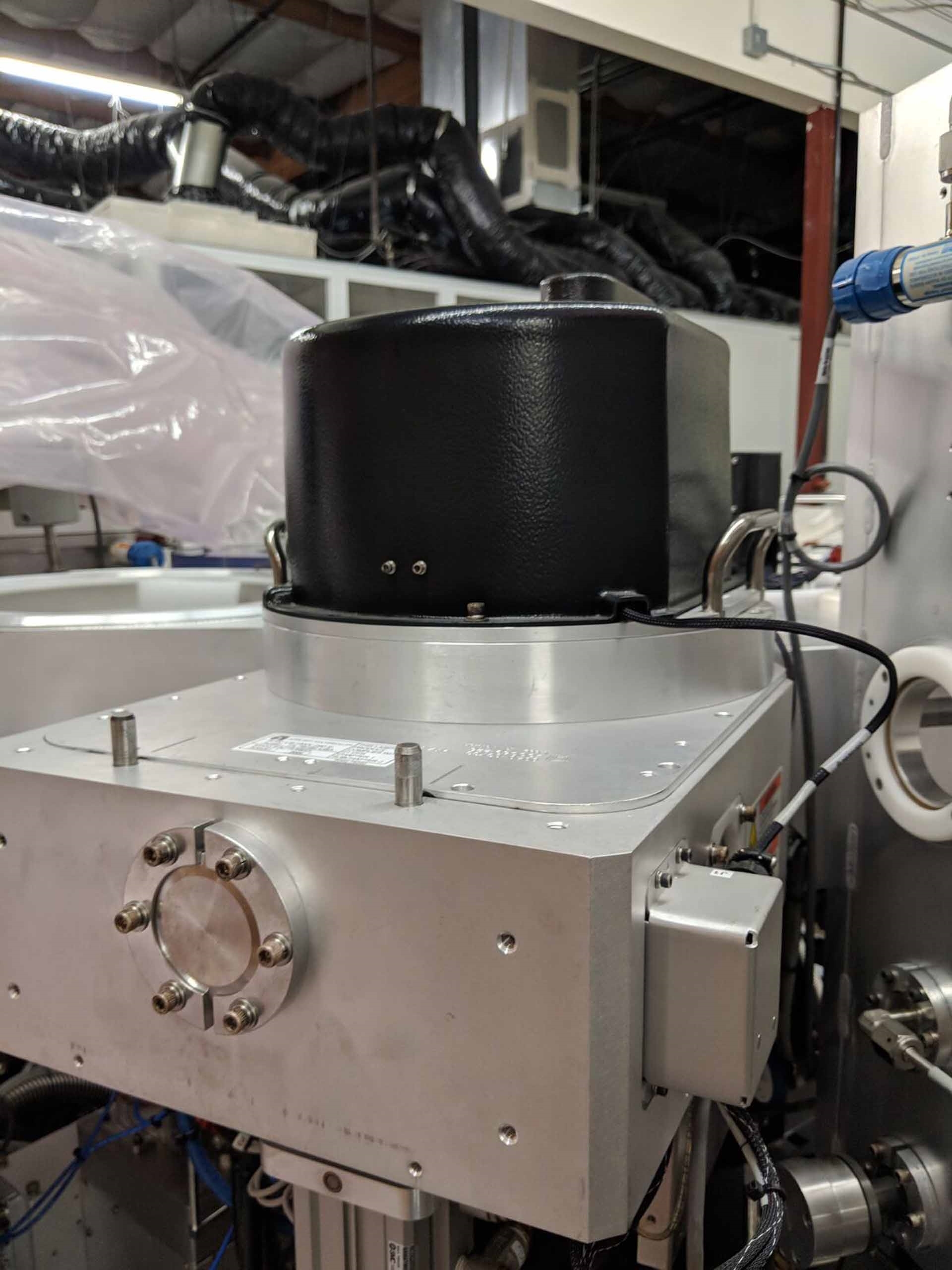

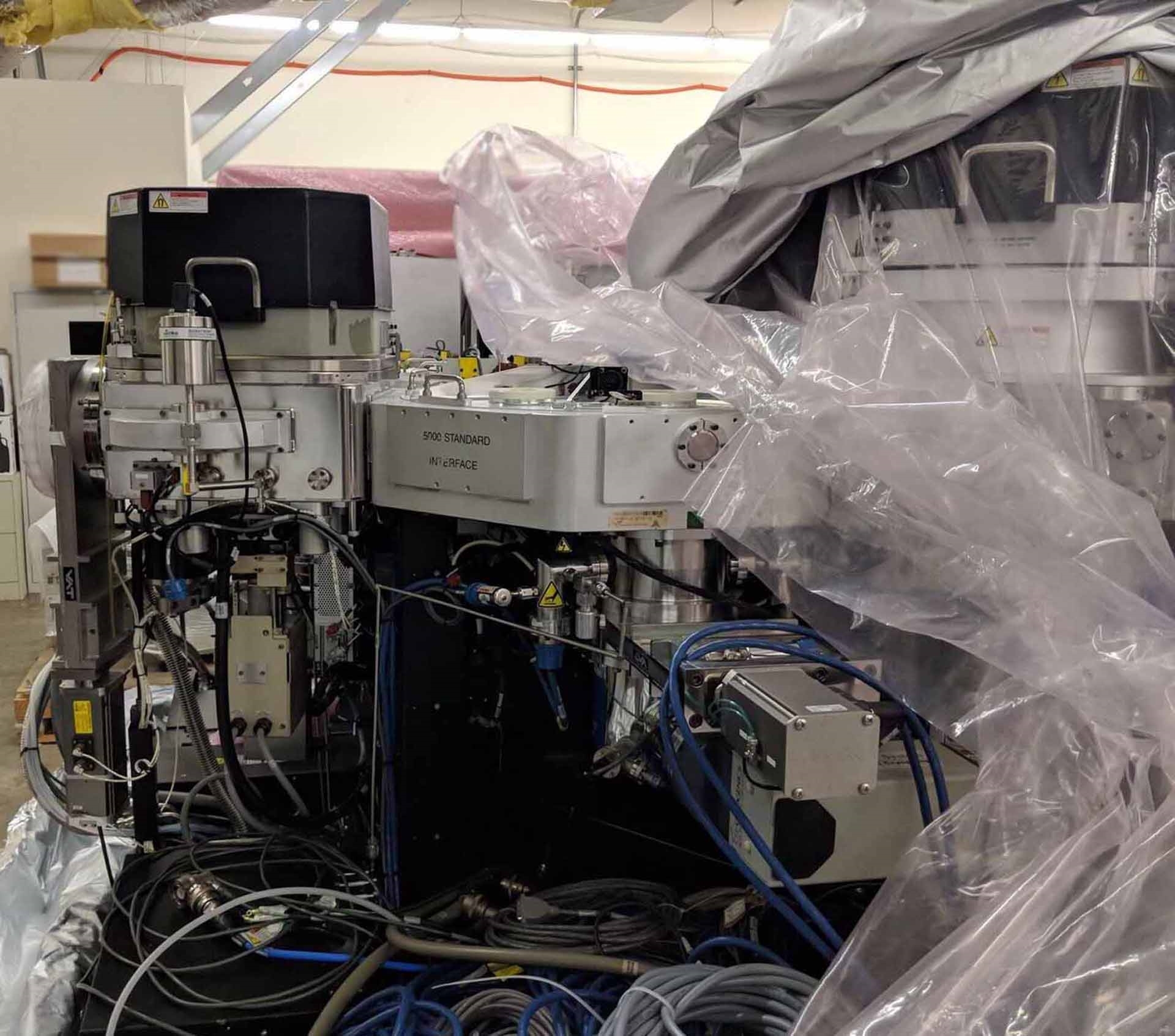

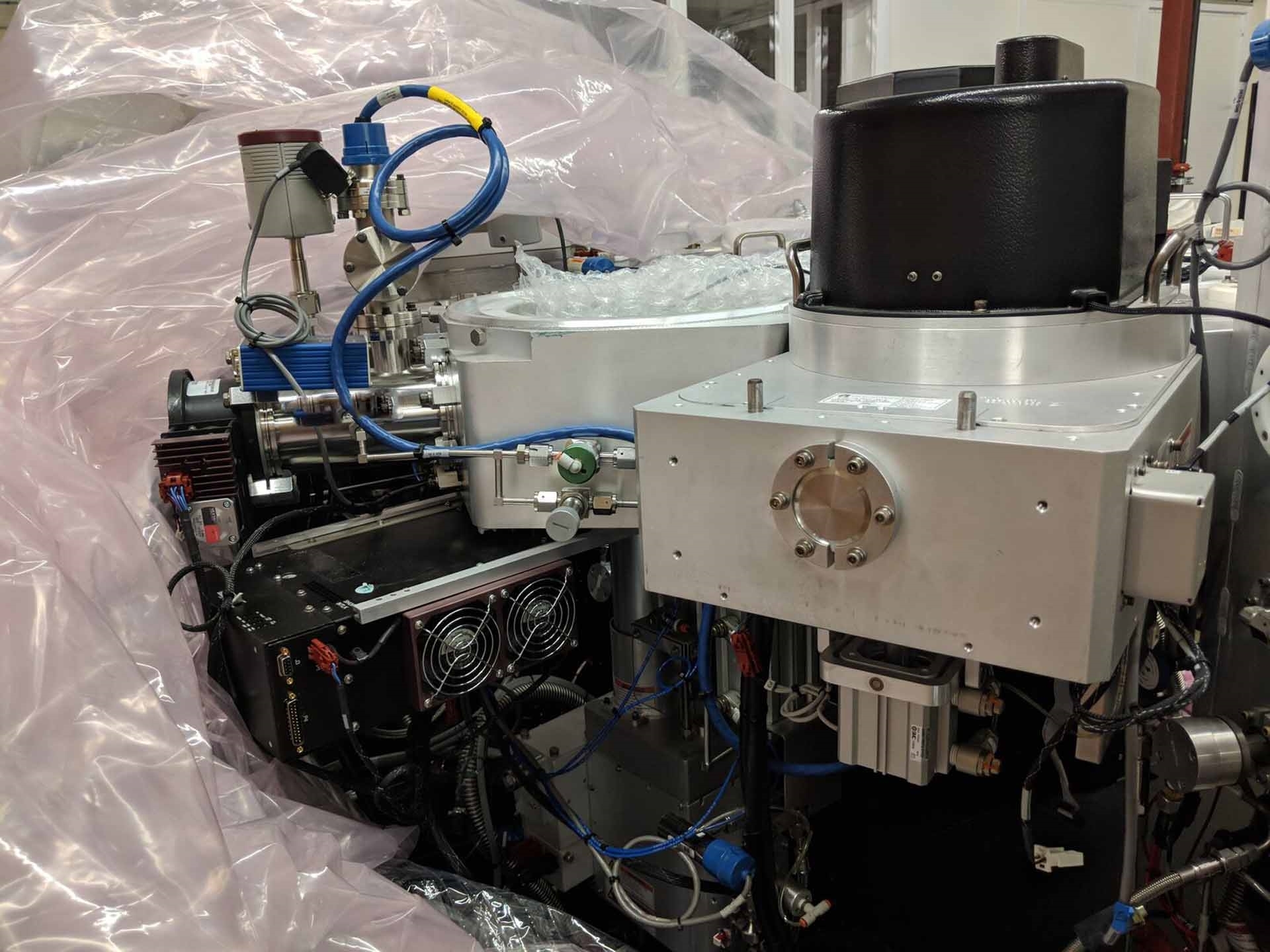

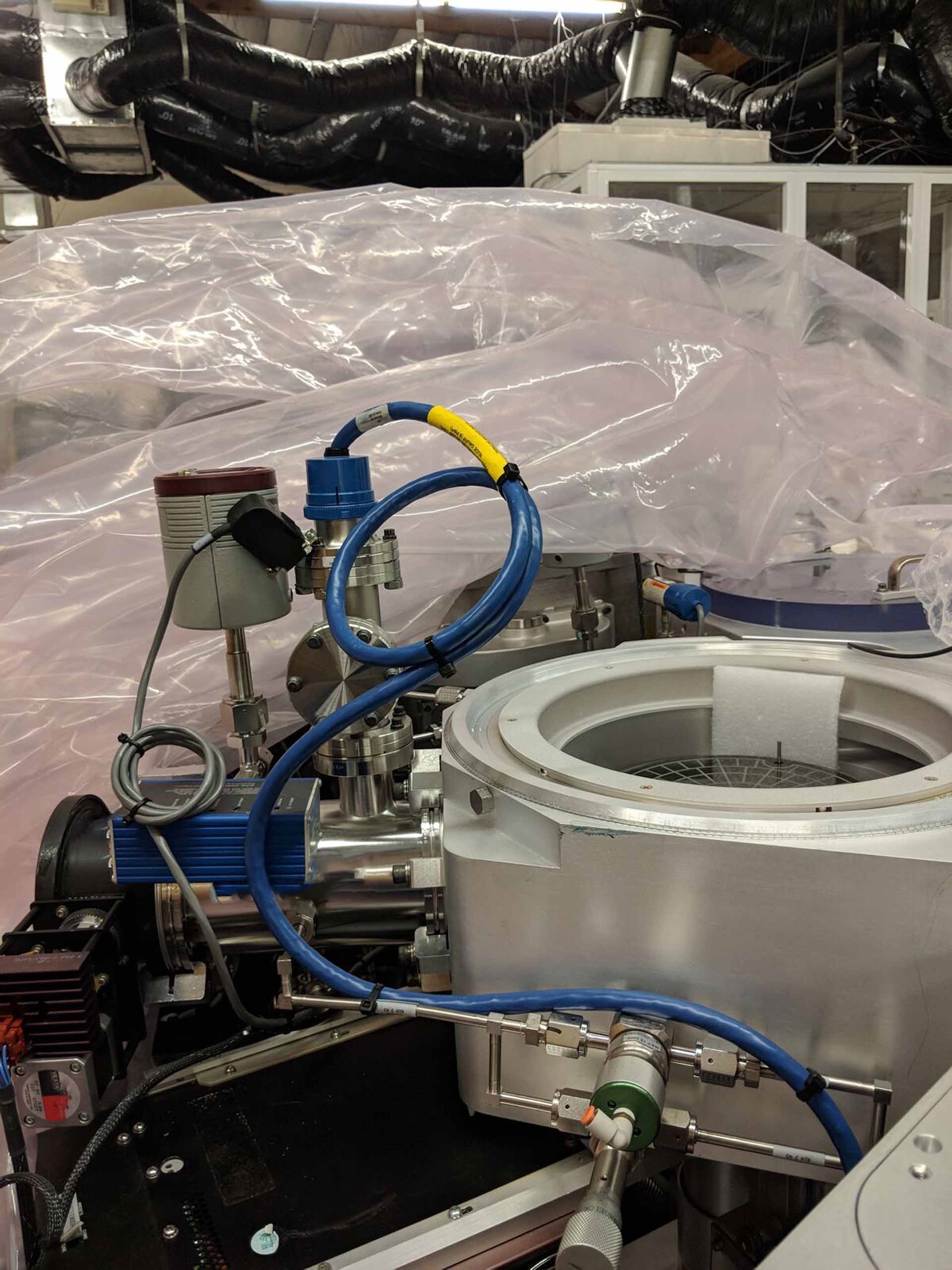

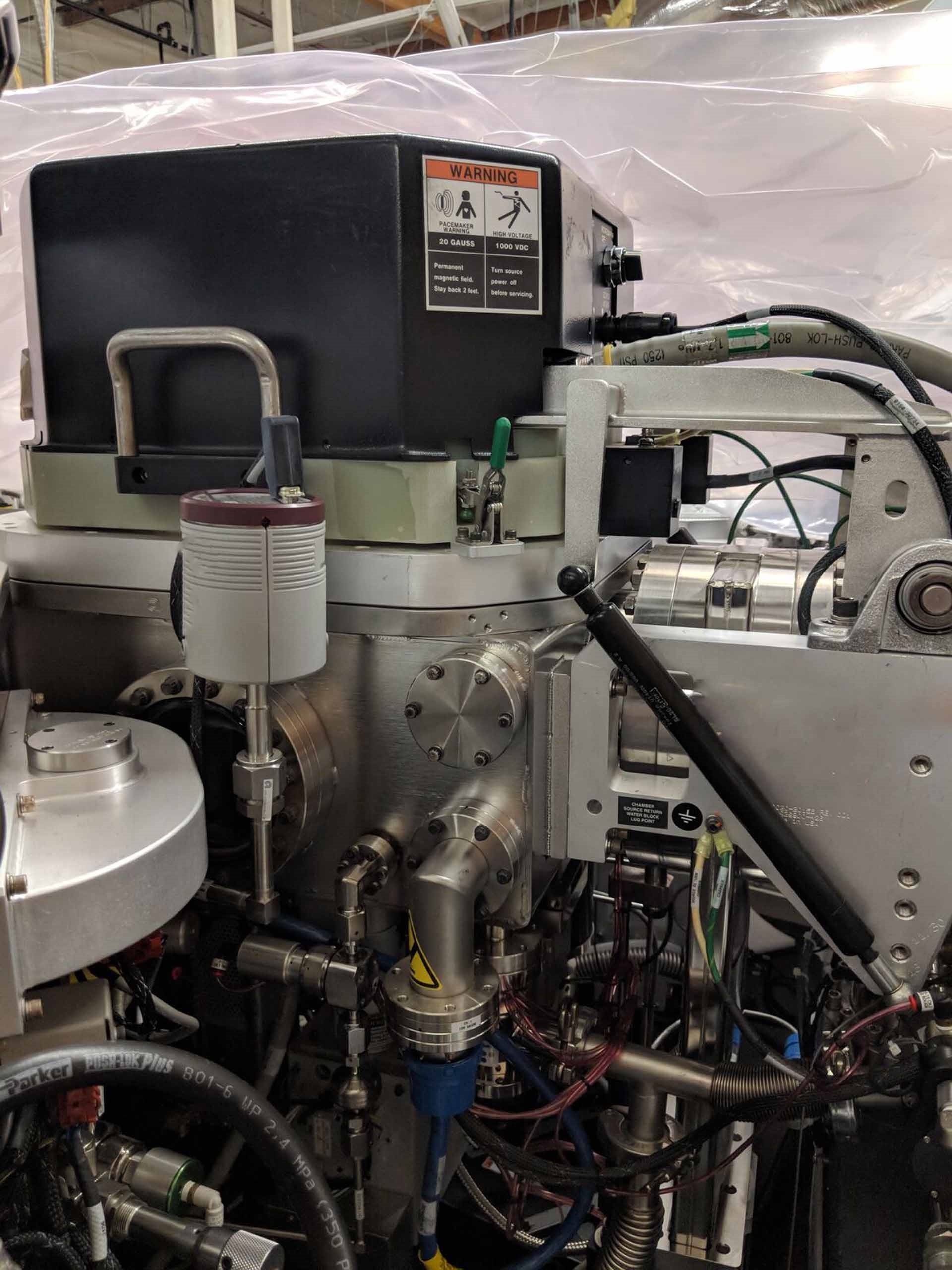

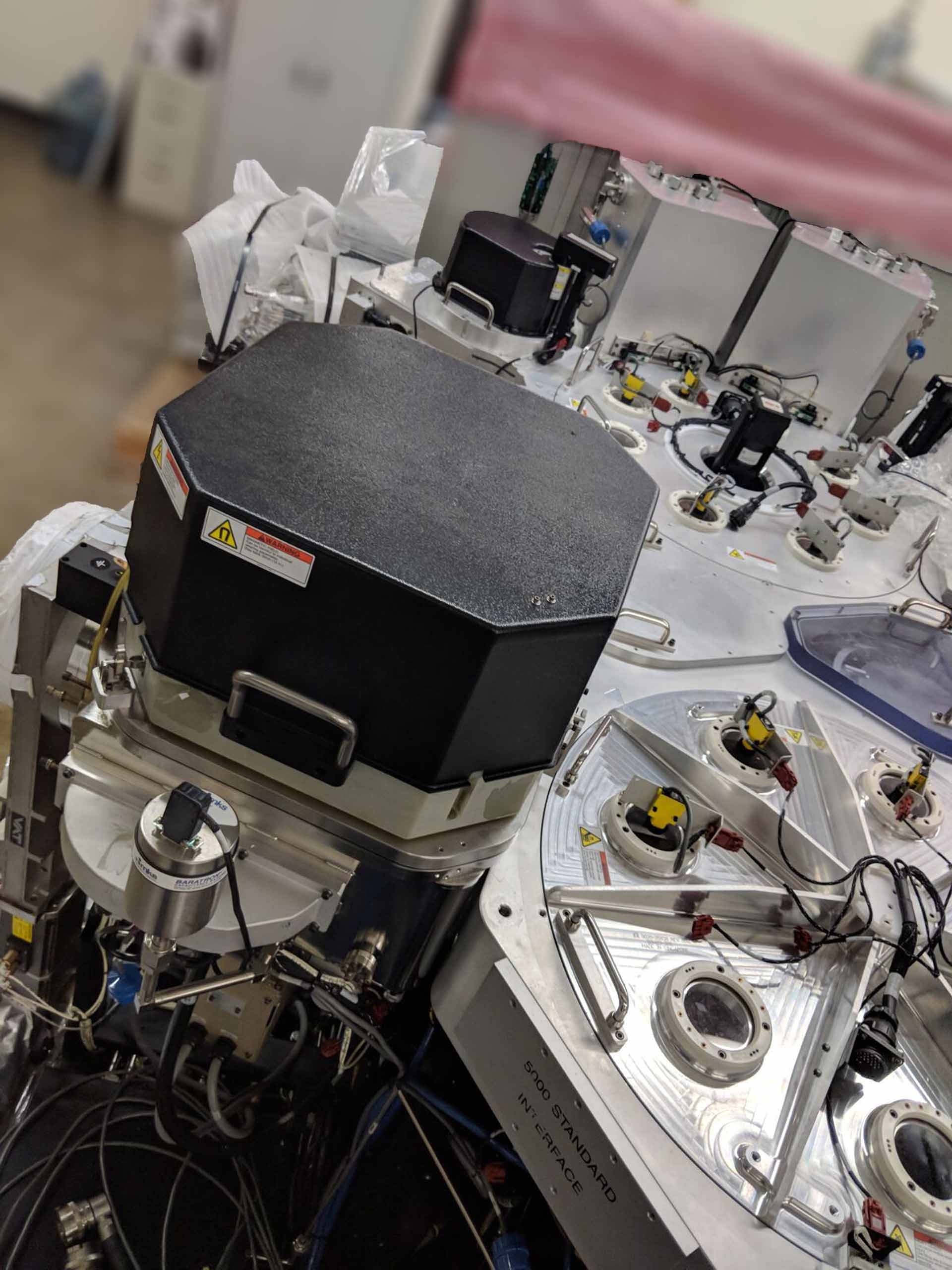

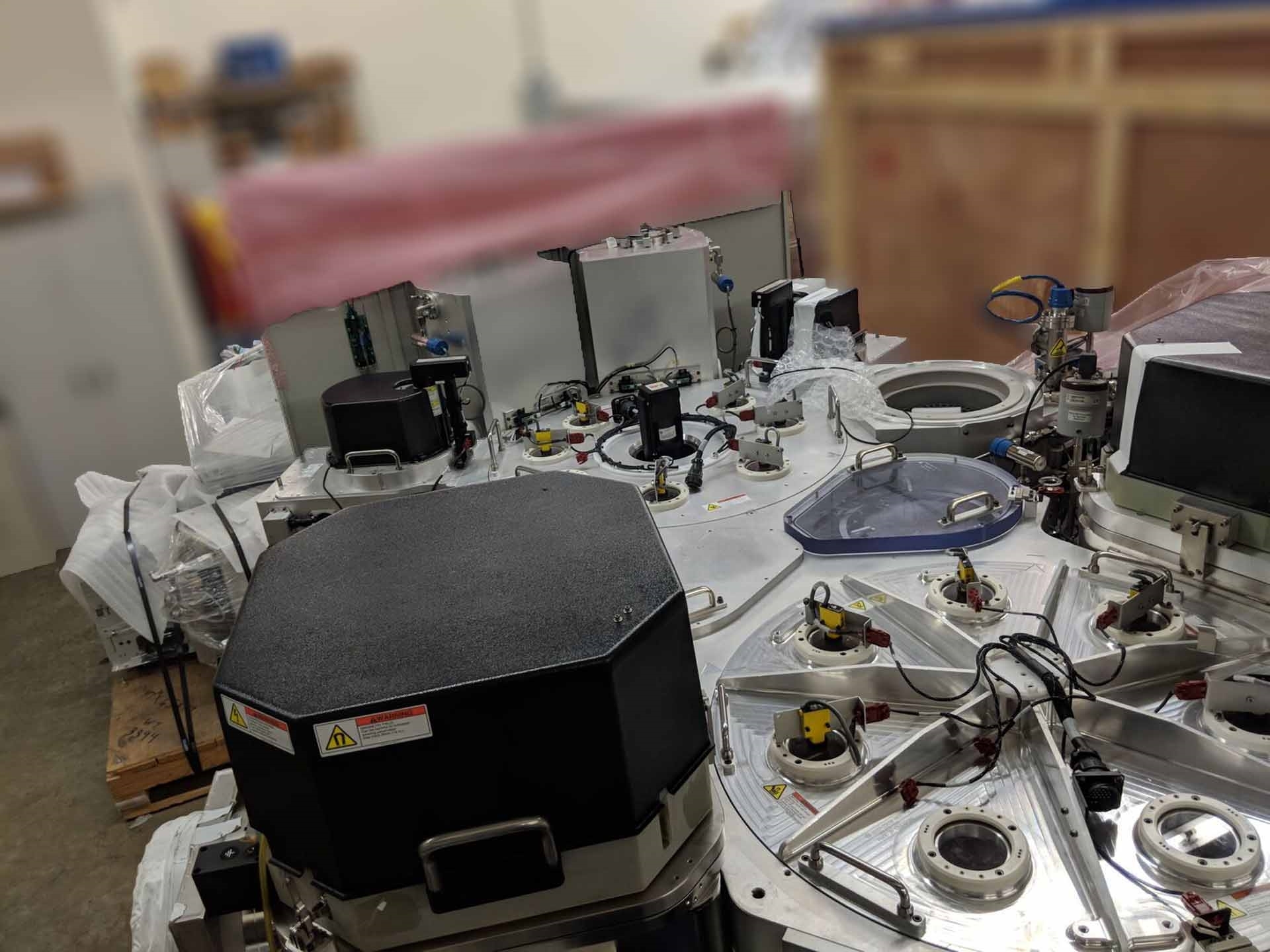

Used AMAT / APPLIED MATERIALS Endura 5500 #9228722 for sale

URL successfully copied!

Tap to zoom

ID: 9228722

Wafer Size: 8"

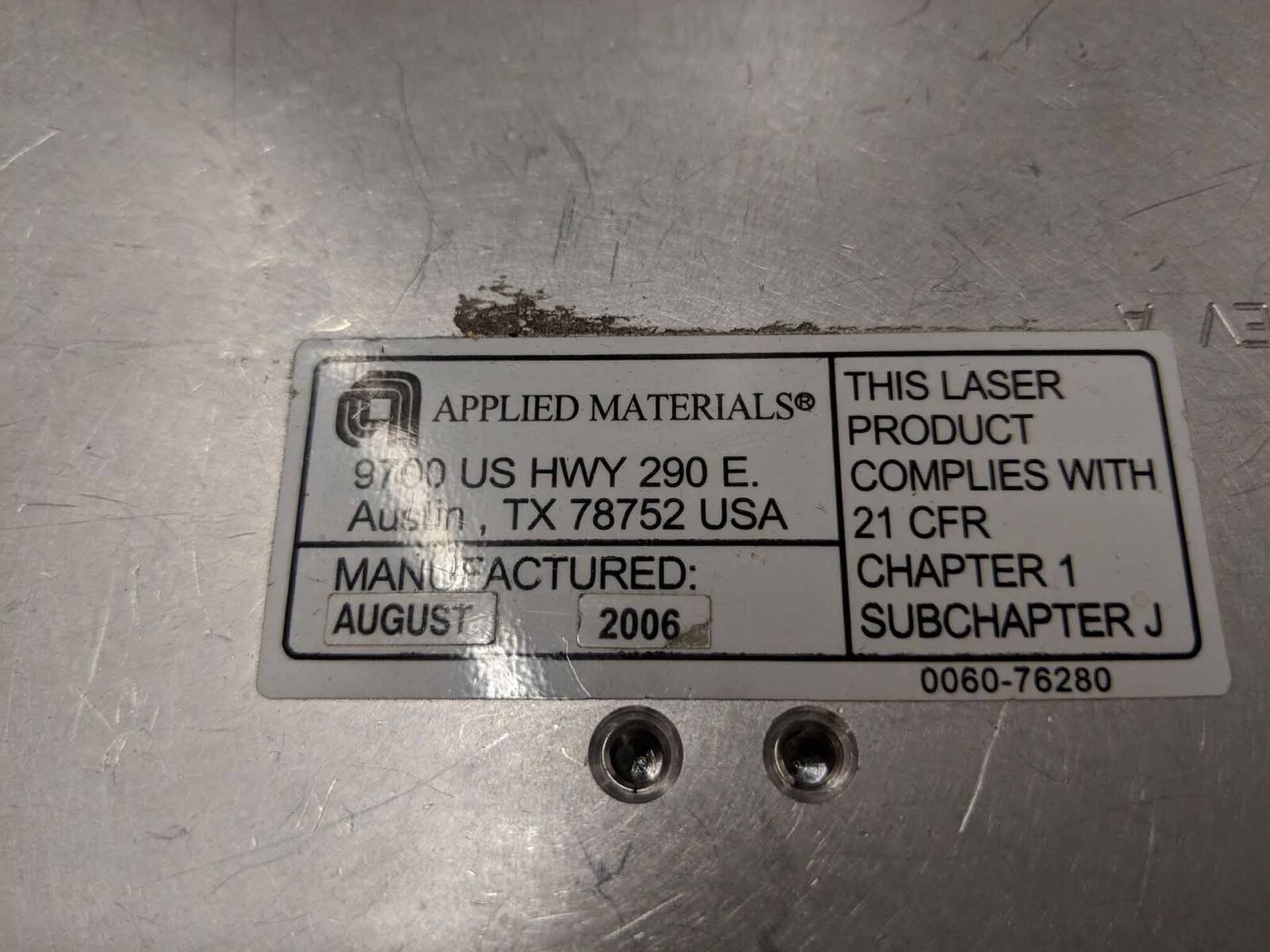

Vintage: 2006

PVD Systems, 8"

Wafer shape: SNNF

Front panel type: Painted

Light tower: R / Y / G

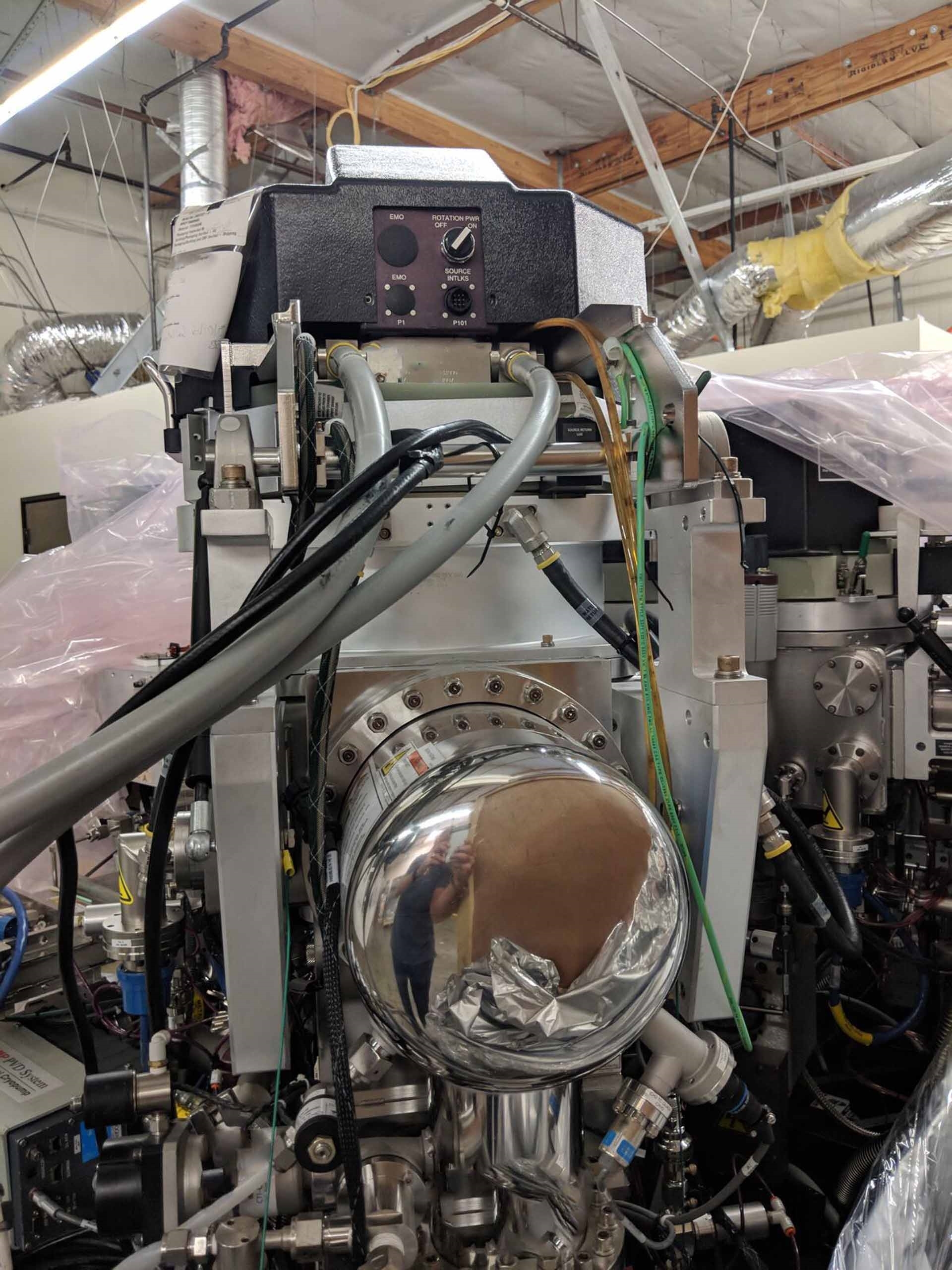

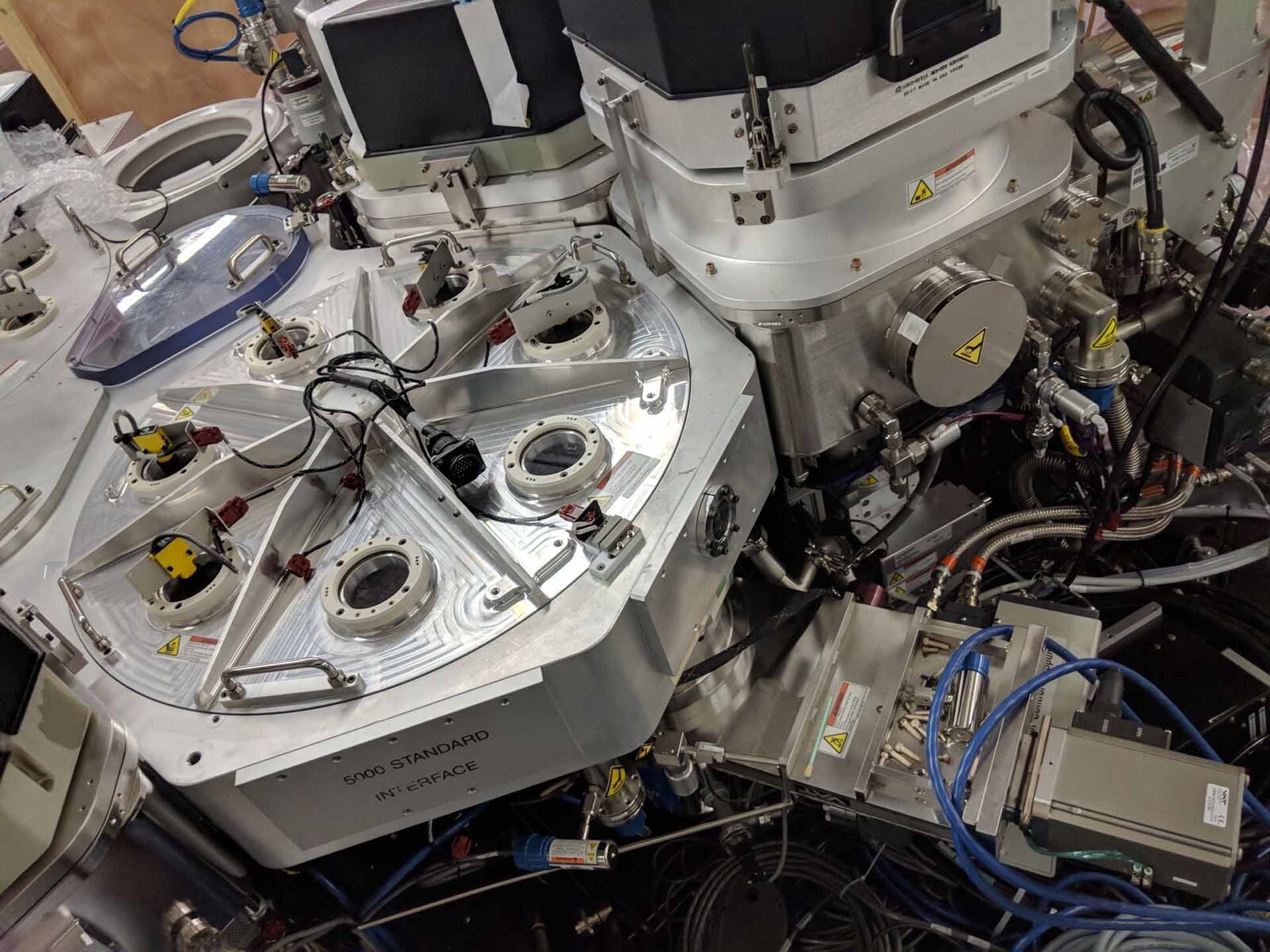

Transfer chamber: VHP Robot

Wide body loadlock

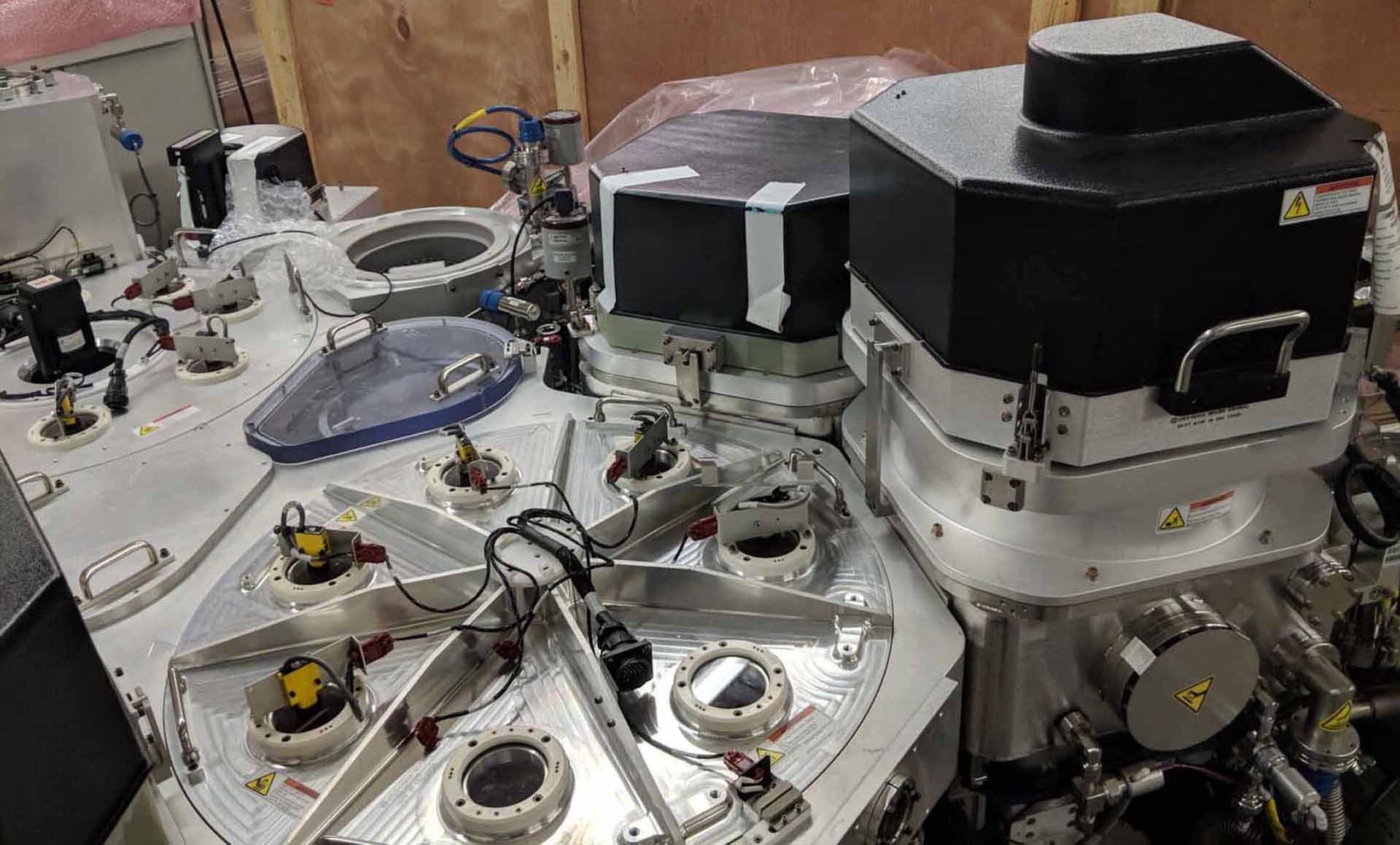

(4) Chambers

Buffer robot: HP+ Metal blade

Transfer robot: VHP With metal blade

Chamber A: Pass through

Chamber B: Cool down

Chamber C: Pre clean

Chamber E & F: Orienter / Degas

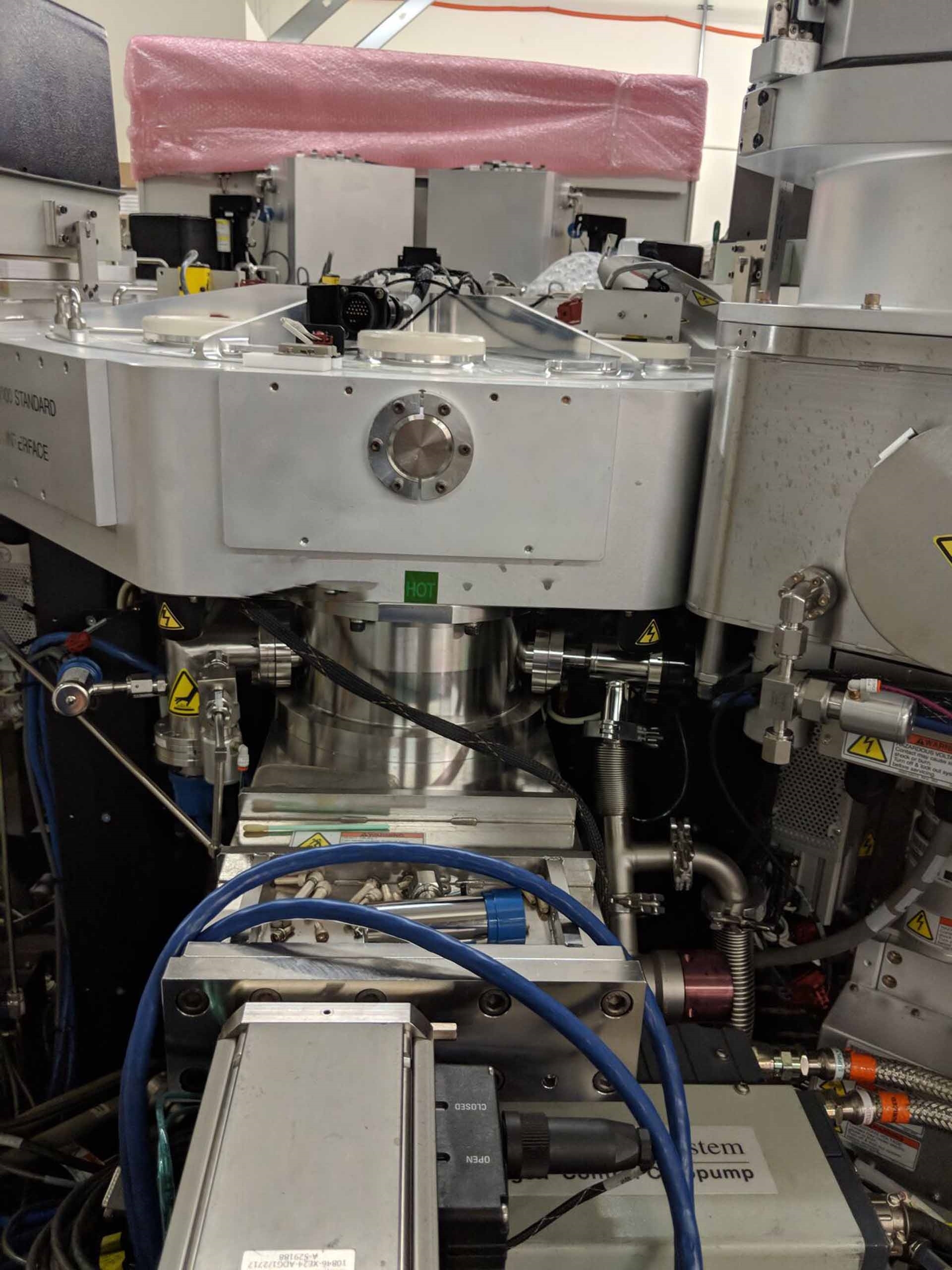

Chamber 1: Standard body AL4 finger

Chamber 2: SIP TTN With bias ESC

Chamber 4: TN Durasource TTN A101

Transformer type: Variable / 150 kVA, 480 - 380 V

System power: Variable / 150 kVA

2006 vintage.

AMAT / APPLIED MATERIALS / AKT Endura 5500 is an innovative reactor designed to meet the needs of modern semiconductor fabrication processes. The reactor combines high-quality manufacturing and robust engineering with advanced materials and technology for increased reliability and process repeatability. AKT Endura 5500 utilizes a full-featured PC-based control equipment that offers a wide range of programmed functions and capabilities, allowing for flexible, precision process control. AMAT ENDURA 5500 is designed to meet the needs of all thin-film coating, deposition, and etching process requirements. This compact, modular system provides the ability to accept and integrate multiple materials and technologies for a wide variety of processes. The automated chamber controls reduce manual operator adjustment requirements while providing the flexibility to accommodate a variety of processes. An intuitive graphical unit is also available for complete operation control. Standard features of Endura 5500 include a robust bell jar design with four edge-welded, flat plate liners for an efficient working environment. The reactor also includes an adjustable one-touch lift, automatic chamber loading and unloading, and a fully sealed double shutter. For additional safety, the machine is also equipped with an automatic vacuum leak detection tool. ENDURA 5500 has a working temperature range of -20° C to +300° C and a substrate temperature ranging from -20° C to +170° C. AMAT / APPLIED MATERIALS / AKT ENDURA 5500 is equipped with a powerful and energy-efficient frequency-switched direct current (DCS) power supply for precise process control. The asset is also capable of performing an array of deposition and etching processes, from rapid thermal processing to chemical vapor deposition (CVD), as well as resistive heating, diffusion, and more. With its advanced capabilities and high-quality manufacturing, AKT ENDURA 5500 is ideal for modern semiconductor fabrication processes. It is designed to be reliable and repeatable with accurate process control for increased efficiency. The reactor meets the strict requirements of the semiconductor industry, providing an exceptional model for today's most demanding processes.

There are no reviews yet