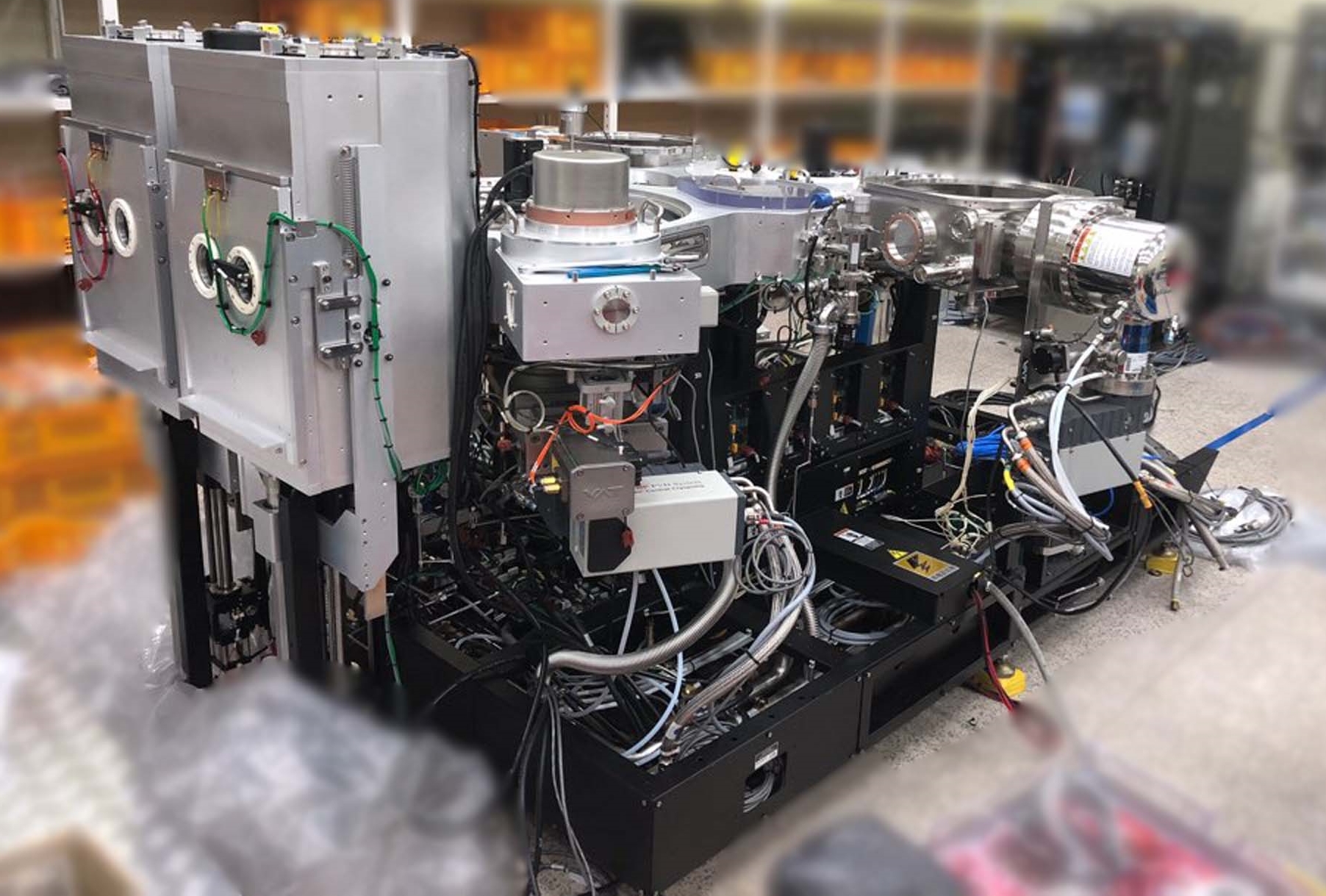

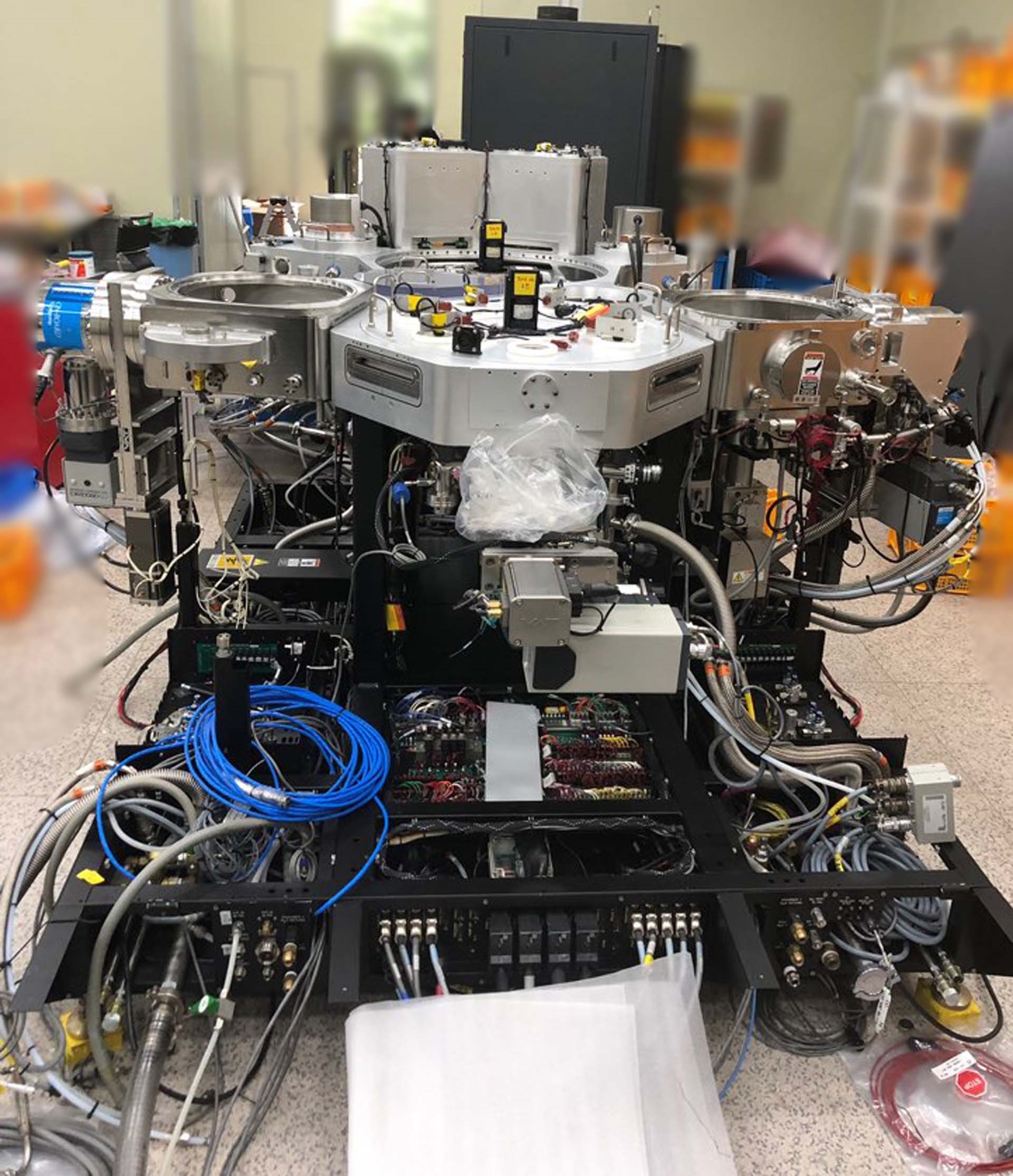

Used AMAT / APPLIED MATERIALS Endura 5500 #9242650 for sale

URL successfully copied!

Tap to zoom

ID: 9242650

Wafer Size: 8"

Vintage: 1996

Sputtering system, 8"

Robot: HP (Buffer and transfer)

(3) Chambers

Load lock: Wide

Component included:

NESLAB Chiller

(2) CTI 9600 Compressor cryo

Pump: CTI OB 8F 3PH Enhanced

Chamber: PVD 4

Chamber E and F: Orient degass

1996 vintage.

AKT/AMAT / APPLIED MATERIALS / AKT Endura 5500 is a cutting edge, advanced PECVD (plasma enhanced chemical vapor deposition) reactor. This reactor is designed to deposit high quality materials as thin films, making it ideal for applications such as semiconductor processes and storage devices fabrication. AKT Endura 5500 features a unique dual frequency radio frequency (RF) powered substrate bias that enables precise control in the deposition of dielectric materials. It is also equipped with a powerful dynamic RF power delivery system that provides instantaneous response to changing process conditions, ensuring consistent, repeatable process results. AMAT ENDURA 5500 is designed to offer maximum productivity, repeatability and conformity. It features a patented Catalyst® technology that supports multiple RF sources with an optimized secondary chamber for improved uniformity, thickness, composition control. The plasma chamber is designed for extremely low power dissipation, allowing it to run at higher peak powers while also reducing the possibility of thermal excursions. In addition, the substrate bias control allows for greater precision and accuracy when depositing dielectric films. AKT ENDURA 5500 enables high deposition rates with superior film thickness uniformity across multiple substrates. It features a digital chamber pressure controller for precise control of substrate temperature and gas flow. The advanced gas delivery system ensures precise gas mixtures and proper delivery. The multi-point thermocouple and sensor array enable real-time monitoring of substrate temperature and uniformity. AMAT / APPLIED MATERIALS / AKT ENDURA 5500 is designed for maximum process latitude and control. Its digital I/O ports offer real-time control and monitoring of all important process parameters. It features an auto-tuning system for easy and reliable tuning of RF shift frequencies and phase, allowing for maximum perfomance throughout the entire process. ENDURA 5500 is specifically designed to meet today's more demanding semiconductor fabrication requirements. It provides superior quality material deposition through repeatable and reliable processing for better device performance. The reactor has been certified by AMAT/APPLIED MATERIALS to be compliant with the SEMI C39 guideline for standard design and manufacture of semiconductor manufacturing equipment.

There are no reviews yet