Used AMAT / APPLIED MATERIALS Endura 5500 #9304004 for sale

URL successfully copied!

Tap to zoom

ID: 9304004

Wafer Size: 6"

Vintage: 1997

System, 6"

MF Facilities: Rear

Heat exchanger: NESLAB I

Buffer robot type: HP

Transfer robot type: HP

Hard Disk Drive (HDD): SCSI

Buff robot blade: Ceramic

Wafer sensor: Mini beam

Loadlock type: Narrow body without tilt out

Transfer robot blade: Metal

Signal tower: 3 Color

System umbilicals: 25 ft

EMO

No GEM

No OTF

Controller

Generator rack

(2) CTI-CRYOGENICS 9600 Compressors

CTI-CRYOGENICS Motor controller: 3 Phase

EBARA A07V Pump

Main AC box

Transformer: 200 VAC,3 Phase, 50/60 Hz

MF Enclousure cover installed

MF Gas box

Laser assy

OB- 8F Cryo pump: Enhanced type

Process lift: Motorize type

SBC BD Type: V452

Buffer / Transfer: VHP Conversion possible type

MF Facility box

UPS: Interface type

Chamber A:

Type: PC-II

ADVANCED ENERGY LF10A RF Generator

COMDEL CPS1001S RF Generator

Gas valves: Nupro

Manometer: 100m Torr

LEYBOLD Turbovac 361C Pump

Lid: Resonator

Match box, 6"

LEYBOLD Turbotronic 150 / 360 Turbo controller

EBARA A07V Pump

Gasses:

LEYBOLD Turbo pump

MFC Size / Gas name / MFC Type

300 / Ar / Stec 4400

20 / Ar / Stec 4400

Chamber B:

Type: Cool down

Gas valves: Nupro

Heater / Cathode cooling: PCW

Lid modified to Quartz lid

Chamber 1:

Process: TTN

Type: STD Body

Manometer configuration: Single

Manometer: 100m Torr

No shutter option

Lid type: 11.3"

ADVANCED ENERGY MDX-L12-650 DC Power supply

Susceptor / Pedestal: 101

3-Position gate valve

OB-8F Pump: 3 Phase

Ion gauge: Nude type

Lift type: Basic motorize type

Gasses:

Gas / MFC Size / Gas name / MFC Type / Qty / Gas stick configuration

Gas 1 / 200 SCCM / N2 / Stec 4400 / (2) / Manifolds

Gas 2 / 100 SCCM / Ar / Stec 4400 / (2) / Manifolds

Gas 3 / 200 SCCM / N2 / Stec 4400 / (2) / Manifolds

Chamber 2:

Process: AL

Type: STD Body

Manometer configuration: Single

Manometer: 100m Torr

No shutter option

Lid type: 11.3"

ADVANCED ENERGY MDX-L12M Power supply

ADVANCED ENERGY MDX-L12 Power supply

Susceptor / Pedestal: 4F

Heater / Cathode cooling: NESLAB I

3-Position gate valve

OB-8F Pump: 3 Phase

MKS Residual gas analyzer installed

Lift type: Basic motorize type

Gasses:

Gas / MFC Size / Gas name / MFC Type / Gas stick configuration

Gas 1 / 100 SCCM / Ar / Stec 4400 / Standard

Gas 2 / 100 SCCM / Ar / Stec 4400 / Standard

Chamber 3:

Process: Ti

Type: STD Body

Manometer configuration: Single

Manometer: 100m Torr

No shutter option

Lid type: 11.3"

ADVANCED ENERGY MDX-10K DC Power supply

Susceptor / Pedestal: 101

3-Position gate valve

OB-8F Pump: 3 Phase

Lift type: Basic motorize type

Gasses:

Gas / MFC Size / Gas name / MFC Type / Qty / Gas stick configuration

Gas 1 / 200 SCCM / N2 / Stec 4400 / (2) / Manifolds

Gas 2 / 100 SCCM / Ar / Stec 4400 / (2) / Manifolds

Gas 3 / 200 SCCM / N2 / Stec 4400 / (2) / Manifolds

Chamber 4:

Process: TTN

Type: STD Body

Manometer configuration: Single

Manometer: 100m Torr

No shutter option

Lid type: 11.3"

ADVANCED ENERGY MDX-650 HiZ DC Power supply

Susceptor / Pedestal: 101

3-Position gate valve

OB-8F Pump: 3 Phase

Lift type: Basic motorize type

Gasses:

Gas / MFC Size / Gas name / MFC Type / Qty / Gas stick configuration

Gas 1 / 200 SCCM / N2 / Stec 4400 / (2) / Manifolds

Gas 2 / 100 SCCM / Ar / Stec 4400 / (2) / Manifolds

Gas 3 / 20 SCCM / Ar / Stec 4400 / (2) / Manifolds

Missing parts for chamber 1:

Drive: 2 Phase

Motor

Gear box

Gear box mount

Belt

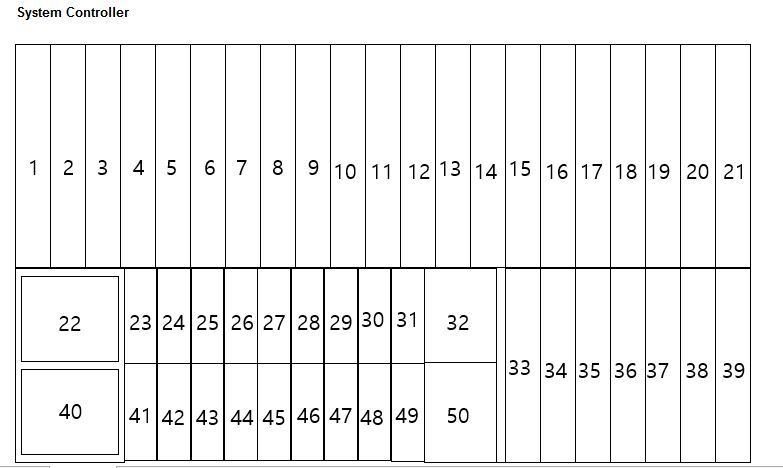

Slot / Top rack boards:

1 / SBC Board

2 / Videl board

3 / OMS Board

4 / DI/O Board

5 / DI/O Board

6 / DI/O Board

7 / DI/O Board

8 / DI/O Board

9 / DI/O Board

10 / SEI Board

11 / No 486C

12 / No seriplex

13 / No DI/O board

14 / No AO board

15 / Stepper board

16 / No spare

17 / No spare

18 / Stepper board

19 / AI Board

20 / AO Board

21 / AO Board

22 / Hard Disk Drive (HDD)

23 / No grounding JAC

24 / Convectron board

25 / Convectron board

26 / Convectron board

27 / Convectron board

28 / No TC

29 / No TC

30 / ION Gauge board

31 / ION Gauge board

32 / No spare

33 / DI/O Board

34 / DI/O Board

35 / DI/O Board

36 / DI/O Board

37 / DI/O Board

38 / No DI/O board

39 / No DI/O board

40 / Floppy Disk Drive (FDD)

41 / No spare

42 / Cryo temp

43 / AI Mux

44 / AI Mux

45 / No AI Mux

46 / No spare

47 / Opto detect board

48 / Opto detect board

49 / Opto detect board

50 / No spare

UPS: 200 VAC, 3 Phase, 50/60 Hz, 350 A

1997 vintage.

AMAT / APPLIED MATERIALS / AKT Endura 5500 is a high throughput, full-featured epitaxial reactor designed for use in semiconductor production. AKT Endura 5500 features a full-auto loader/unloader and multiple process chambers which allow for rapid process setup and optimized process uniformity. AMAT ENDURA 5500 is designed to provide high throughput for both small- and large-diameter epitaxial wafers. AMAT Endura 5500 supports a wide variety of process chemistries, including chemical vapor deposition (CVD) and molecular beam epitaxy (MBE), for the growth of various materials ranging from silicon, silicon-germanium, carbon-doped silicon, and other compounds. This flexibility accommodates the production of a variety of products, including traditional logic devices, MEMS (microelectromechanical systems), advanced logic, and optoelectronic components. The system features a unique, single-source remote control which simplifies process setup, and allows for full remote monitoring of up to three APPLIED MATERIALS ENDURA 5500 systems. This includes real-time access to multiple process parameters such as temperature, growth rate, and process pressure, in addition to allowing the user to company the process chamber directly. This data is invaluable for quickly finding and troubleshooting process issues. ENDURA 5500 offers a variety of process chamber configurations, constrained rafts, and box sizes, allowing for fast, efficient wafer cycling and large-volume production. The constrained rafts feature enhanced uniformity control, allowing wafers to be layed-out in a terraced fashion to ensure consistent thermal uniformity across the entire wafer. With a highly integrated camera system, automated wafer alignment is possible with four, six, eight, and twelve-inch wafers, ensuring consistent and accurate wafer handling and processing. APPLIED MATERIALS Endura 5500 also boasts an entirely automated wafer handling module, eliminating time-consuming manual wafer handling and loading. This includes Endura 5500's signature rotating cassette transfer system, allowing for continuous automated loading and unloading of up to ten wafer cassettes for uninterrupted production. Overall, AKT ENDURA 5500 is a premier, full-featured epitaxial reactor designed for fast, high-volume wafer production. The device is equipped with the latest in process chamber performance and automated wafer loading, as well as remote monitoring and optimized uniformity control, all of which ensure consistent, reliable production.

There are no reviews yet