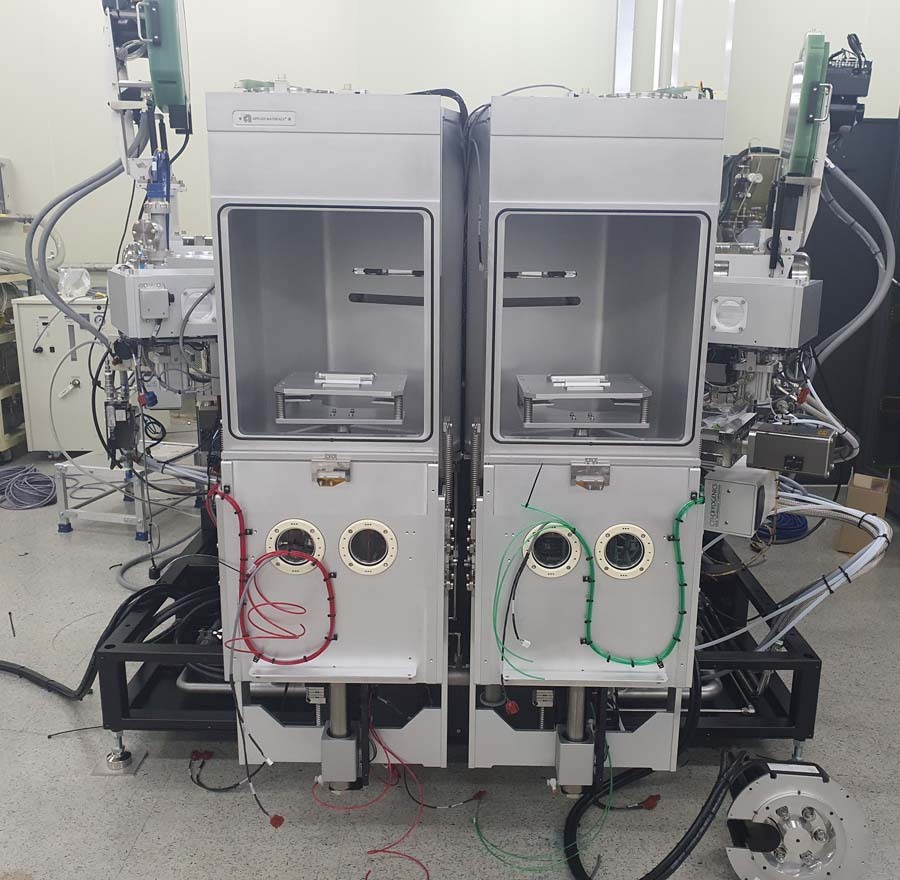

Used AMAT / APPLIED MATERIALS Endura 5500 #9392659 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9392659

Wafer Size: 8"

PVD System, 8"

(25) Slots carrier type

Buffer or transfer chamber: HP Robot

(2) Generator racks

NESLAB III

(2) CTI 9600 Cryo compressors

DC / RF Generator

Convectron gauge

Baratron gauge

MFC 4400M

Umblical cable: 50 Feet

Pump:

(2) Cryp pumps

3 Phase controllers

W/B Load lock:

(25) Slots

Auto tilt out load lock

Chambers:

Chamber A: Pass through

Chamber B: Cooldown

Chamber C: PCII

Chamber D: Blank

Chamber E: Wafer orient / Degas

Chamber F: Wafer orient / Degas

Chamber 1: Ti / TiN

Chamber 2: Al

Chamber 3: Al

Chamber 4: Ti / TiN

System controller:

SBC V452 B/D and OMS VMEX Frame

2 Phase driver box

5 Phase driver box

Ion gauge controller

CTI Network terminal

Power supply:

24V

15V

AC Transformer: 380V, 150KVA.

AKT/AMAT / APPLIED MATERIALS / AKT Endura 5500 is an advanced semiconductor processing reactor designed for chip-scale packaging applications. It is a physical vapor deposition (PVD) tool capable of providing high-speed, in-line coating of thin-film materials with excellent control of film thickness uniformity. This is accomplished through the use of vapor-deposited materials, which can easily be tailored to meet customer requirements. AKT Endura 5500 utilizes a low-pressure, induction-heated, cold-cathode sputtering chamber that provides excellent uniformity and repeatability. AMAT ENDURA 5500 offers several features that make it an attractive choice for chip-scale packaging, including high material efficiency, substrate throughput, and low cycle times. It is also capable of coating thin, transparent films with excellent properties and can be used to coat a wide range of substrates including silicon, glass, ceramic, and metals. The low-pressure, induction-heated sputtering chamber provides rapid deposition rates at low temperatures, which ensures good uniformity of coatings and minimal oxidation of the substrates. AMAT Endura 5500 also comes with an advanced power level control that provides precise control of process power and is capable of producing highly conformal and uniform coatings over a wide range of substrate materials. AKT ENDURA 5500 sputter source is a rotating magnetron source, combined with a powered water-cooled cathode. This allows for high deposition rate and uniformity through the rotation of the source. The deposition rests on the substrate surface, allowing a thin film in the range of 1-15 nanometers to be formed. The high rate of sputter deposition is achieved by avoiding the build-up of overlay films on the substrate surfaces. ENDURA 5500 can also be set up for sequential bottom/top-side sputtering to create a contact between the bottom and top sides of the substrate for further bonding. APPLIED MATERIALS ENDURA 5500 is a versatile package and is suitable for a variety of chip-scale packaging applications. It is capable of providing uniform and precise coatings on a wide range of complex substrates. In addition, its advanced monitor and control capabilities, combined with its rapid deposition rate, make it an attractive solution for industrial and research environments. This makes it the ideal choice for those looking for a reliable and efficient solution for their chip-scale packaging needs.

There are no reviews yet