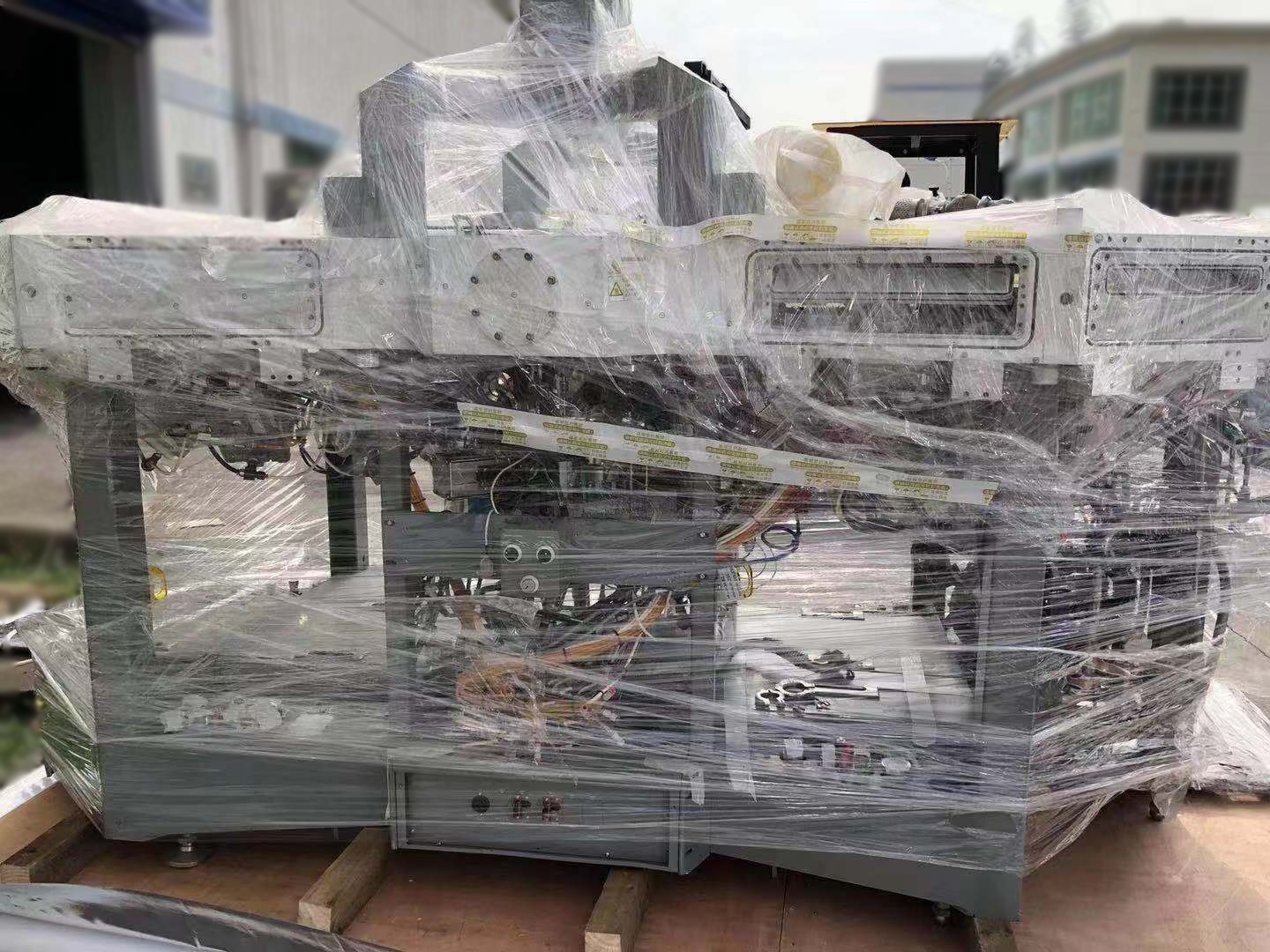

Used AMAT / APPLIED MATERIALS Endura CL #9247978 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9247978

System

Includes:

(2) CU Chambers

(2) Heater chambers

(2) Etch chambers

(3) RF Power racks

(3) AC Racks

TA Chamber

Chiller

FI

Buffer chamber.

AMAT / APPLIED MATERIALS Endura CL is a high throughput cluster-level reactor designed for high volume, precision etch and deposition applications in the semiconductor industry. AMAT Endura CL reactor can process both high aspect ratio (HAR) and complex structures in one single step. It is equipped with an integrated cluster system including two processing chambers, two load locks, a pre-processing chamber and a post-processing chamber. The first processing chamber of APPLIED MATERIALS Endura CL is a high-density plasma etch chamber. It has a four-electrode, 13.56 MHz RF plasma system compatible with hydrogen, chlorine and fluorine-based chemistries. The chamber also features a Diffusion Showerhead for even plasma distribution, mass flow controllers (MFCs) for gas flow control, and a turbo pump for exhaust. The second processing chamber of Endura CL is a high-speed deposition chamber, designed with a dual coil planar coil source. This multi-chamber technology enables the processing of small, high aspect ratio (HAR) structures along with complex structures using the same tool. The chamber also has RF and DC power supplies for process control, a diffusion shower for uniformity, and an integrated scrubber for over-etch. The pre-processing chamber is used for pre-cleaning substrates before processing and the post-processing chamber is used to protect the device from contamination and prevent deposition of unwanted materials. The post-processing chamber is equipped with ion pumps and an integrated scrubber option for purging and cleaning after etch. The load locks of AMAT / APPLIED MATERIALS Endura CL are designed with an automated flex robot and provide quick, low particle loading and unloading operations. The robot is conformal with the toolsets to ensure smooth operation and minimize particles. AMAT Endura CL is designed for high volume production and is equipped with a 24-hour remote monitoring system to enable online maintenance and monitoring. The reactor is ideal for manufacturing production of MEMS, integrated circuit product and thin film devices. It is an efficient multi-chamber etch and deposition tool with the capability to process a wide range of substrates, geometries, materials, and processes.

There are no reviews yet