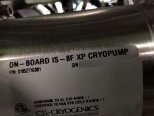

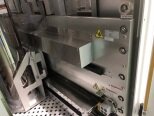

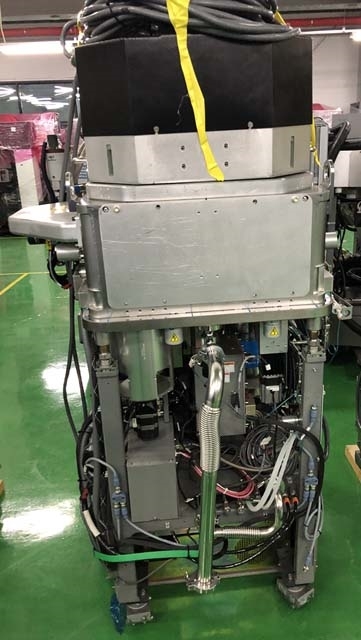

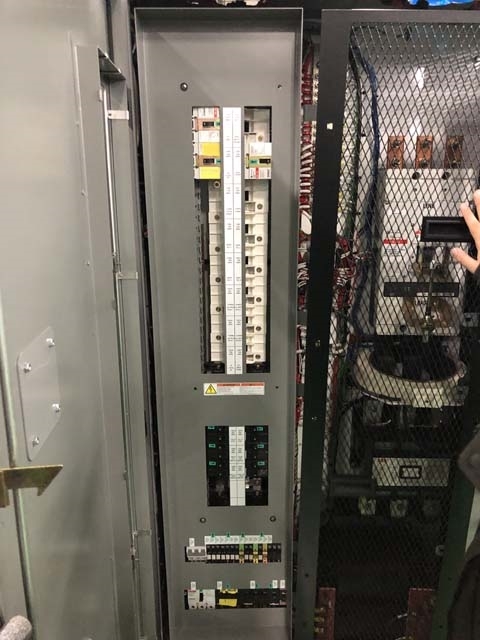

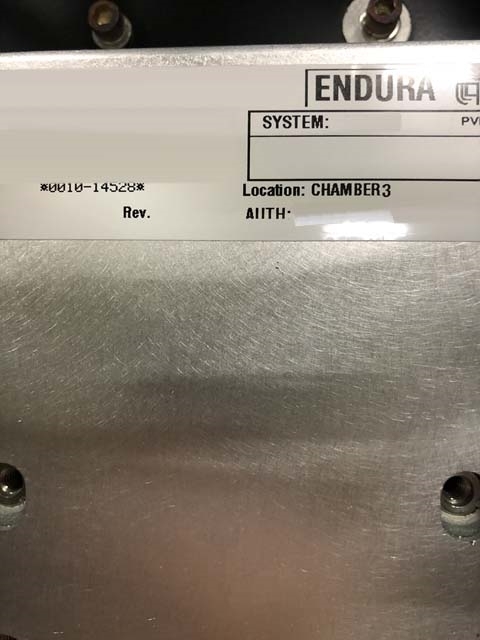

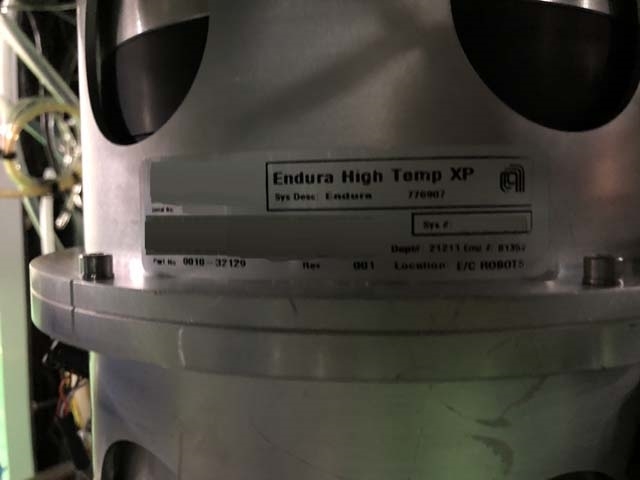

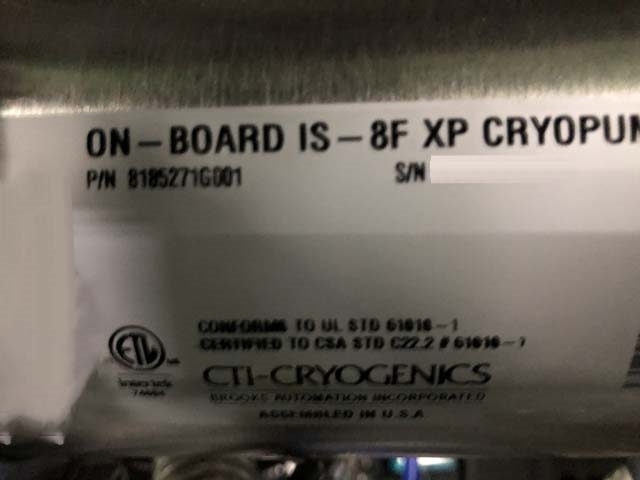

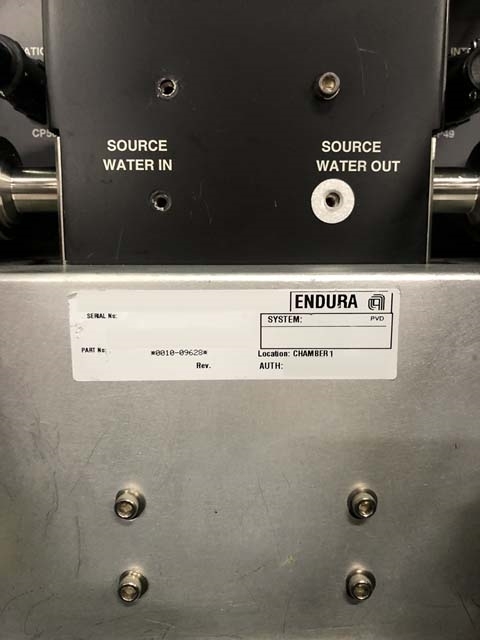

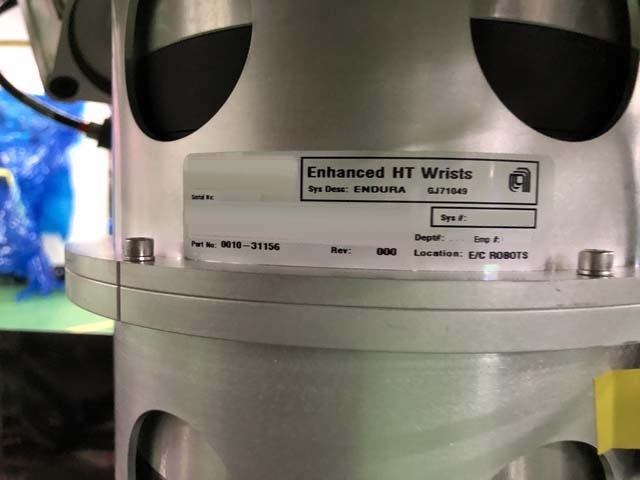

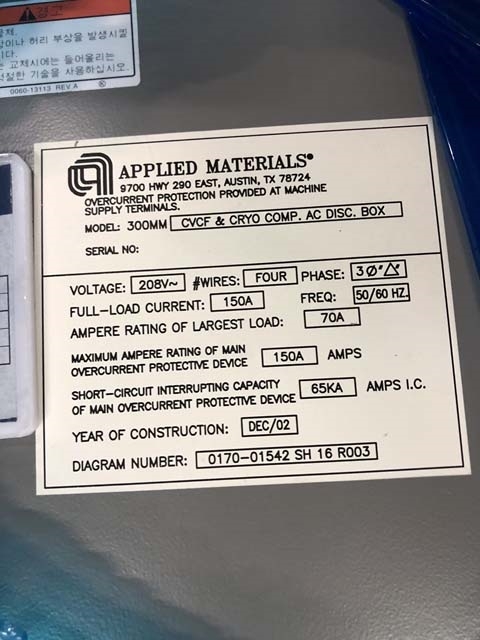

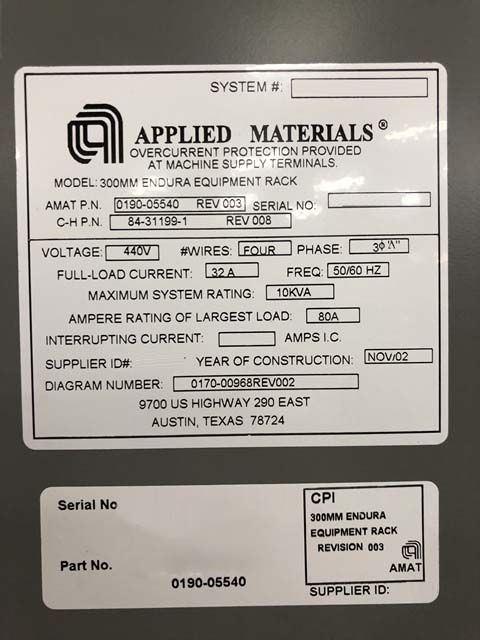

Used AMAT / APPLIED MATERIALS Endura CL #9271325 for sale

URL successfully copied!

Tap to zoom

ID: 9271325

Wafer Size: 12"

Vintage: 2003

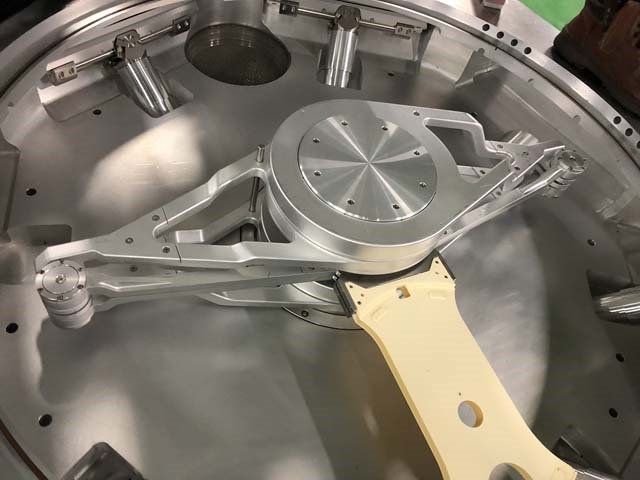

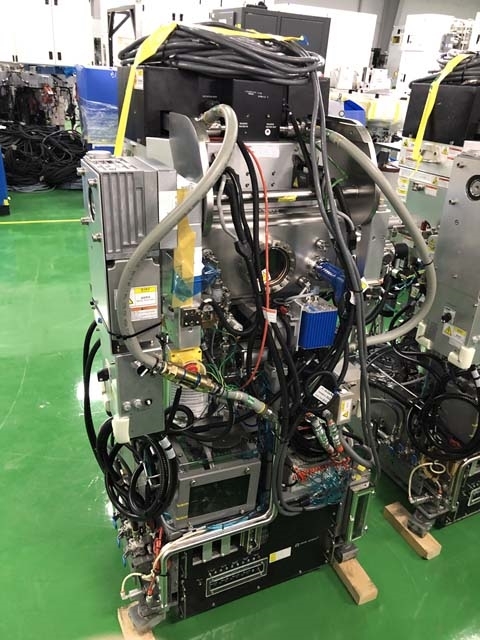

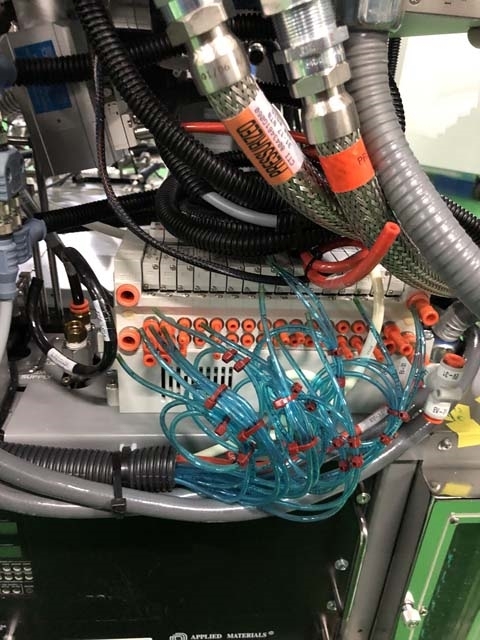

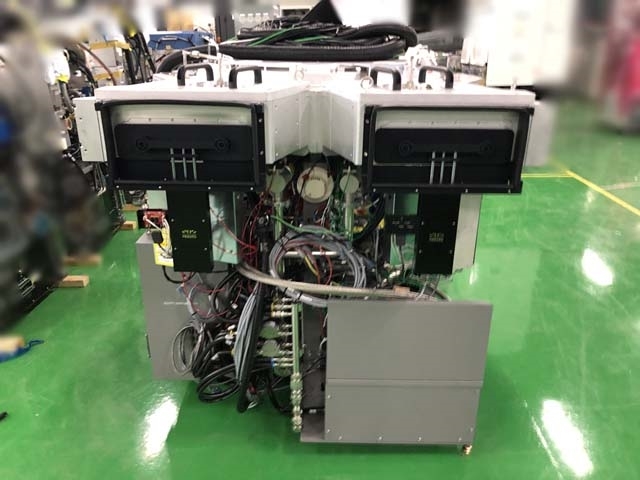

PVD System, 12"

Process: CH-1_Ti / CH-2_AL / CH-3_AL / CH-E&F_Degas

2003 vintage.

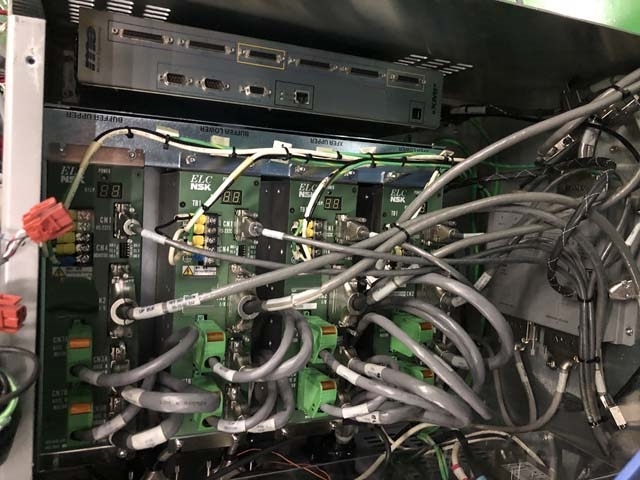

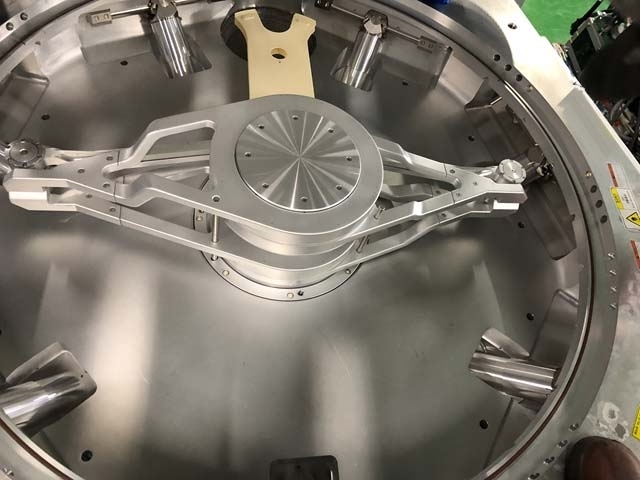

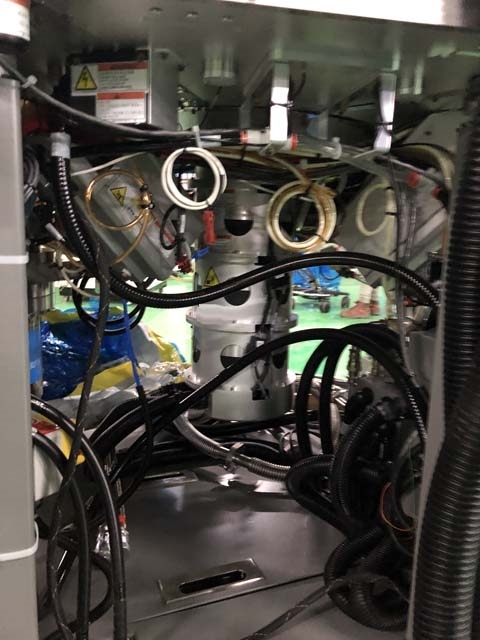

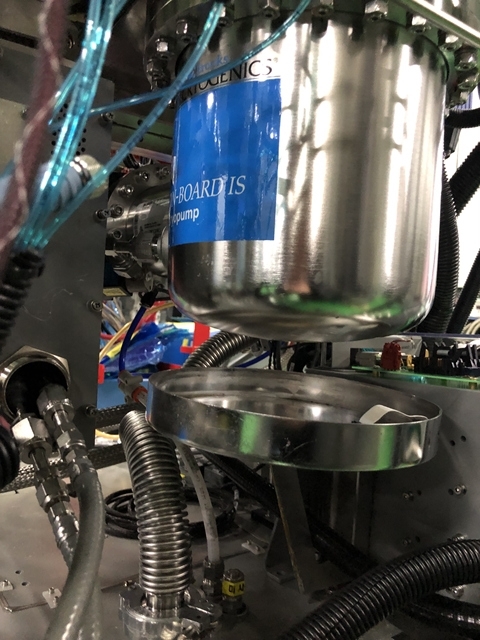

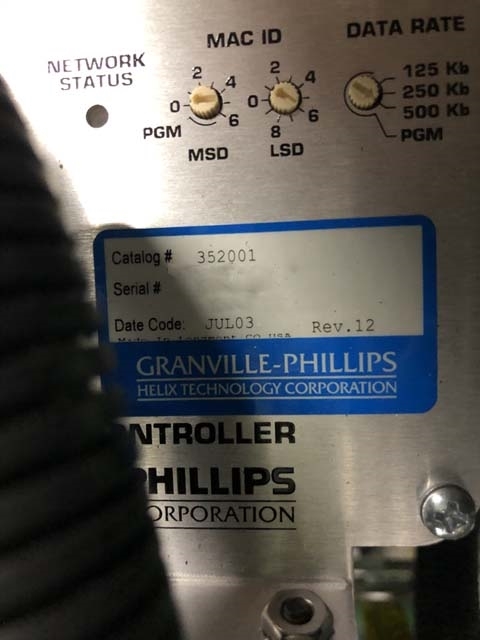

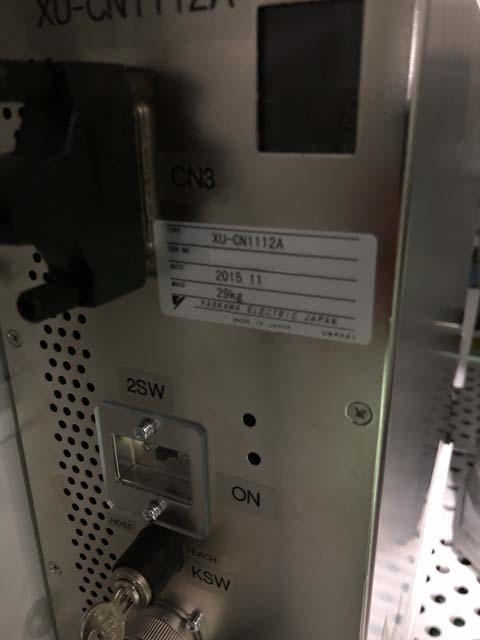

AMAT / APPLIED MATERIALS Endura CL is an advanced clamshell reactor equipment specifically designed to deposit nano-electronic materials with high conformality and uniformity. The chamber construction on AMAT Endura CL features an etch-resistant ceramic construction to ensure superior process results. APPLIED MATERIALS Endura CL system is equipped with vacuum technology that provides maximum wafer coverage via enhanced convection. It features a conveyor-based heat transfer unit to ensure accurate temperature uniformity across the substrate surfaces. Additionally, its low water vapor pressure-vacuum ensures high throughput and low particle issues at the interface. Endura CL's design supports a variety of different process techniques, including rapid thermal processing (RTP) as well as electrochemical deposition (ECD) and molecular beam epitaxy (MBE). It is capable of high temperature processing up to 1,200°C with a chlorine gas ambient of up to 1,300℃. AMAT / APPLIED MATERIALS Endura CL is also able to support crystallization, oxide film deposition, nitride deposition, and ohmic contact applications. AMAT Endura CL is the industry's most advanced low-pressure chemical vapor deposition (LPCVD) reactor with a highly customizable design that allows for custom tools to be built upon it. It features intuitive control software that can be used to create customized recipes to achieve optimal process throughput and yield. The reactor can be used for a variety of film applications, including interconnect layers, interlevel dielectric (ILD), barrier and diffusion layers, and passivation layers. Its design gives it the flexibility to handle a wide range of materials including silicon-germanium, germanium, gallium arsenide, nitride, and polycrystalline silicon films. APPLIED MATERIALS Endura CL machine is specifically designed to process wafers up to 200 mm in diameter. It also offers an inline process monitoring tool (PST) as well as an endpoint control asset that helps users to maximize yield and optimize overall process performance. In conclusion, Endura CL is a powerful clamshell reactor model that offers superior conformality and uniformity for depositing nano-electronic materials. The reactor is equipped with a variety of advanced features and is fully customizable to meet the needs of the customer. It is also capable of handling a wide range of materials and applications with its high temperature processing and customizable tool design.

There are no reviews yet