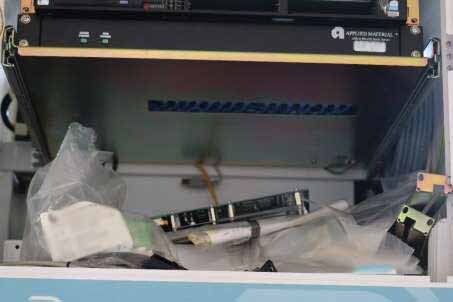

Used AMAT / APPLIED MATERIALS Endura II #293593136 for sale

URL successfully copied!

Tap to zoom

ID: 293593136

Wafer Size: 12"

Vintage: 2009

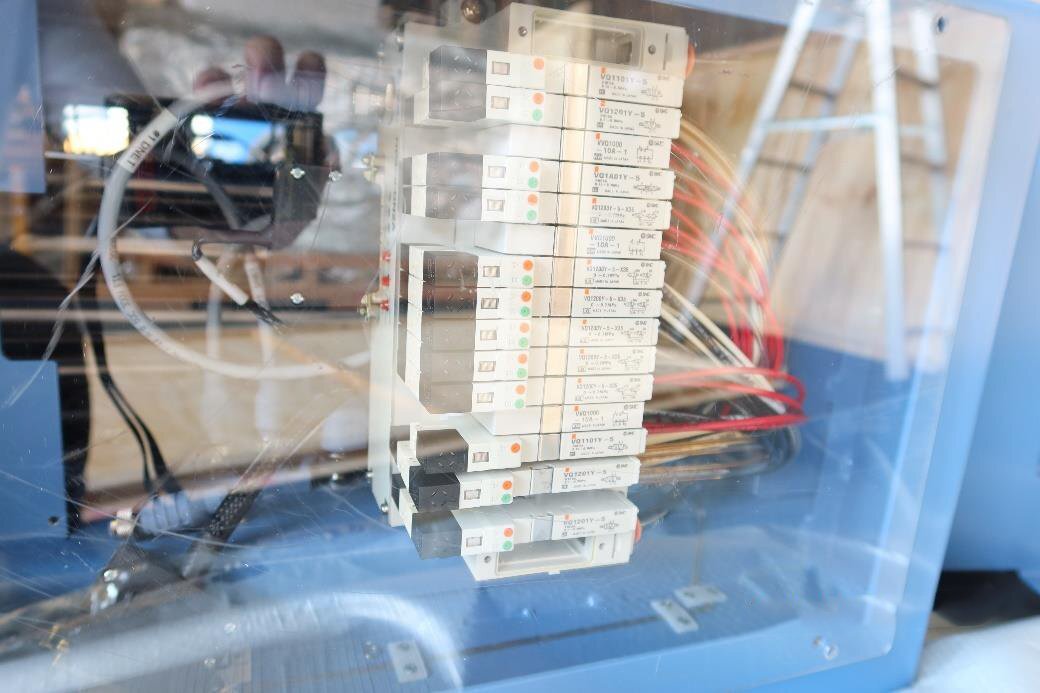

PVD System, 12"

Process: Copper

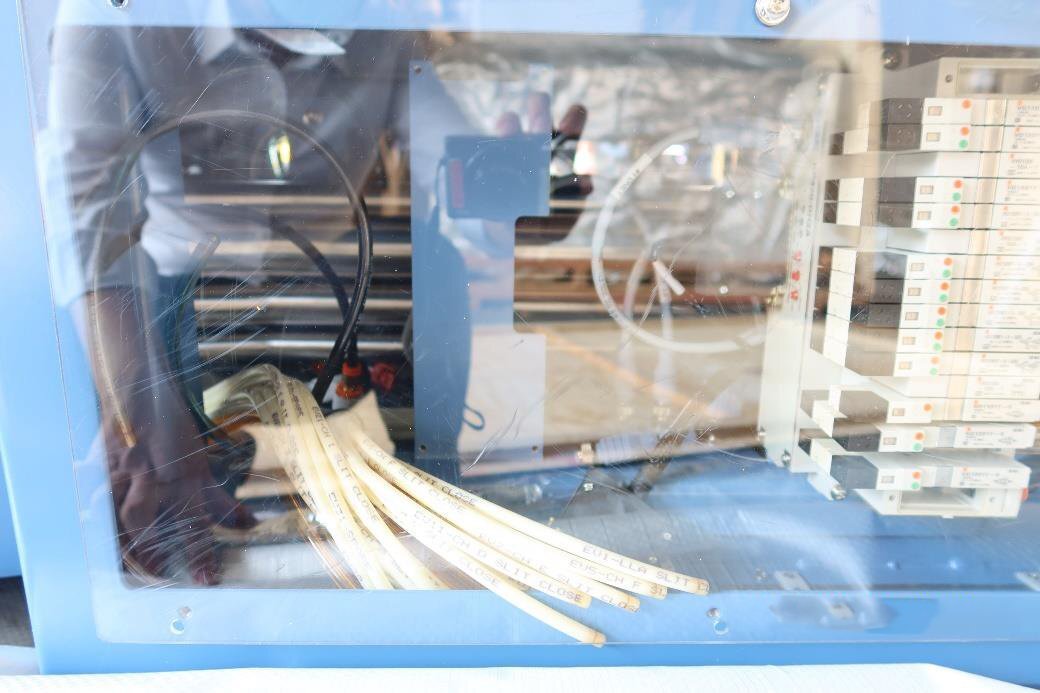

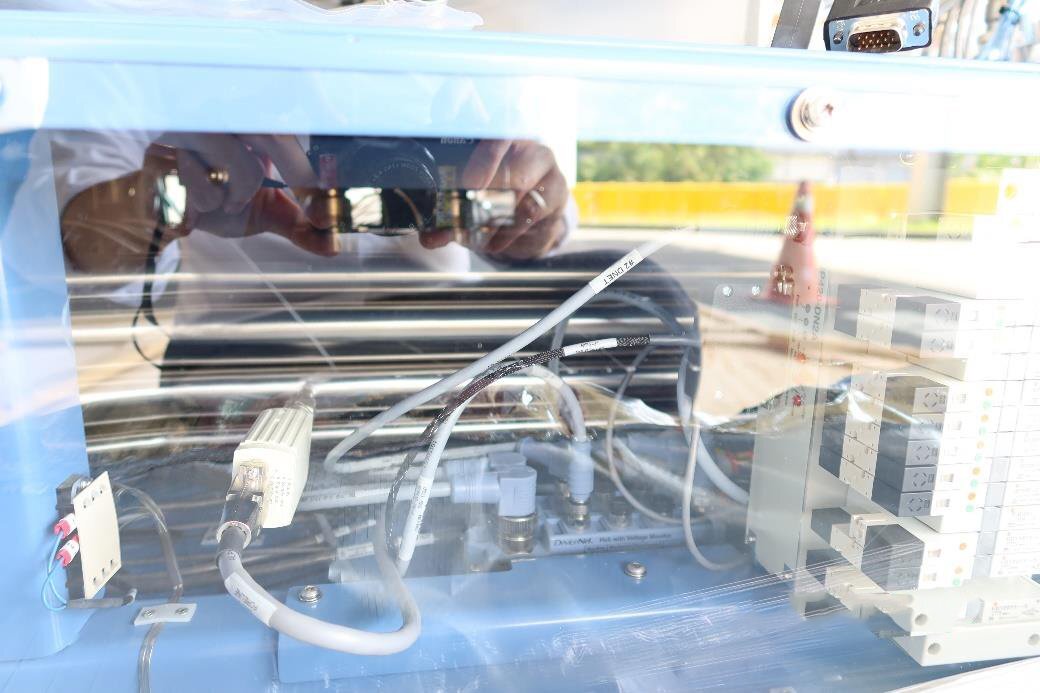

Factory interface

PRI AC Box

SEC AC Box

(3) RF Generator racks

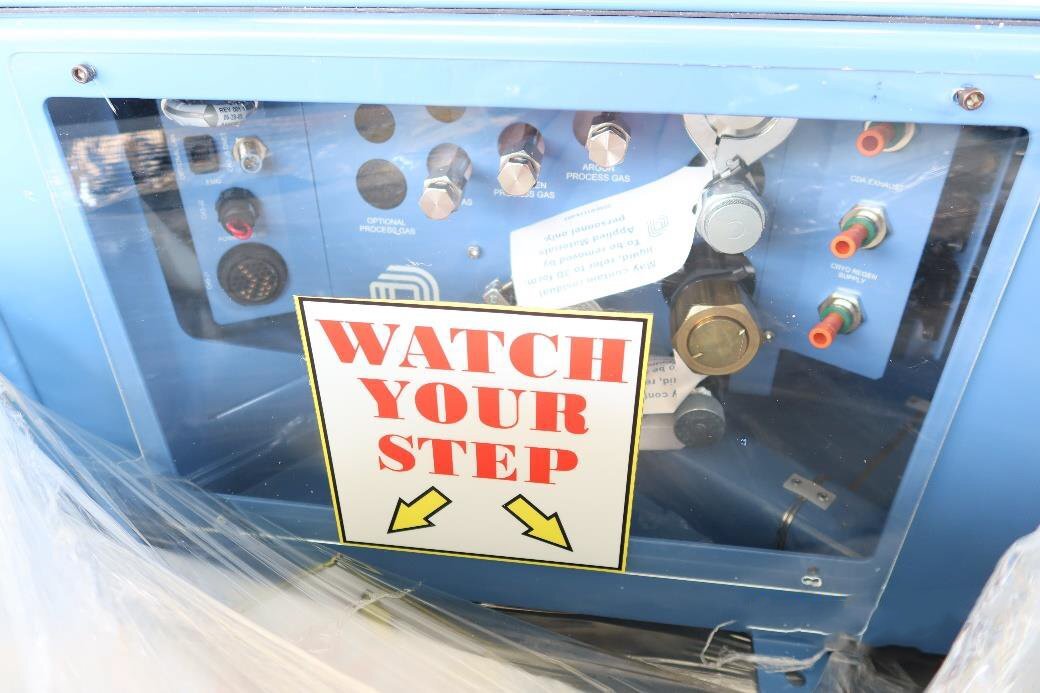

DI Water cooler

(2) Cryo compressors

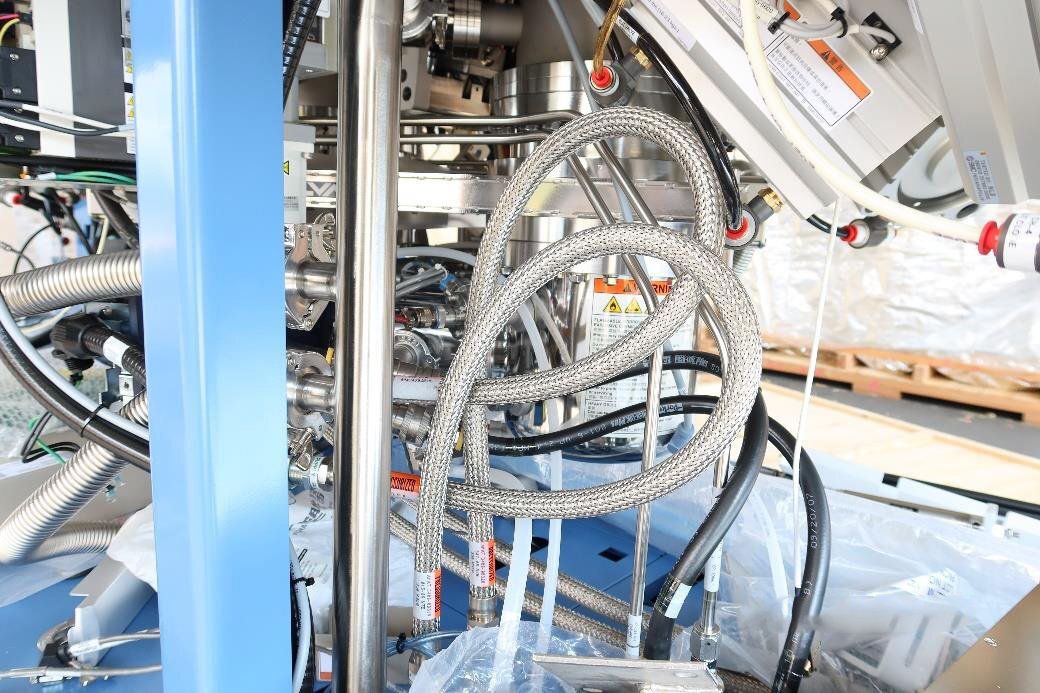

Process chamber (1 / 4): Encore II Tan

Process chamber (2 / 3): Encore II Cu

Process chamber (C / D): RPC

Process chamber (E / F): Degas

(2) Electric distribution boxes

N2 Gun

ALCATEL ADS1202H Loadlock pump

ALCATEL ADS1202H Xfer pump

ALCATEL ADS1202H Pump (Chamber C)

ALCATEL ADS1202H Pump (Chamber D)

EDWARDS iH1000 Pump (Chamber E)

EDWARDS iH1000 Pump (Chamber F)

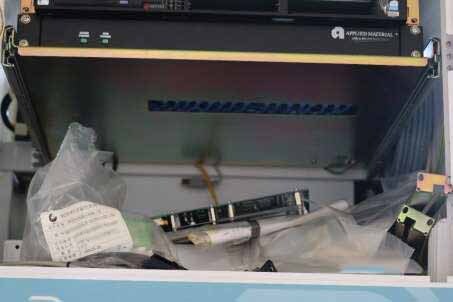

Missing parts:

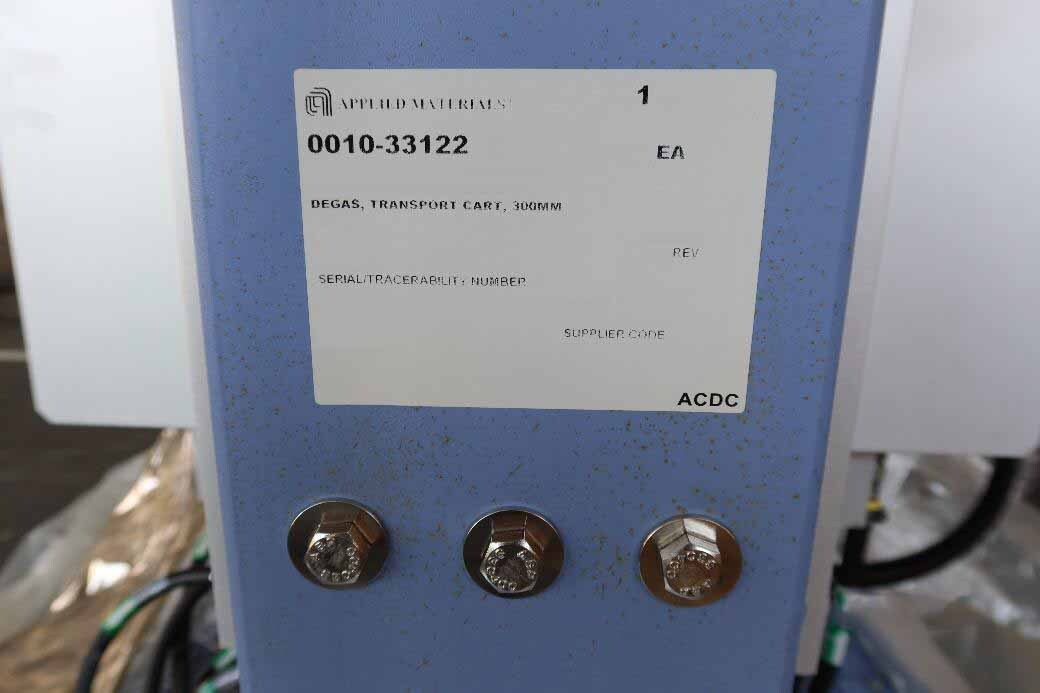

Qty / Part number / Description

(2) / 0242-81627 / NSO Kits, XP Robots with enhanced high temp wrists and shipping case

(4) / 0010-29842 / Robot wrists CIP V2.3

(4) / 0200-06355 / Blades, ceramic open pocket conductive (ACB Blades)

(1) / 0190-25290 / LM Darp edge grip end effector KI (FI Robot blade)

(4) / 0190-41393 / NSK Drivers, 2-axis servo, 110 VAC F47

(1) / 0090-01629 / Assembly, transfer interlock with pos 5, 300mm

(1) / 0090-00353 / MF Buffer interlock PCB

(1) / 0190-24115 / PCB, CDN391R, D-I/O, 300 mm Endura

(2) / 0190-32372 / PCB, CDN396R, A-I/O, 300 mm Endura

(1) / 0190-05682 / PVD Dual chamber degas 208 V heater driver (Degas heat driver)

(1) / 0190-26701 / 0190-43081 / PVD 208 V Dual swill lamp degas driver (Degas lamp driver)

(1) / 0190-54040 / 0190-64793 / On-Board IS Controller (IS2000V Compatible) remote / Pump right mount (IS Controller)

(2) / 0190-54044 / 0190-64799 / Cryo compressors, 208 VAC Mit-ready 300 mm Endura II

(6) / - / Process chambers

(2) / - / RF Generator racks

(1) / - / Xfer Pump

(1) / - / Load lock pump

(4) / - / Chamber pumps (C,D,E,F)

(1) / - / DI Water cooler

(2) / - / Cryo compressors

(1) / - / FI Robot

(1) / - / FI Robot driver

(1) / - / XP Robot driver

(3) / 0190-41014 / LP PCBs

(2) / - / LP EV Modules

2009 vintage.

AMAT / APPLIED MATERIALS / AKT Endura II is an advanced thermal CVD reactor designed specifically for the growth of a wide range of advanced materials. The reactor is capable of performing processes such as Epi, MOCVD, Metal Alloy CVD, and more. Implemented with features such as automated mass flow controllers and thermal process modules, this reactor enables advanced control over growth parameters. This powerful thermal CVD chamber is made of stainless steel and other corrosion-resistant materials for enhanced durability and long-term use. The reactor is equipped with a 25cm diameter quartz boat that enables users to maximize the growth area. A chamber height of 14" combined with an 8" wafer offset make this reactor an optimal choice for advanced deposition processes. AKT Endura II reactor also includes a full set of automated controls, including a PC-controlled process controller, an advanced 2D/3D pattern generator and other related components. This feature helps ensure accurate and precise control over the chemical growth process. The chamber also includes a built-in vacuum blower, which is designed to enhance process flexibility. AMAT Endura II reactor has a load rate of up to 10W/cm2 using advanced controlling techniques such as closed loop temperature control and pressure control. The reactor is capable of working with both inert and reactive gases. Additionally, Endura II is designed to work with custom filtration systems that help eliminate unwanted contaminants and particles. This advanced CVD tool also features high gas flux, high uniformity and high throughput, allowing users to meet the most demanding requirements. APPLIED MATERIALS Endura II has an enclosed design with a small footprint, allowing it to easily fit in a production environment. All in all, AMAT / APPLIED MATERIALS / AKT Endura II is an advanced reactor with the advanced capabilities necessary for advanced deposition processes.

There are no reviews yet