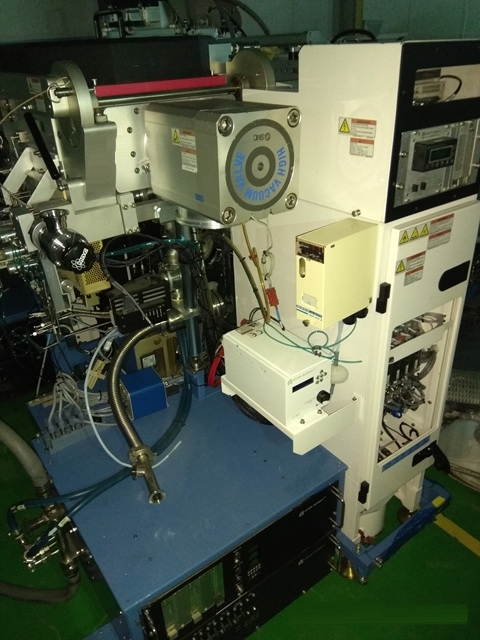

Used AMAT / APPLIED MATERIALS Endura II #9195096 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9195096

CVD TIN Chamber

Process: TXZ

Missing parts:

Showerhead

Isolation ring

H2 Sensor

TMP Leybold.

AMAT / APPLIED MATERIALS / AKT Endura II is a high-productivity, ultra-low-cost wafer processing platform that offers a complete suite of advanced processing solutions. This advanced technology platform is designed to dramatically increase throughput and reduce costs for chip manufacturers. AKT Endura II employs Advanced Metal Etching (AKT) technology, which utilizes a combination of analytical and process knowledge to provide customers with the highest material and performance benefits while reducing time and space costs. AMAT Endura II reactor uses a patented etching method of metal etching to provide customers with unprecedented levels of operational performance and cost-effectiveness. The advanced metal-etching process uses a high frequency, high power and very low frequency (VLF) plasma that is able to etch intricate structural features onto the wafer while retaining the highest levels of accuracy and repeatability. Endura II reactor is optimized for production environments and provides chip manufacturers with ultra-high-resolution uniformity as well as repeatable etching performance. APPLIED MATERIALS Endura II's advanced etching process offers a reduction in plasma etch time, a decrease in the overall etch rate, and improved control over etching profiles and uniformity. This results in increased yields, decreased cost and improved process control. Furthermore, it offers chip manufacturers an advanced technological solution with minimum to zero waste. AMAT / APPLIED MATERIALS / AKT Endura II reactor also employs advanced-edge isolation techniques, which enables chip manufacturers to achieve repeatable high-resolution patterning across a wider range of substrates without having to use any special masks or patterns. From a productivity standpoint, AKT Endura II offers several advantages. Its high throughput system enables chip manufacturers to perform multiple etch-and-print processes simultaneously with minimal contact. The reactor's open architecture also permits for parallel processing, allowing chip manufacturers to quickly complete several processes in parallel. Moreover, its patent AMAT design is capable of reducing the total time and vacuum complexity of chip manufacturing. Combined with its efficient Advanced Metal Etching technology, AMAT Endura II provides chip manufacturers with a versatile and cost-effective solution for high-volume, high-quality manufacturing. Its advanced etching technology also offers chip manufacturers significant advantages in process accuracy, throughput, cost, and repeatability. With its cutting-edge platform, Endura II is the perfect choice for chip manufacturers looking for a complete, ultra-low-cost, high-productivity processing solution.

There are no reviews yet