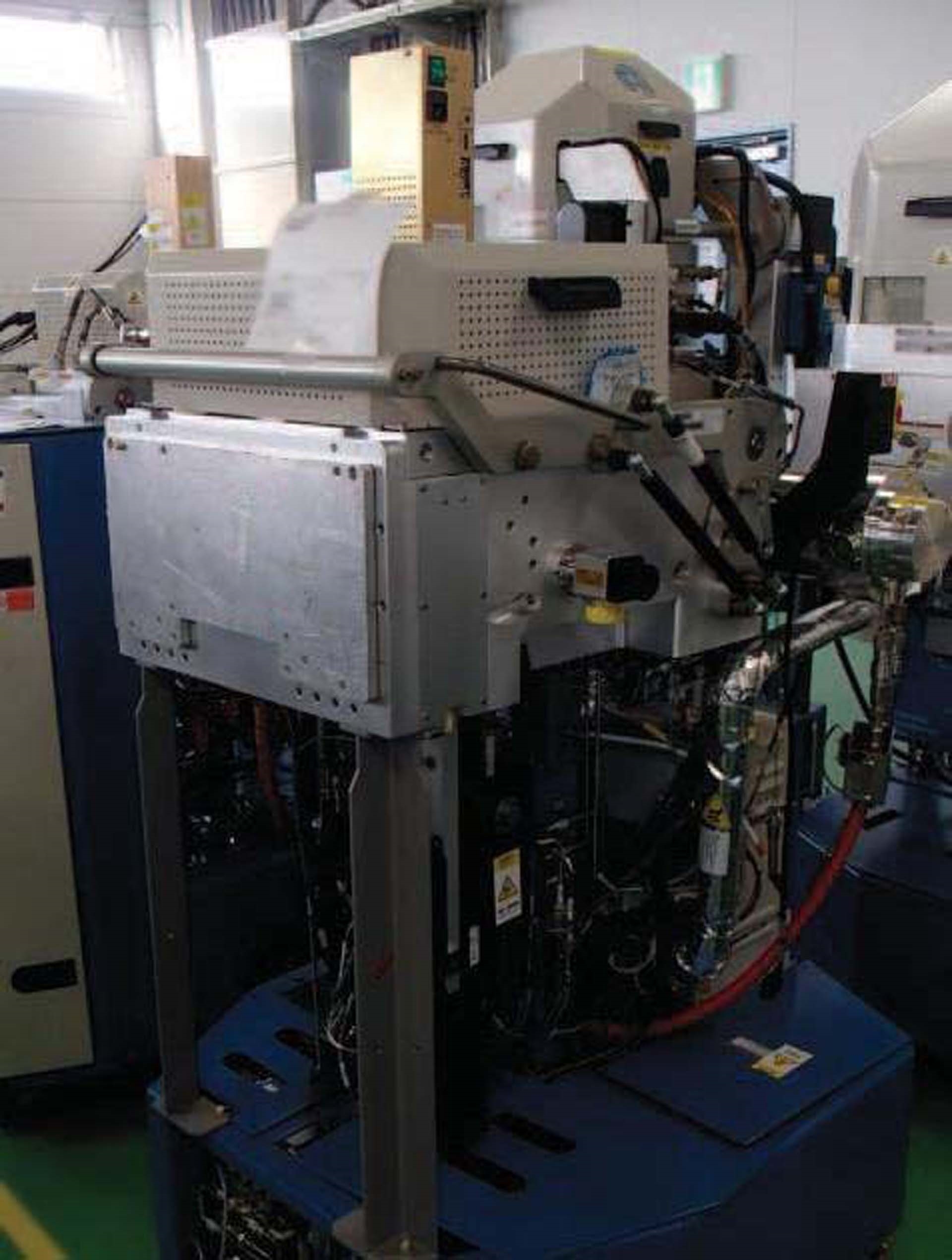

Used AMAT / APPLIED MATERIALS Endura II #9205044 for sale

URL successfully copied!

Tap to zoom

ID: 9205044

Wafer Size: 12"

Vintage: 2004

PVD System, 12"

(3) Scanners

(3) Racks

CVCF Rack

(3) Monitor racks

Front monitor rack

System component information:

Factory information:

FFU Type: Thin type

(3) POD

FLEX 4 Controller long type

Light curtain

Signal tower: 3 Colors

Robot type: YASAKAWA AT Robot

Pass through option: (2) Slots

Degas chamber information:

(2) Chambers

Chamber type: Standard

Cryo pump: IS-8F

Chamber A&B information:

Chamber A: Pass

Chamber B: Cool

Lid type: Clear

Buffer & transfer information:

Robot type: XP

RGA Option: No

Cryo pump: IS-8F

LCF Amplifire:

(14) Buffer

(12) Transfer

Chamber 1:

Process type: ALPS Co

Adapter: 0040-62882

Spacing: 225 mm

Weldment type: Old type

MFC:

UFC 8565C-AR 150 sccm

UFC 8565C-AR 20 sccm, HTR Gas

Chamber 2:

Process type: Ni-10at%Pt

Adapter: 0041-02309

Weldment type: Old type

MFC:

UFC 8565C-AR 100 sccm

UFC 8565C-AR 20 sccm, HTR Gas

Chamber 3:

Process type: TTN

Magnet: DURA

Adapter: 0040-80367

MFC:

UFC 8565C-AR 100 sccm, Process

UFC 8565C-AR 20 sccm, HTR Gas

UFC 8565C-N2 200 sccm, Process

Chamber 4:

Process type: SIP TiN

Adapter:

0040-62877 Bottom, SIP TTN

0040-76943 Upper, SIP TTN(3L)

MFC:

UFC 8565C-AR 50 sccm, Process

UFC 8565C-AR 20 sccm, HTR Gas

UFC 8565C-N2 100 sccm, Process

Chamber 1 / 2 / 3 / 4:

Controller tower type: CCT

Heater type: ESC

Gate valve type: Old type 3 pos

Cryo pump: IS-BF

Shutter option

Sub rack:

Load center rack

(3) Equipment racks

(2) Heater exchangers

Heater exchanger type: SMC Thermo chiller INR-498012D-X007

2004 vintage.

AMAT / APPLIED MATERIALS / AKT Endura II reactor is an advanced, advanced-technology, high-temperature PCVD processing equipment designed to enable advanced lithography and semiconductor applications. AKT Endura II reactor is based on a proprietary high-temperature PCVD process which is capable of coating, depositing, and diffusion of ultra-thin layers. The system includes a high-power cathode to provide high throughput; a multi-dimensional variable frequency modulator for precise process control; a large target area for wafer blanking and high-precision nitrogen/oxygen purge management; and a computer-controlled lift-off unit for exact wafer-thickness control. The machine also includes a powerful plasma treatment operation that can be coupled with the high-temperature PCVD process for enhanced substrate film adhesion. The tool has a large temperature range so that it can be used for a variety of applications, including the deposition of thin layers and the diffusion of metals. AMAT Endura II reactor also offers excellent wafer blanking ability and its process capability is such that it can meet the highest level of precision with minimum human intervention. To ensure maximum throughput and precision, Endura II reactor is also equipped with a powerful gas feed asset that enables the precise control of the thin film deposition process. This gas feed model has a heat-up mode that enables the equipment to operate at different temperatures when required to achieve desired results. In addition to the specific process capabilities of APPLIED MATERIALS Endura II reactor, it is also equipped with advanced data logging and collection capabilities. This system is capable of plotting complex data points with millisecond precision. Furthermore, the unit has been designed to work together with the PC-based software application AKT to enable further customization of processes. AMAT / APPLIED MATERIALS / AKT Endura II reactor is a well-rounded piece of advanced equipment that offers reliable, precise performance to meet the needs of the most demanding applications. Thanks to its powerful cathode, the ability to control gas flow and temperature, and its extensive data logging and collection capabilities, AKT Endura II reactor is the perfect choice for any PCVD processing application.

There are no reviews yet