Used AMAT / APPLIED MATERIALS Endura II #9237854 for sale

URL successfully copied!

Tap to zoom

ID: 9237854

Wafer Size: 12"

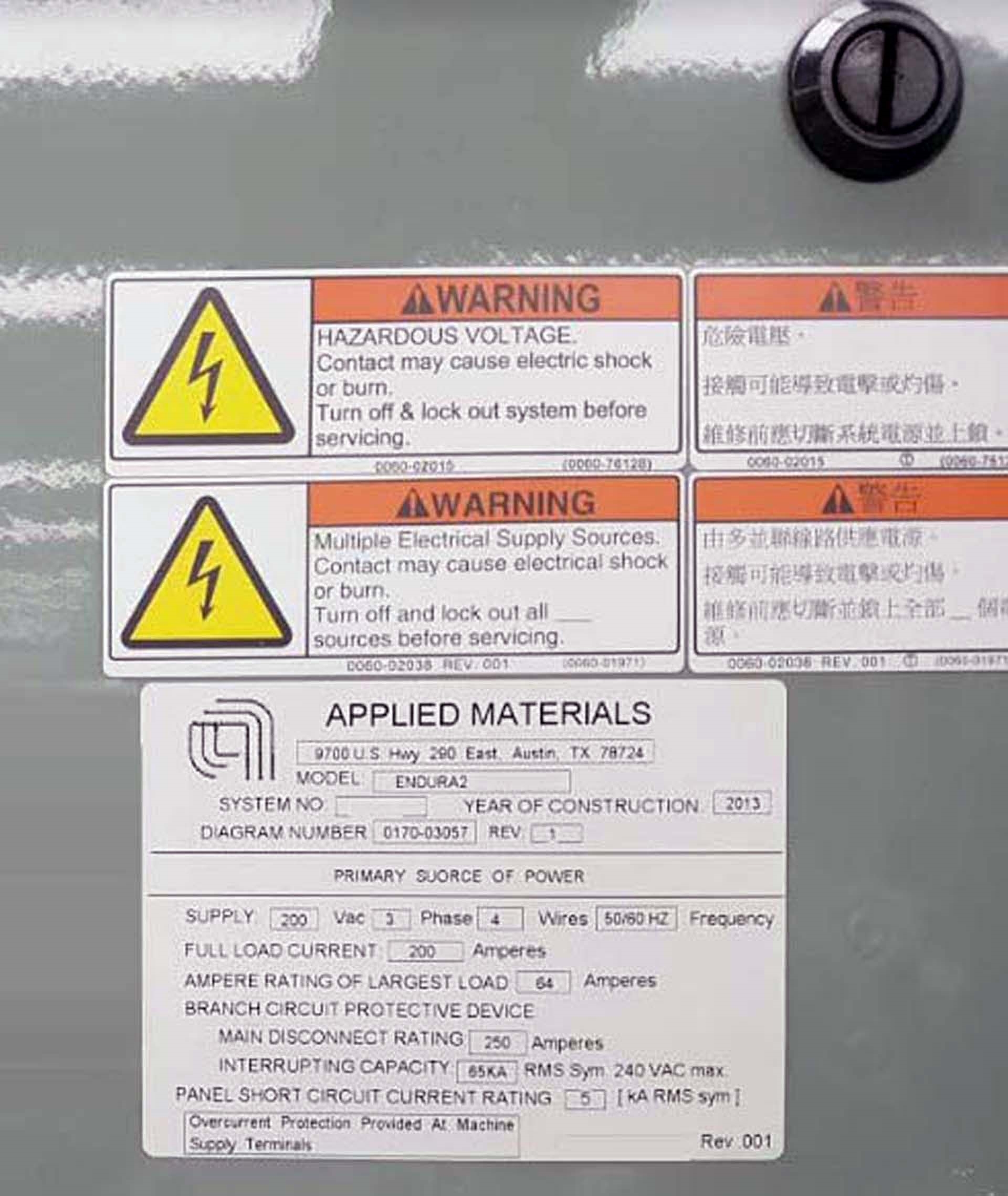

Vintage: 2013

PVD System, 12"

Process: AlCu Depositon

FI

SMIF System: (3) Load ports

Mainframe

(6) Chambers:

(2) HP AL

(2) DS TTN

(2) Degas

Handler system:

FI YASAKAWA Robot

Buffer XP robot

Transfer XP robot

Accessories:

DI MAX

Equipment rack

(2) Compressors

(2) Generator racks

2013 vintage.

AKT/AMAT / APPLIED MATERIALS / AKT Endura II is a state-of-the-art wafer processing reactor that is used in semiconductor and related industries. It has been designed to enable efficient, accurate and reliable processing of wafers. The reactor is made up of several different components, including an induction heating equipment, a gas delivery system, a vacuum chamber, an RF power generator, a cooling fan, a plasma generator, and a Pyrolytic Graphite Reactor (PGR) shield. The induction heating unit uses a specially designed coil to rapidly heat the wafers to the desired temperature for the process to be carried out. The gas delivery machine provides the gases used in the process, which can include nitrogen, oxygen, argon and other simpler molecules. The vacuum chamber maintains a constant vacuum pressure within the chamber, allowing for efficient wafer processing. The RF power generator produces the necessary radio frequency power for the plasma generator to be activated. Once the gases have been injected into the chamber, the plasma generator creates a powerful plasma field which acts to break bonds in the gases, forming a plasma species which can be used to carry out a variety of processes, such as etching, deposition, annealing or growth. The cooling fan keeps the PGR shield at a constant temperature to protect the wafers from damage due to heat. Finally, the reactor can be used to measure parameters such as temperature, pressure, RF power, gas flow and uniformity. Overall, AMAT/AKT Endura II is a highly advanced and reliable wafer processing reactor that provides efficient and accurate processing. It is an ideal choice for semiconductor industry professionals who value accuracy and speed. Thanks to its various features, it is also an efficient and safe option for processes such as etching, deposition, annealing or growth.

There are no reviews yet