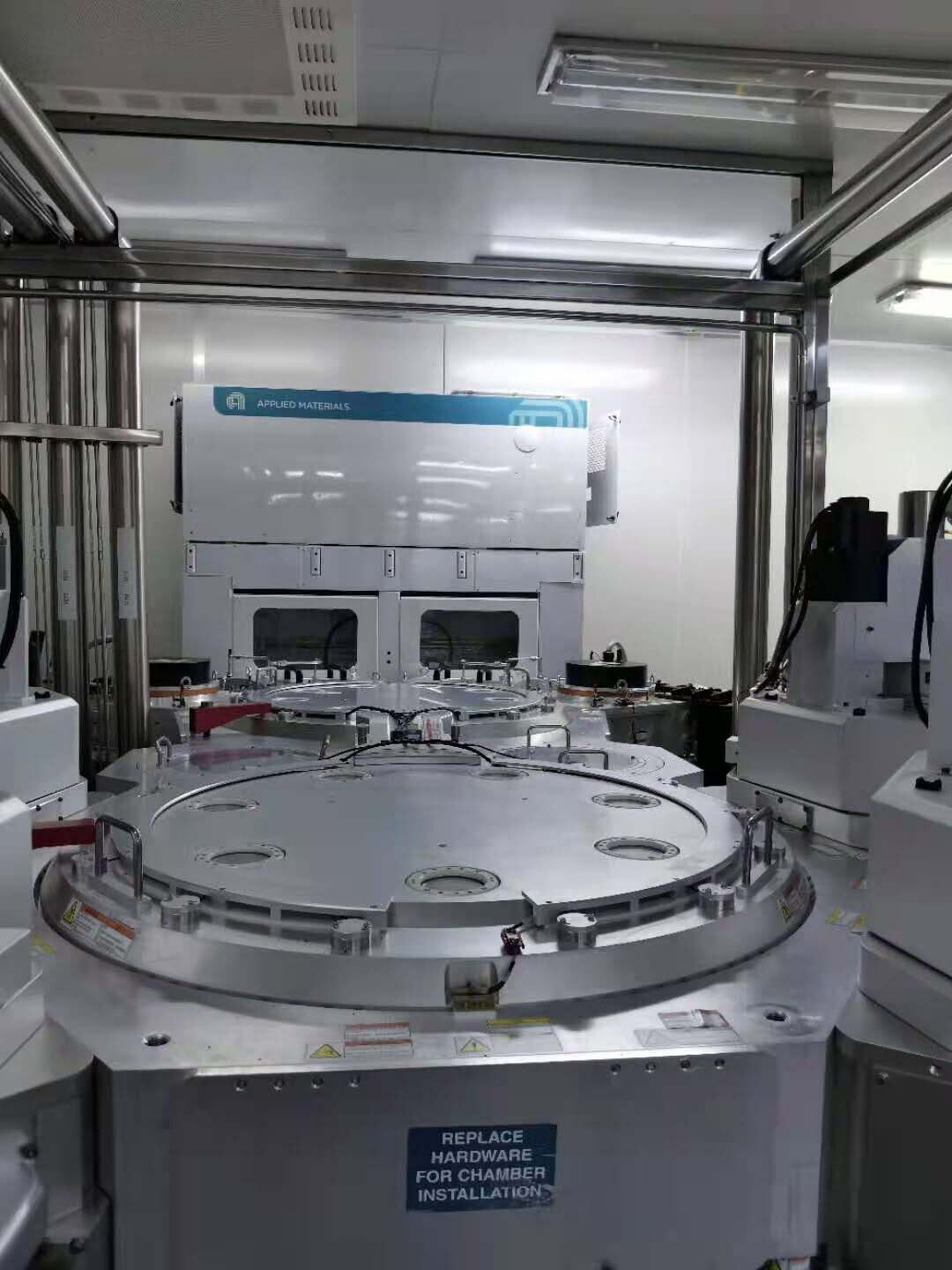

Used AMAT / APPLIED MATERIALS Endura II #9315356 for sale

URL successfully copied!

Tap to zoom

ID: 9315356

Wafer Size: 12"

PVD System, 12"

Wafer type: Notch

3E

(2) Impulse AIN chambers

Chamber A:

Location / Option

Position 1 / Impulse

Position 4 / Impulse

Position A / Cool down

Position B / Cool down

Position E / Dual mode degas

Position F / Dual mode degas

Line frequency: 50 Hz

No UPS / CVCF

Standard mainframe

Single wafer load locks: HT SWLL without degas module

XP Robot with enhanced high temperature wrists

Operating system: Windows XP

Rack

CTI-CRYOGENICS Cryo Pump

(2) Cryo compressors

Cryo compressor voltage: 400 V - 480 V

MFC Type: GF 125

Impulse: Position (2, 3)

Wafer pedestal E-chuck

Process kit type: TAOX

P/N: 1444245-00

Shutter

RGA Valve manual

Turbo cryo pump with water trap

Heat exchanger hose: 50 ft

Power supply: 10 kW, DC

(2) EDWARDS IH1000 Pump

Rough pump voltage: 208 V

Modular remotes umbilical:

AC Rack to rough pump: 75 ft

Mainframe to rack: 75 ft.

AMAT / APPLIED MATERIALS / AKT Endura II is a batch-type, production-grade, advanced PECVD (Plasma Enhanced Chemical Vapor Deposition) reactor used for a variety of substrate deposition processes. AKT Endura II reactor has a unique design that offers high-performance advanced film deposition with improved uniformity and precision. The equipment is highly modular and customizable and offers a wide range of configurations depending on substrate size and deposition requirements. AMAT Endura II offers a variety of performance-enhancing features including a high-resolution LCD touchscreen interface and smart user interface that allows users to select from a wide range of parameters to tailor the performance of the system. APPLIED MATERIALS Endura II also utilizes two independent RF generators to enable optimized tuning of the plasma in terms of increasing the uniformity of the film, reducing the polygonal shape artifacts, and enhancing the selectivity of the deposition process. In addition, Endura II offers effective in-situ cleaning which improves substrate integrity and extends the life of the deposition chamber. AMAT / APPLIED MATERIALS / AKT Endura II utilises a polysilicon chamber that has a cylindrical profile, which offers increased gas distribution for better uniformity, improving the plasma profile and enables larger substrates to be deposited via higher discharge rates. The unit includes a gas manifold that includes up to four gas inlets enabling multi-gas deposition processes and three optional high energy ion cannons for adhesion promotion. The reactor is equipped with an automated control machine, helping to improve reproducibility and process control. The advanced control algorithms, coupled with the large choice of parameters available on the user interface, allows users to tune the plasma reactants to a desired condition, allowing a greater degree of control during the process. AKT Endura II is a versatile tool that offers a range of advantages to the user. In addition to increased gas dispersal and improved uniformity, the multiple gas inlets and in-situ cleaning options make it an ideal solution for manufacturers looking for a cost-effective and reproducible solution for their deposition processes.

There are no reviews yet