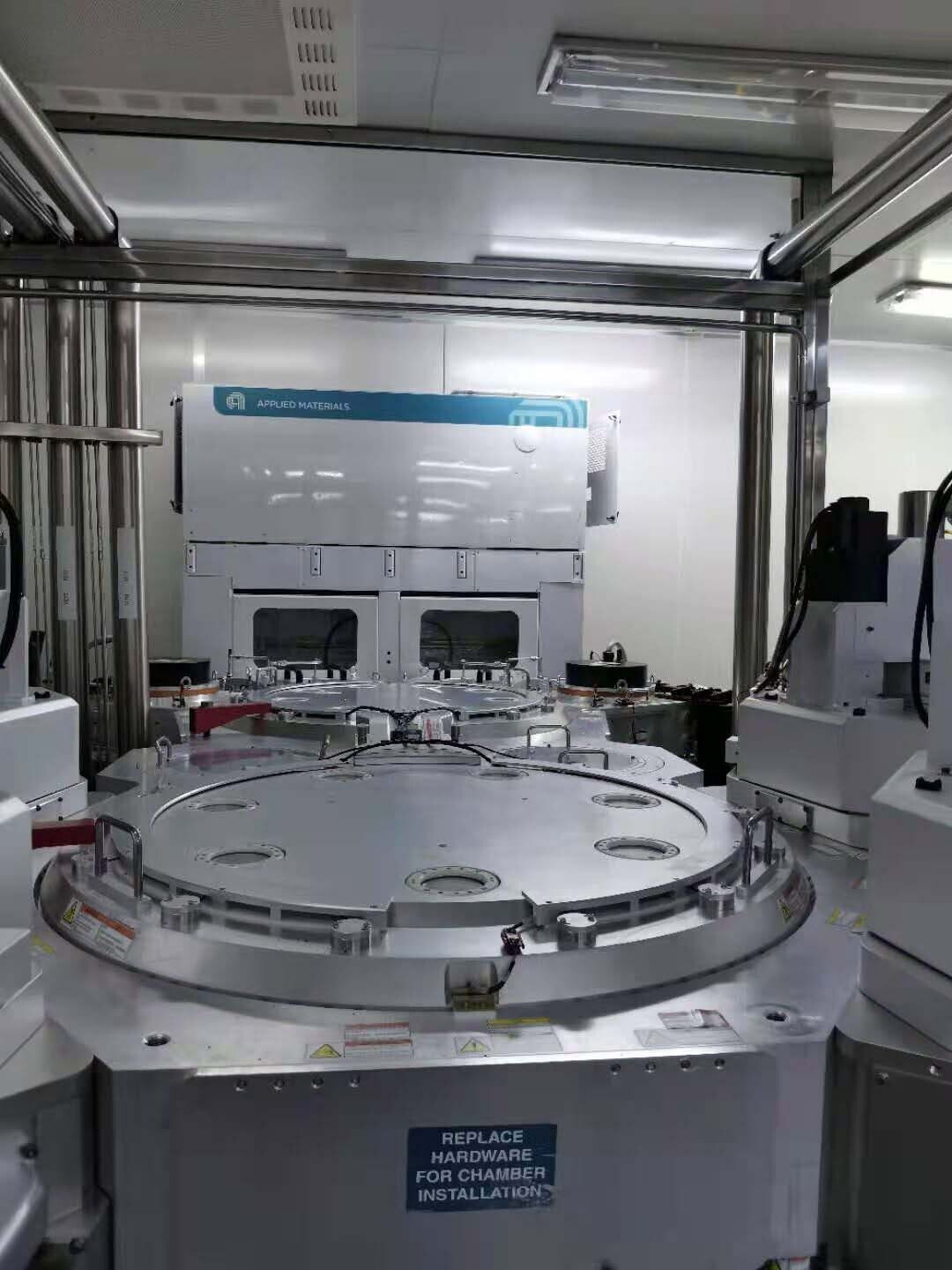

Used AMAT / APPLIED MATERIALS Endura II #9315363 for sale

URL successfully copied!

Tap to zoom

ID: 9315363

Wafer Size: 12"

PVD System, 12"

Wafer type: Notch

3E Impulse AIN System

Chamber location / Option

Level 1 / Endura II

Level 2 / Emerging

Position 1 / Impulse ALN

Position 4 / Impulse ALN

Position A / Cool down

Position B / Cool down

Mainframe

Motion controller

Particle management package

Chamber cool down gas lines

Single wafer load locks: HT SWLL without DEGAS module

XP Robot with enhanced high temperature wrists

Metal robot blade

Rack

CTI-CRYOGENICS Cryo Pump

(2) Cryo compressors

Cryo compressor voltage: 400 V - 480 V

Cryo helium lines: 75 ft

Heat exchanger hose: 75 ft

MFC Type: GF 125

Factory interface:

Front end module

Platform application: CPI

Gen 4 with KVM server and user interface

UPS

HT SWLL With STD / Opera

OHT WIP Delivery

(2) SELOP 7 Load ports

Info pad position: A / B

Colored lights

(8) Lights load port operator interface

E99 Carrier reader: TIRIS With RF

Upper E84 Data logging sensors and cables

Operator access switch

Top air intake systems

(4) Colors light tower

Rack

System monitors:

Flat panel monitor, 19"

Keyboard

Cables: 15 ft with 6 ft effective

Remote flat panel monitor, 19"

Cables: 75 ft with 65 ft effective

Impulse: Position (1, 4)

Biasable wafer pedestal HV E-Chuck

Shutter

Baratron gauge size: 100 mTorr

RGA Valve manual

Turbo cryo pump with water trap

DEGAS RGA Valve manual

(4) EBARA AA70W Pumps

(2) ADIXEN A100L Pumps

Rough pump voltage: 208 V

Umbilical:

AC Rack to mainframe: 75 ft

AC Rack to HX: 75 ft

AC Rack to rough pump: 75 ft

Mainframe to equipment rack: 75 ft

Power supply: 10 kW, DC.

AMAT / APPLIED MATERIALS / AKT Endura II is an advanced plasma etch reactor designed for a wide range of power and process projects. The reactor is ideal for deep anisotropic, directional etching, deposition, oxidation, and low temperature decomposition. The system utilizes a high vacuum evaporation to deposit up to four different deposition materials simultaneously. It uses advanced gas delivery and advanced plasma control. AKT Endura II can operate at vacuum levels from 0.1 to 5.5 milligrams per cubic foot, giving it the capability to perform rapid and precise deposition processes. AMAT Endura II is designed for high power applications and has capabilities to operate at up to 10,000 Watts power level. It has independent electrode tilt to provide angular dependence control of etch rates and uniformity. Endura II also features advanced scrubber and filtration systems to reduce particle contamination and reduce system maintenance requirements. For etching and other PW processes, APPLIED MATERIALS Endura II utilizes dual inductor coils to produce a high density, soft plasma for etching, as well as a high power inductor for deposit of thick film coatings. AMAT / APPLIED MATERIALS / AKT Endura II also has the ability to apply an additional coil to provide highly directional etching. AKT Endura II features a non-contaminating quartz nozzle and tube configuration which allows for low pressure processing. This design eliminates the need for shutting down the system to periodically clean the chamber, by continuously ejecting the particle-laden gases through the quartz filter. The innovative technology of AMAT Endura II allows for precise and repeatable processes, providing a superior quality of etching, deposition and oxidation capabilities. It can also simulate various temperatures from 100 to 1600°C, allowing for a wide range of unique applications. Endura II is ideal for applications where high power, repeatable processes, and low-temperature deposition are needed. It has the capability to process a wide variety of materials and substrates and is available in different levels of complexity, based on size, complexity, and power requirements.

There are no reviews yet