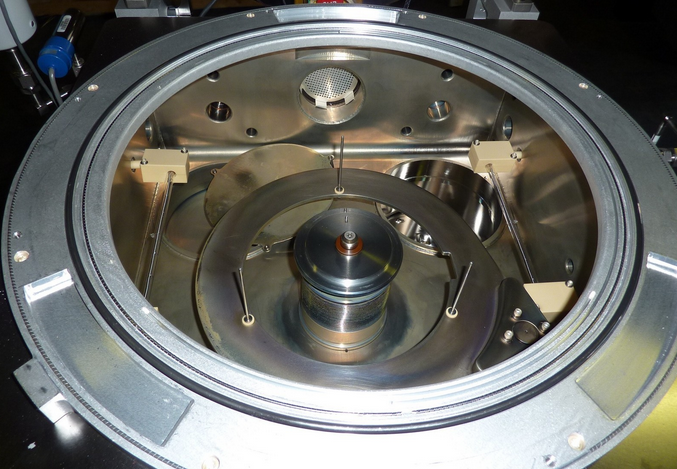

Used AMAT / APPLIED MATERIALS Endura Pre Clean Chamber #9008985 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9008985

Position D, 12"

Includes:

Leybold turbo vac 1000 C turbo pump

Granville-Phillips 352 gauge controller

Gas box distribution PCB - 0100-00567

CDN 396 card

CDN 391 card

Preclean chamber interlock card.

AMAT / APPLIED MATERIALS Endura Pre Clean Chamber is an automated, large-scale Integrated Tool (IT) reactor designed to speed up the fabrication process of making semiconductor chips. It is an efficient method for removing critical contaminant layers from substrates and wafers prior to entering a traditional processing chamber. This chamber is especially useful for removing dirt, dust, and other volatile organic compounds (VOCs) that would otherwise pass through traditional processing chambers and become embedded in the chip's circuitry. AMAT Endura Pre Clean Chamber has a built-in automated control equipment that allows for continual monitoring of the process. It is the first step of a multi-step semiconductor processing system, providing a major advantage of lower cleanroom footprint size due to the high levels of integration. The Endura is controlled by a patented unit enabling control of temperature, pressure, oxygen concentration, and other variables. The Pre Clean Chamber uses programmable parameters and autonomous adjustment of process conditions. It operates in two different procedures, a single-step process for depositing an oxide, and a two-step process for depositing and etching a single layer. The chamber is constructed directly into the wafer processing machine, providing a tightly sealed environment in which to work. The chamber is constructed of stainless steel and is equipped with a high purity O-ring for improved sealing. The chamber also contains three independently operated RF plasma zones and a series of multi-level internal filters, providing a better environment for cleanroom processing. The built-in controller within the chamber enables a wide range of substrate and process parameters to be monitored and adjusted. It also offers rapid temperature and pressure control, as well as real-time defect detection, and control of substrate temperature and RF power. The monitoring tool provides complete visibility of all process variables, ensuring the highest levels of wafer yield. This chamber is extremely reliable and efficient, with the ability to run 24/7 with minimal maintenance. Its user-friendly interface simplifies programming, operation, and control, making it easy for operators to achieve optimal results with minimal effort. This chamber is a great tool to ensure maximum wafer quality and yield in the semiconductor manufacturing process. It provides great value for money, offering a reliable and efficient solution to rapidly remove contaminants from substrates prior to entering a traditional chamber. It is an essential and cost effective component for cleanroom fabrication.

There are no reviews yet