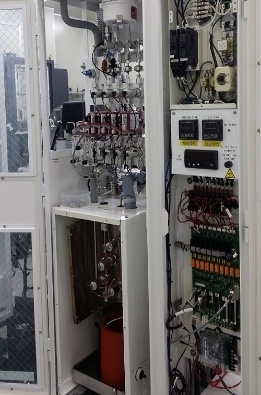

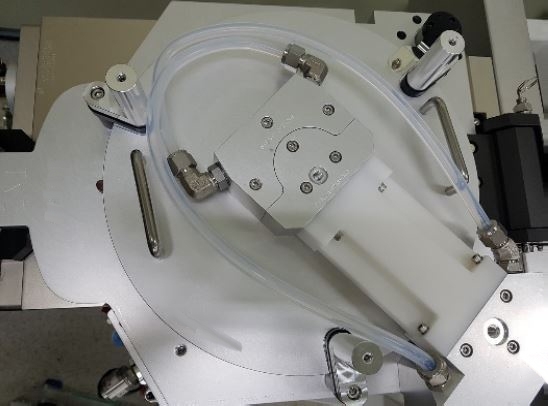

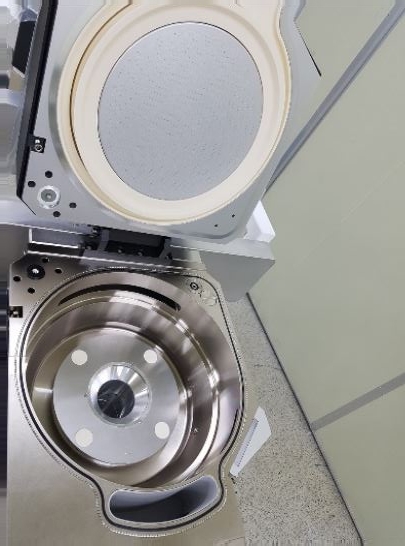

Used AMAT / APPLIED MATERIALS Endura TxZ #9192252 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS Endura TxZ Reactor is a state-of-the-art chemical vapor deposition (CVD) equipment designed to provide users with unmatched process control and accuracy within the semiconductor industry. This system utilizes an array of advanced technologies to achieve optimum process control and product quality, delivering increased long-term productivity while maximizing yield and cost-efficiency. AMAT Endura TxZ Reactor features an ultra-low-thermal-mass (ULTM) generator chamber and substrate cabinets. This design minimizes parasitic losses and maximizes thermal performance, drastically reducing thermal cycle time and providing high process speeds. An innovative multi-zone temperature control unit further maximizes control accuracy and reduces non-productive process time by allowing fine tuning of each individual temperature zone. Additionally, an on-board pressure booster further minimizes thermal cycle time, allowing higher throughput rates. To ensure high-quality device production, APPLIED MATERIALS Endura TxZ Reactor provides absolute process control and repeatability of all parameters, including source temperature, installation height, rotational speed, motion time, gas mixture and gas flow. Further, the machine is designed to integrate a large number of advanced process monitoring and control tools, including real-time in situ process analytics and control, total pressure control, real-time spectroscopy, image recognition systems and quantitative analytics. Endura TxZ Reactor also incorporates a variety of safety features, including automatic pressure release systems and reactor safety shutoff mechanisms. This ensures peace of mind for users and provides an additional level of security for operators and co-workers in the facility. AMAT / APPLIED MATERIALS Endura TxZ Reactor provides an impressive set of features, making it an ideal choice for advanced process control in semiconductor applications. The tool's advanced technology ensures fast thermal cycle time, process repeatability, and excellent product quality results, so users can rely on the asset to help them reach optimum process performance and cost savings.

There are no reviews yet