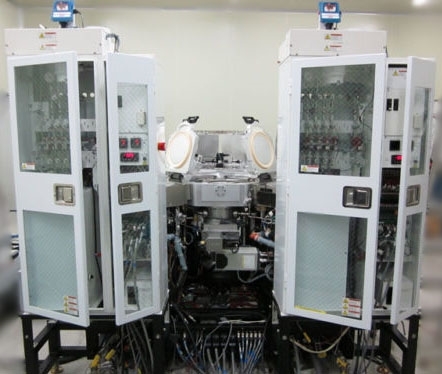

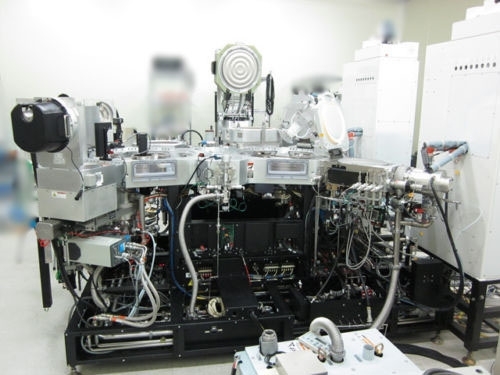

Used AMAT / APPLIED MATERIALS Endura TxZ #9194422 for sale

URL successfully copied!

Tap to zoom

ID: 9194422

Chamber

Configuration:

Chamber 1: IMP

Chamber 2,3: HP + TxZ

Chamber C: Preclean II

Chamber E,F: Orient degas

Robot: Buffer HP

Transfer: VHP.

AMAT / APPLIED MATERIALS Endura TxZ reel-to-reel cluster tool has been developed to provide improved process performance and high throughput for advanced semiconductor device manufacturing. It is a chemical mechanical planarization (CMP) reactor capable of processing large substrates up to 600 mm in size, and delivers repeatable performance with low wafer-to-wafer variation. AMAT Endura TxZ is equipped with two large chambers, two single-wafer polishers and two double-sided wet processing stations. It is designed to perform multiple processing tasks in a single system, including chemical-mechanical planarization (CMP), polishing and chemical etching. The main chamber houses the main CMP robot, which handles the loading and unloading of wafers and controls the loading- and unloading of the polishing pads. The software platform of APPLIED MATERIALS Endura TxZ provides intelligent process control and process monitoring in order to deliver high yields and consistent results. The CMP process parameters are optimized to a given application, allowing for dynamic process control, and can be adjusted according to the material type and application requirements. The main chamber, the main robot and the main dispenser can be controlled and monitored from the software platform. Endura TxZ reactor has high-speed conveying and positioning capability, which results in reduced cycle times and improved throughput. Its dynamic polishing capability allows for uniform polishing over the entire wafer. AMAT / APPLIED MATERIALS Endura TxZ is one of the only CMP systems to offer a DC lap for producing flat, even polishing surfaces. The redundant mechanical design of AMAT Endura TxZ ensures reliability and the long lasting accuracy of the CMP configurations over extended periods of time. The highly automated design of APPLIED MATERIALS Endura TxZ allows for increased throughput, improved safety and environment control, and greater process control to determine the proper material removal rate over the entire wafer. Its stringent wafer-level control minimizes waste and helps to ensure that the proper amount of material is being removed at the right speed and power level. With its auto-detect system, Endura TxZ offers more precise process control when processing larger substrates. AMAT / APPLIED MATERIALS Endura TxZ is designed to work in both front side and back side applications. It is used in a variety of industries, including integrated circuit manufacturing, MEMS fabrication and advanced wafer fabrication. Its standard configuration allows it to be easily adaptable to different technologies and materials, making it a powerful and reliable solution for next generation semiconductor manufacturing.

There are no reviews yet