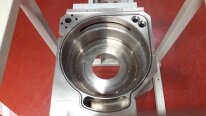

Used AMAT / APPLIED MATERIALS Endura TxZ #9203028 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS Endura TxZ is an advanced in-line, direct thermal processing reactor used in high-volume semiconductor device and photovoltaic cell manufacturing. This tool is capable of processing 300mm (12 inch) wafers, which allows for higher throughput and better productivity. AMAT Endura TxZ process chamber is divided into several zones, each of which is specifically designed to handle different functions. The cassette station can accommodate both electron beam evaporation sources and physical vapor deposition (PVD) sources. The process chamber is also equipped with advanced cooling and temperature control mechanisms. In addition, APPLIED MATERIALS Endura TxZ uses a high-frequency, high-duty cycle power source for rapid heating of the process chamber. Endura TxZ can process multiple types of materials, including compounds such as gallium arsenide, silicon dioxide (SiO2), and indium tin oxide (ITO). It can also evaporate elemental materials like aluminum and magnesium. AMAT / APPLIED MATERIALS Endura TxZ is ideal for precision deposition of antireflective and anti-reflective coating materials, as well as a number of other materials. It also has a wide range of process capabilities, including sputtering, chemical vapor deposition (CVD), electron beam evaporation, and atomic layer deposition (ALD). In addition to its working temperature range of 200-1200°C, the tool features advanced monitoring, diagnostics, and cleaning systems. The built-in sensing and control equipment ensures precise wafer positioning and ensures uniform deposition across the entire wafer surface. It also allows for optimal adjustment of process parameters for improved results. AMAT Endura TxZ includes a real-time monitoring and diagnostics system, which provides consistent data for recipe development and optimization. The diagnostics unit also monitors and reports any potential issues with the machine, giving engineers instant feedback so they are able to quickly respond to any issues. APPLIED MATERIALS Endura TxZ is compatible with other advanced tools used in semiconductor manufacturing. It has been designed to integrate well with robots, dust filters, and other post-processing equipment. This allows engineers to add additional layers of automation to the process, ensuring faster turnaround times, improved accuracy, and higher yields. It also has the flexibility to adapt to changing process requirements, making it suitable for a wide range of applications. From chip manufacturing to photovoltaics, Endura TxZ is a versatile and reliable processing solution.

There are no reviews yet