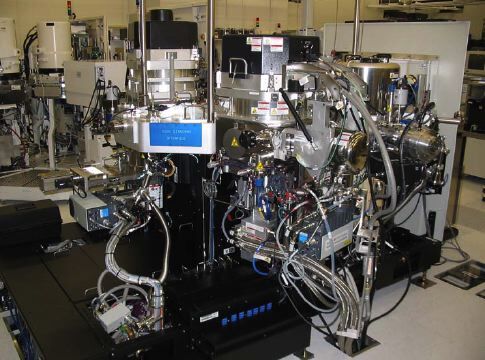

Used AMAT / APPLIED MATERIALS ENDURA #117307 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 117307

Wafer Size: 8"

Vintage: 2001

Barrier / seed, 8" wafers (SNNF)

SMIF

CH A – Pass through

CH B – Cool Down

CH C – Pre-Clean IIe ceramic

CH D – Pre-Clean IIe ceramic

CH E – Orient / Degas

CH F – Orient / Degas

CH 1 –

PVD SIP Ta

Wide Body with shutter

2x Pinnacle

Comdel 600S

SLT ESC

Backside Ar

CH 4 –

PVD SIP Cu

Wide Body with shutter

2x Pinnacle

Comdel 600S

SZB ESC

Backside Ar

Active Thermal Science Chiller

Heat Exchanger - Neslab

Wide Body load locks

Transfer chamber robot – VHP

Buffer chamber robot – HP+

Synergy V452 SBC

Enhanced CTI Fast regen cryo pumps

CTI 9600 cryo compressors

2001 vintage.

AMAT / APPLIED MATERIALS ENDURA Reactor (also known as an AMAT ENDURA Reactor) is a large-scale industrial process equipment designed for the semiconductor industry. The reactor is used for chemical vapor deposition (CVD) processes and is typically used to deposit thin film layers of silicon, diamond-like carbon (DLC) and nitride layers on substrates. APPLIED MATERIALS ENDURA Reactor is a high-temperature, high-pressure CVD reactor capable of monitoring and controlling the process parameters required for consistent and reliable deposition of thin film layers. It is fitted with a heating chamber and a heated susceptor and is compatible with a wide range of gases and reactant materials. The reactor also has a range of advanced process controls, including precise deposition temperature control, pressure sensing and regulation, and flowrate control. ENDURA Reactor is widely used in the semiconductor industry for the fabrication of electronic circuits, micro-structures, MEMS components, and other applications. It is designed for rapid and efficient deposition of layer materials and features excellent temperature uniformity and repeatability for highly precise and repeatable deposition. AMAT / APPLIED MATERIALS ENDURA Reactor is also designed to reduce process times, minimize errors, and maximize throughput. The reactor is composed of two main components: the process chamber and the controller. The process chamber is made of quartz, aluminum or stainless steel and houses the heating element, susceptor, and all of the necessary sensors and valves. It is also the area where the deposition process actually takes place. The controller is an advanced computerized system that includes the necessary software and hardware to regulate the reactor and optimize the process parameters. AMAT ENDURA Reactor offers process engineers and operators full control over the entire deposition process. It can be used with a wide range of materials, including silicon dioxide, nitride, and diamond-like carbon. The reactor also has a highly uniform temperature distribution, precise pressure control and extremely low impurity levels. In addition to its process control capabilities, APPLIED MATERIALS ENDURA Reactor is designed to offer rapid and consistent deposition rates. It also features wear-resistant parts and incorporates features that reduce noise and particulate levels for a cleaner deposition environment. Overall, ENDURA Reactor is an advanced industrial process equipment designed for the semiconductor industry. The reactor is used for CVD processes and can be used to deposit thin film layers of silicon, diamond-like carbon and nitride on substrates. AMAT / APPLIED MATERIALS ENDURA offers precise process control and rapid deposition rates as well as low noise and particulate levels for a cleaner deposition environment.

There are no reviews yet