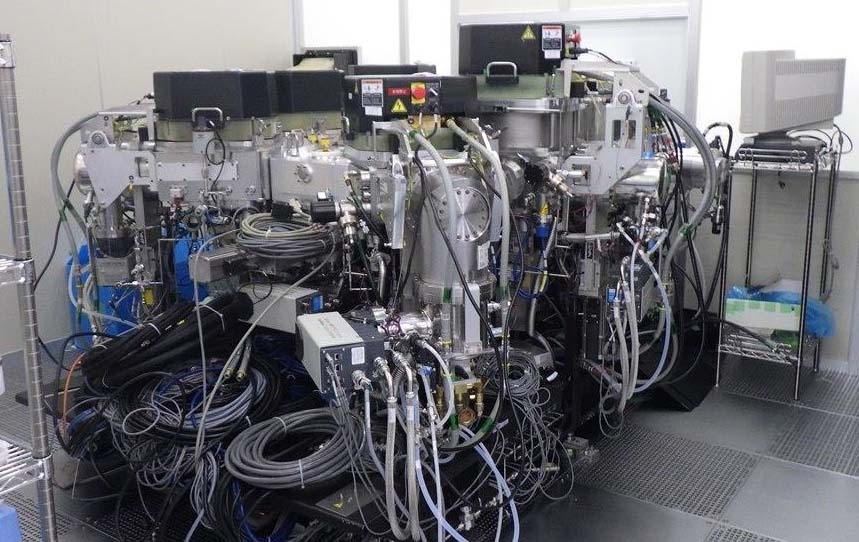

Used AMAT / APPLIED MATERIALS ENDURA #9266968 for sale

URL successfully copied!

Tap to zoom

ID: 9266968

Wafer Size: 8"

PVD System

Load lock: Narrow body (Automated)

Buffer robot: HP

XFER Robot: VHP

Chamber-A: Pass-tru

Chamber-B: Cool

Chamber-C: PC2

LEYBOLD Turbovac 361C Turbo pump

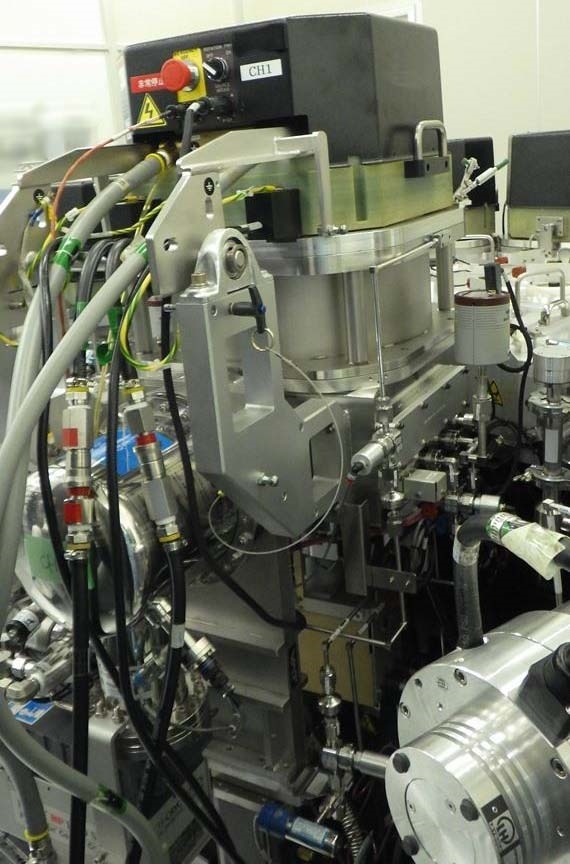

Chamber-D: TiN

Body: Wide

Magnet: K3/P4 Source

Pedestal: 101

CTI-CRYOGENICS On-Board cryo pump

DC Power missing

Chamber-E and F: Orienter-Degas

Chamber-L: Gamma II TI

Body: Wide

Magnet, P/N: 0010-20328

CTI-CRYOGENICS On-Board cryo pump

DC Power:

Master: MDX-L12M-650

Slave: MDX-L12M-650

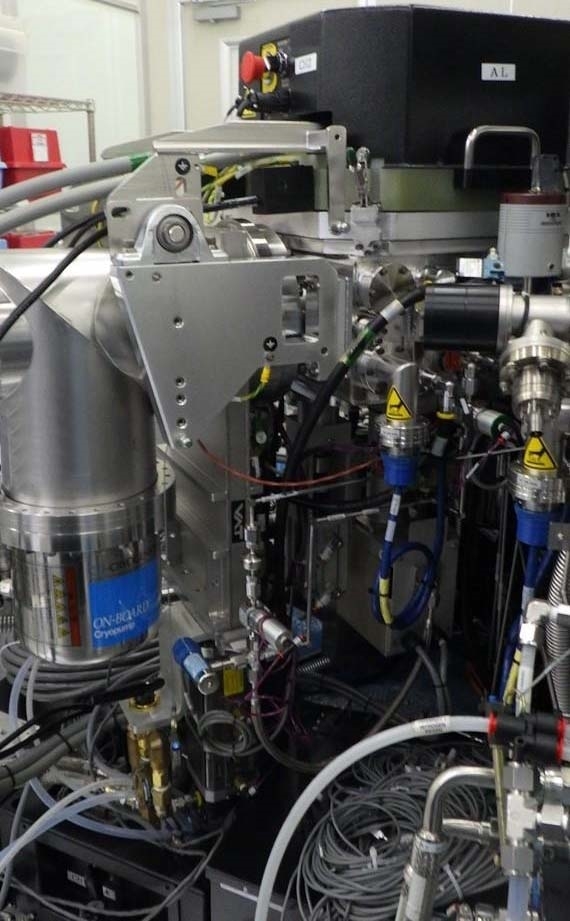

Chamber-2: AL

Body

Magnet, P/N: 0010-20328

Pedestal: Clamp

CTI-CRYOGENICS On-Board cryo pump

Chamber-3: Ti

Body: Wide

Magnet, P/N: G12 0010-20225

CTI-CRYOGENICS On-Board cryo pump

Chamber-4: TiN

Body: Wide

Magnet: G12

Pedestal: 101

CTI-CRYOGENICS On-Board cryo pump

DC Power:

Master: MDX-L12M

Slave missing.

AMAT / APPLIED MATERIALS ENDURA Reactor is a large vacuum processing device used in the fabrication of semiconductor-based circuit boards. Specifically, AMAT ENDURA Reactor is used in the CVD (Chemical Vapor Deposition) process, which is a key step in the production of modern semiconductor components. APPLIED MATERIALS ENDURA Reactor is made up of four major components: the vacuum chamber, the process inlet and outlets, the gas delivery equipment, and the control system. The vacuum chamber is a hermetically sealed vessel that is designed to maintain maximum cleanliness and vacuum levels within the chamber. The process inlet and outlet provide access from the ambient environment to the chamber, allowing gases to enter and products to be removed at the completion of a process cycle. The gas delivery unit is used to inject specific inert and reaction gases into the reactor chamber, which then interact with the substrate material in the CVD process. Finally, the control machine allows the operator to precisely monitor and control the settings of the chamber, gas delivery, and process parameters to ensure a consistent and high-quality product. The features of ENDURA Reactor make it an ideal choice for the fabrication of advanced semiconductor components. It can reach temperatures up to 1000°C, allowing for the interaction of reaction gases with substrates at the atomic level to form intricate structures such as high-K dielectrics and other complex materials. AMAT / APPLIED MATERIALS ENDURA is also optimized for high throughput, allowing for the rapid processing of wafers / substrates in CVD production. The precise control of the reactor environment and process parameters enable accurate and repeatable results, while the integrated safety systems ensure operator safety at all times. Overall, AMAT ENDURA Reactor is an advanced vacuum processing tool designed for the CVD process of fabricating semiconductor devices. Its precise controls and robust features enable accurate and repeatable performance, making it a reliable and best-in-class choice for advanced fabrication processes.

There are no reviews yet