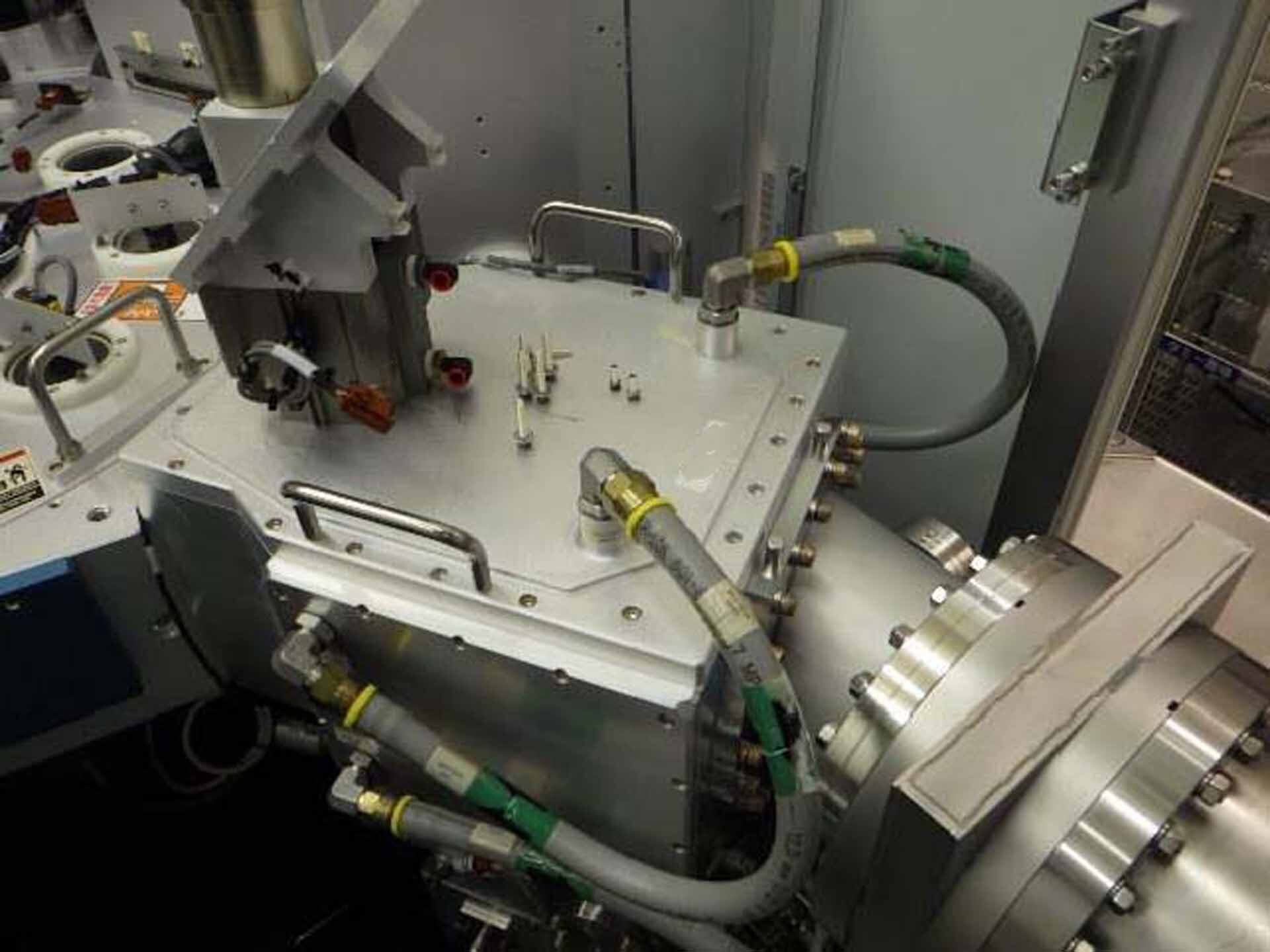

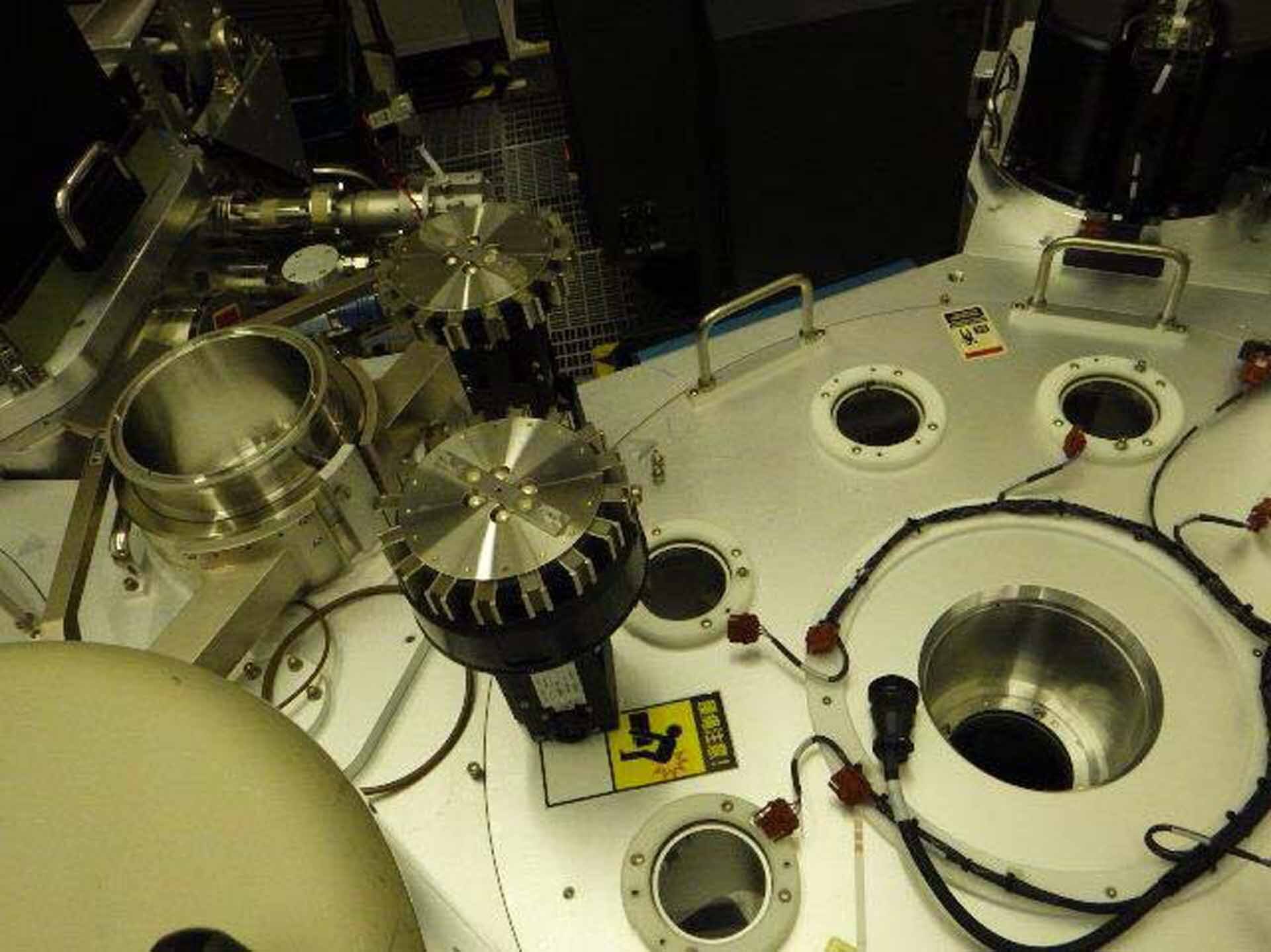

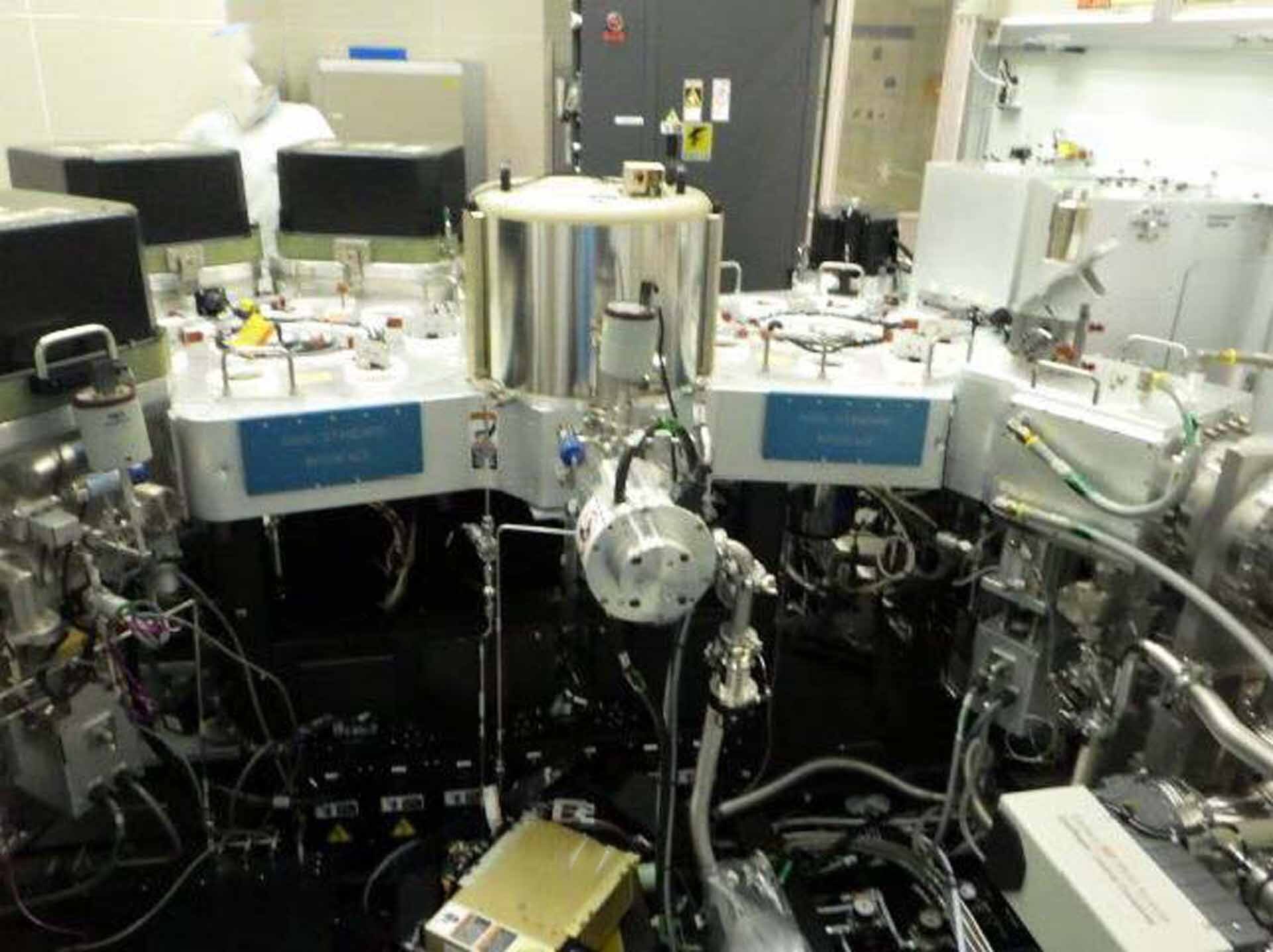

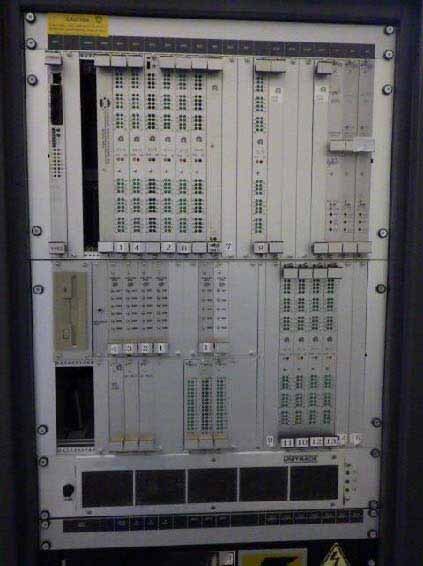

Used AMAT / APPLIED MATERIALS ENDURA #9312919 for sale

URL successfully copied!

Tap to zoom

ID: 9312919

Wafer Size: 6"

PVD System, 6"

Load lock: Narrow body (Automated)

Buffer robot: HP

XFER Robot: HP

Chamber A: PC

Chamber B: Cool

Chamber E: Heat

Chamber F: Orienter-Degas

Chamber 2: AL

Body: Standard

Magnet: Assy 11.3" SRC STD 1

Pedestal: Clamp

DC Power: MDX-L12

CTI-CRYOGENICS On-Board Cryo pump, 3-Phase

Chamber 3: Hot AL

Body: Standard

Magnet: Assy 11.3" SRC STD 1

Pedestal: 101

DC Power: CMDX-L12

CTI-CRYOGENICS On-Board Cryo pump

Chamber 3: Ti

Body: Wide body with shutter

Magnet: Assy 11.3" SRC WB 18

Pedestal: Clamp

DC Power: MDX-L12M and MDX-L12

CTI-CRYOGENICS On-Board Cryo pump

AC Rack

Controller

DC Power rack

CTI-CRYOGENICS 8500 Cryo compressor

CTI-CRYOGENICS 9600 Cryo compressor

Missing parts:

Loadlock cassette indexer assy

Video PCB

Hard Disk Drive (HDD)

5-Phase driver

(3) DC Power supplies

RF Power supply for PC chamber

NESLAB Chiller.

AMAT / APPLIED MATERIALS ENDURA equipment is an advanced deposition reactor designed to produce ultra-thin films with precise layers at rapid rates and precise thicknesses. AMAT ENDURA, which stands for Epitaxy, Deposition, Reactive Etch and Advanced, is a system consisting of three components: APPLIED MATERIALS ENDURA TE, Cell, and Chamber systems. ENDURA Chamber is a state-of-the-art, ultra-precision thermal/vacuum processing chamber capable of producing high quality wafer substrates with high precision. AMAT / APPLIED MATERIALS ENDURA TE includes an integrated advanced gas unit, a high vacuum pump module, a real-time endpoint control, an RF generator block, and an RF power delivery machine. AMAT ENDURA Cell is comprised of the full range of process and deposition components and controllers which are used to deposit and etch layers of deposition material on the wafer substrates. APPLIED MATERIALS ENDURA Cell includes advanced gas distribution components such as the Low Mass Flow Ion source, high-power RF source, anode, cathode and reaction gas line, as well as a pulse LED, pulse laser, and high voltage bias electrode. The advanced gas tool helps to monitor and control the deposition process, while the RF generator and high voltage bias electrode control the substrate's electrical bias. The overall ENDURA asset is designed to produce a uniform deposition layer with a precise, high-precision thickness over the entire wafer surface with a high-precision (+/- 1A) repeatability and high throughput process rate. The entire model, including AMAT / APPLIED MATERIALS ENDURA Cell, is designed to be user friendly and self-diagnostic, ensuring that the user is provided with reliable, high-fidelity performance even during extended operation. AMAT ENDURA Cell, with its integrated gas equipment, RF source, and variable bias, can process multiple films in parallel, allowing for higher throughput processes, and a reduced cost of ownership. APPLIED MATERIALS ENDURA TE is designed to be highly efficient, with a low-consumption power supply and a small footprint, making it ideal for small laboratories. ENDURA system is the perfect choice for any industry requiring high-precision, reliable deposition processes. It is highly efficient and features state-of-the-art, industry-leading thermal/vacuum processing capabilities, gas systems and RF sources, providing excellent repeatability, rapid rates and precise thickness. Its integrated gas systems and variable bias provide complete control of the deposition process, while its low-consumption power supply and small footprint make it ideal for any size laboratory. For reliable, high-fidelity performance, nothing beats AMAT / APPLIED MATERIALS ENDURA unit.

There are no reviews yet